DOI: 10.11817/j.ysxb.1004.0609.2021-41031

静电纺丝法制备锆钛酸钡钙纳米线及其压电性能

周学凡1,王 露2,刘 媛1,王登攀2,李 军2,薛国梁1,罗 行1,张 斗1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中电科技集团重庆声光电有限公司,重庆 401332)

摘 要:采用静电纺丝法制备无铅压电陶瓷0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 (BCZT)纳米线,重点研究制备工艺优化和纳米线的压电性能。首先探索稳定性优异的BCZT溶胶配置方法,再利用静电纺丝法制备BCZT纳米线,研究静电纺丝参数和热处理条件对BCZT纳米线形貌和结晶性的影响。结果表明:最佳的静电纺丝工艺参数为环境温度40 ℃、环境湿度50%RH、施加电压15 kV、供液速度1.00 mL/h、滚筒收集转速800 r/min、接收距离15 cm。经过(120 ℃, 12 h)的烘干处理以及(900 ℃, 1 h)的退火处理,可以获得纯钙钛矿相、结晶性好、长径比大的BCZT纳米线。利用压电力显微镜分析该纳米线的压电响应,证实其具有多畴结构和明显的极化反转行为。

关键词:锆钛酸钡钙;纳米线;静电纺丝;压电响应

文章编号:1004-0609(2021)-08-2029-10 中图分类号:TB34 文献标志码:A

引文格式:周学凡, 王 露, 刘 媛, 等. 静电纺丝法制备锆钛酸钡钙纳米线及其压电性能[J]. 中国有色金属学报, 2021, 31(8): 2029-2038. DOI: 10.11817/j.ysxb.1004.0609.2021-41031

ZHOU Xue-fan, WANG Lu, LIU Yuan, et al. Electrospinning preparation optimization of barium zirconate titanate nanowires and piezoelectric properties[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2029-2038. DOI: 10.11817/j.ysxb.1004.0609.2021-41031

压电材料是一种可以实现电能和机械能相互转换的功能材料,在传感、驱动、能量采集和介电存储等领域中有着广泛的应用[1-3],而随着电子技术的不断进步,对电子元器件的小型化、集成度要求越来越高,大大促进了低维压电材料的发展[4-5]。其中,一维陶瓷纳米线由于在微纳米机电系统、能量采集器和介电电容器等中的重要应用价值而被广泛研究。例如,压电传感器、换能器和纳米发电机都需要充分利用压电材料的压电性,将电能和机械能进行相互转换,而一维结构的纳米线相比其他纳米结构能够更加有效地收集周围环境中不同振幅与频率的机械能,因此高压电响应的一维压电陶瓷纳米线的制备至关重要[6-8]。

目前商业化使用的压电材料主要为锆钛酸铅Pb(Zr1-xTix)O3 (PZT),它是一种钙钛矿结构的二元系固溶体。当n(Zr)/n(Ti)为47/53时,PZT处于三方/四方准同型相界(MPB),两相共存使晶体自发极化方向的概率增大,在电场作用下,极化旋转和畴壁运动更加容易,导致压电和介电性能显著提升[9-10]。PZT压电材料具有优异的压电性能,其压电系数d33为200~600 pC/N[11-13],然而PZT压电材料需要以大量的含铅氧化物为原料来进行合成,由于铅具有高毒性和易挥发性,制备及废弃处理过程中对环境和人体危害大,因此钙钛矿系无铅压电材料成为研究热点,主要包括钛酸钡(BaTiO3)系[14-15]、碱金属铌酸盐(K0.5Na0.5NbO3)系[16-17]和钛酸铋钠(Bi0.5Na0.5TiO3)系[18-20]等。BaTiO3体系在室温下d33值能够达到500~700 pC/N,但是其居里温度低(<100 ℃)。K0.5Na0.5NbO3体系具有高居里温度(200~300 ℃)和高压电性能(d33达300~600 pC/N),但其压电性能主要是通过调控多晶型相变温度而在室温构建多晶型相界最终实现增强的,因此具有很强的温度依赖性,另外其还存在工艺重复性差和无法大尺寸化等问题。Bi0.5Na0.5TiO3体系具有高居里温度(约300 ℃),但其d33通常<300 pC/N,且在居里温度以下就会发生退极化,退极化温度通常低于200 ℃。PZT压电材料的高压电响应与其MPB结构密切相关,2009年西安交通大学任晓兵等模仿PZT相图结构在BaTiO3基无铅压电材料的研究中取得突破性进展。设计了(1-x)Ba(Zr0.2Ti0.8)O3- x(Ba0.7Ca0.3)TiO3 (BCZT)二元组分,发现在x=0.5处其压电系数d33高达620 pC/N,甚至可以媲美PZT材料。BCZT二元相图上存在多相临界点(Tricritical triple point, TCP),在该多相转变点处立方相、三方相和四方相共存,并且能够在室温下演化成三方 相-四方相共存MPB。0.5BZT-0.5BCT组分处于MPB处,又十分靠近TCP,使得其各相之间相互转换的能垒非常小,导致三方相和四方相的极化转向非常容易,所以具有很高的压电响应[21]。

BCZT一维纳米线的制备与应用受到广泛关注。例如胡海燕等[22]利用静电纺丝法制备BCZT纳米线再与聚二甲基硅氧烷(PDMS)混合,并经过电泳作用使纳米线定向排列,制备能量采集纳米器件。迟庆国等[23]通过实验比较了BaTiO3和BCZT纳米线作为无机填料加入聚偏氟乙烯(PVDF)基体材料中的压电输出性能,结果表明BCZT纳米线能有效地提高BCZT纳米线/PVDF复合材料的界面极化率,得到更高的输出电压。WU等[24]采用静电纺丝法制备了单轴取向的Y掺杂BCZT纳米线,并进一步制备了相应的垂直取向纳米发电机,单轴取向的纳米线和垂直排列的复合膜结构得到了较高的性能输出。静电纺丝法是当前制备一维纳米结构的主要方式,具备操作简单、成本低廉、可对纳米线的参量进行控制、生产速度快、可大规模生产等优势[25-26]。BCZT元素组成复杂,难以制备出单晶纳米线,静电纺丝法是制备高压电响应BCZT纳米线的有效方式。本研究中探索了稳定性良好的BCZT溶胶的配置方法,再通过静电纺丝法,研究静电纺丝和热处理工艺参数对BCZT纳米线的影响,以设计和制备具有优异压电响应的BCZT纳米线。

1 实验

1.1 BCZT溶胶及纺丝液配置

采用静电纺丝法制备0.5(Ba0.7Ca0.3)TiO3- 0.5Ba(Ti0.9Zr0.1)O3 (BCZT)纳米线。首先配置BCZT溶胶:溶胶体积为50 mL,浓度为0.4 mol/L,BCZT物质的量为0.02 mol。按照BCZT的化学计量比称取定量的醋酸钡(99.0%,麦克林试剂网)、醋酸钙(99.0%,麦克林试剂网)和乙酰丙酮锆(98.0%,麦克林试剂网)粉末,将其倒入冰醋酸(15 mL,99.8%,国药集团化学试剂有限公司)和乙二醇甲醚(15 mL,99.8%,国药集团化学试剂有限公司)的混合溶液中,在60 ℃条件下加热搅拌至粉末完全溶解,获得澄清透明溶液,冷却至40 ℃后继续搅拌,记为A液。然后再按照BCZT的化学计量比称取定量的钛酸四丁酯(99.0%,麦克林试剂网),加入乙酰丙酮(99.0%,麦克林试剂网),乙酰丙酮与钛酸四丁酯的摩尔比为2:1,在40 ℃下搅拌30 min混合均匀,记为B液。最后在40 ℃和适当转速下将B液逐滴加入A液中,再用乙二醇甲醚定容至50 mL,继续搅拌8 h后获得棕黄色澄清透明溶胶。将溶胶放置48 h陈化,确定其稳定性。然后配置纺丝液:取10 g上述溶胶,缓慢加入0.6 g PVP粉末(相对分子质量为130000,97.0%,国药集团化学试剂有限公司),在40 ℃下搅拌至完全溶解,获得粘度适当的纺丝液。

1.2 静电纺丝及热处理

将纺丝液置于10 mL针筒中,在高压静电作用下使溶液带电,带电溶液在针尖将形成喷射细流,在此喷射过程中溶剂挥发,最终得到纤维结构。纤维的粗细等形貌结构主要受到溶胶浓度、液流速度和施加电场力等工艺参数的影响。本文中静电纺丝环境湿度定为50%RH,滚筒收集转速定为800 r/min,针尖与滚筒之间的距离定为15 cm,研究环境温度、供液速度、施加电压对BCZT静电纺丝纳米线的影响,以获得最优化静电纺丝工艺参数。

在静电纺丝过程中,溶剂等挥发不充分,需要将纤维进行烘干,温度为120 ℃,时间为12 h。将烘干的BCZT纤维从锡箔纸上取下,放到马弗炉中进行退火,首先以3 ℃/min的升温速度加热至400 ℃保温1 h,再以2 ℃/min的升温速率加热至700 ℃、800 ℃、900 ℃和1000 ℃,保温时间为1 h,最后冷却至室温,研究退火温度对BCZT纳米线的形貌和结晶性的影响。

1.3 性能表征

采用JEOL-6360LV型扫描电子显微镜(SEM)对BCZT纳米线的尺寸、形貌进行表征分析。采用D/max 2550型X射线衍射分析仪(XRD)检测样品的晶体结构。采用ESCALAB 250Xi型号的X射线光电子能谱仪对样品进行元素分析。

压电性能由NanoManTM VS原子力显微镜测试,通过原子力显微镜的压电力模式(Piezoelectric force microscopy, PFM),将样品超声均匀分散在酒精中,将悬浊液滴在1 cm×1 cm的镀Pt硅片上并烘干,并将硅片四周及底部涂抹银浆。测试时采用的是SCM-PIT悬臂梁,表面镀有Pt/Ir,弹性系数为2.8 N/m,自由振荡频率为75 kHz。将悬臂梁的针尖对准硅片上的NBT微纳结构,采用接触模式,在针尖上施加频率为41 kHz、振幅为10 V的交流电压,扫描样品表面,获得BCZT纳米线的压电畴结构。将针尖固定在样品表面上一点,施加-10~10 V的直流电压,获得能反应压电性能的振幅-电压蝴蝶曲线。

2 结果与讨论

2.1 BCZT纳米线的静电纺丝工艺优化

在静电纺丝中,环境温度、施加电压和供液速度对最终纳米线的形貌和尺寸有很大影响。本节研究了这些参数对BCZT纳米线的影响规律,以获得高质量的压电纳米线。

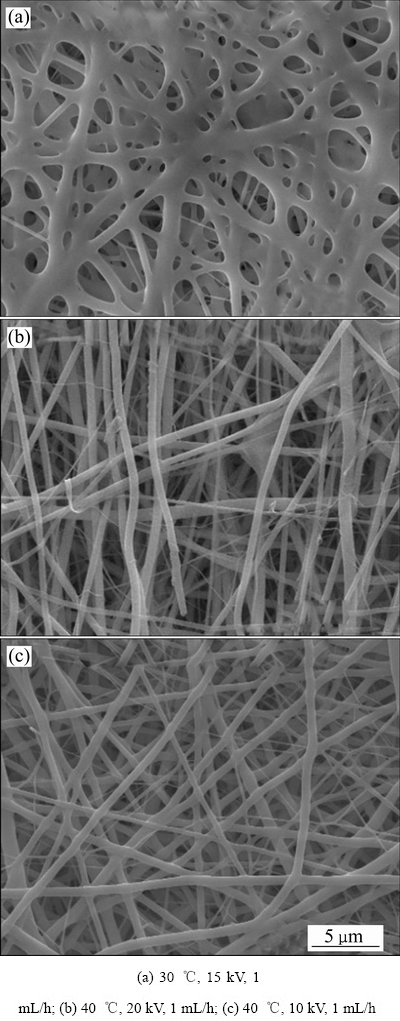

保持其他参量不变,施加电压15 kV,供液速度1.00 mL/h,调节环境温度从30 ℃到60 ℃。结果发现30 ℃条件下,射流中的溶剂未能在飞行过程中有效挥发,纤维坍塌且互相粘连,如图1(a)所示,得到的纤维网膜不能从离型纸上剥离;而60 ℃条件下,纺丝液极易堵塞在针头处,纺丝液不能有效形成射流;40~50 ℃的环境温度较为适宜。

保持其他参量不变,环境温度40 ℃,供液速度1.00 mL/h,调节施加电压从10 kV到20 kV,结果发现电压为20 kV时,射流受到的静电力十分剧烈,鞭动范围过大,一方面导致纤维难以收集,另一方面得到的纤维均匀性降低,出现很多过细纤维,如图1(b)所示;而电压过低则会导致电纺溶液不能有效抽离针管,得到的纤维少,直径较粗,且多呈现弯曲状态,如图1(c)所示。

图1 不同条件下静电纺丝制备的BCZT纳米线形貌

Fig. 1 Morphologies of BCZT nanofibers prepared by electrospinning at different conditions

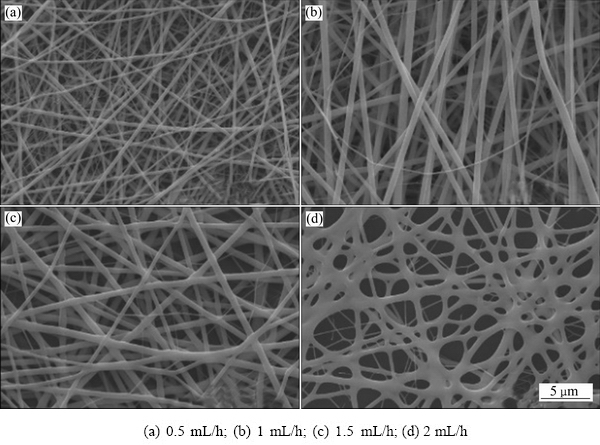

保持其他参量不变,维持环境温度40 ℃,施加电压固定在15 kV,调节供液速度从0.5 mL/h到2 mL/h。结果发现当供液速度从0.5 mL/h提升到1.5 mL/h时,纤维的直径逐渐增加,由约300 nm增加至约600 nm,如图2(a)~(c)所示。然而过快供液会使得溶剂不能有效挥发,导致纤维之间相互粘连,如图2(d)所示。经过一系列实验后,优化的静电纺丝工艺参数为:环境温度40 ℃、施加电压15 kV、供液速度1.00 mL/h,相应的BZCT纳米线在(120 ℃, 12 h)干燥处理后呈现平直状长纤维形貌,没有明显孔洞、裂纹等缺陷,纤维表面光滑、平整,由于静电纺丝过程中形成了稳定射流,纤维直径分布均匀性较好,平均尺寸约为 500 nm。

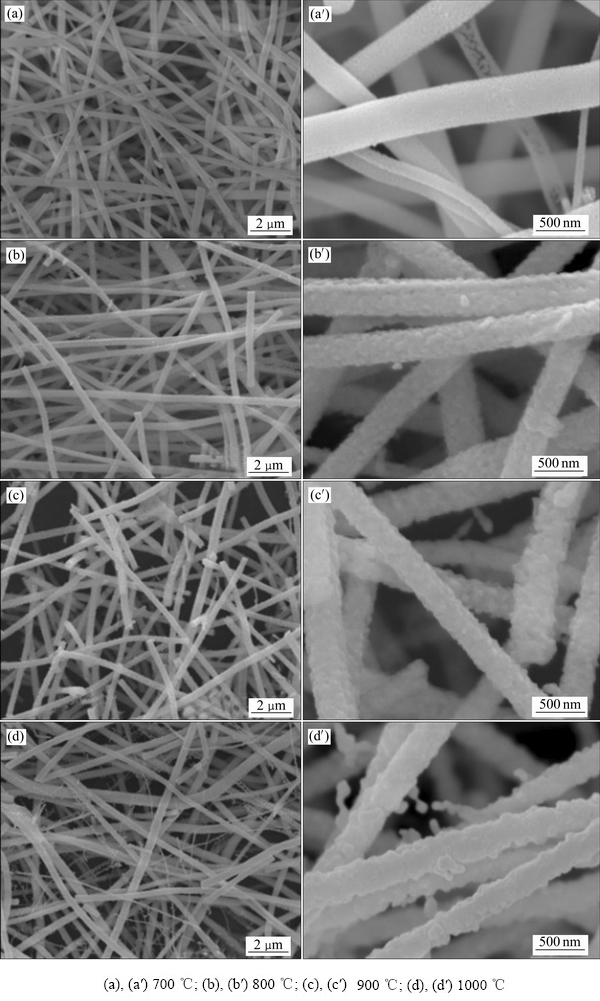

2.2 BCZT纳米线的热处理工艺优化

干燥后的BCZT纳米线在不同的退火温度下进行热处理,如图3所示分别给出了在700 ℃、800 ℃、900 ℃和1000 ℃下退火1 h 后纤维的形貌图。从图3可以看出,热处理导致了有机溶剂挥发和BCZT纤维结晶,纤维表面变得粗糙,直径也明显变小。不同温度退火处理后的直径大致从500 nm减少至300 nm。如图3(a)所示,700 ℃热处理后的纤维表面可以保持较为光滑,从高倍SEM像中可以看出纤维由许多纳米级的小颗粒密集堆积而成,证明纤维热处理后形成多晶结构,随着退火温度的增高,所获得的纤维表面逐渐变得粗糙,如图3(b)~(c)所示,800 ℃和900 ℃热处理后的纤维表面的颗粒尺寸明显增大,边缘清晰,说明纤维的结晶性增强,并且仍然保持大长径比。继续升高热处理温度至1000 ℃后,纤维过于粗糙,部分颗粒从纤维表面脱落,已经不能很好维持纤维的结构。因此,对BCZT纳米线而言,800~900 ℃是较为优异的热处理退火温度。

图2 不同供液速度下制备的BCZT纳米线形貌

Fig. 2 Morphologies of BCZT nanofibers prepared at different solution supply speeds

图3 BCZT纳米线在不同退火温度下热处理后的形貌

Fig. 3 Morphologies of BCZT nanofibers annealed at different temperatures for 1 h

图4 不同温度热处理后BCZT纳米线的XRD谱以及(110)和(200)衍射峰的放大图像

Fig. 4 XRD patterns of BCZT nanowires annealed at different temperatures(a) amplified images of (110) and (200) diffractions(b)

本实验采用XRD对BCZT纳米线的相结构进行检测。图4(a)所示为BCZT纳米线在700 ℃、800 ℃、900 ℃、1000 ℃等不同温度退火1 h后的XRD谱(衍射角2θ范围是20°~80°)。从图4(a)中可以清晰地看到所有样品都呈现出尖锐的衍射峰,证明了其良好的结晶性。随衍射角度增加,各衍射峰分别对应着钙钛矿结构的(100)、(110)、(111)、(200)、(210)、(211)、(220)、(300)和(310)晶面,没有其他杂峰出现,证明该合成过程中没有其他杂质相形成,得到的BCZT纳米线纯度高。图4(b)所示为(110)和(002)衍射峰的放大图像,没有明显衍射峰分裂情况,本研究中设计的BCZT组分处于三方/四方相界,且静电纺丝纳米纤维中初始颗粒的尺寸只有几十纳米,因此精度较低的XRD分析测试难以识别出明显的三方和四方晶格畸变。此外,随着退火温度的升高,衍射峰强度增大,证明BCZT纳米线的结晶性逐渐增强,这与上述微观形貌表征观察到的晶粒明显长大结果相符。1000 ℃退火处理后,衍射峰强度最强,说明结晶性最为优异,然而其纤维形貌结构遭到一定程度的破坏,因此后续测试采用900 ℃退火热处理的BCZT纳米线。

利用X射线光电子能谱图(XPS)对900℃热处理1h后的BCZT纳米线进行元素分析,全谱如图5所示。Ba、Ca、Zr、Ti、O和C六种不同元素被检测到,其中C元素可能来自于空气和仪器的碳污染,符合对BCZT固溶体的预期。图6(a)~(d)所示为Ba 3d,Ca 2p,Zr 3d和Ti 2p的光电子峰的窄谱扫描结果。利用各峰面积和各元素的XPS灵敏度因子可以获得各元素的原子百分比,经过归一化计算,Ba、Ca、Zr、Ti和O元素含量分别为17.7%、3.28%、1.8%、16.9%和60.32%,大体上与目标产物BCZT的化学计量相近,如图5中的插图所示。表明利用溶胶法结合静电纺丝法制备的BCZT纳米线能够较为准确地控制产物元素比例。此外,可以明显地看到Ba 3d5/2,Ca 2p3/2,Zr 3d5/2和Ti 2p3/2光电子峰存在明显的不对称或者分峰现象,这归因于BCZT中Ba和Ca原子共同占据A位而Zr和Ti原子共同占据B位导致电子结合能产生分裂现象。XPS结果结合上述XRD结果表明各元素已融入到BCZT钙钛矿结构的晶格,并占据所设计的位置。

图5 BCZT纳米线的X射线光电子能谱图

Fig. 5 XPS spectrum of BCZT nanofibers

2.3 BCZT纳米线的压电性能分析

本研究中采用接触模式的PFM检测BCZT纳米线的压电响应。图6所示为900 ℃热处理1 h后的BCZT纳米线PFM显微分析结果。图7(a)所示为PFM形貌,从图中可以看出此纳米线具有较为光滑平整的表面。图7(b)和(c)所示分别为BCZT纳米线的PFM振幅图和相位图,展现出了铁电畴结构。一般而言,PFM振幅图的明暗程度显示了压电响应的强度,而PFM相位图的明暗对比则是由检测区域的极化方向决定的。在一根BCZT纳米线内,PFM振幅图和相位图都体现出了一定的明暗对比,证明了在一根BCZT纳米线内存在具有不同极化方向的极化纳米微区,这些纳米微区呈条状,展现出相位变化,说明此BZCT纳米线为多电畴结构。从相位图上的明暗相间可以看出,这些电畴有不同的取向。铁电畴的存在也从侧面反映了纤维的结晶状况良好。PFM检测结果与SEM和XRD的检测结果相一致。

为了校验单根BCZT纳米线的压电响应,本实验进一步利用PFM对单根纤维的局部微区压电性能进行了测试。在其表面施加-10 V到10 V的直流偏置电压,获得该纳米线的振幅量和相位变化。如图8所示,黑色曲线表示BCZT纳米线的PFM振幅与电压关系曲线,红色曲线表示PFM相位与电压的关系曲线。在一个周期的直流偏压作用下,由于外加直流偏压导致极化翻转,相位发生180°的翻转,再结合其典型的振幅-电压蝴蝶曲线,证实该BCZT纳米线具有良好的压电性能。

图6 各元素光电子峰窄谱扫描

Fig. 6 XPS spectra for different elements

图7 BCZT纳米线的PFM显微分析

Fig. 7 PFM analysis of BCZT nanofibers

图8 BCZT纳米线PFM振幅-电压和相位-电压回线

Fig. 8 Amplitude-voltage butterfly loops and phase hysteresis loops of BCZT nanofibers

3 结论

1) 通过静电纺丝法成功制备了直径约300nm的纯钙钛矿相、结晶性好、长径比大的BCZT纳米线。

2) 针对0.4 mol/L的BCZT溶胶配置的静电纺丝溶液,最佳的静电纺丝工艺参数为:环境温度40 ℃、环境湿度50%RH、施加电压15 kV、供液速度1.00 mL/h、滚筒收集转速800 r/min、接收距离15 cm。最佳的干燥和退火条件为(120 ℃, 12 h)和(900 ℃, 1 h)。

3) PFM结果证明该BCZT纳米线具有优异的压电性和明显的极化反转行为。

REFERENCES

[1] JAFFE B, JAFFE H, COOK W R. Piezoelectric ceramics[M]. London: Academic Press, 1971.

[2] HAERTLING G H. Piezoelectric and electro-optic ceramics in ceramic materials for electronics[M]. New York: Marcel Dekker, Inc., 1991.

[3] DAMJANOVIC D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics[J]. Reports on Progress in Physics, 1998, 61: 1267-1324.

[4] BAO N Z, SHEN L M, SRINIVASAN G, et al. Shape-controlled monocrystalline ferroelectric barium titanate nanostructures: From nanotubes and nanowires to ordered nanostructures[J]. Journal of Physical Chemistry C, 2008, 112(23): 8634-8642.

[5] XU G, YANG X, HUA C X, et al. Shape-controlled synthesis of lead zirconate titanate nanocrystallites, microrods, microrolls and 3D complex architectures via the effects of poly-vinylalcohol macromolecular conformation[J]. Cryst Eng Comm, 2012, 14: 6783-6787.

[6] ZHOU X F, JIANG C, CHEN C, et al. Morphology control and piezoelectric response of Na0.5Bi0.5TiO3 synthesized via a hydrothermal method[J]. Cryst Eng Comm, 2016, 18: 1302-1310.

[7] JIN C C, LIU X C, LIU C H, et al. Preparation and structure of aligned PLZT nanowires and their application in energy harvesting[J]. Applied Surface Science, 2018, 447: 430-436.

[8] ZHANG X, CHEN J F, WANG Y. Hierarchical PbZrxTi1-xO3 nanowires for vibrational energy harvesting[J]. ACS Applied Nano Materials, 2018, 1: 1461-1466.

[9] JAFFE B, ROTH R S, MARZULLO S. Piezoelectric properties of lead zirconate-lead titanate solid-solution ceramics[J]. Journal of Applied Physics, 1954, 25: 809-810.

[10] GUO R, CROSS L E, PARK S E, et al. The origin of the high piezoelectric response in PbZr1-xTixO3[J], Physical Review Letters, 2000, 84: 5423-5426.

[11] ZENG T, DONG X L, CHEN H, et al. The effects of sintering behavior on piezoelectric properties of porous PZT ceramics for hydrophone application[J]. Materials Science and Engineering B, 2006, 131: 181-185.

[12] CHENG L Q, XU Z, ZHAO X L, et al. Significantly improved piezoelectric performance of PZT-PMN ceramics prepared by spark plasma sintering[J]. RSC Advances, 2018, 8: 35594-35599.

[13] 周艳明. MnO2/CeO2掺杂PZT压电陶瓷性能研究[J]. 陶瓷, 2019(1): 33-38.

ZHOU Yan-ming. Study on the properties of MnO2/CeO2 doped piezoelectric ceramics[J]. Ceramics, 2019(1): 33-38.

[14] ACOSTA M, NOVAK N, ROJAS V, et al. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives[J]. Applied Physics Reviews, 2017, 4: 041305.

[15] UL R, MARCHET P, PHAM-THI M, et al. Improved properties of doped BaTiO3 piezoelectric ceramics[J]. Physica Status Solidi, 2019, 216: 1900413.

[16] WU J G, XIAO D Q, ZHU J G. Potassium-sodium niobate lead-free piezoelectric materials: Past, present, and future of phase boundaries[J]. Chemical Reviews, 2015, 115: 2559-2595.

[17] 刘绍军, 王鹏飞, 万冰冰, 等. Nd掺杂K0.53Na0.47NbO3基无铅压电陶瓷的结构和性能[J]. 中国有色金属学报, 2012, 22(7): 2010-2015.

LIU Shao-jun, WANG Peng-fei, WAN Bing-bing, et al. Structural and electrical properties of Nd doped K0.53Na0.47NbO3 based lead free piezoceramics[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2010-2015.

[18] BAI W, WANG L, ZHENG P, et al. Pairing high piezoelectric properties and enhanced thermal stability in grain-oriented BNT-based lead-free piezoceramics[J]. Ceramics International, 2018, 44: 11402-11409.

[19] YIN J, LIU G, Lü X, et al. Superior and anti-fatigue electro-strain in Bi0.5Na0.5TiO3-based polycrystalline relaxor ferroelectrics[J]. Journal of Materials Chemistry A, 2019, 7: 5391-5401.

[20] ZHOU X F, QI H, YAN Z N, et al. Superior thermal stability of high energy density and power density in domain- engineered Bi0.5Na0.5TiO3-NaTaO3relaxor ferroelectrics[J]. ACS Applied Materials & Interfaces, 2019, 11: 43107-43115.

[21] LIU W F, REN X B. Large piezoelectric effect in Pb-free ceramics[J]. Physical Review Letters, 2009, 103(25): 257602.

[22] 胡海燕, 陈 乐, 李海华, 等. BCTZ纳米线的制备及其在能量采集中的应用[J]. 传感器与微系统, 2019, 38: 147-156.

HU Hai-yan, CHEN Le, LI Hai-hua, et al. Preparation of BCTZ nanowires and applications in energy harvesting[J]. Transducer and Microsystem Technologies, 2019, 38: 147-156.

[23] CHI Q G, LIU G, ZHANG C H, et al. Microstructure and dielectric properties of BZT-BCT/PVDF nanocomposites[J]. Results in Physics, 2018, 8: 391-396.

[24] WU Y H, MA F, QU J K, et al. Vertically-aligned lead-free BCTZY nanofibers with enhanced electrical properties for flexible piezoelectric nanogenerators[J]. Applied Surface Science, 2019, 469: 283-291.

[25] 王艳芝. 静电纺丝技术发展简史及应用[J]. 合成纤维工业, 2018, 41: 52-57.

WANG Yan-zhi. A brief history of electrospinning technology development and application[J]. China Synthetic Fiber Industry, 2018, 41: 52-57.

[26] 严国荣, 廖喜林, 刘让同, 等. 静电纺丝纳米纤维的应用研究进展[J]. 上海纺织科技, 2018, 46(5): 1-6.

YAN Guo-ron, LIAO Xi-lin, LIU Rang-tong, et al. Advances in application of electrostatic spinning nanofibers[J]. Shanghai Textile Science & Technology, 2018, 46(5): 1-6.

Electrospinning preparation optimization of barium zirconate titanate nanowires and piezoelectric properties

ZHOU Xue-fan1, WANG Lu2, LIU Yuan1, WANG Deng-pan2, LI Jun2, XUE Guo-liang1, LUO Hang1, ZHANG Dou1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Chongqing Acoustic-Opitc-Electronic Co., LTD., Chongqing 401332, China)

Abstract: The electrospinning preparation optimization of lead-free piezoelectric 0.5Ba(Zr0.2Ti0.8)O3- 0.5(Ba0.7Ca0.3)TiO3 (BCZT) nanowires and the piezoelectric response were investigated systematically. The preparation of stable BCZT sol was firstly explored for obtaining the electrospinning solution. The study was mainly focused on the effects of electrospinning and heat treatment parameters on the morphology and crystallinity of prepared BCZT nanowires. The results show that optimized electrospinning parameters are as follows: ambient temperature of 40 ℃, humidity of 50%RH, voltage of 15 kV, solution supply speed 1.00 mL/h, roller speed of 800 r/min, distance between needle tip and roller of 15 cm. The electrospinning BCZT nanowires are dried at 120 ℃ for 12 h and then annealed at 900 ℃ for 1h. As a result, pure perovskite-structured, highly crystalline, and dense BCZT nanowires with a large aspect ratio can be obtained. Moreover, the PFM measurement indicates the piezoelectricity of as-prepared BCZT nanowires, which is evidenced by the obvious ferroelectric domain structure and local polarization switching behavior.

Key words: BCZT; nanowire; electrospinning; piezoelectricity

Received date: 2021-01-29; Accepted date: 2021-06-30

Corresponding author: ZHANG Dou; Tel: +86-731-88877196; E-mail: dzhang@csu.edu.cn

(编辑 王 超)

收稿日期:2021-01-29;修订日期:2021-06-30

通信作者:张 斗,教授,博士;电话:0731-88877196;E-mail:dzhang@csu.edu.cn