稀有金属 2010,34(01),38-43

溅射沉积Cu-W合金薄膜的结构及力学性能

郭中正 孙勇 段林昆 郭诗玫 李玉阁

昆明理工大学云南省新材料制备与加工重点实验室

曲靖师范高等专科学校

摘 要:

用磁控共溅射法制备Cu-W合金薄膜,运用EDX,XRD,TEM,SEM和纳米压痕仪对薄膜成分、结构和力学性能及其关系进行了研究。结果表明,含W较低的Cu82.1W17.9(%,原子分数)和W浓度较高的Cu39.8W60.2薄膜为晶态结构且出现固溶度扩展,分别存在fccCu(W)亚稳过饱和固溶体(固溶度4.8%W)和bccW(Cu)亚稳过饱和固溶体(固溶度5.7%Cu),W含量为31.8%,45.7%,54.8%的Cu-W薄膜呈非晶态,表面粗糙度较晶态Cu-W薄膜低。总体上非晶Cu-W薄膜弹性模量E和硬度H值较低,fccCu-W膜实测E值介于Voigt和Reuss规则预测值之间,bcc和非晶Cu-W膜实测E值分别高于和低于预测值;晶态Cu-W膜实测H值与Voigt规则计算值的符合性优于非晶膜,薄膜结构对力学性能预测可靠性影响较大。

关键词:

Cu-W合金薄膜;微观结构;非晶态;力学性能;

中图分类号: TB383.2

作者简介:郭中正(1983-),男,贵州安顺人,博士研究生;研究方向:金属薄膜材料;孙勇(E-mail:xbysun@sina.com);

收稿日期:2009-05-07

基金:云南省自然科学基金重点资助项目(2004E0004Z);国家自然科学基金(50871049);云南省自然科学基金(2006E0018Q)资助;

Structure and Mechanical Properties of Cu-W Alloy Thin Films Deposited by Sputtering

Abstract:

The composition,structure,mechanical properties of Cu-W alloy thin films fabricated by magnetron co-sputtering were investigated by EDX,XRD,TEM,SEM and nanoindenter. The results showed that Cu82.1W17.9(%,atom fraction) with lower W content and Cu39.8W60.2 with higher W concentration thin films were of crystalline state with the presence of fcc Cu(W) metastable supersaturated solid solution with maximum W solubility of 4.8% and bcc W(Cu) metastable supersaturated solid solution with maximum Cu solubility of 5.7%,respectively. Cu-W thin films with W of 31.8%,45.7%,54.8% were amorphous and exhibited lower surface roughness than crystalline Cu-W thin films. Generally,the values of hardness H and elastic modulus E of amorphous Cu-W thin films were lower than their crystalline counterparts. The measured E value of fcc Cu-W films ranged in values predicted by Voigt and Reuss rule,for bcc and amorphous Cu-W films the measured E values were higher and lower than the predicted values respectively. The compliance of measured H values of crystalline Cu-W films and values calculated by Voigt rule was better than amorphous Cu-W films. The estimation credibility of mechanical properties by rule-of-mixture was significantly influenced by the structure of Cu-W thin films.

Keyword:

Cu-W alloy thin films; microstructure; amorphous; mechanical properties;

Received: 2009-05-07

Cu-W体系混合焓为很高的正值(ΔH>35.5kJ?mol-1),固态互溶度极微,作为典型难混溶体系而广受关注,除作为传统点焊、电触头材料外,由于导电导热性、高温性能和应力抗性优异,在微电子和航天领域潜力巨大[1]。W-C,W-Si等W基涂层耐磨抗蚀性高,在高温、高真空环境得以应用,W-Cu则可能成为高热流等离子体衬面元件领域新型热沉材料[2]。含少量难混溶高熔点金属(W,Mo等)的Cu基Cu-Refractory金属合金薄膜因电阻率低、电迁移抗性高于Al基材料并能避免Cu/Si间反应而在超大规模集成电路(ULSI)器件领域前景广阔,可望用于无阻挡层互联[3]。溅射沉积是薄膜主要制备工艺之一,由于远离平衡态,以溅射法制备Cu基膜材料时,发现在Cu-W[4,5],CuNb[6],Cu-Ag[7]等体系中存在固溶度延展、亚稳相形成甚至非晶合金化,导电性及硬度增强[8]等现象,与机械合金化制备的难互溶Cu-Cr[9]等Cu基合金体系呈现的现象相似,显示出重要意义,研究其机制并控制此类材料的性能已成热点。本文采用磁控共溅射技术制备宽成分范围Cu-W合金薄膜,考察其微观结构和显微力学性能,得出了成分对Cu-W薄膜结构和性能的影响规律并进行了探讨。

1 实验

制样设备为FJL520型高真空磁控溅射仪,圆片状Cu-W复合靶尺寸Φ50 mm×4 mm,粉冶法制作,原料Cu粉纯度99.99%(4N)、W粉纯度99.95%(3N5),直流磁控溅射成膜。衬底为玻璃,依次以丙酮、乙醇及去离子水超声清洗作预处理。本底真空2.0×10-4 Pa,工作气体为分析纯Ar,溅射气压2.0 Pa,基片以10 r·min-1自转以提高膜均匀性。衬底水冷,靶功率选择较低的25~30 W以尽量减小衬底因二次电子和离子轰击而致的温升,内置测温仪监测温度,衬底温度20~30℃,膜厚850~900 nm。为探讨力学性能,制备等厚纯Cu,W膜。用于TEM测试的膜厚约350 nm,衬底为PVF膜。

薄膜成分用PHOENIX能谱仪测定,D8-Advance型X射线衍射仪上进行结构分析,Cu Kα线,波长0.15406 nm,管压36 kV,管流30 mA。TEM测试采用Philips电镜,Philips XL30ESEM扫描电镜观察表面形貌。MTS NanoindenterXP型纳米压痕仪测试力学性能,Berkovich压头,连续硬度测试法,应变速率0.1 s-1,压入深度100~150 nm,采样点15个,结果取均值。

2 结果与讨论

2.1 Cu-W合金薄膜成分、沉积率与靶成分关系

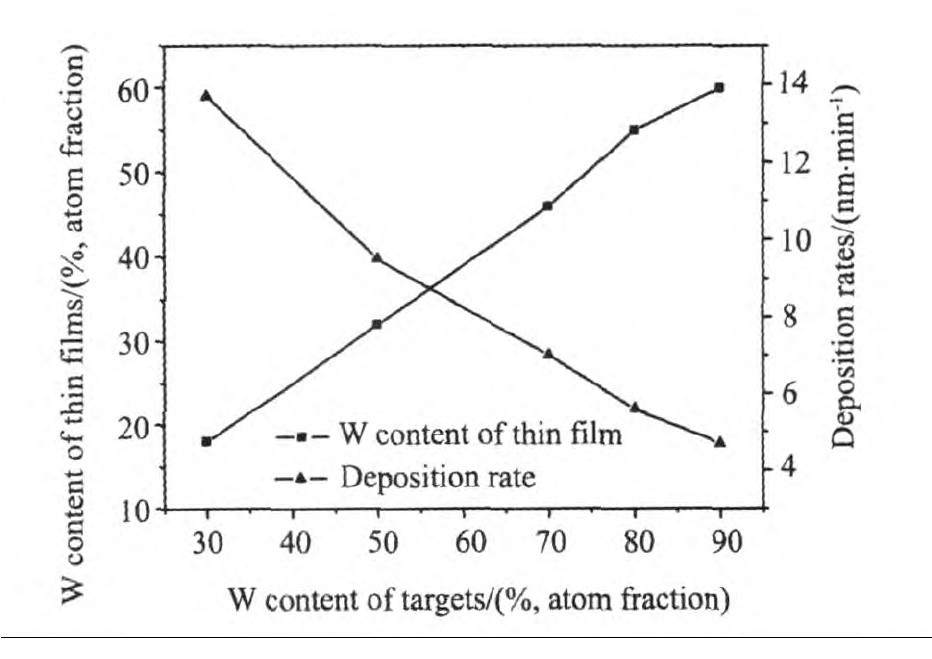

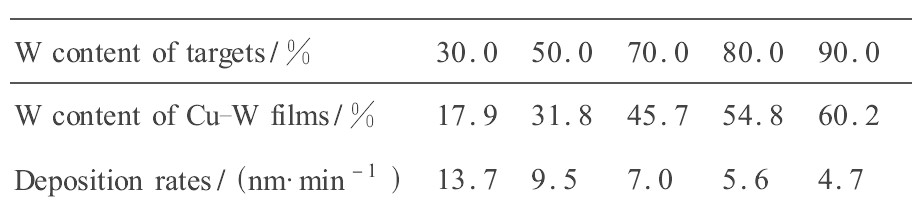

表1列出不同靶成分下Cu-W合金薄膜沉积率和W含量,图1为趋势图。可以看出,随靶W含量增加,薄膜W浓度增加,沉积率下降。这是由于W溅射产额较低,相同Ar+入射能量下较Cu低2.4倍以上,薄膜W浓度总低于相应靶材,Cu择优溅射显著,膜成分自动补偿效应不明显。

2.2 Cu-W合金薄膜结构

2.2.1 Cu-W合金薄膜XRD分析

图2为5个不同成分Cu-W薄膜X射线衍射谱。Cu100-xWx(x=31.8,45.7,54.8)的3个样品峰特征极相似(因此仅以一图代表),仅在低角度有漫散包峰,无结晶峰,膜呈非晶态。Cu82.1W17.9膜仅出现Cu衍射峰,Cu39.8W60.2膜则出现W,Cu衍射峰。相对标准谱(取自JCPDS衍射数据库,卡号为04-0836,04-0806),前者的Cu特征峰位向低角度方向有所偏移,后者的W峰位向高角方向偏移(而Cu峰几无偏移)。表2列出样品XRD实测与标准峰位。由Bragg方程,考虑引起峰位偏移的晶格常数变化因素,说明Cu82.1W17.9膜中Cu点阵常数增加、Cu39.8W60.2膜中W点阵常数减小。推测W在Cu中及Cu在W中形成亚稳过饱和置换式固溶体,W,Cu原子半径分别为0.13706,0.12781 nm,这种作用使铜晶格常数增大、钨晶格常数减小。因此Cu-W膜中存在互溶度扩展。铜和钨晶体结构不同,将W原子半径折算为配位数12时的值(0.141 nm),构建的fcc钨晶格常数为0.399 nm,以Vegard定律估算固溶度[10],结果显示Cu82.1W17.9膜存在fcc Cu(W)亚稳过饱和固溶体,固溶度为4.8%W;Cu39.8W60.2膜存在固溶度5.7%Cu的bcc W(Cu)亚稳固溶体。Cu-W薄膜结晶形态与W含量密切相关,钨浓度31.8%~54.8%间时呈非晶,较低W含量膜为fcc结构,高W浓度时主晶型为bcc,晶态Cu-W薄膜出现铜钨互溶度延展,形成亚稳固溶相。溅射沉积气相淬火(VQ)是高度非平衡过程,对Cu-Ag,Cu-Sn薄膜研究表明[11],受控于衬底温度的沉积原子体扩散迁移距离决定相结构,常温时两类膜分别呈过饱和非平衡相和单相。本实验Cu-W膜在低W和高W两端含过饱和非平衡相,特定W浓度区为单非晶相,与Radic等[4]报道相似,说明钨浓度对迁移距离影响大。文献[3]认为,因W原子量大,到达速率低、扩散有限,形核自由能ΔG小于其最低形核能,未及形核即已近原位附着。虽Cu原子量较小,但扩散迁移激活能较高,在基片上长程扩散几率低,为难混溶Cu-W系形成非晶和出现互溶度扩展提供了条件。本实验2.0 Pa的较高溅射气压增加沉积原子到达基片前的碰撞几率、降低动能[12],也利于减弱随后的扩散迁移,促进固溶扩展和非晶形成。

图1 Cu-W薄膜沉积率及W含量随靶成分的变化Fig.1 Variations of deposition rate and W content in Cu-W thin films with the composition of targets

表1 Cu-W复合靶和薄膜W含量(原子分数)及沉积率Table 1 Chemical compositions of targets,W concentration(atom fraction)in thin films and deposition rate 下载原图

表1 Cu-W复合靶和薄膜W含量(原子分数)及沉积率Table 1 Chemical compositions of targets,W concentration(atom fraction)in thin films and deposition rate

图2 Cu-W薄膜样品XRD谱Fig.2 XRD spectrums of Cu-W thin films

表2 Cu-W薄膜XRD谱Cu,W衍射峰位与标准衍射峰位(2θ)对比Table 2 Standard Cu,W peak position and measured Cu,W peak position of Cu-W thin films 下载原图

表2 Cu-W薄膜XRD谱Cu,W衍射峰位与标准衍射峰位(2θ)对比Table 2 Standard Cu,W peak position and measured Cu,W peak position of Cu-W thin films

2.2.2 Cu-W合金薄膜TEM分析

图3为CuW薄膜TEM明场像及选区电子衍射(SAD)谱(选区范围Υ1μm)。可以看出,Cu100-xWx(x=31.8,45.7,54.8)薄膜高倍明场像仍呈均匀衬度,SAD谱为漫散环甚至仅有中心漫散斑(图3(d)),为典型非晶结构。Cu82.1W17.9和Cu39.8W60.2膜明场像衬度明显,膜成分影响像特征。SAD谱可见6个明显衍射环,呈多晶结构,均存在W,Cu衍射谱,因此Cu82.1W17.9膜XRD谱W峰的缺失不能简单归结为文献[13]所认为的钨完全溶于铜中形成超饱和固溶体,而应考虑二者衍射能力、原子尺寸的差异及膜结构等因素。表3为SAD谱得出的晶面间距d、点阵参数a和相对衍射强度,样品Cu,W点阵参数均值分别为0.364,0.315 nm,Vegard定律估算Cu82.1W17.9,Cu39.8W60.2膜中亚稳固溶度分别约5.0%W和6.1%Cu,与XRD分析相似,SAD谱分析误差主要源于电镜相机常数及衍射环半径测差。Cu39.8W60.2膜的Cu点阵常数与标准值相近,W在Cu中几乎无置换式固溶,与XRD结果一致。

2.2.3 Cu-W合金薄膜SEM分析

图4,5分别为Cu-W薄膜背散射电子(BSE)像及二次电子(SE)像。可以看出,Cu100-xWx(x=31.8,45.7,54.8)膜BSE像无明显衬度,呈非晶结构特征,与XRD,TEM分析一致,说明Cu,W以极小尺度均混形成金属玻璃,SE像说明表面起伏很小,膜面光滑平整,体现非晶膜特征。Cu82.1W17.9,Cu39.8W60.2膜的BSE像则衬度明显,富W相粒子粒度约50 nm,SE像表明富W相突出于表面,表面粗糙度高于非晶样品。

表3 Cu-W薄膜SAD谱分析结果Table 3 SAD Pattern analysis of Cu-W thin films 下载原图

表3 Cu-W薄膜SAD谱分析结果Table 3 SAD Pattern analysis of Cu-W thin films

2.3 Cu-W合金薄膜力学性能

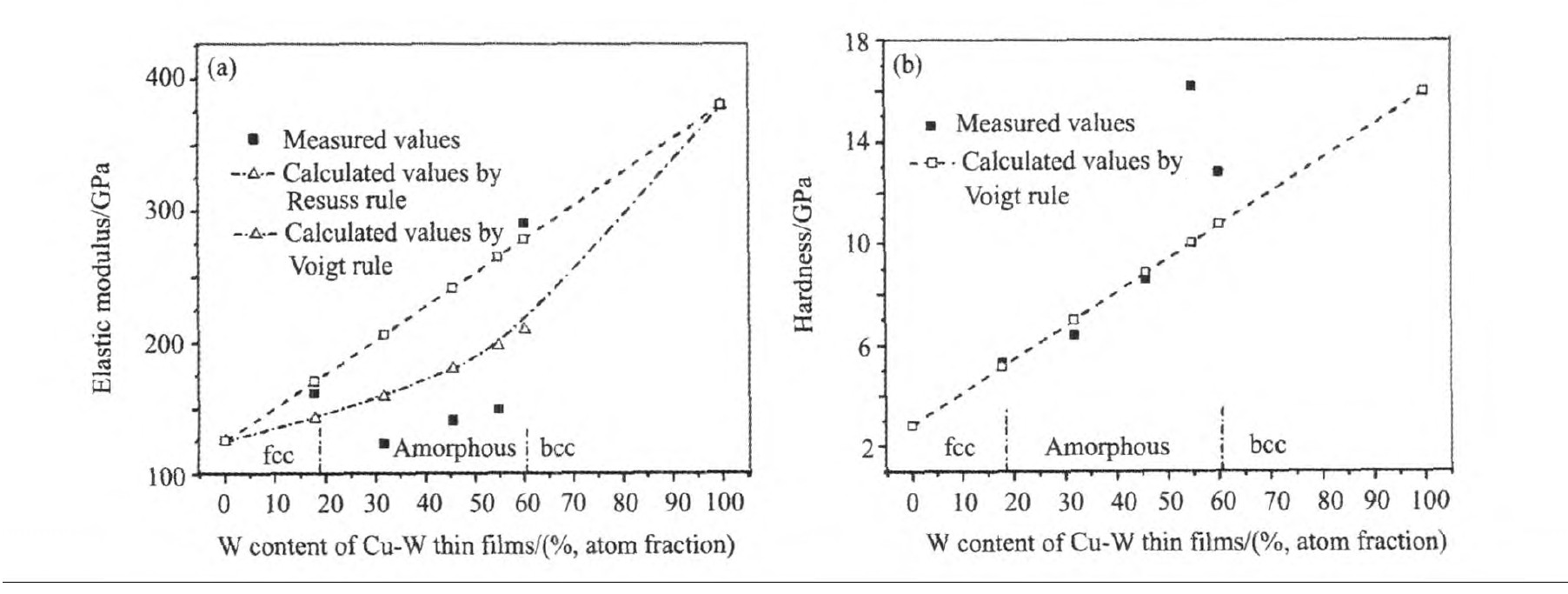

图6示出用纳米压痕仪测定的Cu-W合金膜及Cu,W膜的弹性模量E(GPa)和显微硬度H(GPa)。可以看出非晶Cu-W薄膜E值随W浓度增加而提高,但均低于晶态薄膜,而含W高的bcc结构Cu-W薄膜E值高于低W的fcc Cu-W薄膜。总体上膜硬度随W含量上升而增加,但极值出现于非晶Cu45.2W54.8膜(16.2 GPa,纯W膜为16GPa),区别于Rizzo等[14]报道的蒸积Cu-W薄膜中非晶硬度总低于bcc固溶体的现象。

但总体上非晶Cu-W薄膜的E,H值较低,这是由于非晶中存在大量原子位移、非简谐振动、类空位缺陷和自由体积,密度较低[15]。图6(a)示出了用Voigt和Reuss混合规则计算的E值,Voigt公式表示为[16]:

其中fCu,fW分别为铜及钨的摩尔分数,ECu,EW分别为铜及钨的弹性模量(GPa)。由于薄膜弹性模量与体材料相异,取纯Cu,W薄膜E值作参量。Reuss公式为:

图6 Cu-W合金薄膜力学性能实测与计算值(a)弹性模量,(b)硬度Fig.6 Measured and calculated values of Cu-W alloy thin films(a)Elastic modulus;(b)Hardness

式中参数意义与(1)式同。图6(a)表明,fcc Cu-W膜E值介于上述两式预测值之间,bcc Cu-W膜E值高于预测值,非晶Cu-W膜E值甚至低于Reuss公式计算值。显微硬度实测值与Voigt模型模拟(取纯Cu、W薄膜H值作参量)结果相比(图6(b)),说明对晶态Cu-W膜吻合较好(实测值略高于计算值),但对非晶膜则有偏高或偏低的现象。因此,Cu-W薄膜结构对力学性能预测结果的可靠性影响较大。

3 结论

1.Cu82.1W17.9(%,原子分数)和Cu39.8W60.2薄膜为晶态结构且出现固溶度扩展,分别存在fcc Cu(W)亚稳过饱和固溶体(固溶度4.8%W)和bcc W(Cu)固溶体(固溶度5.7%Cu),Cu100-xWx(x=31.8,45.7,54.8)薄膜呈非晶态,表面粗糙度较晶态膜低。

2.总体上非晶Cu-W膜弹性模量E和硬度值H较低,fcc Cu-W膜实测E值介于Voigt和Reuss规则预测值之间,bcc和非晶Cu-W膜实测E值分别高于和低于预测值;Voigt规则计算的H值与晶态Cu-W膜实测值的符合性优于非晶膜,因此薄膜结构对力学性预测可靠性影响较大。

参考文献

[1] Xia Yang,Song Yueqing,Cui Shun,Lin Chenguang,Han Shen-gli.Preparation and properties of Mo-Cu and W-Cu alloy[J].Chinese Journal of Rare Metals,2008,32(2):240.(夏扬,宋月清,崔舜,林晨光,韩胜利.Mo-Cu和W-Cu合金的制备及性能特点[J].稀有金属,2008,32(2):240.)

[2] Wang C,Brault P,Zaepffel C,Thaiult J,Pineau A,Sauvage T.Deposition and structure of W-Cu multilayer coatings by magne-tron sputtering[J].J.Phys.D,Appl.Phys.,2003,36:2709.

[3] Chu J P,Lin C H,Heieh Y Y.Thermal performance of sput-tered insoluble Cu(W)films for advanced barrierless metalliza-tion[J].Journal of Electronic Materials,2006,35(1):76.

[4] Radic N,Stubi cˇar M.Microhardness Properties of Cu-Wamor-phous thin films[J].J.Mater.Sci.,1998,33:3401.

[5] Wang Yuan,Li Xiaohua,Song Zhongxiao,Xu Kewei,Wei Xiuy-ing.Phase structure and residual stress in annealed Cu-W films[J].Rare Metal Materials and Engineering,2007,36(3):435.(汪渊,李晓华,宋忠孝,徐可为,尉秀英.退火Cu-W薄膜组织结构与残余应力[J].稀有金属材料与工程,2007,36(3):435.)

[6] Mahalingam T,Lin C H,Wang L T,Chu J P.Preparation and characterization of sputtered Cu films containing insoluble Nb[J].Materials Chemistry and Physics,2006,100:490.

[7] Smita Gohil,Rajarshi Banerjee,Sangita Bose,Pushan Ayyub.Influence of synthesis conditions on the nanostructure of immisci-ble copper-silver thin films[J].Scripta Materials,2008,58:843.

[8] Castelnau O,Geandier G,Renault P O,Goudeau Ph,Bourhis E Le.Characterization and modelling of the elastic properties of nano-structured W/Cu multilayers[J].Thin Solid Films,2007,516:320.

[9] Wang Debao,Wu Yucheng,Wang Wenfang,Zong Yue.Ex-tension solid solubility of immiscible Cu-Cr alloy system induced by mechanical alloying[J].Chinese Journal of rare Metals,2008,32(1):17.(王德宝,吴玉程,王文芳,宗跃.机械合金化诱导难互溶系Cu-Cr合金固溶度扩展的研究[J].稀有金属,2008,32(1):17.)

[10] Pan Jinsheng,Tong Jianmin,Tian Minbo.Fundamentals of Materials Science[M].Beijing:Tsinghua University Press,1998.91.(潘金生,仝健民,田民波.材料科学基础[M].北京:清华大学出版社,1998.91.)

[11] Saunders N,Miodownik A P.Phase formation in co-deposited metallic alloy thin films[J].Journal of Materials Science.,1987,22:629.

[12] Cantor B,Cahn R W.Metastable alloy phases by Co-sputtering[J].Acta Metall.,1976,24:845.

[13] Chu J P,Liu C J,Lin C H,Lin TN,Wang S F.Characteriza-tions of super hard Cu films containing insoluble W prepared by sputter deposition[J].Materials Chemistry and Physics,2001,72:286.

[14] Rizzo H F,Massalski T B,Nastasi M.Metastable crystalline and amorphous structures formed in the Cu-W system by vapor deposition[J].Metallurgical Transactions A,1993,24(5):1027.

[15] Lam N Q,Okamoto P R.A unified approach to solid-state amorphization and melting[J].Material Research Bulletin,1994,19:41.

[16] Kim HS,Estrin Y,Bush MB.Plastic deformation behaviour of fine-grained materials[J].Acta Mater.,2000,48:493.