铝箔轧制过程中油泥形成机理

来源期刊:中国有色金属学报2000年第3期

论文作者:周亚军 毛大恒

文章页码:459 - 463

关键词:铝箔轧制; 油泥; 形成机理

Key words:aluminums; foil rolling; oil sludge; producing mechanism

摘 要:采用红外光谱、 X射线衍射和XPS等分析方法, 分析了铝箔轧制过程中所形成油泥的物质组成及结构。结果表明, 油泥主要由约40%的铝屑、 60%的轧制油及其氧化物组成的粘稠状黑色混合物; 铝屑表面脂肪酸铝盐在促使铝屑聚集成油泥过程中起着重要作用,轧制油氧化也是生成油泥的一个不可忽视的因素; 油泥的生成与轧制油的性能密切相关, 轧制油的润滑性能差、 承载能力低、 酸值高、 抗氧化稳定性能低均可促使油泥的生成。提出了减少或抑制油泥生成的对策。

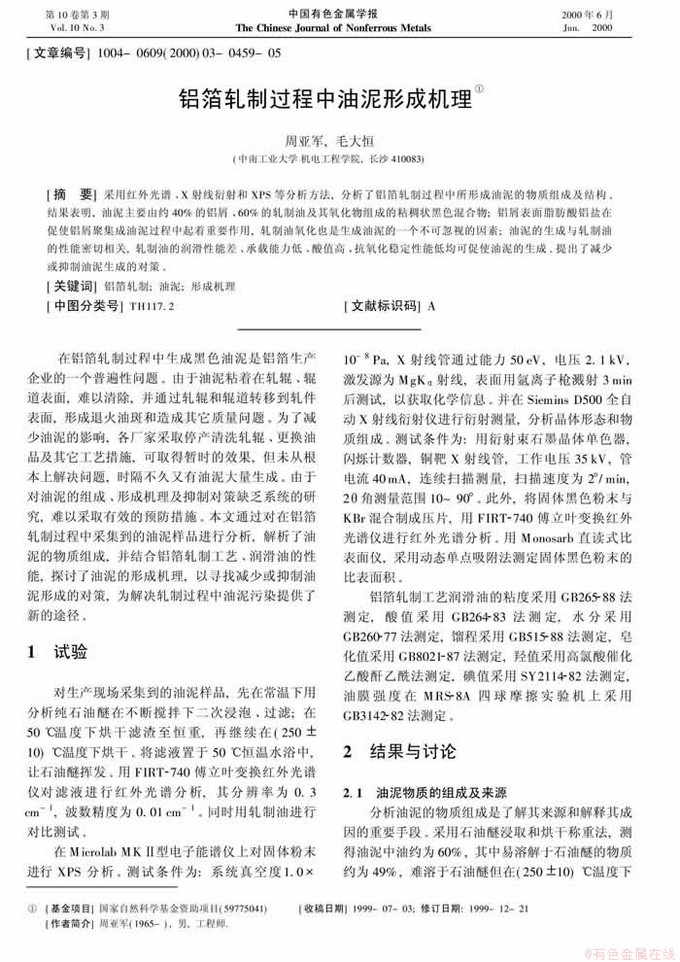

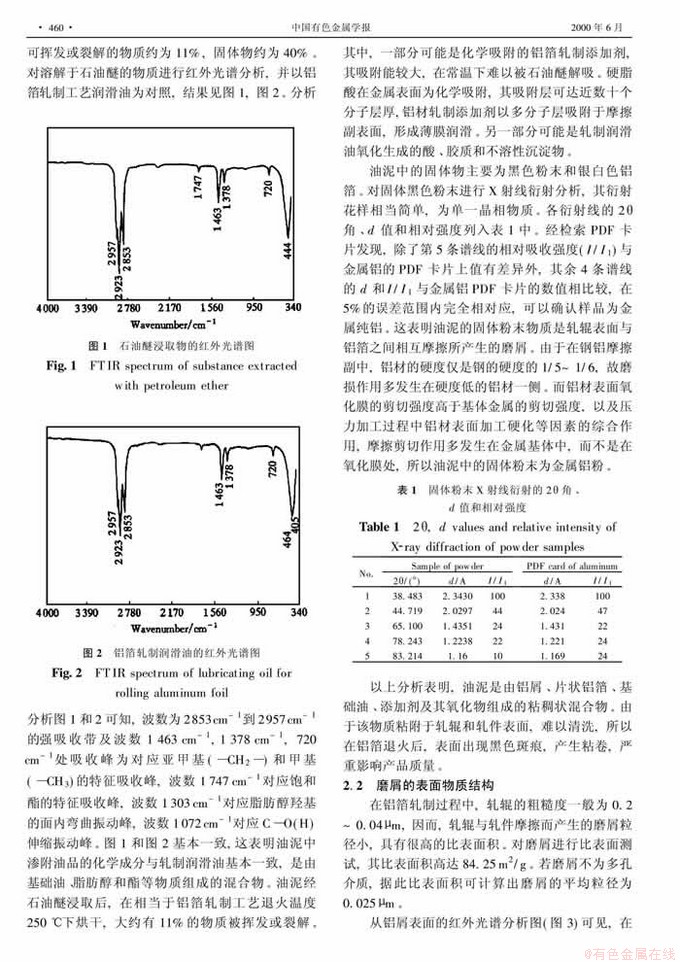

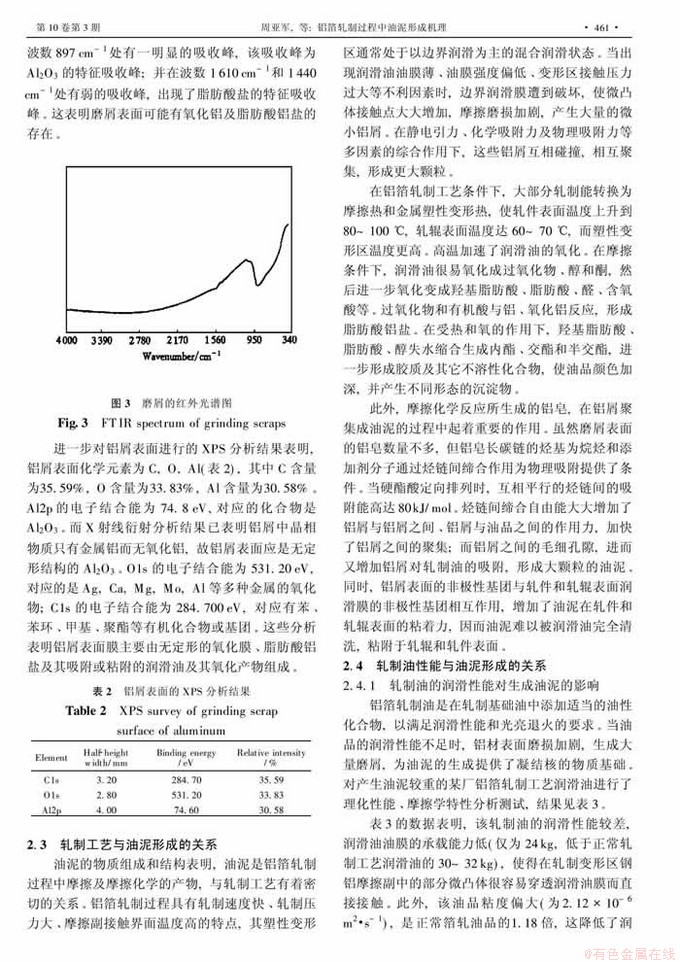

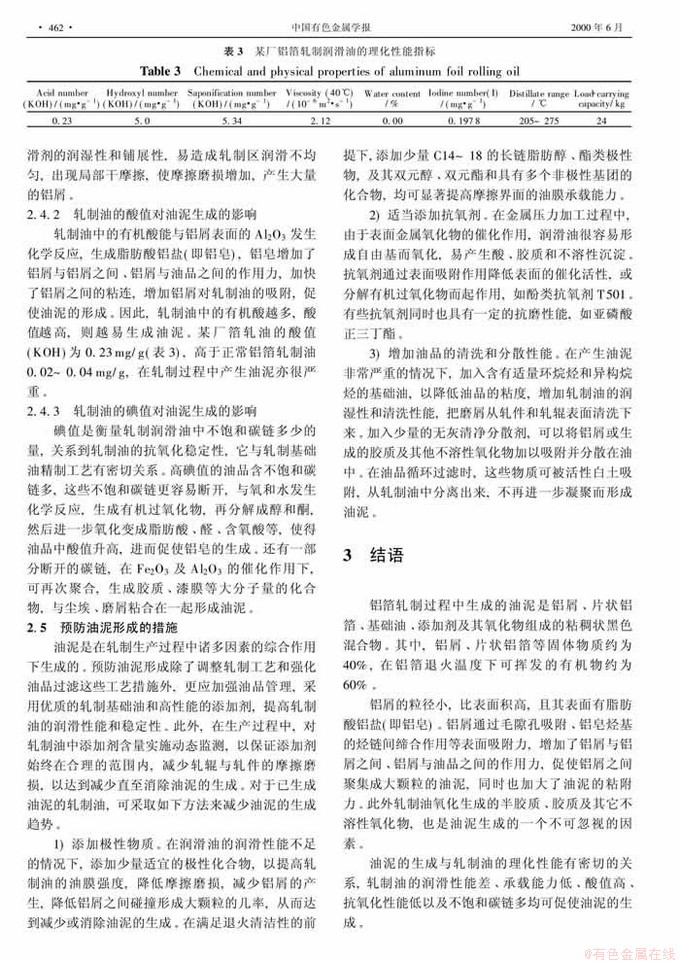

Abstract: The constitutes and structures of oil sludge produced in the process of rolling aluminum foil were analyzed by means of infrared spectrum analysis and X-ray diffraction analysis and XPS analysis. The results showed that the oil sludge is a kind of viscous black mixture of about 40% aluminum powder, 60% rolling lubricant and its oxidate, and the aluminum soap in the surface of aluminum powder plays an important role in accelerating aggregation of aluminum powder, and the oxidation of rolling lubricant is not a negligent factor of producing oil sludge. The oil sludge formation is correlative with the lubricant character, the poor behaviors of the lubricant, such as low carrying capacity and/or high acid value and/or low inoxidizable stabilization, can result in formation of oil sludge, the countermeasure in reducing or restraining oil sludge was introduced accordingly.