DOI:10.19476/j.ysxb.1004.0609.2018.01.03

Ce对高强Al-Cu-Li合金组织及拉伸性能的影响

潘 波1,李 睿1,李劲风1,马鹏程2,陈永来2,张绪虎2,郑子樵1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 航天材料及工艺研究所,北京 100076)

摘 要:采用金相显微镜、透射电镜、扫描电镜及拉伸性能在测试研究0.11% Ce(质量分数)添加对一种Al-Cu-Li系高强铝锂合金薄板T8态时效(5%冷轧预变形+155 ℃时效)组织和力学性能的影响。结果表明:0.11% Ce添加明显降低合金强度,但伸长率略有增加。微量Ce添加可细化铸态晶粒组织及固溶再结晶晶粒组织;而且微量Ce添加未改变铝锂合金中时效析出相的种类,主要强化相仍然为T1相(Al2CuLi)及θ′相(Al2Cu),但其数量减少。铝锂合金中添加微量Ce,凝固时可形成含Ce且富Cu的Al8Cu4Ce相粒子,在后续均匀化及固溶处理时均难以完全溶解,导致固溶基体中的Cu含量降低,时效时含Cu析出相T1相及θ′相含量减少,合金强度降低。

关键词:铝锂合金;Ce微合金化;显微组织;强度

文章编号:1004-0609(2018)-01-0021-10 中图分类号:TG146.2 文献标志码:A

新型铝锂合金是航空航天最理想的结构材料[1-3],迄今为止已发展了三代铝锂合金,其中第三代铝锂合金已在航天航空结构件上获得广泛应用。目前,欧美正致力于开发第四代新型铝锂合金。

添加微合金化元素是开发新型铝锂合金最重要的方法。一些微合金化元素在不改变铝锂合金析出相类型的基础上,通过改善析出相的分布提高铝锂合金的力学性能。如Mg、Ag原子间具有很强的相互作用,淬火后及时效初期可形成大量Ag-Mg原子团簇,促使Li和Cu原子不断向Ag-Mg原子团簇扩散,因而Mg、Ag复合微合金化的铝锂合金时效时可析出更细小、更弥散分布的T1相(Al2CuLi),相应地可以较大幅度提高Al-Cu-Li系铝锂合金的时效强化效果[4-7]。基于Mg、Ag复合微合金化的作用,美国开发了高强Weldalite 049系列的高强铝锂合金,其中的2195 铝锂合金已应用于航天飞机外挂低温燃料贮箱[8]。同时,Mg、Zn的复合微合金化作用具有类似于Mg、Ag的复合微合金化作用[9-10],相应的铝锂合金包括2099、2199及具有国内独立知识产权的2A97合金等[11-13]。

稀土在铝合金中具有很多积极的作用,主要包括以下几个方面[14-15]:1) 变质作用,能减小铝合金铸造枝晶间距,细化铸造组织;2) 净化熔体,消除H、Fe等有害杂质;3) 微合金化作用,对铝合金起一定的改性作用。Ce是铝合金中最常添加的稀土元素,大量研究表明,铝导体材料中添加微量Ce可以显著细化其铸态晶粒组织,并与其中杂质形成化合物析出,改变杂质原来的固溶存在方式,一定程度提高强度并明显提高其导电性能[16-18]。同时,也有研究表明,在不同系列铝合金中,微量Ce添加对强度具有不同的作用效果。在Al-Zn-Mg-(Cu)合金中添加0.25%以上的Ce会降低合金的强度[19-20],而在Cu含量接近极限固溶度的Al-Cu-Mg-Ag-Zr合金(Cu含量5.3%,质量分数)[21-22]及Al-Cu-Li-Mg-Ag-Zr合金(Cu含量5.8%,质量分数)[23]中,微量Ce添加可提高其强度。

超高强铝锂合金是第四代新型铝锂合金的一个重要发展方向,其中Mg、Ag、Zn多元复合微合金化是开发超高强铝锂合金的一个重要思路[24-26]。鉴于稀土元素Ce可提高Cu含量为固溶度极限附近铝锂合金的强度[23],而目前高强铝锂合金中Cu含量范围一般在3.5%~4.5%之间,本工作研究了微合金化元素Ce对Mg、Ag、Zn多元复合微合金化的Al-4.25Cu-1.2Li- 0.12Zr超高强铝锂合金组织和力学性能的影响。

1 实验

以Al-4.25Cu-1.2Li-0.12Zr-0.4Mg-0.4Ag-0.45Zn

(质量分数,%)为基础,分别熔铸制备了不含Ce及含0.11% Ce两种成分的铝锂合金。经化学分析,合金中Cu、Li、Ce的化学成分如表1所列。铸锭经(470 ℃,8 h)+(530 ℃,24 h)双级均匀化退火、热轧、中间退火后,冷轧成2 mm厚度薄板。冷轧薄板经510 ℃盐浴固溶处理40 min,冷水淬火处理后进行T8时效处理。T8时效处理工艺为淬火后先进行5%的冷轧预变形,再于155 ℃进行不同时间的人工时效。

表1 实验用铝锂的化学成分

Table 1 Chemical compositions of experimental Al-Li alloy

原始铸态组织及淬火处理后板材晶粒组织经打磨抛光及阳极覆膜处理后采用Leica DMILM 金相显微镜进行金相组织观察。

原始铸态组织及淬火组织采用Sirion 200场发射扫描电镜(SEM)进行观察,并利用其附带的背散射(BSE)系统成像,第二相粒子成分采用能谱(EDS)进行分析。

采用MTS 858材料试验机对T8时效处理后铝锂合金进行室温拉伸性能测试,拉伸速率为2 mm/min。取样方向为轧制方向,样品平行段宽度8 mm,标距长度30 mm。采用Tecnai G220型透射电镜(TEM)对T8时效的显微组织(时效析出相)和选区电子衍射(SAED)进行观察。TEM试样首先机械减薄至0.08 mm左右,而后采用双喷电解减薄仪制取,TEM观察时加速电压为200 kV。

2 实验结果

2.1 室温拉伸性能

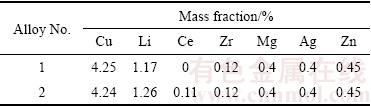

图1所示为铝锂合金在T8处理时拉伸性能随时效时间的变化曲线。由图1可见,两种合金强度均随着时效时间的延长而逐渐增加,达到峰值后缓慢下降;伸长率则随着时效时间的延长而逐渐降低,而后长时间趋于稳定。

在整个时效过程中,不含Ce合金1的强度明显较高,峰值抗拉强度达620 MPa以上,而含0.11% Ce合金2的强度下降约30 MPa。由于合金2的Li含量(1.26%)稍高于合金1的(1.17%),当无Ce微合金化作用时,这种Cu、Li成分特征应该导致合金2的强度高于合金1的[27]。因此,本研究中合金2的强度较低应该是Ce微合金化的影响。另外,但值得注意的是,含0.11% Ce合金2的伸长率稍高。

图1 铝锂合金在T8态时效(5%冷轧预变形+155 ℃时效)时性能随时效时间的变化

Fig. 1 Change of tensile strength (a), yield strength (b) and elongation (c) of Al-Li alloys with aging time at T8 aging

2.2 Ce微合金化对组织的影响

2.2.1 晶粒组织

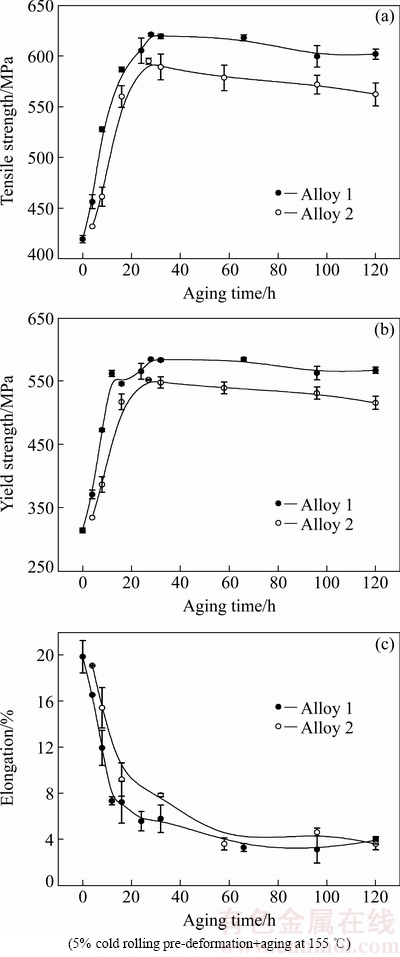

图2所示为不含Ce(合金1)及含0.11% Ce(合金2)的铸态金相照片,两种铝锂合金都呈树枝状晶粒组织。但从晶粒尺寸而言,合金1的晶粒尺寸约300~800 mm(见图2(a)),而合金2的晶粒尺寸约100~400 mm(见图2(b))。0.11% Ce的添加比较显著细化了铝锂合金铸态晶粒组织。

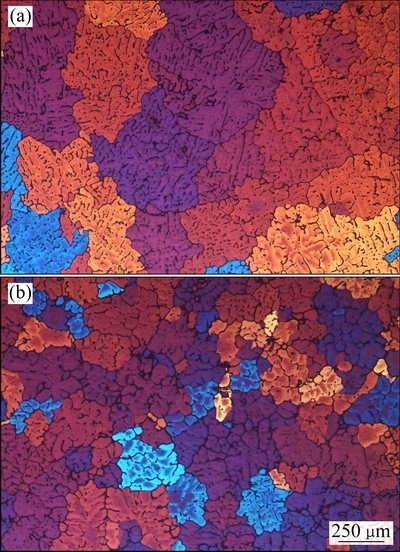

图3所示为不含Ce(合金1)及含0.11% Ce(合金2)的冷轧并固溶、淬火处理后的纵截面金相照片。由于冷轧薄板的储能较高,盐浴固溶处理时两种铝锂合金均发生了明显再结晶。合金1淬火态的再结晶晶粒尺寸较大,部分晶粒尺寸可达100 mm以上(见图3(a));而合金2的再结晶晶粒尺寸均小于80 mm(见图3(b)),即0.11% Ce的添加同样细化了该铝锂合金淬火态再结晶晶粒组织。

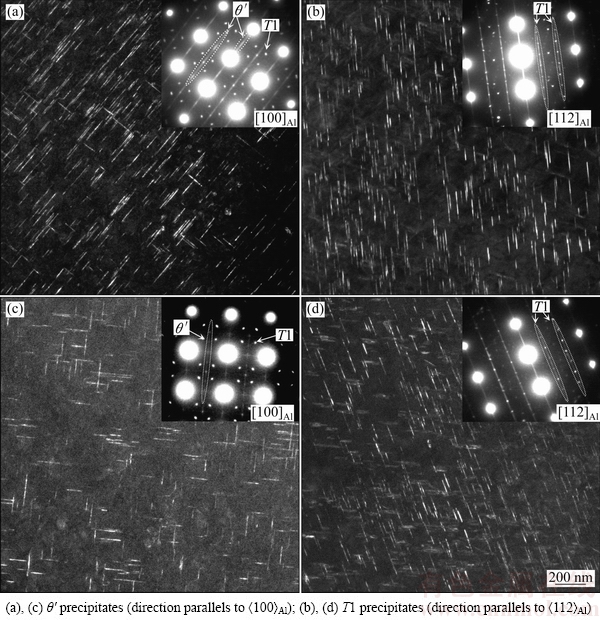

2.2.2 时效析出相

图4所示为不含Ce及含0.11% Ce合金T8峰时效的SAED谱及TEM暗场像照片。合金1<100>方向入射的SAED谱中可以发现明亮的θ′相斑点,其对应TEM暗场像中也出现较多尺寸约为230 nm、互相垂直分布的θ′相(见图4(a)),即合金1中析出了大量θ′相。同时,<112>方向入射的SAED谱中出现了明亮的T1相斑点,相应TEM暗场像可以发现其中析出了大量分布密集的T1相,其尺寸约为300 nm(见图4(b))。

图2 不含Ce及含0.11% Ce合金的铸态金相组织

Fig. 2 Metallographic images of Ce-free (a) and 0.11%Ce-containing (b) alloy cast ingots

图3 不含Ce及含0.11% Ce合金淬火态纵截面金相组织

Fig. 3 Metallographic images of longitudinal sections of qunched state Ce-free (a) and 0.11% Ce-containing (b) alloys

由合金2<100>方向入射SAED谱中可观察到θ′相斑点但相对比较微弱,TEM暗场像中观察到的θ′相相对较少,其尺寸约为260 nm(见图4(c))。另外,<112>方向入射的SAED谱中也出现了明亮的T1相斑点,对应的暗场像则观察到大量尺寸约为280 nm的T1相(见图4(d))。与合金1比较,合金2的时效析出相仍然为T1相及θ′相,T1相数量基本相当,但θ′相数量明显减少。

为相对定量描述0.11% Ce添加对铝锂合金峰时效时析出相的影响,采用Photoshop软件对上述暗场像照片中的T1相和θ′相数量进行统计,计算T1相和θ′相的平均数密度并统计其尺寸;统计时一般选取3张照片,统计结果如表2所列。

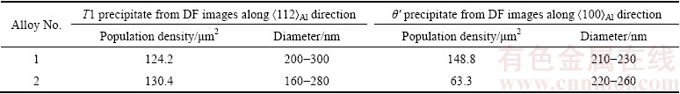

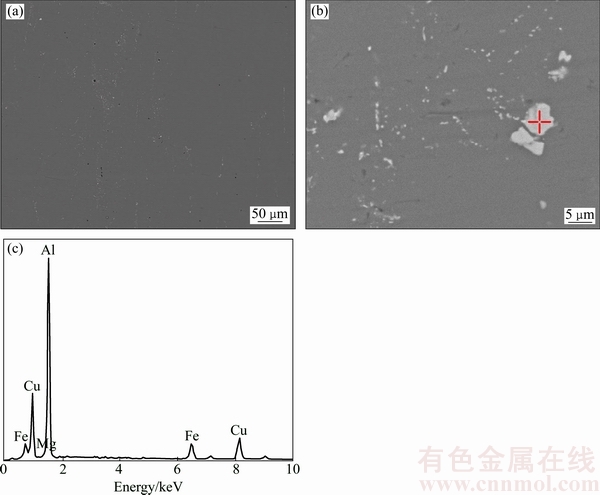

2.2.3 铸态组织中第二相

图5所示为不含Ce的合金1铸态组织的BSE像及其中第二相粒子EDS分析。铸态组织中均存在较多的非平衡凝固共晶相(见图5(a)和(b)),而EDS分析(见图5(c)和(d))表明这些非平衡凝固共晶相主要为θ相(Al2Cu)及少量含Ag的S相(Al2CuMg)。另外,还有极少量常见的含Fe杂质相粒子。

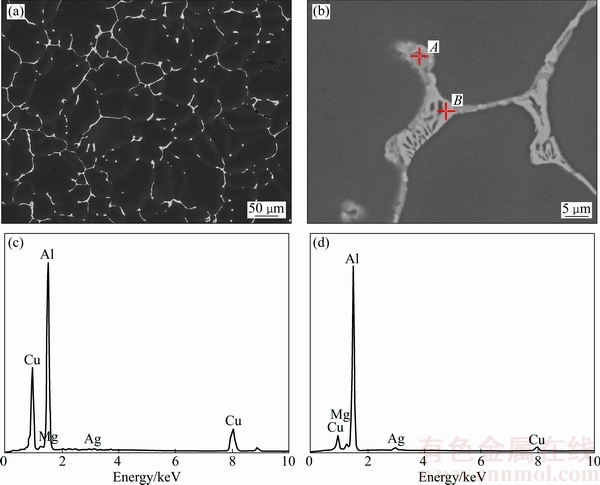

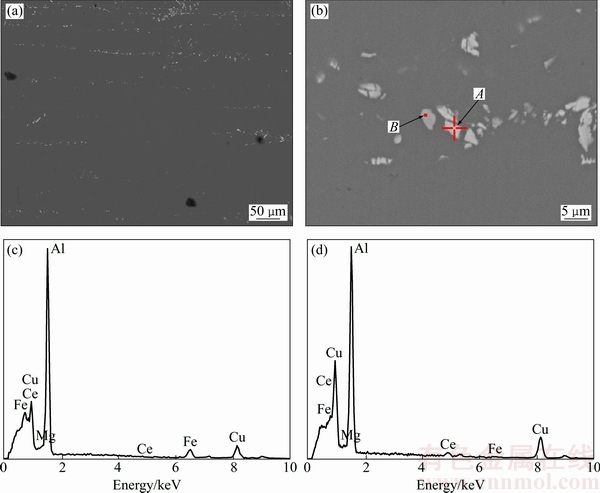

图6所示为含0.11% Ce的合金2的铸态组织BSE像及其中第二相粒子EDS分析。铸态组织中的非平衡凝固共晶相呈连续网状分布(见图6(a)和(b))。EDS分析合金中的非平衡凝固共晶相主要为θ相(见图6(c)),同时还存在许多含Ce且富Cu的第二相粒子(见图6(d))。根据文献[28],这种含Ce且富Cu的粒子应该为Al8Cu4Ce。同样,铸态组织中还含有极少量常见的含Fe杂质相粒子。

图4 不含Ce及含0.11% Ce合金T8峰时效时的SAED谱及TEM暗场像

Fig. 4 SAED patterns and dark field (DF) TEM images of Ce-free ((a), (b)) and 0.11% Ce-containing ((c), (d)) alloys after T8 peak-aging

表2 不含Ce及含0.11% Ce合金T8峰时效时T1相和θ′相数密度及尺寸

Table 2 Population density and diameter of T1 and θ′ precipitates in T8 peak-aged Ce-free and 0.11% Ce-containing alloys

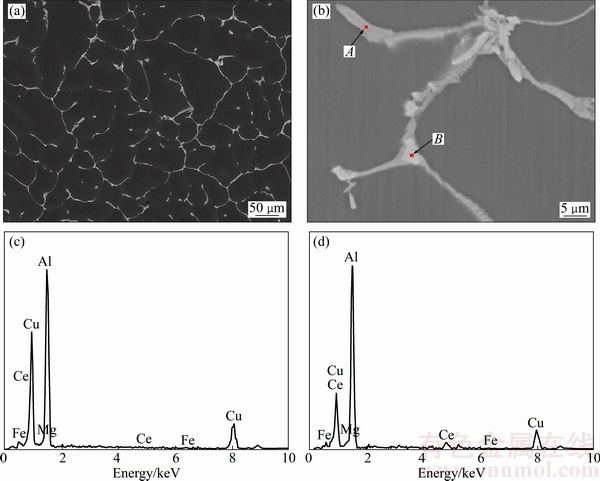

2.2.4 固溶组织中第二相

图7所示为不含Ce合金1淬火态的BSE像及未溶残余第二相粒子的EDS分析。合金中未溶残留第二相非常少(见图7(a));EDS分析表明,这些粒子主要为含Fe杂质相粒子(见图7(b)和(c)),应该主要为Al7Cu2Fe粒子。

在含0.11% Ce的合金2中,淬火态的未溶残余第二相粒子明显增加(见图8(a))。经EDS分析,这些未溶的残余第二相粒子分为两种类型,第一种与合金1中残余第二相粒子一致,为Al7Cu2Fe型含Fe杂质相粒子(见图8(b)和(c));第二种为富Cu且含Ce的第二相粒子Al8Cu4Ce(见图8(b)和(d))。

图5 不含Ce的合金1的铸态BSE像及第二相粒子EDS的分析

Fig. 5 BSE images of Ce-free alloy 1 cast ingot ((a), (b)) and EDS analysis of positions A (c) and B (d) in Fig.(b)

图6 含0.11% Ce的合金2铸态的BSE像及第二相粒子的EDS分析

Fig. 6 BSE image of 0.11% Ce-containing alloy 2 cast ingot ((a), (b)) and EDS analysis of positions A (c) and B (d) in Fig.(b)

图7 不含Ce的合金1淬火态的BSE像及第二相粒子的EDS分析

Fig. 7 BSE image of quenched Ce-free alloy 1 (a), (b) and EDS analysis (c) of particle in Fig.(b)

图8 含0.11% Ce合金2淬火态的BSE像及第二相粒子EDS分析

Fig. 8 BSE images of quenched 0.11% Ce-containing Al-Li alloy 2 ((a), (b)) and EDS analysis of positions A (c) and B (d) in Fig.(b)

3 分析与讨论

综上所述可知,上述Al-Cu-Li系铝锂合金中Ce的微合金化作用主要体现在以下几个方面:1) 形成难溶的含Ce且富Cu的第二相粒子;2) 细化铸态组织晶粒及再结晶晶粒组织;3) 降低时效态铝锂合金的强度。

研究表明,在Al-Cu-Ce合金中,含Ce且富Cu的Al8Cu4Ce第二相粒子凝固过程中就开始形成。形成的Al8Cu4Ce初晶可促进凝固时非均匀形核[28],通过提高凝固时的形核率,细化铸态组织晶粒。而后凝固过程中形成的Al8Cu4Ce粒子在均匀化过程中很难完全溶解至合金基体中,虽然部分连续的第二相粒子由于轧制加工而破碎,但固溶处理时这些破碎的粒子仍不能完全溶解,导致含0.11% Ce的合金2中未溶残余粒子数量较多(见图8(a))。这些未溶的Al8Cu4Ce粒子在固溶处理时的再结晶过程中可阻碍晶界迁移,从而细化了固溶处理时再结晶晶粒组织。

研究的铝锂合金主要通过时效热处理进行强化,其时效强化相是从固溶体基体中析出的T1相及θ'相。TEM观察表明,添加微量Ce将导致时效析出相T1相特别是θ′相析出数量减少(见图4),这是含0.11% Ce合金2强度降低的直接原因。

在上述铝锂合金中添加0.11% Ce,通过形成难溶相Al8Cu4Ce粒子细化了铸态晶粒组织及再结晶晶粒组织,一定程度上具有有益的作用;但固溶处理时Al8Cu4Ce难溶残余相粒子可导致固溶基体的合金化成分改变。由于这些粒子含有较多的Cu元素,导致固溶处理后合金中许多Cu原子仍然以Al8Cu4Ce粒子的形式存在,而不是以固溶Cu原子存在于固溶基体中。相比于不含Ce的合金1,含0.11% Ce合金2固溶基体中的Cu原子含量降低。

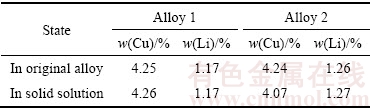

本文作者在此做一简单定量计算,分析由于Ce元素添加导致固溶基体中Cu、Li含量的变化。计算前先进行如下假设处理:1) 杂质元素Fe及含Fe杂质相忽略不计;2) 固溶处理后Mg、Ag、Zn、Li及剩余Cu元素均固溶至基体中;3) 所有Zr元素形成Al3Zr粒子;4) 根据Al-Ce二元相图,Ce在Al中的极限固溶度仅约0.01%(摩尔分数),因此,假设Ce原子全部与Cu结合形成富Cu且含Ce的第二相Al8Cu4Ce粒子。根据上述假设,将所有元素质量分数先转化为摩尔分数,而后重新计算固溶处理后固溶基体中的Cu、Li摩尔分数。为有利于直观认识,进一步将计算后固溶基体中Cu、Li摩尔分数再转化为质量分数,计算结果如表3所列。由此可见,固溶处理后,由于Zr元素形成Al3Zr粒子消耗了少量Al元素,导致合金1固溶基体中Cu含量略高于合金原始Cu含量(即原始化学分析的Cu含量)。而合金2中添加0.11% Ce,导致固溶基体中Cu含量低于合金原始Cu含量;原始合金的Cu含量为4.24%,而固溶处理后基体中固溶Cu含量较大幅度降低至4.07%。

表3 铝锂合金原始Cu、Li的浓度及淬火处理后固溶体的Cu、Li的浓度

Table 3 Cu and Li concentrations in original Al-Li alloys and their solid solution

由于强化相T1相和θ′相是在时效过程中从固溶基体中析出,而Cu元素既是T1相也是θ′相的组成元素。固溶基体中Cu含量降低,将减少T1相和θ′相含量。因而在相同预变形量(5%)的T8态时效时,由于含0.11% Ce合金2固溶基体中的Cu含量减少(见表3),导致时效后含Cu的析出相减少(见表2)。另外,由于时效前预变形在淬火态基体中形成的位错主要有利于时效时T1相的竞争析出[29],因而,0.11% Ce的添加更主要导致T8时效时θ′相的减少。

另外,添加0.11% Ce可稍提高该铝锂合金的伸长率,这应该与以下几个因素有关:1) 稀土元素Ce能够有效吸附杂质元素,减少杂质元素对铝锂合金的危害;2) 稀土元素在铝合金中具有良好的精炼除气作用,能与铝熔体中氢形成氢化物,降低合金中的氢含量,提高铝锂合金质量[14-15],增加其塑性变形能力。

4 结论

1) 0.11% Ce的添加比较显著细化铝锂合金铸态晶粒组织,并减小冷轧薄板固溶后的再结晶晶粒尺寸。

2) 铝锂合金中添加的微量Ce与Cu结合,在凝固时形成含Ce且富Cu的Al8Cu4Ce粒子,可促进凝固时的形核,同时这种粒子在均匀化及固溶处理时难以溶解至固溶体基体中,可阻碍固溶处理时再结晶过程中的晶界迁移,因而Ce微合金化在一定程度上有细化晶粒的作用。

3) 0.11% Ce的添加未改变铝锂合金中时效析出相的种类,合金的强化相仍为T1相及θ′相。但含Ce且富Cu的难溶粒子Al8Cu4Ce导致固溶基体中Cu含量降低,时效析出相的数量减少,合金强度降低。

REFERENCES

[1] RIOJA R J, LIU J. The Evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical & Materials Transactions A, 2012, 43: 3325-3337.

[2] 李劲风, 郑子樵, 陈永来, 张绪虎. 铝锂合金及其在航天工业上的应用[J]. 宇航材料工艺, 2012, 42(1): 13-19.

LI Jin-feng, ZHENG Zi-qiao, CHEN Yong-lai, ZHANG Xu-hu. Al-Li alloys and their application in aerospace industry[J]. Aerospace Materials & Technology, 2012, 42(1): 13-19.

[3] RIOJA R J, DENZER D K, MOOY D, VENEMA G B. Lighter and stiffer materials for use in space vehicles[C]//Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13). Pittsburg: John Wiley & Sons, Inc, 2012: 593-598.

[4] 王瑞琴, 郑子樵, 陈圆圆, 李世晨, 魏修宇. Ag, Mg合金化对Al-Cu-Li合金时效特性和显微组织的影响[J]. 稀有金属材料与工程, 2009, 38(4): 622-626.

WANG Rui-qin, ZHENG Zi-qiao, CHEN Yuan-yuan, LI Shi-chen, WEI Xiu-yu. Effects of Ag, Mg micro-alloying on aging characteristics and microstructure of Al-Cu-Li alloy[J]. Rare Metal Materials & Engineering, 2009, 38(4): 622-626.

[5] 易宏坤, 郑子樵. 微量Mg, Ag对Al-Li-Cu系合金性能和组织的影响[J]. 中南工业大学学报(自然科学版), 1999, 30(3): 292-294.

YI Hong-kun, ZHENG Zi-qiao. The influence of small additions of silver and magnesium on microstructures and properties of Al-Li-Cu system alloys[J]. Journal of Central South University of Technology (Nature Science), 1999, 30(3): 292-294.

[6] HIROSAWA S, SATO T, KAMIO A. Effects of Mg addition on the kinetics of low-temperature precipitation in Al-Li-Cu-Ag-Zr alloys[J] . Materials Science and Engineering A, 1998, 242: 195-201.

[7] MURAYAMA M, HONO K. Three dimensional atom probe analysis of pre-precipitate clustering in an Al-Cu-Mg-Ag alloy[J]. Scripta Materialia, 1998, 38(8): 1315-1319.

[8] JIANG Na, GAO Xiang, ZHENG Zi-qiao. Microstructure evolution of aluminum-lithium alloy 2195 undergoing commercial production[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 740-745.

[9] 魏修宇, 郑子樵, 佘玲娟, 陈秋妮, 李世晨. Mg、Zn在2099铝锂合金中的微合金化作用[J]. 稀有金属材料与工程, 2010, 39(9): 1583-1587.

WEI Xiu-yu, ZHENG Zi-qiao, SHE Ling-juan, CHEN Qiu-ni, LI Shi-chen. Microalloying roles of Mg and Zn additions in 2099 Al-Li alloy[J]. Rare Metal Mat Eng, 2010, 39(9): 1583-1587.

[10] 朱小辉, 郑子樵, 钟 申. Mg和Zn对2099合金时效组织与拉伸性能的影响[J]. 中国有色金属学报, 2010, 20(10): 1861-1867.

ZHU Xiao-hui, ZHENG Zi-qiao, ZHONG Shen. Effect of Mg and Zn on microstructure and tensile properties of 2099 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1861-1867.

[11] ROMIOS M, TIRASCHI R, PARRISH C, BABEL H W, OGREN J R, ES-SAID O S. Design of multistep aging treatments of 2099 (C458) Al-Li alloy[J]. Journal of Materials Engineering and Performance, 2005, 14(5): 641-646.

[12] 袁志山, 陆 政, 谢优华, 戴圣龙, 刘常升. 高强Al-Cu-Li-X铝锂合金2A97三级时效工艺及性能研究[J]. 航空材料学报, 2006, 26(3): 79-82.

YUAN Zhi-shan, LU Zheng, XIE You-hua, DAI Sheng-long, LIU Chang-sheng. Study on triple aging and mechanical properties of high strength Al-Cu-Li-X aluminum-lithium alloy 2A97[J]. Journal of Aeronautical Materials, 2006, 26(3): 79-82.

[13] 王 哲. 2A97铝锂合金的热处理工艺及性能研究[D]. 长沙: 中南大学, 2014.

WANG Zhe. The study on heat-treatment process and performance of 2A97 aluminium-lithium alloy[D]. Changsha: Central South University, 2014.

[14] 杨遇春. 稀土在有色金属合金中应用的新进展[J]. 稀有金属材料与工程, 1993, 22(4): 1-6.

YANG Yu-chun. The new evolution of application of rare-earth on nonferrous metal and alloy[J]. Rare Metal Materials and Engineering, 1993, 22(4): 1-6.

[15] 曹大力, 石忠宁, 杨少华, 王吉坤, 王兆文, 邱竹贤. 稀土在铝及铝合金中的作用[J]. 稀土, 2006, 27(5): 88-93.

CAO Da-li, SHI Zhong-ning, YANG Shao-hua, WANG Ji-kun, WANG Zhao-wen, QIU Zhu-xian. Effects ofrare earth on aluminium and its alloys[J]. Chinese Rare Earths, 2006, 27(5): 88-93.

[16] 李红英, 孙 远, 宾 杰, 刘 洋, 曹 俊. Ce 对耐热铝导体材料铸态组织和性能的影响[J]. 中南大学学报(自然科学版), 2011, 42(10): 3026-3032.

LI Hong-ying, SUN Yuan, BIN Jie, LIU Yang, CAO Jun. Effect of cerium on as-cast microstructure and properties of heat-resistant aluminum conductor[J]. Journal of Central South University (Science and Technology), 2011, 42(10): 3026-3032.

[17] 章德胜, 刘 平, 刘新宽, 李 伟, 马凤仓, 陈小红. 高导电率、高强度耐热铝合金导体材料的研究进展[J]. 热加工工艺, 2012, 41(24): 24-27.

ZHANG De-shen, LIU Ping, LIU Xin-kuan, LI Wei, MA Feng-can, CHEN Xiao-hong. Research on progress of high-conductivity and high-strength of aluminum conductor material[J]. Hot Working Technology, 2012, 41(24): 24-27.

[18] 刘顺华, 王桂芹, 高洪吾, 李长茂, 梁效礼, 张应俊. 稀土元素对铝导体导电性能的影响[J]. 机械工程材料, 2005, 29(10): 46-49.

LIU Shun-hua, WANG Gui-qin, GAO Hong-wu , LI Chang-mao, LIANG Xiao-li, ZHANG Ying-jun. The influence of RE on the electric properties of aluminum conductors[J]. Materials for Mechanical Engineering, 2005, 29(10): 46-49.

[19] 胡桂云, 陈送义, 姜慧丽, 王培吉, 陈康华. 稀土Ce对7A52铝合金组织与性能的影响[J]. 中国有色金属学报, 2016, 26(7): 1372-1382.

HU Gui-yun, CHEN Song-yi, JIANG Hui-li, WANG Pei-ji, CHEN Kang-hua. Effect of RE Ce on microstructure and properties of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(7): 1372-1382.

[20] 王大庆, 王庆良. 稀土对AlZnMgCu合金铸态组织和力学性能影响[J]. 特种铸造及有色合金, 1998(S1): 3-7.

WANG Da-qing, WANG Qing-liang. Effects of rare earth additions on the as cast microstructures and the mechanical properties of AlZnMgCu alloy[J]. Special-cast and Non-ferrous Alloys, 1998(S1): 3-7.

[21] 肖代红, 陈康华, 宋 旼. 铈对Al-Cu-Mg-Mn-Ag合金时效析出与显微组织的影响[J]. 中国有色金属学报, 2007, 17(5): 669-675.

XIAO Dai-hong, CHEN Kang-hua, SONG Min. Effect of cerium addition on precipitation and microstructure of Al-Cu-Mg-Mn-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 669-675.

[22] 肖代红, 王健农, 丁冬雁, 陈世朴. 微量Ce和Ti对AlCuMgAg合金组织和性能的影响[J]. 稀有金属材料与工程, 2004, 33(4): 404-407.

XIAO Dai-hong, WANG Jian-nong, DING Dong-yan, CHEN Shi-pu. Effect of Ce and Ti doping on microstructure and properties of the alloy AlCuMgAg[J]. Rare Metal Materials and Engineering, 2004, 33(4): 404-407.

[23] YU Xin-xiang, YIN Deng-feng, YU Zhi-ming. Effects of cerium and zirconium microalloying addition on the microstructures and tensile properties of novel Al-Cu-Li alloys[J]. Rare Metal Materials and Engineering, 2016, 45(8): 1917-1923.

[24] DENZER D K, RIOJA R J, RIOJA R J, VENEMA G B, COLVIN E L. The evolution of plate and extruded products with high strength and fracture toughness[C]//Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13), Pittsburg: John Wiley & Sons, Inc, 2012: 587-592.

[25] 罗先甫, 郑子樵, 钟继发, 张海锋, 钟 警, 李世晨, 李劲风. Mg、Ag、Zn多元微合金化对新型Al -Cu -Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian-fu, ZHENG Zi-qiao, ZHONG Ji-fa, ZHANG Hai-feng, ZHONG Jing, LI Shi-chen, LI Jin-feng. Effects of Mg, Ag and Zn multi alloying on aging behavior of new Al -Cu- Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[26] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[27] 李劲风, 陈永来, 张绪虎, 郑子樵. Cu、Li含量对Mg、Ag、Zn复合微合金化铝锂合金力学性能及微观组织的影响[J]. 宇航材料工艺, 2015, 45(2): 24-28.

LI Jin-feng, CHEN Yong-lai, ZHANG Xu-hu, ZHENG Zi-qiao. Influence of Cu and Li contents on mechanical properties and micro-structures of Mg-, Ag- and Zn-microalloyed Al-Li alloys[J]. Aerospace Materials and Technology. 2015, 45(2): 24-28.

[28] YU Xin-xiang, YIN Deng-feng, YU Zhi-ming, ZHANG Yi-ran, LI Shu-fei. Effects of cerium addition on solidification behaviour and intermetallic structure of novel Al-Cu-Li alloys[J]. Rare Metal Materials and Engineering, 2016, 45(6): 1423-1429.

[29] LI Jin-feng, YE Zhi-hao, LIU Dan-yang, CHEN Yong-lai, ZHANG Xu-hu, XU Xiu-zhi, ZHENG Zi-qiao. Influence of pre-deformation on aging precipitation behavior of three Al-Cu-Li alloys[J]. Acta Metallurgica Sinica, 2017, 30(2): 133-145.

Effect of Ce on structures and tensile properties of high-strength Al-Cu-Li alloy

PAN Bo1, LI Rui1, LI Jin-feng1, MA Peng-cheng2, CHEN Yong-lai2, ZHANG Xu-hu2, ZHENG Zi-qiao1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Aerospace Research Institute of Materials and Processing Technology, Beijing 100076, China)

Abstract: Through metalloscopy, transmission electron microscopy, scanning electron microscopy and tensile tests, the effect of 0.11% Ce (mass fraction) addition on structures and tensile properties of a high-strength Al-Cu-Li alloy with T8 aging (5% cold rolling pre-deformation and aging at 155 ℃) was investigated. The results show that the addition of 0.11% Ce significantly decreases the strength, but enhances the elongation a little. The cast structure and re-crystallized grains after solution treatment are refined by the Ce addition. The precipitate types does not change with the small addition of Ce, and the aging precipitates are still T1(Al2CuLi) and θ′(Al2Cu) phases, but their amount decreases. As 0.11% Ce is added to the Al-Li alloy, Ce-contained and Cu-rich Al8Cu4Ce particles form during solidification process, which cannot be completely dissolved into the alloy matrix during homogenization and solution process. The concentration of dissolved Cu in solid solution decreases, which decreases the fraction of T1 and θ′ precipitates and lowers the alloy strength.

Key words: Al-Li alloy; Ce micro-alloying; microstructure; strength

Foundation item: Project(2013AA032401) supported by National High Technology Research and Development Program of China

Received date: 2016-10-12; Accepted date: 2017-03-24

Corresponding author: LI Jin-feng; Tel: +86-13278861206; E-mail: lijinfeng@csu.edu.cn

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2013AA032401)

收稿日期:2016-10-12;修订日期:2017-03-24

通信作者:李劲风,教授,博士;电话:13278861206;E-mail:lijinfeng@csu.edu.cn