文章编号:1004-0609(2012)10-2960-10

低能耗下铝电解槽阳极结构的优化

李贺松1,曹 曦1,田应甫2

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 重庆天泰铝业有限公司,重庆 401328)

摘 要:为了进一步降低铝电解工业能耗,以仿真软件ANSYS及ANSYS-FLUENT为平台,应用阳极穿孔方式对铝电解用阳极进行结构优化,并进行工业试验,以研究其工业应用并验证仿真结果。计算结果表明:新型阳极下气泡层厚度为1.28 cm,比普通阳极气泡层厚度减少0.72 cm,对应极距电压差约240 mV;阳极表面温度最低为704.3 ℃,阳极电压降为379 mV,电场分布与普通阳极保持一致;阳极碳块热应力最大值为17.4 MPa,远低于碳块的许用应力。新型阳极在3台槽上进行试验,长期运行的平均槽电压比传统电解槽的降低了229 mV,穿孔阳极结构电解槽电流效率从91.15%提高到91.85%,生产每吨铝直流电耗降低了683 kW·h。仿真结果与实验结果相符,说明此结构阳极能够快速排出气泡进而减小极距。

关键词:铝电解槽;低能耗;穿孔阳极结构;气泡层厚度;多物理场耦合;数值模拟;工业试验

中图分类号:TF821 文献标志码:A

Optimization of anode structure in aluminum reduction cells under

low power consumption

LI He-song1, CAO Xi1, TIAN Ying-fu2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Chongqing Tiantai Aluminum Industry Co., Ltd., Chongqing 401328, China)

Abstract: The perforation in the carbon block to optimize the structure of anode was researched by using simulation software ANSYS and ANSYS-FLUENT in order to reduce the energy consumption of aluminium reduction industry further more. The industrial test was carried out to study the industrial applications and verify the simulation result. The simulation results show that the bubble layer thickness of the perforated anode is 1.28 cm, reduced by 0.72 cm compared with that of the normal anode, the corresponding voltage is about 240 mV. The minimum temperature of anode block is 704.3 ℃, and the voltage drop of the perforated anode is 379 mV and the current density distribution of the perforated anode and ordinary anode are consistent. The maximum of thermal stress is 17.4 MPa in the perforated anode, which is far less than the allowable stress. The perforated anode industrial test was conducted on three cells. The average cell voltage of perforated anodes decreases by 229 mV compared with the traditional reduction cell after long-term operation, and the current efficiency increases from 91.15% to 91.85%. The production per ton aluminium direct current (DC) consumption of perforated anode reduces by 683 kW·h. The experimental results agree with the theoretical calculation, which indicates that the polar distance of the perforated anode is decreased because the bubbles exhaust quickly.

Key words: aluminum reduction cell; low power consumption; perforation structure anode; bubble layer thickness; coupled multi-field; numerical simulation; industrial test

基金项目:国家自然科学基金资助项目(51004115);中央高校中南大学自由探索计划项目(20101220062)

收稿日期:2011-09-10;修订日期:2012-04-10

通信作者:李贺松,教授,博士;电话:18684696162;E-mail: lihesong611@yahoo.com.cn

霍尔-埃鲁特熔盐电解炼铝法的工业应用已有100多年,其中电解铝生产工艺过程和容量发展迅猛,使铝的产量大大提高。随着技术进步,电解铝能耗有所降低,直流电耗已由20世纪初的每吨铝40 MW·h降低到每吨铝13 MW·h [1],但目前最先进的铝电解工艺能量利用率也只有52%左右[2],有一半左右的电能转变成了热量散发流失了。而节能和环境保护已经成为全球共同面对的问题,因此,改进铝电解槽设备,在提高或保持电流效率的基础上,将能量利用率提高到55%~58%,甚至60%以上,将是电解铝行业科技技术的发展方向。

降低铝电解工艺直流电耗的方法有很多种,应用较多的方法是降低槽电压。目前国内采用异型阴极或高效电解工艺[3]来降低铝液波动,进而为降低槽电压提供稳定性条件,取得了明显的效果。如果还想进一步挖掘降低槽电压的潜力,就要从气泡层着手。针对气泡层的研究,目前国外主要集中在开槽阳极,已经有电解铝厂在尝试使用此阳极[4-6]。国内一些铝厂也 研究了此阳极[7-10],但效果没有国外的明显。槽电压的降低幅度一般在50 mV左右,换算成极距即降低了0.14 cm的气泡层,虽然有一些效果,但相比2 cm气泡层,还有更大的降低空间。在阳极气泡行为的研究上,国内外一般采用模型试验和仿真相结合的方 式[11-15]。因此,改进电解槽的阴极结构、阳极结构及电解工艺条件,在保证高电流效率的情况下尽可能降低槽电压,是目前电解铝节能技术发展的主要趋势。

1 大幅降低槽电压的两种途径

铝电解槽平均电压U由以下各部分组成:

式中:UE为阴阳极之间液体电解质层电阻产生的电压降;Up为氧化铝理论分解电压和阴极、阳极极化(钝化)电压降之和;Ua与Uc分别为铝电解槽阳极与阴极电压降,其与材料、高度及电流密度有关,电解槽设计定型后基本为定值;Ub在电解槽设计时一次定型,基本为定值;Ue为阳极效应分摊电压降,目前为0.01 V左右,已是较低水平。因此,降低电解槽平均电压只能从降低Up与UE入手。

阳极极距模型中阳极极距由3部分构成(见图1)[16]:第一部分为下部铝液波动层,其厚度一般为1.5~2.0 cm(见图1中第2层);第二部分为上部气泡层,其厚度一般为2.0 cm(见图1中第4层);第三部分为防止气泡与铝液接触发生二次反应的电解质隔离层,其厚度一般为0.5~1.0 cm(见图1中第3层)。当铝液波动减弱时,电解质隔离层可以适当减薄。

图1 电解槽极距分层示意图

Fig. 1 Schematic diagram of cell polar distance decomposition

1—Liquid aluminium; 2—Liquid aluminium fluctuation layer; 3—Bath layer; 4—Bubble disturbance layer; 5—Bath; 6—Anode carbon

由于UE为阴阳极之间液体电解质层电阻产生的电压降,因此UE取决于阳极下表面到阴极铝液的距离,可以通过减弱铝液波动,以减少电解质隔离层厚度的方式降低UE。

由于Up为氧化铝理论分解电压和阴极、阳极极化(钝化)电压降之和,现有大型预焙铝电解槽Up一般为 1.65 V左右,其主要是气泡层的存在导致的。所以目前大幅度降低槽电压的研究主要集中在这一区域。

因此,从本质上分,降低槽电压主要分为两种途径:减弱铝液波动和减薄阳极气体层。

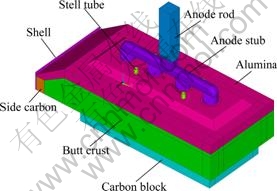

2 优化的新型阳极(穿孔阳极)

穿孔阳极结构是针对降低槽电压及迅速排出阳极气体提出的一种新思路,具体结构如图2所示。此结构阳极是在阳极底部开出数个垂直气孔,并贯穿阳极,阳极底部任何一点产生的CO2气泡溢出阳极底部所需的移动距离均在200 mm以内。该结构可以降低CO2气泡在溢出过程中所需克服的液态电解质流体粘滞力所做功,使气体能够及时排出,进而有效减薄阳极底部气泡层厚度及气泡下渗距离,从而缩短极距,为降低吨铝电耗创造条件。本文作者建立了穿孔阳极及阳极底掌气泡层的物理和数学模型,运用仿真软件ANSYS及ANSYS-FLUENT对穿孔阳极的热场、电场、应力场分布,及穿孔阳极下气体分布进行了模拟,探讨了穿孔阳极的作用机理及孔对气体的影响。同时进行了穿孔阳极工业试验,以验证模型并得到穿孔阳极的作用效果。

图2 穿孔阳极结构示意图

Fig. 2 Schematic diagram of perforated anode

3 穿孔阳极气泡层模型

铝液和电解质在铝电解槽内受到3种力的作用,即电磁力、重力和浮力(气泡、温度和浓度梯度所引起的)。本模型主要研究了浮力因素,包括极距区的气液两相流和气泡带动下地电解质运动。铝电解槽极距区的气液两相流比较复杂,包括电化学反应、溶解、扩散、热传递和其他物理化学过程,影响因素繁多。因此,本模型作如下假设:

1) 忽略悬浮在电解质中氧化铝颗粒的影响;

2) 假定电解质和铝液的温度是恒定的,不考虑温度梯度所引起的流动;

3) 假设相邻阳极产生气体互不影响。

3.1 CFD模型

CFD软件ANSYS-FLUENT中的VOF模型可以用来计算气泡的生成和溢出过程。相比欧拉和混合模型,本文作者采用VOF模型更应用于追踪气泡的行为和计算每项流体的体积分数。该模型体积分数方程如下

(2)

(2)

式中:mqp是q项到p项的传输质量;mpq是p项到q项的传输质量; 是q相的密度;

是q相的密度; 是q相的体积分数;vq是q相的速度;

是q相的体积分数;vq是q相的速度; 是q相的生产率;n为总相数。

是q相的生产率;n为总相数。

主相体积分数的计算基于如下约束 :

:

(3)

(3)

该模型动量方程取决于所有项的体积分数,动量方程为

(4)

(4)

式中: 为哈密顿算子;F为作用在控制容积上的体积力,N;

为哈密顿算子;F为作用在控制容积上的体积力,N; 为密度,kg/m3;

为密度,kg/m3; 为分子粘性系数,Pa·s;v为流体速度;vT为v的转置矩阵;g为重力加速度。

为分子粘性系数,Pa·s;v为流体速度;vT为v的转置矩阵;g为重力加速度。

3.2 模型和边界条件

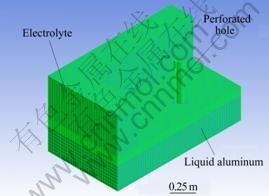

在GAMBIT中建立模型后输出到ANSYS- FLUENT中设置边界条件和求解。出于简化计算和对称性的考虑,本文作者只建立了穿孔阳极和气液两相流的四分之一模型(图3),模型中阳极宽度为660 mm。

图3 穿孔阳极电解质层和铝液层三维网格模型

Fig. 3 Three-dimensional mesh model of perforated anode liquid aluminium layer and electrolyte layer

这一模型涉及浮力、重力等大的体积力,因此,采用Body-force-weighted方式进行压力插值。模型采用非稳态模式进行计算,因此压力速度耦合采用PISO方式。入口设置为速度入口,气体速度由式(5)得到[17]:

(3)

(3)

式中:I为电流;R为理想气体常数;T为温度;F为法拉第常数;P为压力; 为气体体积分数;S为浸入电解质阳极面积。CO2和电解质之间的表面张力经过测试为0.117 N/m。

为气体体积分数;S为浸入电解质阳极面积。CO2和电解质之间的表面张力经过测试为0.117 N/m。

3.3 材料属性和工艺参数

本模型使用的重庆天泰铝业有限公司电解槽生产工艺和材料属性参数具体见表1[18]。

表1 槽工艺参数和运行参数[18]

Table 1 Cell process parameters and operation parameters[18]

3.4 结果和讨论

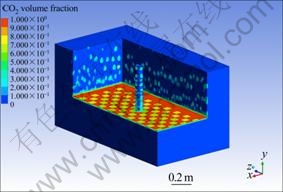

电解质层中某时刻气液二相分布如图4所示。由图4可以看出,穿孔阳极的底掌形成一层气泡层。气泡逸出有两种方式,一是从碳块四周逸出,另一种是从孔中逸出。从图4上可以看出,气泡层厚度与孔的直径相比,约为孔直径的三分之一。气泡层厚度实际平均值为1.28 cm,相比660 cm阳极宽度气泡层厚度减少了0.72 cm(普通阳极以同样方式计算)。取电流密度为0.74 A/cm2,电解质电阻取0.45 ?/cm,则极间压降(Ur)为:

(5)

(5)

理论计算表明穿孔阳极与普通阳极相比,槽电压降低了0.24 mV,本文作者将在工业试验中验证该结果。

图4 穿孔阳极电解质层中某时刻气液二相分布

Fig. 4 Perforated anode bath layer gas-liquid two-phase distribution at some moments

4 穿孔阳极多物理场耦合模型

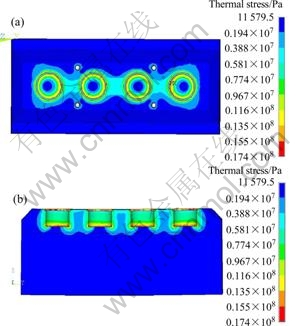

阳极过程对铝电解生产中的顺畅与否关系密切,因此阳极在生产中的稳定性影响甚大。在铝电解过程中,阳极结构会随着温度变化而变化。温度升高后,阳极各个部分发生膨胀,钢爪,磷生铁和炭块之间相互挤压,产生热应力。热应力过大可能造成阳极破损、断裂,导致脱极,对正常生产造成巨大的不利影响。在阳极上槽后,由于工作环境的限制,热应力无法通过试验测得,但是可以通过仿真模拟计算出来。在有限元软件ANSYS中建立穿孔阳极的有限元模型,耦合计算穿孔阳极的热场、电场和热应力场后,比较热应力与阳极炭块许用应力,确定穿孔阳极正常生产稳定性。

本模型研究针对的是单一阳极,并且由于槽内的复杂性,模型做如下假设:

1) 整台电解槽及电解槽内的分析域为稳态模型。

2) 氧化铝为绝缘体,铝液区为等势体。

3) 阳极高度恒定,并且每组阳极电流相同,为整体电流的均摊值。

4.1 多场耦合ANSYS求解过程

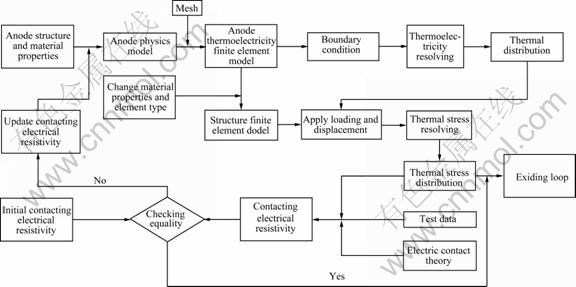

磷生铁和炭块之间的接触部分分析在阳极结构分析中占据重要地位。对接触电阻的实现是采用修正接触电阻的办法进行确定的。根据国外学者研究[19],接触电阻在0.1 m2的碳碗中为2 m?,取2 mm的接触电阻层,计算可得接触电阻率为1×10-4 ?。以此接触电阻率为初始值,进行热电和热应力分析,根据应力场结果再结合电接触理论和现场测试数据,计算修正后的接触电阻率,与初始值比较,若收敛则得到热应力分布,若不相符,则进一步迭代到收敛后结束。计算流程如图5所示。

4.2 模型和边界条件

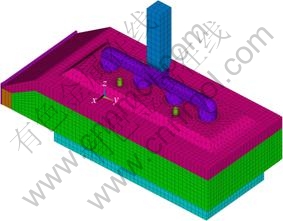

图6所示为穿孔阳极的模型。由图6可看出,模型包括阳极炭块、磷生铁、氧化铝覆盖料、电解质结壳、侧部炭块和槽壳等。模型采用SOLID69单元耦合热电后,转为SOLID45单元计算热应力。坐标系定义为x方向为从出铝端到烟道端,y方向从槽侧部到槽中央,z方向垂直向上。模型只单独建立阳极结构,因此,在阳极炭块底部分别施加零电位边界条件。由于铝液与电解质的流动,熔体区的温度基本均匀,所以浸入电解质部分阳极炭块边界条件可通过对其表面施加对流负载来简化处理。氧化铝覆盖料、阳极钢爪和阳极导杆采用对流和辐射边界条件。侧部与相邻阳极接触部分采取对称面。

图5 修正接触电阻法热应力求解过程

Fig. 5 Solution procedure of thermal stress by revised contact resistivity

图6 穿孔阳极计算模型

Fig. 6 Perforated anode calculation mesh model

4.3 材料属性和结构参数

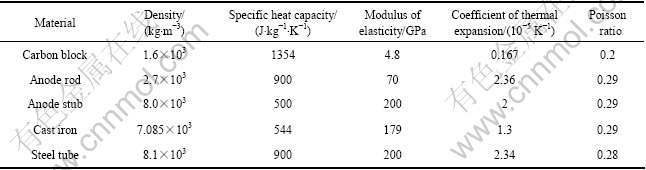

建模所用的结构参数及部分物性参数取自重庆天泰铝业提供资料及现场实测。材料属性和结构参数如表2~5所列。

4.4 结果和讨论

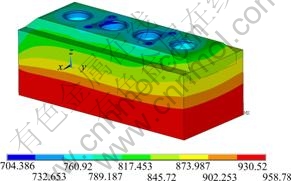

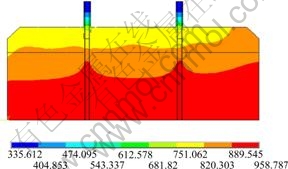

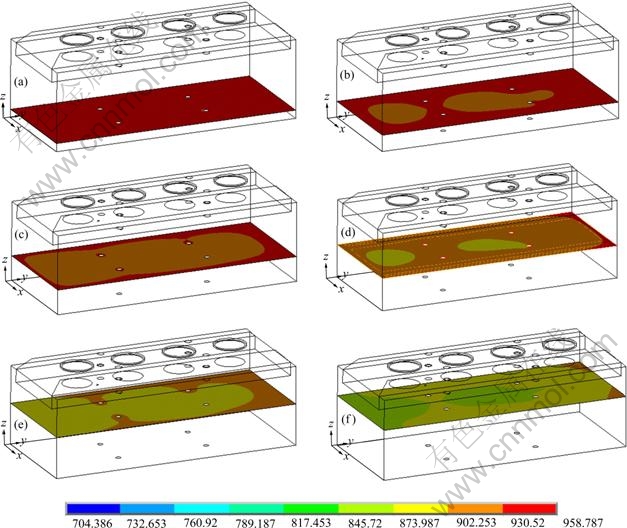

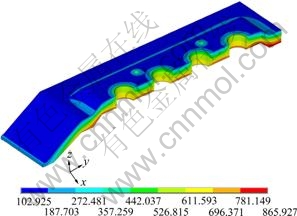

图7表明由于槽外和槽内温度有别,炭块温度分布沿炭块大面方向对称分布,而沿小面方向不对称。靠近槽侧部位置温度比槽中位置温度低,其中孔周围温度分布最低,表面最低温度为704.3 ℃。图8和9所示分别为穿孔面和炭块内部不同层的温度分布。由图8和9可以看出,因为炭块下部浸入电解质内,电解质的对流和电解产生气体的上升,在炭块内部沿孔方向垂直向上温度逐渐降低,气体出口处温度为335.6 ℃,说明炭块内部同一水平面内温度在穿孔处分布最高。同时较大梯度的温度分布会导致较大的热应力分布,这可能造成炭块,特别是孔周围的炭块部分破损,因此进行热应力分析是必要的。图10所示为氧化铝颗粒覆盖层的温度分布。由图10可看出,阳极氧化铝粉末其表面温度约为102.9 ℃左右,而底部由于和阳极直接接触,其温度达到800 ℃以上。这是由于烟气被抽走引起的对流现象带走部分热量,且由表层一直辐射到低温的槽罩所造成。而穿孔处与周围差别较大,达到200 ℃左右,这是由于钢的热传导性较好,炭块内部热量可以通过钢管传递上来所致。

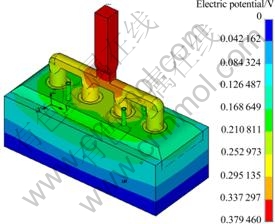

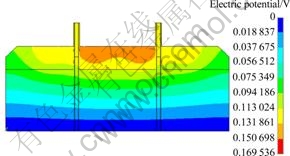

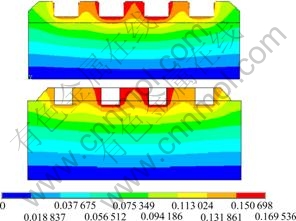

图11和12所示分别为穿孔阳极和穿孔面的电势分布。图11和12表明穿孔阳极结构整体电压降为379.5 mV,阳极炭块的电压降为169.5 mV。图13说明,穿孔阳极与普通阳极的相比,电压分布没有区别。

表2 阳极相关结构参数[20]

Table 2 Structure parameters of anode[20]

表3 不同温度时材料的电阻率

Table 3 Resistivity of materials at different temperatures

表4 不同温度时材料的热导率[19, 21-22]

Table 4 Thermal conductivity of materials at different temperatures [19, 21-22]

表5 材料的相关物性参数[20]

Table 5 Physical parameters of materials[20]

图7 炭块温度分布

Fig. 7 Temperature distribution of carbon block (℃)

图8 穿孔面的温度分布

Fig. 8 Temperature distribution of perforated section (℃)

图9 距离阳极炭块底部不同层温度分布

Fig. 9 Temperature distribution of level sections above bottom of anode in perforated carbon block (℃): (a) 5 mm; (b) 10 mm; (c) 15 mm; (d) 20 mm; (e) 25 mm; (f) 30 mm

图10 氧化铝颗粒覆盖层的温度分布

Fig. 10 Temperature distribution of alumina mulch (℃)

图11 穿孔阳极的电势分布

Fig. 11 Electric potential of perforated anode

图14所示为穿孔阳极的等效应力分布。由图14可看出,热应力主要集中在磷生铁和炭块的接触部分,以及炭块与钢管的接触部分。穿孔周围应力为5 MPa左右,最大应力分布在与磷生铁相接触部分,为17.4 MPa,但该值还远远低于炭块的许用应力。理论计算结果表明,穿孔阳极和普通阳极一样能安全进行工业运行,但计算结果仍需工业试验的验证。

图12 穿孔面的电势分布

Fig. 12 Electric potential distribution of perforated section

图13 穿孔阳极与普通阳极电势对比(上为穿孔阳极)

Fig. 13 Comparison of electric potential distribution between the perforated and normal anode (perforated anode upside) (V)

5 穿孔阳极的工业试验验证

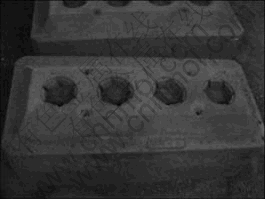

合作方重庆天泰铝业在现有阳极成型模具基础上进行技术改造,生产穿孔阳极。其焙烧后如图15所 示。一次性振动成型合格率达到了99.2%,生产脱极率1.87%。如表6所示,检测每批穿孔阳极性能指标,均达到普通阳极国标要求。

表6 穿孔阳极物理性能

Table 6 Physical performance assessment of perforated anode

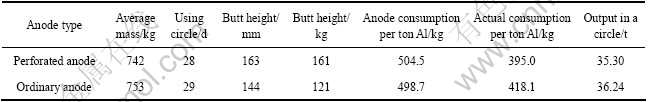

在天泰铝业168 kA电解槽生产系列选择256#、257#、258#槽作为试验槽进行工业试验(图16),从2009年12月1日到2010年12月31日止,对试验槽和对比槽(254#、255#)进行了对比考核,表7和8所列为阳极消耗和技术指标对照。

图14 炭块上表面和对称中心面热应力分布

Fig. 14 Thermal stress distributions of top surface(a) and center symmetry section(b) of carbon block

图15 穿孔阳极成品图

Fig. 15 Perforated anodes production after being baked

图16 在电解槽上生产的穿孔阳极

Fig. 16 Perforated anodes in aluminium reduction cell

由表7和8的试验结果可以看出:穿孔阳极使用周期为28 d,比普通阳极少1 d,但其生产每吨铝实际消耗为395.0 kg,与普通阳极消耗418.1 kg相比,节约了23.1 kg。穿孔结构电解槽长期运行的平均槽电压为3.75 V,与传统电解槽的3.98 V相比降低了0.23 V;电流效率从91.15%提高到91.85%,提高了0.7%;生产每吨铝直流电耗降低了683 kW·h,平均直流电耗达到了12 248 kW·h,为企业带来巨大经济效益。

表7 穿孔阳极和普通阳极消耗对比

Table 7 Comparison of consumption of perforated anode and ordinary anode

表8 试验槽和对比槽技术参数

Table 8 Technical parameters of test cell and contrast cell

6 结论

1) 现在工业要求铝电解生产必须降低能耗,但是传统铝电解槽为了保证电解槽稳定运行,槽电压无法继续降低,因此改变阳极结构,减薄气泡层厚度是降低槽电压的一个重要方向。

2) 穿孔阳极是节能降耗的新思路。阳极底掌下气泡层厚度为1.28 cm,对应槽电压降低240 mV。炭块温度分布沿炭块大面方向对称分布,表面内部温度分布同一水平面上穿孔处温度最高。炭块压降为169.5 mV,电场分布与普通阳极保持一致。穿孔阳极在电解槽内所受最大热应力为17.4 MPa,远低于碳块许用应力,可以保证电解槽正常生产。

3) 该技术在重庆天泰铝业3台168 kA系列电解槽中的进行工业试验,考核期穿孔阳极结构电解槽长期运行的平均槽电压比传统电解槽降低了0.23 V,电流效率从91.15%提高到91.85%,提高了0.7%;生产每吨铝直流电耗降低了683 kW·h,达到了12 248 kW·h。试验槽在低电压下稳定运行,为企业带来巨大经济效益。

REFERENCES

[1] VANVOREN C, HOMSI P, BASQUIN J L. AP 50: The Pechiney 500 kA Cell[C]//ANJIER J L. Light Metals 2001. New Orleans: TMS, 2001: 221-226.

[2] 赵兴亮. 新型铝电解槽换热系统的研究[D]. 沈阳: 东北大学, 2008: 13-14.

ZHAO Xing-liang. The study of new aluminum cell heat transfer system[D]. Shenyang: Northeastern University, 2008: 13-14.

[3] 彭建平, 田应甫, 冯乃祥, 王耀武, 王紫千. 新型阴极结构电解槽铝电解试验[J]. 材料与冶金学报, 2009, 8(3): 165-171.

PENG Jian-ping, TIAN Ying-fu, FENG Nai-xiang, WANG Yao-wu, WANG Zi-qian. Test of novel energy-saving cell for aluminum electrolysis[J]. Journal of Materials and Metallurgy, 2009, 8(3): 165-171.

[4] DIAS H P, MOURA R R. The use of transversal slot anodes at albras smelter[C]//KVANDE H. Light Metals 2005. San Francisco: TMS, 2005: 341-344.

[5] TANDON S C. Energy Saving in hidalgos aluminum smelter[C]//KVANDE H. Light Metal 2005. San Francisco: TMS, 2005: 369-373.

[6] RYE K A. The effect of implementing slotted anodes on some key operational parameters of a PB-ling[C]//LAMOUR J. Light Metals 2007. Orlando: TMS, 2007: 293-298.

[7] 王金融. 带沟槽阳极的开发及在铝电解槽上的应用[J]. 矿冶工程, 2008, 28(6): 251-253.

WANG Jin-rong. The research and application of slotted anode in aluminum reduction cell[J]. Minning and Metallurgical Engineering, 2008, 28(6): 251-253.

[8] 任必军, 王兆文, 石忠宁. 大型铝电解槽阳极开槽试验的研究[J]. 矿冶工程, 2007, 27(3): 61-63.

REN Bi-jun, WANG Zhao-wen, SHI Zhong-ning. Experimental research on anode grooving in large-scale aluminum electrolytic cell[J]. Minning and Metallurgical Engineering, 2007, 27(3): 61-63.

[9] 谢斌兰. 开槽阳极的使用及制造[J]. 中国有色冶金, 2008(5): 79-82.

XIE Bin-lan. Usage and manufacture of slotted anode[J]. China Nonferrous Metallurgy, 2008(5): 79-82.

[10] 秦晓明, 孙海生, 崔瑞军. “船形”阳极炭块在预焙电解槽中的应用[J]. 轻金属, 2008(9): 45-46.

QIN Xiao-ming, SUN Hai-sheng, CUI Rui-jun. The application of “ship shape” anode carbon block in pre-baked anode pot[J]. Light Metal, 2008(9): 45-46.

[11] JOHANSEN S T, BOYSAN F. Fluid dynamics in bubble stirred ladles: Part Ⅱ. Mathematical modeling[J]. Metallurgical Transactions B, 1998, 19B: 755-764.

[12] FRASER K J, TAYLOR M P, JENKIN A M. Electrolyte heat and mass transport processes in hall heroult electrolysis cells[C]// KRTAGAWA H, TANAKA T. Light Metals 1990. Warrendale: TMS, 1990: 221-226.

[13] PURDIE J M, BILEK M, TAYLOR M P. Impact of anode gas evolution on electrolyte flow and mixing in aluminum electrowinning cells[C]//FROES F H, CAPLAN I. Light Metals 1993. Salt Lake City: TMS, 1993: 335-360.

[14] 李相鹏, 李 劼, 赖延清, 刘业翔. 预焙铝电解槽阳极底部开排气沟对电解质流场的影响[J]. 中国有色金属学报, 2006, 16(6): 1088-1093.

LI Xiang-peng, LI Jie, LAI Yan-qing, LIU Ye-xiang. The effect on the flow field of slotted in the bottom of the anode in the pre-baked aluminium reduction cells[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 1088-1093.

[15] 张延利, 侯光辉, 邱仕麟. 铝电解槽阳极气泡行为研究新动态[J]. 轻金属, 2007(12): 41-44.

ZHANG Yan-li, HOU Guang-hui, QIU Shi-lin. New research of the anode bubbles behavior in the aluminium reduction cell[J]. Light Metal, 2007(12): 41-44.

[16] 田应甫. 铝电解槽基于最佳极距运行的探讨[J]. 有色矿冶, 2009, 6: 23-25.

TIAN Ying-fu. Discuss on best polar distance of industrial aluminum cell[J]. Non-ferrous Mining and Metallurgy, 2009, 6: 23-25.

[17] SOLHEIM A, JOHANSEN S T, ROLSETH S,THONSTAD J. Gas driven flow in Hall-Heroult cells[C]//CAMPBELL P G. Metallurgical Society of AIME. Lsa Vegas: TMS, 1989: 245-252.

[18] 周 萍. 铝电解槽内电磁流动模型及铝液流场数值仿真的研究[D]. 长沙: 中南大学, 2002: 13-14.

ZHOU Ping, The model of electromagnetic hydrodynamics in aluminium reduction cell and the simulation of the motions of melt study[D]. Changsha: Central South University, 2002: 13-14.

[19] DUPUIS M. Development and application of an ANSYS based thermo-electro-mechanical anode stub hole design tool[C]// HAGNI A M. Light Metals 2010. San Francisco: TMS, 2010: 1295-1301.

[20] 邓星球. 160 kA预焙阳极铝电解槽阴极内衬电-热-应力计算机仿真研究[D]. 长沙: 中南大学, 2004: 19-20.

DENG Xing-qiu. The thermo-electric-structural emulation study of the cathode lining in the 160 kA prebaked aluminium reduction cell[D]. Changsha: Central South University, 2004: 19-20.

[21] 张程浩, 何生平, 兰 周, 周 洋. 降低预焙铝电解槽阳极覆盖料厚度的实践与分析[J]. 有色冶金节能, 2010, 26(5): 13-15.

ZHANG Cheng-hao, HE Sheng-ping, LAN Zhou, ZHOU Yang. The practice and analysis of reducing the thickness of the anode mulch in the prebaked aluminium reduction cells[J]. Energy Saving of Non-ferrous Metallurgy, 2010, 26(5): 13-15.

[22] 田本良. 碳素材料的弹性模量、强度和破坏变形率[J]. 碳素技术, 1994, 4: 1-8.

TIAN Ben-liang. The modulus of elasticity, strength and deformation damage of the carbon material[J]. Carbon Technology, 1994, 4: 1-8.

(编辑 李艳红)