DOI: 10.11817/j.ysxb.1004.0609.2020-35817

热处理工艺对Mg-11Gd-3.6Y-2Zn-0.6Zr合金组织和力学性能的影响

吴星辰,程 眉,张治民

(中北大学 材料科学与工程学院,太原 030051)

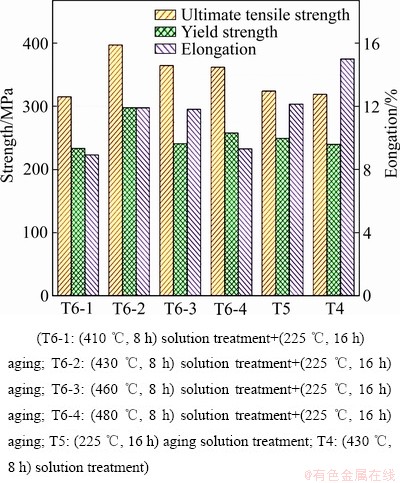

摘 要:利用DSC、OM、SEM、EDS和力学性能测试研究Mg-11Gd-3.6Y-2Zn-0.6Zr(质量分数,%)合金的形变组织和变形态合金分别在T4、T5、T6处理下的组织和力学性能的变化。结果表明:T6处理对合金综合力学性能的改善更有利。T6处理时,随固溶温度的增加,合金的综合力学性能呈现先增大后减小的趋势,其中,在(430 ℃, 8 h)+(225 ℃, 16 h)时,抗拉、屈服强度和伸长率均表现良好,分别为397 MPa、300 MPa和12%,强度比挤压态分别提高了14.9%和28.8%,伸长率有所下降。T6处理的固溶温度过高时,尽管组织更加均匀,但是由于层片状和块状LPSO相的减少和晶粒长大,强度下降严重。

关键词:变形镁合金;固溶温度;时效处理;显微组织;力学性能

文章编号:1004-0609(2020)-08-1750-11 中图分类号:TG146.2 文献标志码:A

镁合金作为最轻的工程应用结构材料,以其良好的比强度、减震性及电磁屏蔽性在航空航天领域得到了广泛应用。近年来,随着新型高强耐热稀土镁合金材料的开发,克服了一般镁合金材料绝对强度较低,耐热性较差等问题,拓展了镁合金材料的应用领域[1-3]。ROKHLIN等[4]、FAN等[5]和TANG等[6]发现重稀土元素Gd的加入可以提高镁合金的强度和耐热性,但单纯加入Gd元素成本高且室温伸长率过低,通过添加Y元素代替部分Gd,可以增加合金的时效强化作用。KAMADO等[7]又在Mg-Gd-Y合金的基础上加入Zr细化镁合金晶粒,结果表明Mg-Gd-Y-Zr系合金性能最好。近年来,人们又发现在稀土镁合金中添加Zn会形成LPSO相,降低了层错能并提高了合金的强度和热稳定性[8-9]。

研究表明,稀土镁合金材料可通过塑性变形及热处理等方式改善其延展性及强度[10-11],航空航天领域应用的镁合金零件大都为大尺寸薄壁类零件,镁合金基体为密排六方晶格结构,变形困难,在加工过程中,受加工设备制约,大尺寸铸坯变形均匀性差,晶粒得不到有效细化,同时,现有的大塑性变形方式受技术和经济条件限制难以实现工业应用,所以需要通过热处理来改善不均匀的变形组织,进一步提高合金的综合力学性能。马志新等[12]研究了温度及保温时间对固溶强化行为的影响,结果表明温度在固溶过程中起主要作用。周会会等[13-14]发现提高固溶温度后,晶界化合物向晶内有更宽的层状相生长,性能方面,合金强度提高,但伸长率略有下降。不同的固溶处理对之后的时效处理和最终的力学性能有很大的影响。

本文作者对变形态的Mg-Gd-Y-Zn-Zr合金在不同温度下进行T6处理,研究不同固溶温度的T6处理对合金组织和力学性能的影响。

1 实验

实验材料选用Mg-11Gd-3.6Y-2Zn-0.6Zr(质量分数,%)铸态稀土镁合金。先对镁合金进行均匀化处理,根据镁合金的热处理特性和DSC曲线,制定均匀化试验方案,得到均匀化处理的温度为520 ℃,时间为8 h。随后在410 ℃下多向锻变形,总共锻造三道次,原始坯料尺寸为300 mm×200 mm×200 mm,前两道次变形量设定为 0.5,第三道次变形量设定为

0.5,第三道次变形量设定为 0.8,每道次锻造结束后,锻造方向改变90°。多向锻变形后,变形后合金切割成15 mm×15 mm×100 mm的试样,之后再次通过热处理来提升合金的综合力学性能。

0.8,每道次锻造结束后,锻造方向改变90°。多向锻变形后,变形后合金切割成15 mm×15 mm×100 mm的试样,之后再次通过热处理来提升合金的综合力学性能。

变形态稀土镁合金的热处理实验方案分别为:T4处理,固溶温度为430 ℃,保温时间8 h,保温后在70 ℃的热水中淬火;T5时效,在225 ℃下保温16 h;T6处理,分4种保温温度,分别为410 ℃、430 ℃、460 ℃、480 ℃,保温时间均为8 h,然后在70 ℃的热水中淬火。最后在225 ℃下保温16 h。

热处理实验分别在中温电阻炉和低温时效箱中进行。通电加热设备,达到实验温度后放入试样进行保温。

为了观察热处理后的显微组织,需要通过研磨、抛光、腐蚀来制备金相试样。使用不同目数的砂纸进行研磨,然后在MP-2A双盘无极变速磨抛机上抛光,抛光后的试样使用乙酸苦味酸试剂(2 mL乙酸+2 mL蒸馏水+14 mL酒精+0.5 g苦味酸)腐蚀完毕后在ZEISS Imagine AI光学显微镜下观察显微组织。使用SU5000扫描电镜(SEM)观察合金的微区形貌,再通过其配套的EDS进行成分分析,扫描电压为20 kV,扫描电流为0.69 NA,工作距离为10 mm。

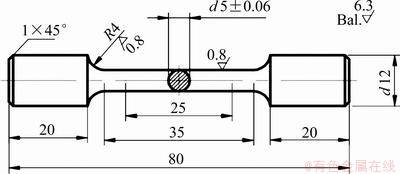

用Instron 3382电子拉伸机在常温下进行拉伸试验来测定热处理后试样的力学性能,设定拉伸速率为3mm/min。拉伸准备工作完成后为试样装夹引伸计,测定试样的屈服强度,等到达屈服点后去除引伸计。每组实验方案取3个拉伸试样进行测试,实验结果取平均值,保留为整数(偏差为±1.3 MPa),拉伸试样示意图如图1。

图1 拉伸试样几何尺寸

Fig. 1 Geometry of tensile test specimens (Unit: mm)

2 结果与分析

2.1 变形组织

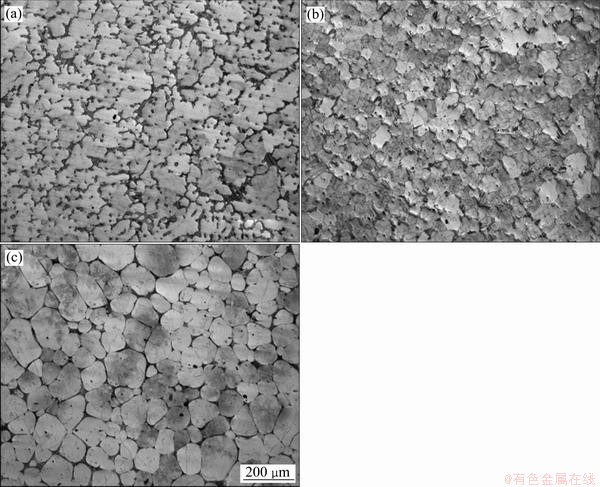

在锻造变形前,对铸态合金进行均匀化处理,促进共晶相回溶,消除偏析,以防止合金在锻造变形中开裂。通过差热分析实验得到的DSC曲线可知,晶界共晶相溶解温度的外推起始点为520 ℃,外推终止点为535 ℃,吸热反应的峰值温度为531.9 ℃。在520~535 ℃的温度区间内,做不同温度和不同时间的均匀化实验。可以发现,当均匀化温度超过530 ℃时,晶粒呈球状,且晶间出现复溶物质,组织过烧。520 ℃下均匀化处理8 h后,组织均匀性好,共晶相回溶较为完全,晶间大部分为条块状或羽毛状的LPSO相(如图2(b)所示)。所以,对于该镁合金选择520 ℃、8 h的均匀化处理方案。

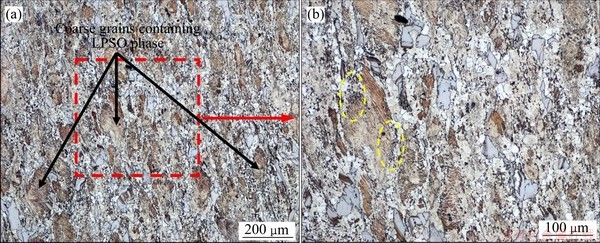

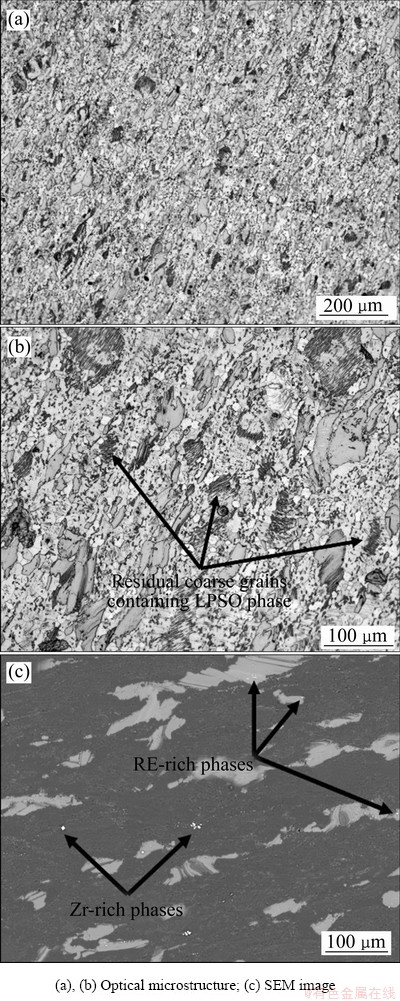

图3所示为变形态合金的显微组织。图3(b)所示为图3(a)的局部放大图。可以看出,经过多向锻造变形,动态再结晶现象明显。再结晶在晶内和晶界都有发生(图中黄色圆圈所示),随着变形道次的增加,再结晶程度也随之增加,原始的条块状和羽毛状LPSO相破碎,使整体的合金组织发生细化[15]。由于变形道次较少,锻造过程中又受变形温度和变形速率的影响,再结晶并不完全,合金中仍存在大量的变形组织,且变形组织中析出大量清晰可见的LPSO相(黑色箭头所示)。另外,晶界处也生成了条块状的LPSO相,其中有部分LPSO相是均匀化组织所留并发生了显著宽化形成的,这是由于变形过程中基体析出的RE(Gd、Y)、Zn原子向LPSO相处富集的结果。层片状和条块状的LPSO相在变形过程中阻碍了位错运动,产生位错塞积,造成应力集中,多道次变形过程中应力逐渐增大,为协调变形,LPSO相发生扭折[16]。合金在410℃下进行锻造,由于锻造变形温度较低,晶粒变形程度相较于高温变形更大,LPSO相扭折程度也更高。基体的变形扭折是整个塑性变形的过渡形式,随着变形加剧,晶内扭折带处塞积和增殖的位错将可能导致亚晶的形成,从而为再结晶提供形核核心,由图3(a)和(b)可知,大部分晶粒内部LPSO相扭折处都发生了动态再结晶[17]。同时,晶界处也出现了动态再结晶现象,并由晶界向晶内进行,这可能是由于变形晶粒晶界发生迁移导致了晶界弓出形核。这两种再结晶方式是锻造过程中协调变形的主要机制。

2.2 热处理对显微组织的影响

合金多向锻造变形后,动态再结晶并不完全,合金中仍有大量变形组织,由图3很明显可以看到,变形晶粒内部再结晶进行程度较大,但并未彻底贯穿并破碎晶粒,需要进一步细化组织。此外,稀土镁合金的析出强化和弥散强化是影响合金力学性能的重要因素,而合金的锻造变形无法完全发挥这两种强化作用,所以为提高合金的强度,综合改善合金的力学性能,需要对合金进行热处理,研究热处理对显微组织的影响,得到合金力学性能最佳时的显微组织特征。

图2 合金铸态和均匀化的显微组织

Fig. 2 Optical microstructures of alloy as-cast(a) and homogenized at 520 ℃(b), 530 ℃(c) for 8 h

图3 变形态合金的显微组织

Fig. 3 Optical microstructures of deformed alloy

2.2.1 T5处理对显微组织的影响

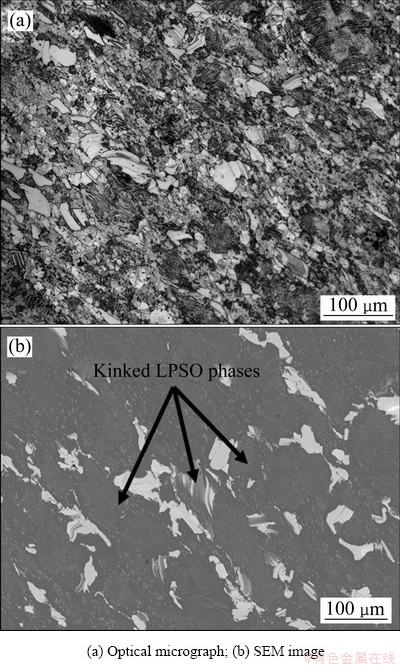

经过T5处理后,基体中的Gd、Y元素通过时效处理以弥散的第二相析出,析出第二相与位错相互作用,阻碍位错运动,从而强化合金。合金经过三道次锻造变形后位错大量增殖,一方面增加了析出相形核的位置,另一方面提高了时效过程中原子的扩散速度。又由于变形之前已经对铸态合金进行了均匀化处理,形成了Gd、Y元素的过饱和固溶体,变形后的T5处理会使稀土元素更有效析出,形成细小弥散的β′相[18-19]。由图4可知,当变形态合金在225 ℃下进行T5时效处理时,合金发生了静态再结晶,新的再结晶晶粒形成而原有动态再结晶晶粒长大,合金整体组织的均匀性有所提高。但是由于温度较低,原子的扩散能力有限,静态再结晶不完全,合金中的扭折依然明显(如图4(b)黑色箭头所示)。时效结束后,变形残留的块状第二相有所粗化,由于再结晶晶粒增加,且初始再结晶晶粒内不存在LPSO相,合金中整体的LPSO相含量下降。实际上在T5处理过程中,第二相的析出[20]较少,这是因为均匀化后的过饱和固溶体在挤压过程中受挤压力和变形温度的驱动,原子扩散速度相对更高,在锻造过程中,伴随着位错密度的增加和晶界处缺陷的形成,晶界处就不可避免的析出了较多的第二相。T5处理时,由于变形态合金基体中稀土元素含量的减少,过饱和度降低,第二相难以析出。此外,图4(b)中灰白衬度的块状LPSO相上可以看到白色的块状相,经EDS分析可知其为富稀土相。

2.2.2 T4处理对显微组织的影响

合金经过T4处理后挤压过程中动态析出的第二相部分回溶,由于T4的热处理温度比T5的高,合金静态再结晶程度比较完全,只残留少数变形组织(如图5(b)黑色箭头所示)。静态再结晶时,新晶粒形成过程中不断吞噬原有变形组织中的层片状LPSO相,形成的新晶粒中不存在层片状的LPSO相,而之前变形过程中形成的动态再结晶晶粒开始长大,同时,又析出了少量新的针状相。在固溶过程中,大块状LPSO相以及晶界和晶内存在排列方向不同的短棒状LPSO相在固溶过程中均发生了一定程度的粗化,合金中可能还有变形时的析出相也转变为小的短棒状LPSO相。

图4 变形态合金T5处理后的显微组织

Fig. 4 Microstructures of deformed alloy after T5 treatment

图5 变形态合金T4处理后的显微组织

Fig. 5 Microstructures of deformed alloy after T4 treatment

总体上来看,固溶过程中晶粒长大程度较小,这是因为变形合金中细小的第二相和颗粒状LPSO相体积分数较大[21],有效地钉扎了晶界,阻止晶粒长大,随着保温时间地增加,细小的第二相部分溶解和颗粒状LPSO相发生粗化导致钉扎作用小于晶粒长大驱动力而解钉,晶粒才开始长大。从图5(c)中可以看出,T4处理后Zr的团簇在基体上析出,同时也可以看到富稀土相的存在。

2.2.3 T6处理对显微组织的影响

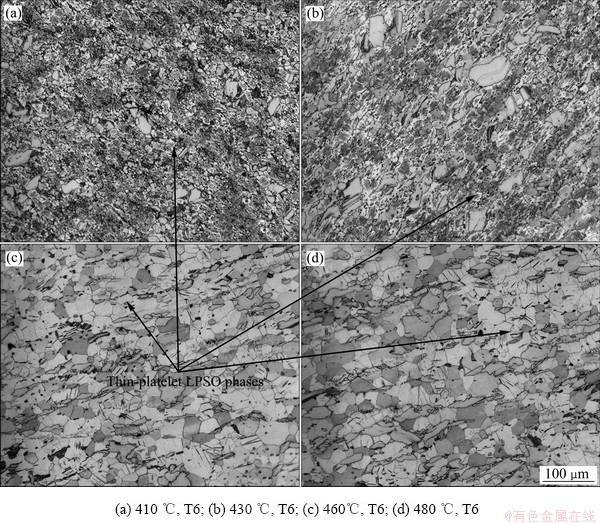

图6所示为变形态合金经T6处理后的光学显微组织。从图6中可以看出,经过T6热处理后,合金中几乎不存在原始变形组织,再结晶程度比T4处理更大,这是因为固溶和之后的时效处理都为再结晶提供了驱动力[22]。对比不同T6热处理后的金相图可以发现,晶界处的块状LPSO相热稳定性好,T6处理难以使其溶解,变形过程中块状相的扭折也因此保留下来。在整个热处理过程中,固溶温度较低时,块状LPSO相界面较为圆滑,随着温度的升高和保温时间的延长,界面愈发无规则,界面部分突出有向晶内生长的趋势且逐渐开始粗化、分解、转化为条状或短棒状相。随着固溶温度的升高,一方面,静态再结晶晶粒逐渐长大,固溶温度为410 ℃时,晶粒长大不明显,与动态再结晶晶粒的尺寸差较大;固溶温度为430 ℃时,合金晶粒的尺寸大小趋于一致,温度进一步升高,晶粒明显长大。另一方面,基体中的层片状相逐渐变短(如图6黑色箭头所示)成短棒状相直至最终消失,而且在固溶过程中随着再结晶的进行,位错密度急剧降低,形核位置随之减少,所以尽管温度升高,基体内固溶的稀土元素含量增加,但是析出相的数目没有显著增多。此外,T6处理使晶界处原有的短棒状LPSO相发生宽化,这些短棒状相可能是挤压过程中条状LPSO相破碎形成的。

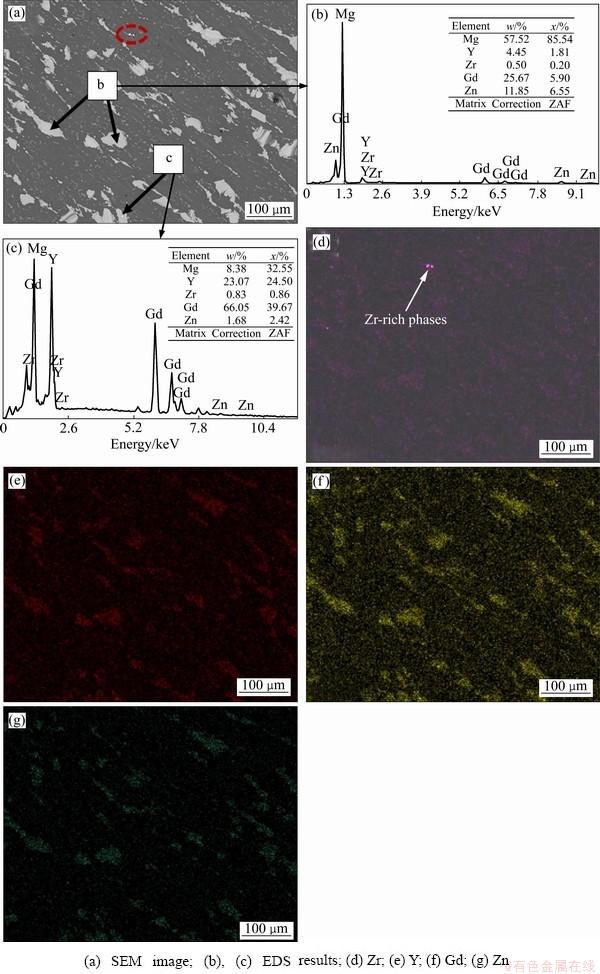

图7所示为430 ℃、T6热处理后合金显微组织的BSE图像和EDS分析结果。从图7(b)和(c)的EDS结果可以看出,灰白衬度块状相为LPSO相,结合文献[23]可知,其成分为Mg12(Y,Gd)Zn,块状相间的白色方块相为富稀土相,还可以从SEM像中看到Zr的团簇(如红色箭头和圆圈所示)。从元素分布来看,稀土元素和Zn元素在LPSO相处偏聚,其中Gd元素由于含量多,偏聚效果也最明显,含稀土元素较多的块状LPSO相起到了第二相强化的作用。由之前分析可知,随着固溶温度升高,T6热处理后,晶界间的块状相逐渐减少,而合金组织的整体均匀性升高(如图7(c)和(d)所示),但是基体组织层片状相和晶界间块状相作为主要强化相的过分减少又会影响到合金的强度。所以总的来看,430 ℃,T6热处理后的组织对合金的性能更加有利。

2.3 合金的力学性能

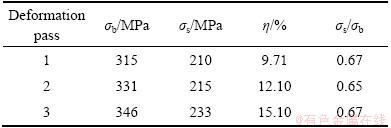

表1所列为合金各道次变形后的力学性能。实验所用铸态合金的抗拉强度( )为197 MPa,屈服强度(

)为197 MPa,屈服强度( )为143 MPa,伸长率(

)为143 MPa,伸长率( )为4.15%。实验中合金进行了3道次锻造变形,从表1中可以看出,每道次变形后的综合力学性能均比之前状态的合金优良,合金的屈服强度、抗拉强度和伸长率都有所提高,其中塑性变形能力的改善尤为明显。相比铸态合金,三道次变形后合金的屈服强度增加了62.6%,抗拉强度增加了75%,伸长率增加了263%。

)为4.15%。实验中合金进行了3道次锻造变形,从表1中可以看出,每道次变形后的综合力学性能均比之前状态的合金优良,合金的屈服强度、抗拉强度和伸长率都有所提高,其中塑性变形能力的改善尤为明显。相比铸态合金,三道次变形后合金的屈服强度增加了62.6%,抗拉强度增加了75%,伸长率增加了263%。

图6 变形态合金经T6处理后的光学显微组织

Fig. 6 Optical microstructure of deformed alloy after T6 treatment

图7 经430 ℃、T6热处理后合金扫描图像和能谱分析结果

Fig. 7 SEM micrograph, EDS results and microprobe maps showing element distribution in alloy after 430 ℃, T6 heat treatment

表1 不同道次变形后合金的力学性能

Table 1 Mechanical properties of alloys after different deformation passes

合金塑性的改善原因较多,在变形态合金的整个拉伸至断裂过程中,合金的集中变形(缩颈)不太明显,所以屈服之后的塑性变形可视为均匀变形。材料在均匀塑性变形变形阶段的应力-应变关系由Hollomon关系式可表示为

(1)

(1)

式中:S为真应力; 为真应变;K为强度系数;n为形变强化指数。

为真应变;K为强度系数;n为形变强化指数。

而材料塑性失稳条件为

(2)

(2)

临界塑性失稳时,上述等号成立,有

(3)

(3)

得到最大均匀应变量 为

为

(4)

(4)

由式(4)可以知道,形变强化指数n反应了材料的塑性变形量,n值越大,意味着形变强化能力越好且材料塑性越优[24]。而形变强化指数又和材料的层错能密切相关,层错能越低,指数n越大。合金中的Y元素大幅度降低了组织的层错能,合金变形之前的固溶处理使晶界的脆性共晶相和部分枝晶间第二相溶解,Gd、Y等原子以置换固溶的方式进入α-Mg基体,基体中Y元素的浓度随之升高,使层错能进一步下降,从而使合金的塑性有了较大程度的提高[25-26]。其次,变形过程中的动态再结晶会在一定程度上细化晶粒,在降低晶粒中塞积位错数目的同时促进了位错源的开动,大量可动位错发生滑移,同样,有利于合金塑性的提高。相对于铸态合金,变形合金抗拉强度的增幅要大于屈服强度(置换固溶对抗拉强度的影响更大),屈强比减小,说明合金屈服之后需要经历更长时间的塑性变形才能达到抗拉强度,这同样意味着合金塑性有了一定程度的提高。合金的变形作用对塑性的提升贡献很大,抵消了其他强化(位错强化等)作用对塑性造成的一定的不利影响,表现为各道次之间伸长率的提高程度大于强度的提升程度。

一道次变形对合金力学性能的提升作用最大,变形使合金晶粒细化,相同体积的合金中晶粒越细小,晶界越多,对位错的阻碍越大,需要更大的外力才能使晶体滑移,根据Hall-Petch公式( )可知,材料的屈服强度增大,相应的抗拉强度也会增大,晶粒细化程度不大时,细晶强化对两者的增幅大致相同。尽管一道次变形对合金晶粒的细化程度有限,在之后的变形过程中合金晶粒仍在不断细化,但是对强度的提升作用并不明显。

)可知,材料的屈服强度增大,相应的抗拉强度也会增大,晶粒细化程度不大时,细晶强化对两者的增幅大致相同。尽管一道次变形对合金晶粒的细化程度有限,在之后的变形过程中合金晶粒仍在不断细化,但是对强度的提升作用并不明显。

变形过程中层片状LPSO相在基体内形核,随着变形的继续进行,位错的运动被限制在形成的LPSO片层相间,形成平面塞积群,屈服强度显著提高。但是位错强化对屈服强度的影响更大,由于变形导致的位错缠结和胞状亚结构无法阻止裂纹的扩展,位错密度较高后,抗拉强度很难再提升。不过稀土镁合金中的层错能对抗拉强度起了积极作用,固溶之后的合金层错能更低,合金不易产生交滑移,使变形抗力增大。此外,层错能的下降也使位错胞难以形成,阻止了裂纹的萌生。

图8所示为不同热处理后合金的拉伸力学性能。合金经过不同的热处理后塑性下降,强度都有不同程度的提升。T5处理后相比于第三道次的变形合金,强度略微提升而伸长率有所下降,这说明时效析出相在该实验条件下的强化作用不佳且时效作用导致了塑性的下降,同时,时效过程中发生的部分静态再结晶虽然细化了晶粒,但是程度不大,对合金的综合力学性能并没有造成明显的影响。对第三道次变形后的合金进行T4热处理(430 ℃),未处理时块状LPSO相与基体有良好的共格或半共格关系,塑性变形过程中微裂纹不易在界面处萌生,热处理后晶界处的块状和棒状LPSO相粗化,共格关系受到破坏,强化效果减弱。同时,位于晶界处的部分第二相溶解,第二相相界对裂纹扩展的阻止作用减弱。并且经过固溶处理后基体中的位错密度下降,弱化了位错强化的效果。以上因素都造成了抗拉强度的下降,但是由于基体中Y元素浓度不变,且固溶会使组织更加均匀,所以合金塑性变化不大。

随着固溶温度的升高,T6处理后基体中的层片状LPSO相逐渐消失,位错密度不断下降,位错强化能力减弱,而且第二相的溶解程度增大,第二相强化作用逐渐降低。但是T6处理过程中基体的稀土元素浓度升高,生成的析出相数量因之增多,析出相β′对合金强化起了主要作用,所以合金的强度明显升高。固溶温度升高使晶间LPSO相的粗化加剧,晶粒尺寸增加,影响了合金的强度和塑韧性。另外,固溶作用导致晶界处的位错缺陷减少,致使形核位置减少,固溶温度升高一定程度后,析出相数量减少过多,会严重弱化析出强化效果。大体上来看,随固溶温度变化,合金的抗拉强度呈先增大后减小的趋势,固溶温度为430 ℃时,T6处理后合金的各项力学性能达到最高,而受析出强化的影响,合金塑性相对于变形合金略微降低。

图8 变形态合金热处理后的力学性能

Fig. 8 Tensile properties of deformed alloy after heat treatment

2.4 合金断口分析

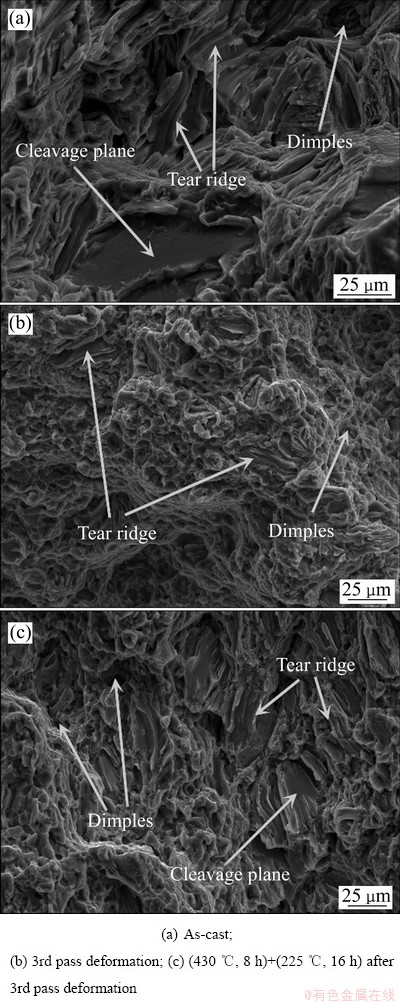

室温拉伸断口形貌如图9所示。图9(a)所示铸态合金中存在着大量的撕裂棱和拉长的韧窝,少量宽大的解理面。这是由于随着外应力的不断增加,材料发生塑性变形,当合金达到临界应变时,某些已发生较大变形的晶粒中形成解理裂纹并在晶内的解理面上扩展,当应力达到裂纹失稳扩展的应力值时,材料内部发生塑性撕裂使得各解理裂纹互相联结,合金就以穿晶解理的方式断裂[27],合金的塑性较差,伸长率仅为4.15%。图9(b)所示为经过3道次变形后合金的拉伸断口的SEM像,其中出现了大量韧窝和少量撕裂棱,韧窝的产生需要消耗大量的能量,尤其是之后的裂纹扩展所需能量更高,故属于韧性断裂[28]。在塑性变形过程中,合金的变形受阻部位形成应力集中,当应力集中程度过大时,微裂纹在这些部位开始形核并随着塑性变形程度的增加不断扩大,超过一定应力水平后,材料内部出现缩颈将各裂纹联结起来,合金发生微孔聚集形韧窝断裂,此时合金的伸长率达到15%,塑性较好。对变形合金进行T6热处理(430 ℃, 8 h)+ (225 ℃, 16 h)后可以发现合金的拉伸断口(见图9(c))中韧窝和撕裂棱都较多,呈现明显的塑性断裂特征。撕裂棱的增多说明经过热处理后合金的塑性有一定程度的下降,具体情况反映到伸长率上(减少为12%)。

图9 Mg-11Gd-3.6Y-2Zn-0.6Zr合金拉伸断口的SEM像

Fig. 9 SEM images of tension fractures of Mg-11Gd-3.6Y- 2Zn-0.6Zr alloys before and after heat treatment

3 结论

1) T4(430 ℃, 8 h)处理后,随着第二相的和位错密度的减少,抗拉强度相较挤压态有所降低,塑性几乎没有变化,而T5处理后,强度稍有提升,塑性略微下降。采用固溶加时效的方式(T6)能更有效地改善合金的综合性能。

2) T6处理时,随固溶温度的增加,合金的综合力学性能呈先增大后减小的趋势,其中,在(430 ℃, 8 h)+ (225 ℃, 16 h)时,抗拉强度、屈服强度和伸长率均表现良好,分别为397 MPa、300 MPa和12%,强度比挤压态分别提高了14.9%和28.8%,伸长率有所下降。

3) T6处理的固溶温度过高时,尽管组织更加均匀,但是由于层片状和块状LPSO相的减少和晶粒长大,强度下降严重。

4) 铸态合金的断裂方式为穿晶解理型断裂,合金塑性较差,变形态合金塑性大幅度提高,合金以微孔聚集型的方式断裂,T6处理后合金的断裂方式仍为韧性断裂,撕裂棱相较变形态增多。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004.

[2] FRIEDRICH D I H E, MORDIKE B L. Magnesium technology[M]. Berlin: Springer, 2006.

[3] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ru-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[4] ROKHLIN L L, NIKITINAL N I. Mg-Gd and Mg-Gd-Y alloys[J]. Zeitschriftfur Metallkunde, 1994, 85(12): 819-823.

[5] FAN Xiao-wei, YANG Jun-jie, LI Yao. Effect of Gd and Y on high temperature mechanical properties of AM60 magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2015, 25(12): 1329-1332.

[6] TANG Chang-ping, LIU Wen-hui, CHEN Yu-qiang, LIU Xiao, DENG Yun-lai. Effect of Y content on microstructures and mechanical properties of Mg-Gd-Y-Nd-Zr casting alloy[J]. Materials Review, 2016, 30(8): 86-90, 99.

[7] POLMEAR I A, KAMADO S, KOJIMA Y. Creep properties of Dy alloys[J]. Japan Institute Light Metals, 1994, 44(1): 3.

[8] LI Hui-zhong, LIU Hong-ting, CHEN Jian-mei, WANG Hai-jun, LIANG Xiao-peng. Effects of Zn addition on microstructure and mechanical properties of Mg-10Gd-4.8Y- 0.6Zr alloy[J]. Journal of Aeronautical Materials, 2011, 31(5): 298-302.

[9] HAGIHARA K, YAMASAKI M, HONNAMI M, LZUNO H, TANE M, NAKANO T, KAWAMURA Y. Crystallographic nature of deformation bands shown in Zn and Mg-based long-period stacking ordered (LPSO) phase[J]. Philosophical Magazine, 2015, 95(2): 132-157.

[10] KHRAISHEH M K, ABU-FARHA F K, WEINMANN K J. Investigation of post-superplastic forming properties of AZ31 magnesium alloy[J]. CIRP Annals-Manufacturing Technology, 2007, 56(1): 289-292.

[11] XUE Zhi-yong, REN Yue-juan, LUO Wen-bo, REN Yu, XU Ping, XU Chao. Microstructure evolution and mechanical properties of a large-sized ingot of Mg-9Gd-3Y-1.5Zn-0.5Zr (wt%) alloy after a lower-temperature homogenization treatment[J]. Journal of Mineral Metallurgy and Materials: English, 2017, 24(3): 271-279.

[12] 马志新, 张家振, 李德富, 张 奎. 铸态Mg-Gd-Y-Zr合金均匀化工艺研究[J]. 特种铸造及有色合金, 2007(9): 659-662.

MA Zhi-xin, ZHANG Jia-zhen, LI De-fu, ZHANG Kui. Study on homogenization process of as-cast Mg-Gd-Y-Zr alloy[J]. Special Casting & Nonferrous Alloys, 2007(9): 659-662.

[13] 黄太红, 宋 鹏, 周会会, 陆建生. 固溶温度对Mg-10Gd-3Y-1.2Zn-0.5Zr合金的组织演变规律和时效硬化行为的影响[J]. 稀有金属材料与工程, 2016, 45(2): 667-672.

HUANG Tai-hong, SONG Peng, ZHOU Hui-hui, LU Jian-sheng. Effects of solution temperature on microstructure evolution and aging hardness of Mg-10Gd-3Y-1.2Zn-0.5Zr alloy[J]. Rare Metal Materials and Engineering, 2016, 45(2): 667-672.

[14] ZHOU Hui-hui, SONG Peng, HUANG Tai-hong, LU Jian-sheng. Influence of different solution treatments on mechanical properties and fracture behavior ofMg-10Gd-3Y-1.2Zn-0.5Zralloys[J]. Rare Metal Materials and Engineering, 2016, 45(3): 732-736.

[15] JIANG M G, YAN H, CHEN R S. Twinning, recrystallization and texture development during multi-directional impact forging in an AZ61 Mg alloy[J]. Journal of Alloys and Compounds, 2015, 650: 399-409.

[16] ZHOU Xiao-jie, LIU Chu-ming, GAO Yong-hao, JIANG Shu-nong, HAN Xiu-zhu, CHEN Zhi-yong. Evolution of LPSO phases and their effect on dynamic recrystallization in a Mg-Gd-Y-Zn-Zr alloy[J]. Metallurgical and Materials Transactions A, 2017, 48(6): 1-13.

[17] 罗素琴. Mg-Zn-Zr-Y合金固溶强化和第二相强化的理论和实验研究[D]. 重庆: 重庆大学, 2011.

LUO Su-qin. Theoretical and experimental study on solid solution strengthening and second phase strengthening of Mg-Zn-Zr-Y alloy[D]. Chongqing: Chongqing University, 2011.

[18] ZENG Xiao-qin, WU Yu-juan, PENG Li-ming, LIN Dong-liang, DING Wen-jiang, PENG Ying-hon. LPSO structure and aging phases in Mg-Gd-Zn-Zr alloy[J]. Acta Metallurgica Sinica, 2010, 46(9): 1041-1046.

[19] 汤伊金, 章桢彦, 靳 丽, 董杰, 丁文江. Mg-Gd系合金时效析出研究进展[J]. 中国有色金属学报, 2014, 24(1): 8-24.

TANG Yin-jin, ZHANG Zhen-yan, JIN Li, DONG Jie, DING Wen-jiang. Research progress on aging precipitation of Mg-Gd alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 8-24.

[20] XUE Zhi-yong, REN Yue-juan, LUO Wen-bo, ZHNEG Rui-peng, XU Chao. Effect of aging treatment on the precipitation behavior and mechanical properties of Mg-9Gd-3Y-1.5Zn-0.5Zr alloy[J]. Journal of Materials Engineering and Performance, 2017, 26: 5963-5872.

[21] LI C Q, XU D K, ZENG Z R, WANG B J, SHENG L Y, CHEN X B, HAN E H. Effect of volume fraction of LPSO phases on corrosion and mechanical properties of Mg-Zn-Y alloys[J]. Materials & Design, 2017, 121: 430-441.

[22] YANG M, LIU Y H, LIU J A, SONG Y L. Effect of T6 heat treatment on corrosion resistance and mechanical properties of AM50 magnesium alloy[J]. Materials Research Innovations, 2015, 19(S10): 259-264.

[23] LI Yang-xin, YANG Chang-lin, ZENG Xiao-qin, JIN Pei-peng, QIU Dong, DING Wen-jiang. Microstructure evolution and mechanical properties of magnesium alloys containing long period stacking ordered phase[J]. Materials Characterization, 2018, 141: 286-295.

[24] 雍歧龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.

YONG Qi-long. Second phase in steel material[M]. Beijing: Metallurgical Industry Press, 2006.

[25] 张 伟, 刘伟东, 曾 莉, 屈 华. 用价电子理论分析Y对Mg-Al合金力学性能的影响[J]. 有色金属, 2008, 60(4): 9-12.

ZHANG Wei, LIU Wei-dong, ZENG Li, QU Hua. Analysis of the effect of Y on the mechanical properties of Mg-Al alloys by valence electron theory[J]. Non-ferrous metal engineering, 2008, 60(4): 9-12.

[26] ZHANG Ya, ZENG Xiao-qin, LIU Liu-fa, LU Chen, ZHOU Han-tao, LI Qiang, ZHU Yan-ping. Effects of yttrium on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr alloys[J]. Materials Science & Engineering A, 2004, 373(1/2): 320-327.

[27] GUI Zhen-zhen, KANG Zhi-xin, LI Yuan-yuan. Evolution of the microstructure and fracture characteristics of a Mg-Nd-Zn-Zr-Mn alloy through heat treatment and extrusion[J]. Journal of Alloys and Compounds, 2018, 765: 470-479.

[28] NARLA S P, NARASIMHAN R, SUWAS S. Role of tensile twinning on fracture behavior of magnesium AZ31 alloy[J]. Magnesium Technology, 2016, 94: 281-293.

Effect of heat treatment process on microstructure and mechanical properties of Mg-11Gd-3.6Y-2Zn-0.6Zr alloy

WU Xing-chen, CHENG Mei, ZHANG Zhi-min

(School of Materials Science and Engineering, North University of China, Taiyuan 030051, China )

Abstract: The microstructure and mechanical properties of Mg-11Gd-3.6Y-2Zn-0.6Zr (mass fraction, %) magnesium alloy under the conditions of multi-directional forging, T4, T5, T6 treatment were investigated by DSC, OM, SEM, EDS and mechanical properties tests. The results show that T6 treatment is more beneficial to the improvement of comprehensive mechanical properties of the alloy. After T6 treatment, with the increase of solution temperature, the comprehensive mechanical properties of the alloy increase firstly and then decreases. And all of the ultimate tensile strength, yield strength and elongation performed well under T6(430 ℃, 8 h+225 ℃, 16 h) treatment reach 397 MPa, 300 MPa and 12%, respectively. The ultimate tensile strength and yield strength are increased by 14.9% and 28.8% compared with those of the as-forged alloy, respectively, and the elongation decrease. When the solution temperature of T6 treatment is too high, although the microstructure is more uniform, the strength decreases seriously due to the reduction of lamellar and the block-like LPSO phase, and the grain size increases.

Key words: wrought magnesium alloy; solution temperature; aging treatment; microstructure; mechanical properties

Received date: 2019-08-05; Accepted date: 2019-12-24

Corresponding author: CHENG Mei; Tel: +86-13603534560; E-mail: 104082569@qq.com

(编辑 李艳红)

收稿日期:2019-08-05;修订日期:2019-12-24

通信作者:程 眉,副教授,博士;电话:13603534560;E-mail:104082569@qq.com