文章编号:1004-0609(2014)12-3162-07

基于倾斜管实验的膏体自流输送规律

李公成1, 2,王洪江1, 2,吴爱祥1, 2,于少峰1, 2,陈 辉1, 2,王晓宁1, 2,严庆文3

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083;

2. 北京科技大学 土木与环境工程学院,北京 100083;

3. 云南驰宏锌锗股份有限公司,曲靖 654212)

摘 要:采用自制的倾斜管实验装置,利用4因素6水平均匀设计方案,通过回归分析得到各因素对膏体料浆流变参数的影响规律;从充填倍线角度出发,分析膏体料浆流变参数和自流输送的规律,并建立最大允许充填倍线与流变参数模型。针对云南某铅锌矿实际充填情况,得到料浆质量分数为77%~80%时,其最大允许充填倍线分别为10.83、6.49、5.00和4.12,此结果能为井下不同位置采空区选择不同质量分数的膏体料浆提供理论依据。

关键词:倾斜管;屈服应力;塑性黏度;充填倍线;自流输送

中图分类号:TD861 文献标志码:A

Gravity transport law of paste based on inclined pipe experiment

LI Gong-cheng1, 2, WANG Hong-jiang1, 2, WU Ai-xiang1, 2, YU Shao-feng1, 2, CHEN Hui1, 2,

WANG Xiao-ning1, 2, YAN Qing-wen3

(1. Key Laboratory for High Efficient Mining and Safety in Metal Mine, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Yunan Chihong Zn & Ge Co., Ltd., Qujing 654212, China)

Abstract: A four-factor of six-level uniform design scheme was used on the basis of a self-made inclined pipe experimental device. Affecting laws between each factor and rheological parameters for paste slurry were got by regression analysis. Laws of rheological parameters for paste slurry and gravity transport were analyzed, and then the models between the maximum stowing gradient and rheological parameters were established. According to the real filling conditions of a certain Pb &Zn mine in Yunnan Province, China, when the mass fraction of slurry is from 77% to 80%, its maximum filling times lines are 10.83, 6.49, 5.00 and 4.12, respectively. These results provide theoretical basis for determining mass fraction of paste slurry in different underground goafs.

Key words: inclined pipe; yield stress; plastic viscosity; filling times line; gravity transport

随着对矿产资源需求量的增加和浅部资源的不断消耗,国内外越来越多的金属矿山进入深部或更深的开采状态[1],由此带来高应力等问题,势必诱发地质灾害,而充填采矿法能很好地预防此类安全事故的发生,膏体充填技术由于环保、安全、经济等优点,越来越多的国家已经将此项技术应用于矿山开采中[2-5]。

管道输送技术是膏体充填的核心技术之一,管道输送系统设计的成败直接关系到充填系统能否正常运行[6]。膏体自流管道输送更是成功运用膏体充填的必要前提,特别是对当前深井膏体管道输送自流输送的研究显得尤为重要。为了评价膏体自流输送的可行性与可靠性,国内外对膏体的流变特性进行了大量的研究[6-8]。目前应用较为广泛的浆式流变仪虽然能够有效降低壁面滑移的影响[9],但在实际应用过程中,操作方法不同,即使使用同一种流变仪所得的检测结果仍然存在较大差异,从而使管输系统的设计偏离实际值[10-11]。同时,与现场实际最为接近的环管实验法由于实验装置复杂、测试周期长、费用高[12],因此,其应用并不广泛。针对流变仪及环管法的缺点,本文作者采用自制的倾斜管道测定膏体料浆流变参数,该实验装置简单,操作方便,费用低,与工程实际较为吻合。

以云南某铅锌矿膏体充填系统为工程背景,为最大限度地减少尾砂库存量,该矿将库存尾砂一并充入采空区,结合膏体制备工艺,选择灰砂质量比、料浆质量分数、库存尾砂掺比和废石掺比4个因素,在考察4个因素对膏体流变特性影响的基础上,研究该矿膏体充填系统自流输送规律,为下一步研究充填物料制备膏体提供理论依据。

1 倾斜管实验原理

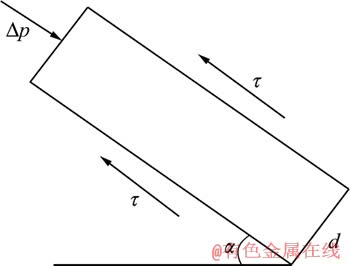

一般地,国内外文献均将膏体充填料视为塑性结构流,并应用宾汉( Bingham )流变模型来研究,其流态属于非牛顿流体[12-13]。在倾斜管道内沿横断面取一微元体,进行图1所示的受力分析,则在管道的倾斜方向上有:

(1)

(1)

图1 浆体微元受力分析示意图

Fig. 1 Schematic diagram of stress analysis of slurry infinitesimal section

式中:τ为浆体切应力,Pa;d为料浆微元体直径,m;l为料浆微元体长,m; 为料浆微元体倾角,(°);

为料浆微元体倾角,(°); 为浆体微元断面压力差,Pa;ρ为料浆密度,kg/m3;g为重力加速度,m/s2。

为浆体微元断面压力差,Pa;ρ为料浆密度,kg/m3;g为重力加速度,m/s2。

沿倾斜长积分得

(2)

(2)

式中:L为管道长度,m; 为管道两端压力差,Pa;从式(2)可得出,管道内壁处浆体的最大切应力为

为管道两端压力差,Pa;从式(2)可得出,管道内壁处浆体的最大切应力为

(3)

(3)

式中:τw为浆体管壁处切应力,Pa;D为管道直径,m。对于宾汉流体,管壁处切应力τw和切变率8v/D之间的关系可以用伯金汉(Buckingham)方程表示:

(4)

(4)

式中:τ0为膏体料浆屈服应力,Pa;μB为膏体料浆塑性黏度,Pa·s;v为料浆流速,m/s;在结构流区域内,壁面剪切应力τw与切变率8v/D在切变率高值范围内呈直线关系,简化4次方项,式(4)转化为

(5)

(5)

取倾斜管道入口和管道出口处两通流断面进行分析,根据伯努利方程:

(6)

(6)

式中:h为倾斜管道入口及出口高差,m;v为料浆流速,m/s;hw为沿程阻力损失,m;在以往的研究中,推导出膏体水平管道水力坡度的理论公式为[14]

(7)

(7)

式中:im为水平管道水力坡度,Pa/m; 为水的密度,g/cm3。沿程阻力损失与水力坡度

为水的密度,g/cm3。沿程阻力损失与水力坡度 关系为

关系为

(8)

(8)

对于倾斜管道水力坡度的计算,料浆除克服沿程的管道阻力以外,还应考虑固体垂直分量,则倾斜管道水力坡度为

(9)

(9)

式中: 为料浆体积分数。联立式(3)~(9)得

为料浆体积分数。联立式(3)~(9)得

(10)

(10)

对于确定的倾斜管道装置,管道直径D、管道长度L、管道入出口高差h及倾斜角度 已经测定,为已知值;对于某一配合比和一定浓度的料浆,其物理力学性质固定不变,料浆密度

已经测定,为已知值;对于某一配合比和一定浓度的料浆,其物理力学性质固定不变,料浆密度 及体积分数

及体积分数 为定值。由式(10)推算得到式(11),测定该管道两个不同倾角

为定值。由式(10)推算得到式(11),测定该管道两个不同倾角 和

和 下的浆体平均流速v1及v2,继而得到膏体料浆的τ0及μB:

下的浆体平均流速v1及v2,继而得到膏体料浆的τ0及μB:

(11)

(11)

2 实验

2.1 实验材料

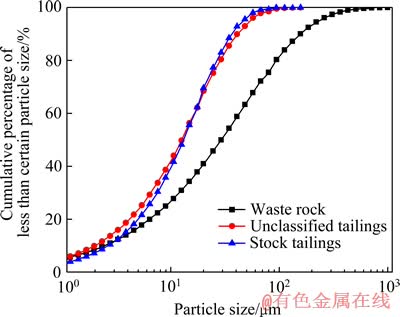

水泥型号为32.5R的普通硅酸盐水泥;全尾砂密度为2.75 g/cm3,容重为1.75 g/cm3,孔隙率为36.36%;其粒级组成较细,平均粒径为75.59 μm,中值粒径为34.95 μm,粒径小于20 μm的颗粒累计含量占37.20%,库存尾砂与全尾砂性质相似;废石粒径小于1000 μm,密度为2.66 g/cm3,容重为1.50 g/cm3,孔隙率为31.78%。全尾砂、库存尾砂及废石粒级组成分别采用激光粒度仪及人工筛分获得,充填骨料粒级组成如图2所示。

2.2 实验装置

图2 膏体物料粒级组成曲线

Fig. 2 Grain size curves of paste materials

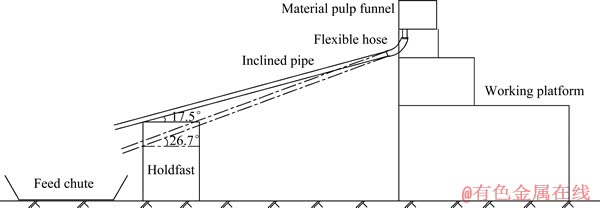

倾斜管实验装置是由备料漏斗、一段倾斜管道、支撑物及盛料槽等组成,其装置见图3。倾斜管道长为3 m,管道直径为0.063 m。测试时,将制备好的高浓度料浆倒入受料漏斗,不断添加使漏斗内的料浆面保持在同一高度,该铅锌矿膏体料浆输送速度小于1 m/s。为更好地模拟实际生产,将倾斜角度 分别设置为17.5°及26.7°,得到料浆入口与出料口的垂直高度分别为h1=0.9 m和h2=1.35 m,同时测定全断面浆体平均流速,为获取准确的流量,应将稳定速度状态保持30 s以上时间。

分别设置为17.5°及26.7°,得到料浆入口与出料口的垂直高度分别为h1=0.9 m和h2=1.35 m,同时测定全断面浆体平均流速,为获取准确的流量,应将稳定速度状态保持30 s以上时间。

为验证该倾斜管实验所得数据的准确性,本实验中选用R/S型软固体流变测试仪,并配备V40-20型浆式转子,监测数据导入计算机中进行分析。

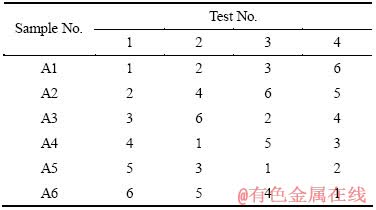

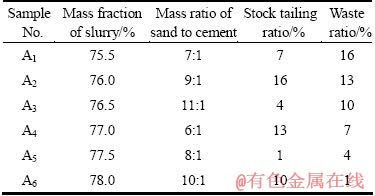

2.3 实验方案

实验因素取灰砂质量比、料浆质量分数、库存尾砂掺比和废石掺比这4个因素,库存尾砂及废石掺比均为全尾砂掺量的质量分数,采用4因素6水平进行实验。均匀设计表及具体实验方案设计分别见表1和2。

图3 倾斜管实验装置

Fig. 3 Experimental device of inclined pipe

表1 U6*(64)均匀设计表

Table 1 U design table of U6*(64)

表2 U6*(64)实验设计方案

Table 2 Scheme of experiment U6*(64)

3 结果与讨论

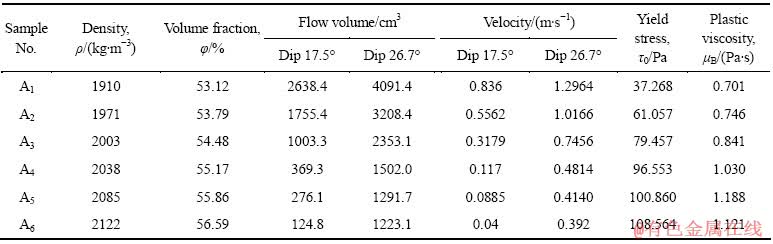

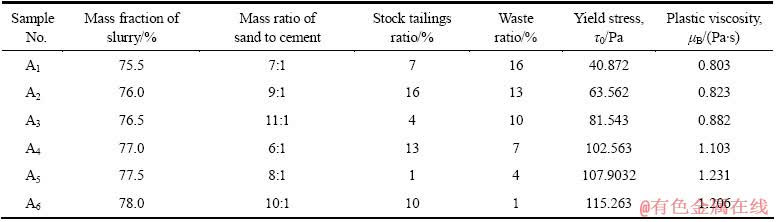

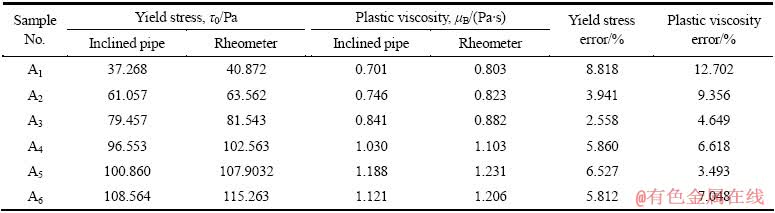

将配制好的料浆搅拌均匀,根据实验操作要求及规定测得不同料浆质量分数、不同配比条件下料浆的性能参数,结合式(11),倾斜管实验得到膏体料浆流变参数,见表3;流变实验所得流变参数见表4。将倾斜管实验和流变仪实验得到的数值进行比较,结果见表5。由表5可知,屈服应力最大误差为8.818%,平均误差为5.586%;塑性黏度最大误差为12.702%,平均误差为7.311%。因此,倾斜管实验所得流变参数结果的可信度较高。

3.1 屈服应力影响因素分析

根据4因素6水平均匀设计实验结果,对屈服应力进行回归分析:

(12)

(12)

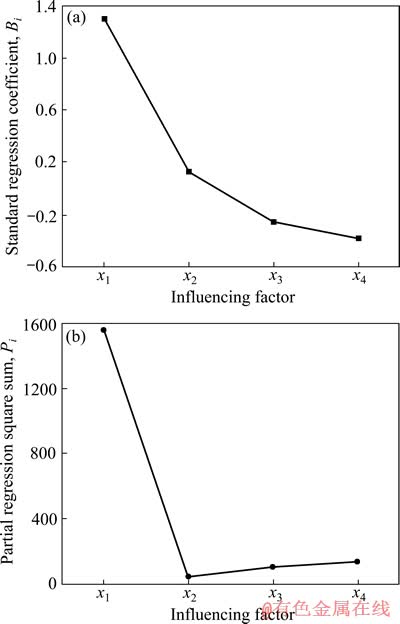

式中:y1为料浆的屈服应力,Pa;x1为料浆质量分数,%;x2为料浆砂灰质量比;x3为库存尾砂掺比,%;x4为废石掺比,%。相关系数为 R2=0.9995,可信度较高。各项标准回归系数Bi的绝对值越大,表示该项的越重要;偏回归平方和Pi的值越大,表示该项对回归的贡献越大。此两种系数见图4。

表3 倾斜管实验得到的料浆流变参数

Table 3 Rheological parameters of slurry obtained by inclined pipe experiment

表4 采用流变仪测定的料浆流变参数

Table 4 Rheological parameters of slurry measured by rheometer

表5 屈服应力和塑性黏度误差分析

Table 5 Error analysis of yield stress and plastic viscosity

由图4可以看出,料浆的屈服应力受料浆质量分数、砂灰质量比、库存尾砂掺比及废石掺比4因素的影响,其影响程度由大到小顺序为料浆质量分数、废石掺比、库存尾砂掺比、砂灰质量比,料浆质量分数对屈服应力的回归贡献最大,砂灰质量比、库存尾砂掺比及废石掺比对回归贡献相当。根据偏相关系数可以得到:料浆质量分数和砂灰比与屈服应力呈正相关;库存尾砂掺比和废石掺比与屈服应力呈负相关。

图4 料浆屈服应力的标准回归系数及偏回归平方和

Fig. 4 Standard regression coefficient(a) and partial regression square sum(b) of yield stress of slurry

由以上屈服应力及塑性黏度分析可知,对于质量分数≥75.5%的膏体料浆,料浆质量分数和废石掺比对膏体的流动性影响最大, 砂灰比影响最小,说明当膏体质量分数达到一定值时,料浆的物料级配对膏体影响较大,相比于一般的低质量分数充填料浆,砂灰比对改变该铅锌矿的膏体流动性能不显著。

3.2 塑性黏度影响因素分析

根据4因素6水平均匀设计实验结果,对料浆塑性黏度进行回归分析:

(13)

(13)

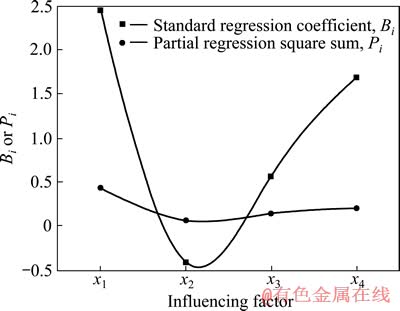

式中:y2为料浆的塑性黏度,Pa·s;复相关系数R2=0.9999,可信度较高。各方程项的标准回归系数Bi和偏回归平方和P i见图5。

图5 料浆塑性黏度的标准回归系数及偏回归平方和

Fig. 5 Standard regression coefficient and partial regression square sum of plastic viscosity of slurry

由图5可以看出,料浆的塑性黏度受料浆质量分数、砂灰比、库存尾砂掺比及废石掺比因素的影响,其影响程度由大到小顺序为料浆质量分数、废石掺比、库存尾砂掺比、砂灰比;且此4因素中料浆质量分数和库存尾砂比与塑性黏度呈正相关;砂灰比和废石掺比与塑性黏度呈负相关。各因素对回归的贡献相当。

3.3 膏体自流输送规律

充填倍线是管路输送中的一个重要参数[15]。充填倍线的大小是管道能否实现自流的一个决定性因素。充填倍线过大,料浆自然压头产生的压力不能完全克服管道阻力损失,系统输送困难,易发生堵管;充填倍线过小,料浆自由下落高度增大,管道磨损严重,寿命短。为保证顺利实现管道自流输送,其几何充填管路倍线N应小于最大允许充填倍线Nmax[16-17]:

(14)

(14)

式中:H为垂直管高度,m;L*为水平管道长度,m。

料浆产生的重力势能大于所受到的阻力是实现自流输送的前提条件。除式(9)之外,根据能量守恒定律得管道的沿程水头损失hw与水力坡度im的关系为

(15)

(15)

根据伯努利方程,管道垂直高度H与沿程水头损失hw的关系为

(16)

(16)

式中: ,β取值为0.1~0.3;联立式(14)、(15)、(16)得膏体允许最大充填倍线为

,β取值为0.1~0.3;联立式(14)、(15)、(16)得膏体允许最大充填倍线为

(17)

(17)

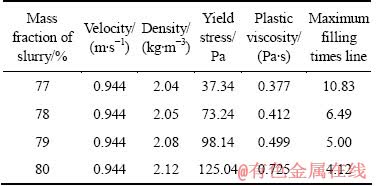

根据该铅锌矿实际充填情况,充填系统流量为60 m3/h,管道直径为0.15 m,充填管线较长,充填倍线较大,相比于倾斜管实验,不同质量分数料浆的流速基本一致,砂灰比为8:1,库存尾砂掺比为12%,废石掺比为4%,料浆质量分数为77%~80%,据此得到矿山不同质量分数下满足自流输送的最大充填倍线如表6所列。

充填配比不变的情况下,以表6中不同质量分数的最大允许倍线为理论依据,针对井下不同位置的采空区,调整充填质量分数以达到自流输送的目的。

表6 不同质量分数料浆自流输送最大充填倍线

Table 6 Maximum filling time line slurry with different mass ratios for gravity transport

4 结论

1) 针对流变仪及环管法的缺点,采用自制的倾斜管道测定膏体料浆流变参数,该实验装置简单,操作方便,费用低,与工程实际较为吻合,并用R/S型软固体流变测试仪验证实验结果的准确性,提出倾斜管实验测量膏体流变参数原理。

2) 对于呈结构流形态的膏体料浆,基于宾汉流变模型,得到倾斜管实验测量膏体料浆流变参数原理。分析表明:在管道属性及膏体料浆物理力学性质确定的情况下,只要测定同一种管道两个不同倾角下充填料浆的平均流速,即可得到膏体料浆的屈服应力及塑性黏度。

3) 基于云南某铅锌矿膏体充填配比,建立了膏体流变料浆参数与各影响因素之间的模型。分析认为:屈服应力与塑性黏度均受料浆质量分数、砂灰比、库存尾砂掺比及废石掺比4因素的影响,屈服应力受影响程度由大到小顺序为料浆质量分数、废石掺比、库存尾砂掺比、砂灰质量比;塑性黏度受影响程度由大到小顺序为料浆质量分数、废石掺比、库存尾砂掺比、砂灰比。

4) 通过理论推导,构建了最大允许充填倍线与流变参数的理论模型,为膏体充填料浆制备提供了理论基础,并针对云南某铅锌矿料浆实际充填情况,得到料浆质量分数为77%~80%时,最大充填倍线分别为10.83、6.49、5.00和4.12。

REFERENCES

[1] 李夕兵, 姚金蕊, 宫凤强. 硬岩金属矿山深部开采中的动力学问题[J]. 中国有色金属学报, 2011, 21(10): 2551-2563.

LI Xi-bing, YAO Jin-rui, GONG Feng-qiang. Dynamic problems in deep exploitation of hard rock metal mines[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2551-2563.

[2] GRABINSKY M W. In situ monitoring for ground truthing paste backfill design[C]// Proceedings of the 13th International Seminar on Paste and Thickened Tailings. Perth: Australian Centre for Geomechancis, 2010: 85-98.

[3] FALL M, NASIR O. Predicting the temperature and strength development within cemented paste backfill structure[C]// Proceedings of the 13th International Seminar on Paste and Thickened Tailings. Perth: Australian Centre for Geomechancis, 2010: 125-136.

[4] BELEM T, FOURIE A B, FAHEY M. Time-dependent failure criterion for cemented paste backfills[C]// Proceedings of the 13th International Seminar on Paste and Thickened Tailings. Perth: Australian centre for Geomechancis, 2010: 147-162.

[5] NASIR O, FALL M. Coupling binder hydration temperature and compressive strength development of underground cemented paste backfill at early at ages[J]. Tunnelling and Underground Space Technology, 2010, 25: 9-20.

[6] 黄玉诚, 孙恒虎. 尾砂作骨料的似膏体料浆流变特性实验研究[J]. 金属矿山, 2003(6): 8-10.

HUANG Yu-cheng, SUN Heng-hu. Experimental study on the rheological characteristic of paste-like slurry with tailings as aggregate[J]. Mental Mine, 2003(6): 8-10.

[7] 王 星, 赵学义, 瞿圆源, 胡伟伟, 陈 洁, 吴 淼. 高浓度赤泥颗粒特性和流变特性的试验研究[J]. 金属矿山, 2008(1): 107-109.

WANG Xing, ZHAO Xue-yi, QU Yuan-yuan, HU Wei-wei, CHEN Jie, WU Miao. Experimental research on particle characteristics and rheological properties of high concentration red mud[J]. Metal Mine, 2008(1): 107-109.

[8] JEWELL R, FOUIRE A. Paste and thickened tailing—A guide[M]. Perth: Australia Centre for Geomchancis, 2006: 25-37.

[9] BAUGER E, JOSE G G D S, ELVIO A G, SILVA F G S. Study of the laboratory vane test on mortars[J]. Building and Environment, 2007, 42: 86-92.

[10] SAAKA A W, JENNINGS H M, SHAHB S P. The influence of wall slip on yield stress and viscoelastic measurements of cement paste[J]. Cement and Concrete Research, 2001, 31: 205-212.

[11] 吴爱祥, 焦华喆, 王洪江, 李 辉, 仪海豹, 刘晓辉. 膏体尾矿屈服应力检测及其优化[J]. 中南大学学报: 自然科学版, 2013, 44(8): 3370-3376.

WU Ai-xiang, JIAO Hua-zhe, WANG Hong-jiang, LI Hui, YI Hai-bao, LIU Xiao-hui. Yield stress measurements and optimization of paste tailings[J]. Journal of Central South University: Science and Technology, 2013, 44(8): 3370-3376.

[12] 周爱民. 矿山废料胶结充填[M]. 北京: 冶金工业出版社, 2007: 89-91.

ZHOU Ai-min. Waste cement filling in mine[M]. Beijing: Metallurgical Industry Press, 2007: 89-91.

[13] 孙恒虎. 当代胶结充填技术[M]. 北京: 冶金工业出版社, 2002: 214-215.

SUN Heng-hu. Technology of cement filling in contemporary[M]. Beijing: Metallurgical Industry Press, 2002: 214-215.

[14] 翟永刚, 吴爱祥, 王洪江, 陈琴瑞, 李航空, 严佳龙. 全尾砂膏体料浆的流变特性研究[J]. 金属矿山, 2010(12): 30-32, 57.

ZHAI Yong-gang, WU Ai-xiang, WANG Hong-jiang, CHEN Qin-rui, LI Hang-kong, YAN Jia-long. Study on rheological properties of the unclassified-tailings paste[J]. Metal Mine, 2010(12): 30-32, 57.

[15] WANT F M, COLOMBERA P M, NGUYENO D. Pipeline design for the high density bauxite residue slurries[C]// Proceedings of the 8th International Conference on Hydraulic Transport of Solids in Pipes Johannesburg, 1982: 242-262.

[16] 王新民. 基于深井开采的充填材料与管道输送系统的研究[D]. 长沙: 中南大学, 2005: 144-145.

WANG Xin-min. Research on filling material and pipe transport system based on deep mining[D]. Changsha: Central South University, 2005: 144-145.

[17] 张卓成, 张小娟. 砂浆输送倍线对充填系统安全运行的探讨[J]. 金属矿山, 2009(11): 287-290.

ZHANG Zhuo-cheng, ZHANG Xiao-juan. Discussion on effect of times line of slurry transmission on the safety operation of filling system[J]. Metal Mine, 2009(11): 287-290.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51374034,51304011);国家“十二五”科技支撑计划项目(2012BAB08B02)

收稿日期:2014-04-17;修订日期:2014-08-06

通信作者:王洪江,教授,博士;电话:010-62334680;E-mail: wanghj1988@126.com