文章编号:1004-0609(2012)09-2553-06

钨含量对W-Cu复合材料高温变形行为的影响

刘 勇1, 2,孙永伟1,田保红1, 2,赵瑞龙1,张 毅1, 2

(1. 河南科技大学 材料科学与工程学院,洛阳 471003;

2. 河南科技大学 河南省有色金属材料科学与加工技术重点实验室,洛阳 471003)

摘 要:采用Gleeble-1500D热模拟试验机,在温度为650~950 ℃、应变速率为0.01~5 s-1、总应变量为0.7的条件下,对25%W-Cu和50%W-Cu(质量分数)复合材料的热变形行为及其热加工图进行研究和分析。结果表明:此两种复合材料的高温流动应力—应变曲线主要以动态再结晶为特征,峰值应力随变形温度的降低或应变速率的升高而增大;在真应力—应变曲线基础上建立的W-Cu复合材料高温变形本构模型较好地表征了其高温流变特性;同时,利用50%W-Cu复合材料DMM加工图分析了其变形机制和失稳机制,确定其热加工工艺参数应优先选择变形温度为650~700 ℃、应变速率为1~5 s-1,或者变形温度为850~950 ℃、应变速率为0.01~0.1 s-1。

关键词:W-Cu复合材料;应变速率;峰值应力;动态再结晶;加工图

中图分类号:TG146 文献标志码:A

Effect of W content on hot deformation behavior of

W-Cu composite at elevated temperature

LIU Yong1, 2, SUN Yong-wei1, TIAN Bao-hong1, 2, ZHAO Rui-long1, ZHANG Yi1, 2

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China;

2. Henan Key Laboratory of Advanced Non-Ferrous Materials, Henan University of Science and Technology,

Luoyang 471003, China)

Abstract: Using the Gleeble-1500D simulator, the high-temperature plastic deformation behavior and processing map of 25%W-Cu and 50%W-Cu (mass fraction) composites were investigated at 650-950 ℃ with the strain rate of 0.01-5 s-1 and total strain of 0.7. The results show that the softening mechanism of the dynamic recrystallization is a feature of high-temperature flow stress—strain curves of the two composites, and the peak stress increases with the decrease of deformation temperature or the increase of strain rate. Based on the true stress—strain curves, the established constitutive equation represents the high-temperature flow behavior of W-Cu composite, and the calculated results of the flow stress are in good agreement with the experimental results of the high-temperature deformation of the two composites. Meanwhile, the obtained processing map of dynamic material modeling is used to analyze the deformation mechanism and the destabilization mechanism of 50%W-Cu composite, the optimal deformation processing parameters of the deformation temperatures range and the strain rates range are 650-700 ℃ and 1-5 s-1 or 850-950 ℃ and 0.01-0.1 s-1, respectively.

Key words: W-Cu composite; strain rate; peak stress; dynamic recrystallization; processing map

基金项目:国家自然科学基金资助项目(51101052);河南科技大学博士科研启动基金资助项目(09001199)

收稿日期:2011-09-03;修订日期:2011-12-28

通信作者:刘 勇,教授,博士;电话:0379-64229405;E-mail: liuyong@mail.haust.edu.cn

W-Cu复合材料是由高熔点、低热膨胀系数的钨和高电导率、热导率的铜组成的复合材料,它具有较高的密度、强度和硬度,良好的延展性、导电性和热性及较低热膨胀系数。近年来,现代电子信息业和国防工业高尖端领域的快速发展使钨合金及其复合材料的应用日益扩大,其中W-Cu复合材料因其性能优良、成本较低,被认为是极具发展潜力和应用前景的新型功能材料[1-4]。但是,对于不同钨含量的W-Cu复合材料,其性能随着成分的变化而变化。因此,研究不同钨含量的W-Cu复合材料的综合性能,对制备高性能的钨铜制品具有重要意义。

目前,对于W-Cu复合材料的研究主要集中在致密度、制备工艺等方面;而关于W-Cu复合材料高温塑性变形的研究,在国内外还鲜见报道。研究材料流动特性主要采用热模拟试验法,不仅可以建立金属的高温流动应力与变形温度、应变速率、变形程度的本构关系,进行塑性成形数值模拟,而且可以建立金属塑性成形能力的表征关系来描述材料加工性能[5-7]。本文作者通过热压缩试验,建立不同钨含量的W-Cu复合材料的本构模型,并采用DMM加工图理论研究材料的热加工性能,为W-Cu复合材料热加工工艺制定与优化提供理论依据。

1 实验

实验材料采用真空热压烧结制备的25%W-Cu和50%W-Cu复合材料,其致密度、显微硬度和电导率见表1。由表1可知,两种W-Cu复合材料的致密度较高,组织致密;且随着钨含量的增加,其显微硬度增大、电导率降低。这是由于随着钨颗粒质量分数的增加,其弥散强化作用增强,材料的硬度增加;同时,其对电子的散射作用增强,从而导致电导率下降。

表1 不同钨含量W-Cu复合材料的物理性能

Table 1 Physical properties of W-Cu composites with different W contents

沿轴向将试样加工成d8 mm×12 mm圆柱,在Gleeble-1500D热模拟机上进行热压缩试验,压缩时在试样两端均匀涂敷润滑剂(石墨+机油)以减小试样与压头之间的摩擦。两种复合材料的变形温度均分别为650、750、850和950 ℃,应变速率分别为0.01、0.1、1和5 s-1。变形后立即水淬,以保留热变形组织便于观察和分析。

2 结果与讨论

2.1 真应力—真应变曲线

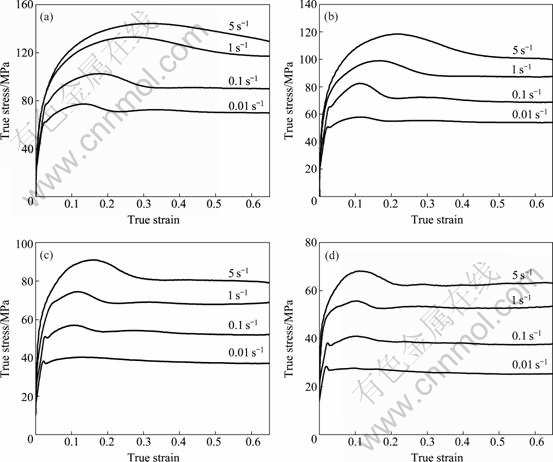

图1和2分别为25%W-Cu和50%W-Cu复合材料在不同温度、不同应变速率下的真应力—真应变曲线。

由图1和2可以看出,25%W-Cu和50%W-Cu复合材料都是动态再结晶类型,即所有的应力—应变曲线上都出现了一个明显的应力峰值;而在整个压缩过程中,流变应力随着应变量的增加均呈现先增大后减小的趋势,这是加工硬化和动态回复、再结晶软化共同作用的结果。此外,在相同的温度和应变速率下,随着钨含量的增加,流变应力呈增大趋势:即在相同变形条件下,与25%W-Cu复合材料相比,50%W-Cu复合材料的流变应力整体上提高20 MPa,这是因为随着钨含量的增加,钨颗粒的钉扎作用增强,导致流变应力增大。在相同温度下,流变应力随着应变速率的增加而增大,且其应力峰值也相应地在更大应变量时才出现;当应变速率相同时,流变应力随着温度的升高而降低,其峰值应力对应的应变量则相应降低。

图1 不同温度下25%W-Cu复合材料热压缩变形的真应力—真应变曲线

Fig. 1 True stress—true strain curves of 25%W-Cu composite during hot compression deformation at different temperatures: (a) 650 ℃; (b) 750 ℃; (c) 850 ℃; (d) 950 ℃

图2 不同温度下50%W-Cu复合材料热压缩变形真应力—真应变曲线

Fig. 2 True stress—true strain curves of 50%W-Cu composite during hot compression deformation at different temperatures: (a) 650 ℃; (b) 750 ℃; (c) 850 ℃; (d) 950 ℃

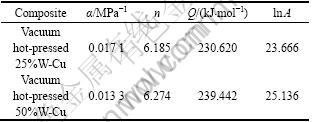

表2 W-Cu复合材料的参数拟合值

Table 2 Fitted values of W-Cu composite constants

可见,应变速率的降低和温度的升高都有利于动态再结晶的发生,即应变速率和温度对W-Cu复合材料的热变形行为具有显著影响。

2.2 流变应力方程

金属材料的高温塑性变形过程与高温蠕变过程相似,都存在热激活过程,流变应力取决于变形温度和应变速率,通常可以用Arrhenius方程来描述[8]:

(ασ<0.8) (1)

(ασ<0.8) (1)

(ασ>1.2) (2)

(ασ>1.2) (2)

(for all stress) (3)

(for all stress) (3)

式(1)~(3)中:A1、A2、A、α、n、n′和β均为材料常数,与温度无关;式(3)中的α为式(2)中β与式(1)中n′的比值; 为应变速率;T为热力学温度;R为摩尔气体常数;Q为热变形激活能;求出A、α、n和Q即可描述材料的高温流变特性。SELLARS和MCTEGART[7]提出并用实验验证了热变形条件,通常可以用温度补偿的应变速率因子Zener-Hollomon参数Z来表示[8-10]:

为应变速率;T为热力学温度;R为摩尔气体常数;Q为热变形激活能;求出A、α、n和Q即可描述材料的高温流变特性。SELLARS和MCTEGART[7]提出并用实验验证了热变形条件,通常可以用温度补偿的应变速率因子Zener-Hollomon参数Z来表示[8-10]:

Z=A[sinh(ασ)]n (4)

对式(1)、(2)和(4)两边取对数,可得

(5)

(5)

(6)

(6)

ln Z=ln A+nln[sinh(ασ)] (7)

在一定的应变和应变速率下,由式(3)对1/T求偏导数得

(8)

(8)

由式(5)和(6)可知,直线 —

— 和

和 —

— 的斜率分别为

的斜率分别为 和β。采用最小二乘法进行线性回归,可求得

和β。采用最小二乘法进行线性回归,可求得 和β。取峰值应力和其对应温度,可得出相应的

和β。取峰值应力和其对应温度,可得出相应的 —ln[sinh(ασ)]和ln[sinh(ασ)]—1/T的线性关系,设直线ln[sinh(ασ)]—1/T斜率的平均值为S,设直线

—ln[sinh(ασ)]和ln[sinh(ασ)]—1/T的线性关系,设直线ln[sinh(ασ)]—1/T斜率的平均值为S,设直线 —ln[sinh(ασ)]斜率的平均值为M,采用最小二乘法进行线性回归,可求得S、M和Q。由

—ln[sinh(ασ)]斜率的平均值为M,采用最小二乘法进行线性回归,可求得S、M和Q。由 与T,可求得对应ln Z值,绘制出ln[sinh(ασ)]—ln Z曲线,求其斜率ln A值。

与T,可求得对应ln Z值,绘制出ln[sinh(ασ)]—ln Z曲线,求其斜率ln A值。

25%W-Cu和50%W-Cu复合材料在热变形过程中的拟合参数值如表2所列。由表2可知,不同钨含量的W-Cu复合材料的Q值也不相同,且随着钨含量的增加,其Q值增大。25%W-Cu复合材料的热变形激活能比50%W-Cu复合材料的低,主要是由于钨含量的降低,第二相粒子的钉扎作用减弱,这也表明了25%W-Cu复合材料的热变形比50%W-Cu复合材料的热变形更容易,可成形性较高。

将以上所求得的参数值代入式(3),即可得到25%W-Cu和50%W-Cu复合材料的高温热变形流变应力本构方程分别如式(9)和(10)所示:

(9)

(9)

(10)

(10)

2.3 DMM加工图

印度学者RAO等[11]与PRASAD等[12]提出了动态材料模型,它是基于材料在热加工过程中的不可逆热力学的最大值定理在大应变塑性变形方面的应用[13]。在给定应变 和变形温度T的条件下,应变速率敏感

和变形温度T的条件下,应变速率敏感

指数m可以由耗散量函数G(G= )和耗散协量函

)和耗散协量函

数J(J= )的变化率来表示[14]:

)的变化率来表示[14]:

(11)

(11)

无量纲的功率耗散效率因子 可以由应变速率敏感指数m来描述:

可以由应变速率敏感指数m来描述:

(12)

(12)

描述的是材料在热处理变形过程中因组织改变而消耗的能量与理想线性耗散状态下因显微组织改变而消耗的能量的比值。

描述的是材料在热处理变形过程中因组织改变而消耗的能量与理想线性耗散状态下因显微组织改变而消耗的能量的比值。

在功率耗散图中,并不是功率耗散效率越高,材料的内在可加工性能就越好,因为在加工失稳区功率耗散效率也可能较高,所以有必要先判断合金的加工失稳区。根据大应变塑性变形时极大值原理,可推导出保持塑性流变稳定的条件式[15-16]为

(13)

(13)

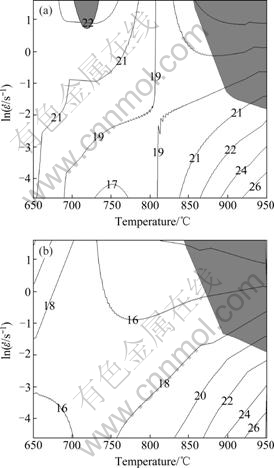

DMM加工图是功率耗散图和失稳图的叠加,可用来研究和确定材料热加工工艺参数。图3所示为50%W-Cu复合材料在不同真应变时的DMM加工图。

从图3可知,50%W-Cu复合材料在变形温度为850~950 ℃、应变速率大于0.1 s-1时均会发生流变失稳,这可能是由于变形温度较高时,钨颗粒与铜基体界面和铜基体晶界更容易发生滑移,界面处产生严重的应力集中,从而引起界面出现裂纹,在热加工时应避开这部分区域;而在低应变速率下,界面滑移产生的应力集中有足够的时间通过扩散等途径释放,从而避免开裂。加工图中随着应变速率的减小,功率耗散效率逐渐提高,当变形温度为950 ℃、应变速率0.01 s-1时,出现功率耗散效率极值为26%,较高的功率耗散效率意味着出现特殊的显微组织或导致流变失稳。

图3 50%W-Cu复合材料在不同真应变时的DMM加工图

Fig. 3 DMM processing maps of 50%W-Cu composite at various true strains (Numbers in Fig. 3 are values of power dissipation efficiency, %): (a) = 0.4; (b)

= 0.4; (b) =0.6

=0.6

图4所示为50%W-Cu复合材料热变形后的显微组织。从图4可以看出,在加工图中功率耗散效率较高区域即变形温度为850~950 ℃、应变速率为0.01~0.1 s-1时复合材料都发生了完全动态再结晶,得到等轴状再结晶组织,这个区域的组织易于控制,其

图4 不同变形温度和应变速率时50%W-Cu复合材料的显微组织

Fig. 4 Microstructures of 50%W-Cu composite at various deformation temperatures and strain rates: (a) t=950 ℃,  = 0.01 s-1; (b) t=850 ℃,

= 0.01 s-1; (b) t=850 ℃,  =0.01 s-1

=0.01 s-1

对应的变形温度和应变速率即为最佳变形工艺参数。在加工图中失稳区域,即变形温度为950 ℃、应变速率为5 s-1条件下,压缩试样表面产生了宏观裂纹,在热变形时应避开此区域。

综上所述,根据加工图及显微组织可以确定该复合材料优先选择的高温塑性变形工艺参数如下:变形温度650~700 ℃、应变速率1~5 s-1,或变形温度850~ 950 ℃、应变速率0.01~0.1 s-1。

3 结论

1) 不同钨含量的W-Cu复合材料在热变形过程中的动态软化机制以动态再结晶机制为主,峰值应力均随变形温度的降低或应变速率的增大而增大,W-Cu复合材料是温度和应变速率敏感材料。

2) 25%W-Cu和50%W-Cu复合材料的本构方程分别如下:

,

,

。

。

3) 根据50%W-Cu复合材料的DMM加工图和显微组织,结合其流变失稳条件,可以确定其高温塑性变形优先选择工艺参数如下:变形温度650~700 ℃、应变速率1~5 s-1,或变形温度850~950 ℃、应变速率0.01~0.1 s-1。

REFERENCES

[1] KIM Y D, OH N L, OH S T, MOON I H. Thermal conductivity of W-Cu composites at various temperatures [J]. Materials Letters, 2001, 51(5): 420-424.

[2] 周武平, 吕大铭. 钨铜材料应用和生产的发展现状[J]. 粉末冶金材料科学与工程, 2005, 10(1): 21-25.

ZHOU Wu-ping, L? Da-ming. Development of application and production in W-Cu materials [J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10(1): 21-25.

[3] 杨明川, 宋贞祯, 卢 柯. W-20%Cu纳米复合粉的制备[J]. 金属学报, 2004, 40(6): 639-642.

YANG Ming-chuan, SONG Zhen-zhen, LU Ke. Synthesis of W-20%Cu nanocomposite powders [J]. Acta Metallurgica Sinica, 2004, 40(6): 639-642.

[4] 陈文革, 丁秉均. 钨铜基复合材料的研究及进展[J]. 粉末冶金工业, 2001, 11(3): 45-50.

CHEN Wen-ge, DING Bing-jun. The progress and research of W-Cu matrix composites [J]. Powder Metallurgy Industry, 2001, 11(3): 45-50.

[5] 黄树海, 赵祖德, 夏志新, 蔡海艳, 康 凤, 胡传凯, 舒大禹. AZ80合金高温变形行为及加工图[J]. 稀有金属材料与工程, 2010, 39(5): 848-852.

HUANG Shu-hai, ZHAO Zu-de, XIA Zhi-xin, CAI Hai-yan, KANG Feng, HU Chuan-kai, SHU Da-yu. Study on high-temperature deformation behavior and processing map of AZ80 alloy [J]. Rare Metal Materials and Engineering, 2010, 39(5): 848-852.

[6] 范永革, 汪凌云. AZ31镁合金的中温流变失稳特征[J]. 中国有色金属学报, 2005, 15(10): 1062-1066.

FAN Yong-ge, WANG Ling-yun. Instability flow characteristics of AZ31 magnesium alloy at moderate temperature [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1062- 1066.

[7] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation [J]. Acta Metall, 1966, 14: 1136-1138.

[8] 孟 刚, 李伯龙, 黄 晖, 李红梅, 聂祚仁. Al-4.7Mg-0.7Mn- 0.1Zr-0.4Er合金高温变形行为[J]. 材料热处理学报, 2010, 31(2): 95-99.

MENG Gang, LI Bo-long, HUANG Hui, LI Hong-mei, NIE Zuo-ren. Hot deformation behavior of Al-4.7Mg-0.7Mn-0.1Zr- 0.4Er alloy [J]. Transactions of Materials and Heat Treatment, 2010, 31(2): 95-99.

[9] ZENER C, HOLLOMON J H. Effect of strain-rate upon the plastic flow of steel [J]. J Appl Phys, 1944, 15(1): 22-27.

[10] 寇琳媛, 金能萍, 张 辉, 韩 逸, 吴文祥, 李落星. 7150铝合金高温热压缩变形流变应力行为[J]. 中国有色金属学报, 2010, 20(1): 43-48.

KOU Lin-yuan, JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, LI Luo-xing. Flow stress behavior of 7150 aluminum alloy during hot compression deformation at elevated temperature [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 43-48.

[11] RAO K P, DORAIVELU S M, ROSHAN H M, PRASAD Y V R K. Deformation processing of an aluminum alloy containing particles: Studies on Al-5%Si alloy 4043 [J]. Metallurgical and Materials Transactions A, 1983, 14(8): 1671-1679.

[12] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242 [J]. Metallurgical and Materials Transactions A, 1984, 15(10): 1883-1892.

[13] 汪凌云, 范永革, 黄光杰, 黄光胜. 镁合金AZ31B的高温塑性变形及加工图[J]. 中国有色金属学报, 2004, 14(7): 1069-1072.

WANG Ling-yun, FAN Yong-ge, HUANG Guang-jie, HUANG Guang-sheng. Plastic deformation at elevated temperature and processing maps of magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1069-1072.

[14] NARAYANA M S V S, NAGESWARA R B. On the development of instability criteria during hot working with reference to IN718 [J]. Materials Science and Engineering A, 1998, 254(1/2): 76-82.

[15] 曾卫东, 周义刚, 周 军, 俞汉清, 张学敏, 徐 斌. 加工图理论研究进展[J]. 稀有金属材料与工程, 2006, 35(5): 673-677.

ZENG Wei-dong, ZHOU Yi-gang, ZHOU Jun, YU Han-qing, ZHANG Xue-min, XU Bin. Recent development of processing map theory [J]. Rare Metal Materials and Engineering, 2006, 35(5): 673-677.

[16] 鞠 泉, 李殿国, 刘国权. 15Cr-25Ni-Fe基合金高温塑性变形行为的加工图[J]. 金属学报, 2006, 42(2): 218-224.

JU Quan, LI Dian-guo, LIU Guo-quan. The processing map of hot plastic deformation of a 15Cr-25Ni-Fe base superalloy [J]. Acta Metallurgica Sinca, 2006, 42(2): 218-224.

(编辑 陈卫萍)