DOI: 10.11817/j.ysxb.1004.0609.2020-39545

凝固压差对真空差压铸造ZL114A合金微观组织及高温蠕变性能的影响

黄朋朋,芦 刚,严青松,刘 慧,晏玉平

(南昌航空大学 航空制造工程学院,南昌 330063)

摘 要:采用真空差压铸造技术在不同凝固压差下制备ZL114A合金试样,通过金相、扫描电镜、高温蠕变性能测试等技术考察凝固压差对真空差压铸造ZL114A合金初生相组织、共晶硅形貌和高温蠕变性能的影响。结果表明:随着凝固压差的增大,合金的初生相组织得到明显细化,由粗大的树枝晶转变为细小的等轴晶,共晶硅形貌也由粗大的针状向短棒或颗粒状转变;同时ZL114A合金的高温蠕变性能得到显著改善;当凝固压差为90 kPa时,其蠕变时间达到100 h后合金试样仍未见断裂,此时试样的变形量仅为0.21%。

关键词:ZL114A合金;真空差压铸造;凝固压差;微观组织;高温蠕变

文章编号:1004-0609(2020)-07-1535-09 中图分类号:TG249.6 文献标志码:A

随着能源紧缺和生态污染问题的日益突出,人们对材料轻量化的发展愈发关注[1]。由于具有高强高韧性,优良的铸造性能以及价格低廉等优点,铸造铝合金被广泛应用于各个工业领域[2-4]。然而随着工业科技迅速发展,航空航天等产品对高温性能的要求愈发苛刻,改善铸造铝合金的高温性能仍然是一个很重要的问题[5-8]。目前,国内外关于铸造铝合金的研究主要集中在合金组织、力学性能、常温强度等方面,且取得了显著成果,但关于其在高温性能方面的研究报道还较少。LIU等[9]研究了铸造铝合金在蠕变温度为100~210 ℃、蠕变应力为150~300 MPa下的高温蠕变行为,表明在蠕变过程中第二相沉淀Ω和θ′共同存在是导致欠时效合金的高温蠕变性能更高的主要原因。王珊玲等[10]研究并分析了ZL107合金的高温蠕变性能,表明热处理对ZL107合金高温下的静态蠕变和循环蠕变行为具有显著影响。韩玉科等[11]研究了不同含量的La对ZL205A合金的高温蠕变作用机制的影响,发现ZL205A合金经过La变质处理后稳态蠕变速率降低,且在La含量为0.3%(质量分数)时稳态蠕变速率达到最小值。

ZL114A合金作为铸造铝合金的代表,具有优良的耐蚀性和铸造性能[12-13]。真空差压铸造是一种低压充型、高压凝固的反重力铸造技术,由于在整个凝固过程中受到高压场的作用,能够获得结构性能良好的铸件[14-16]。因此被广泛应用于生产高质量复杂薄壁ZL114A合金铸件。杨普超等[17]在真空差压铸造的充型凝固过程中开启超声振动装置,研究了凝固压力和超声功率对ZL114A合金硬度的影响,表明当施加的超声功率为600 W时,随着凝固压力的增加,ZL114A合金的硬度不断增大,在凝固压力为350 kPa时硬度达到峰值。

目前,大量专家学者对真空差压铸造过程中凝固压力对铸造铝合金的力学性能的影响规律进行了研究报道[18-19],但对真空差压铸造补缩过程中凝固压差对铸造铝合金性能影响的研究报道较少,特别是凝固压差对真空差压铸造铝合金高温蠕变性能影响的研究未见报道。所以,选取ZL114A合金作为本文的研究对象,研究凝固压差对真空差压铸造ZL114A合金高温蠕变性能的影响,旨在为生产高温蠕变性能良好的高质量复杂薄壁铸铝件提供理论基础及技术支持。

1 实验

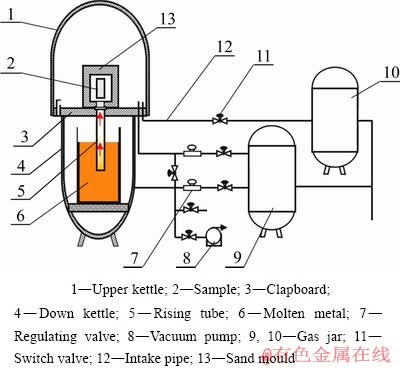

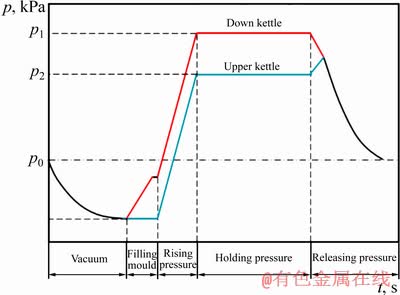

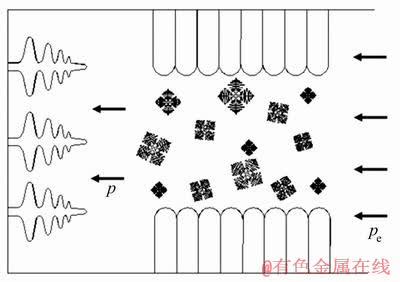

采用VCPC型真空差压铸造设备制备ZL114A合金试样,图1所示为系统示意图,图2所示为实验理想工艺曲线。

图1 真空差压铸造设备系统示意图

Fig. 1 Schematic diagram of vacuum counter-pressure casting equipment system

图2 实验理想工艺曲线图

Fig. 2 Experimental ideal process curve

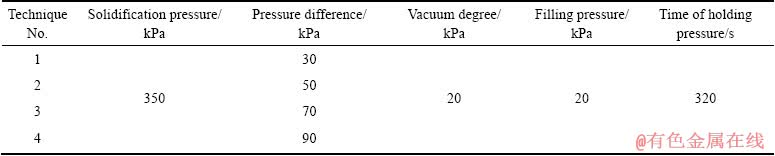

铸件为圆柱状,外形尺寸为直径45 mm×210 mm,铸型由酚醛树脂覆膜砂制成,预热温度设定为120 ℃,合金为ZL114A(ZAlSi7Mg1A),浇注温度设为700 ℃,凝固压差选为30、50、70、90 kPa,真空差压铸造工艺参数如表1所列。从铸件中加工4个直径为16 mm的圆形试样,其中3个加工为直径10 mm的蠕变标准试样用于蠕变实验,其他试样用于微观组织及共晶硅形貌分析。

用CSS-3905型蠕变试验机对真空差压铸造ZL114A合金试样进行蠕变实验,蠕变实验温度为200 ℃,应力为120MPa。利用型号为Quanta200的电子显微镜观察ZL114A合金的共晶硅形貌及蠕变断口形貌,利用型号为XJP-6A的金相显微镜观察ZL114A合金的微观组织。

2 结果与分析

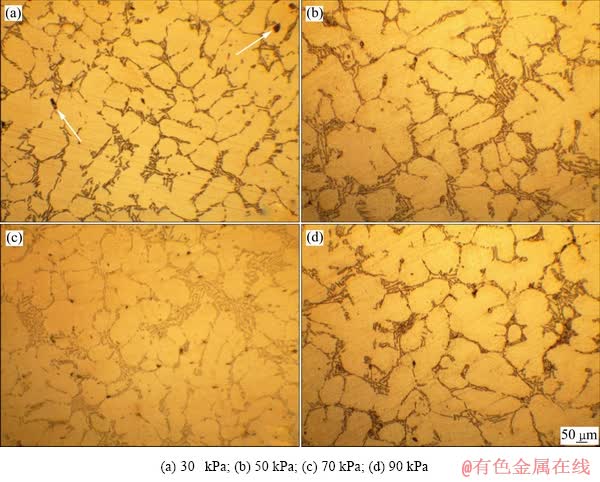

2.1 凝固压差对真空差压铸造ZL114A合金初生相组织的影响

图3所示为不同凝固压差下真空差压铸造ZL114A合金的微观组织。从图3可以看出,随着凝固压差的增大,真空差压铸造ZL114A合金的初生相形貌发生显著转变。图3(a)所示为凝固压差为30 kPa时合金的微观组织。图中显微组织中的初生相尤为粗大,主要为发达的树状枝晶,并存在一定数量的缩孔缺陷(见图3(a)中箭头所示);图3(b)所示为凝固压差为50 kPa时合金的微观组织。图中树状枝晶开始逐渐变为蔷薇状晶,出现很多的棒状、柱状晶,局部出现细小的粒状晶;图3(c)所示为凝固压差为70 kPa时合金的微观组织。图中棒状、柱状晶转变成少量细小圆整的初生α(Al)晶粒,数量虽然大大减少,但总体来说,微观组织的分布仍较不均匀;图3(d)所示为凝固压差为90 kPa时合金的微观组织,图中初生α(Al)晶粒得到较大程度的细化,树枝状晶的数量大大减少,棒状、柱状的晶粒大部分被破碎,转变为细小且圆整的初生α(Al)晶粒。

真空差压铸造技术是在真空状态下低压充填、高压凝固,具有高压力场作用于铸件整个结晶凝固过程的特点[20-21]。凝固压力使熔融金属通过凝固枝晶间狭窄的通道向补缩区进行补缩的驱动作用被称为挤滤渗流作用,其示意图如图4所示。

表1 真空差压铸造工艺参数

Table 1 Vacuum counter-pressure casting process parameter table

图3 不同凝固压差下真空差压铸造ZL114A合金微观组织

Fig. 3 Microstructures of vacuum counter-pressure casting ZL114A alloy under different solidification pressure differences

图4 枝晶间渗流模型示意图

Fig. 4 Schematic diagram of interdendritic seepage model

真空差压铸造挤滤渗流能力可由式(1)表示[22]:

(1)

(1)

式中: 为挤滤时间;

为挤滤时间; 为挤滤的压力差;

为挤滤的压力差; 为挤滤到缩孔中的金属容量;F为挤滤面积;

为挤滤到缩孔中的金属容量;F为挤滤面积; 为金属液的动力黏度系数;

为金属液的动力黏度系数; 为挤滤深度;L为渗透系数。

为挤滤深度;L为渗透系数。

从式(1)可以看出,当其他工艺参数确定后, 与

与 成正比,即随着挤滤的压力差

成正比,即随着挤滤的压力差 增大,真空差压铸造的挤滤能力也在增强。凝固压差是真空差压铸造挤渗作用的主要影响因素,随着凝固压差的增大,真空差压铸造挤渗作用也会逐渐增强,当受到强劲的挤渗作用时,金属液就可以较易地通过凝固枝晶间的狭窄通道对正在凝固的区域进行补缩,尽管组织中形成了部分骨架状树枝晶,但只要挤渗作用强度超过枝晶强度,枝晶在挤渗作用下就会产生塑性变形甚至断裂,导致金属液中游离晶粒的数量增加,枝晶变得细小。当凝固压差为30 kPa进行真空差压铸造时,此时由于凝固压差较小,挤滤渗流作用较弱,显微组织主要为粗大的发达树状枝晶;当凝固压差为50 kPa进行真空差压铸造时,金属液的挤滤渗流作用随着凝固压差的增大有所增强,并能够对组织中出现的骨架状树枝晶产生一定的冲刷作用,此时的微观组织主要为蔷薇状晶,局部出现细小的粒状晶;当凝固压差为70 kPa甚至90 kPa进行真空差压铸造时,随着凝固压差的增大金属液的整体流动性能变得良好,金属液的挤滤能力进一步增强,在较高的外界压力条件下,金属液的补缩能力得到增强,更重要的是棒状、柱状晶被破碎,转变为细小圆整的初生α(Al)晶粒。

增大,真空差压铸造的挤滤能力也在增强。凝固压差是真空差压铸造挤渗作用的主要影响因素,随着凝固压差的增大,真空差压铸造挤渗作用也会逐渐增强,当受到强劲的挤渗作用时,金属液就可以较易地通过凝固枝晶间的狭窄通道对正在凝固的区域进行补缩,尽管组织中形成了部分骨架状树枝晶,但只要挤渗作用强度超过枝晶强度,枝晶在挤渗作用下就会产生塑性变形甚至断裂,导致金属液中游离晶粒的数量增加,枝晶变得细小。当凝固压差为30 kPa进行真空差压铸造时,此时由于凝固压差较小,挤滤渗流作用较弱,显微组织主要为粗大的发达树状枝晶;当凝固压差为50 kPa进行真空差压铸造时,金属液的挤滤渗流作用随着凝固压差的增大有所增强,并能够对组织中出现的骨架状树枝晶产生一定的冲刷作用,此时的微观组织主要为蔷薇状晶,局部出现细小的粒状晶;当凝固压差为70 kPa甚至90 kPa进行真空差压铸造时,随着凝固压差的增大金属液的整体流动性能变得良好,金属液的挤滤能力进一步增强,在较高的外界压力条件下,金属液的补缩能力得到增强,更重要的是棒状、柱状晶被破碎,转变为细小圆整的初生α(Al)晶粒。

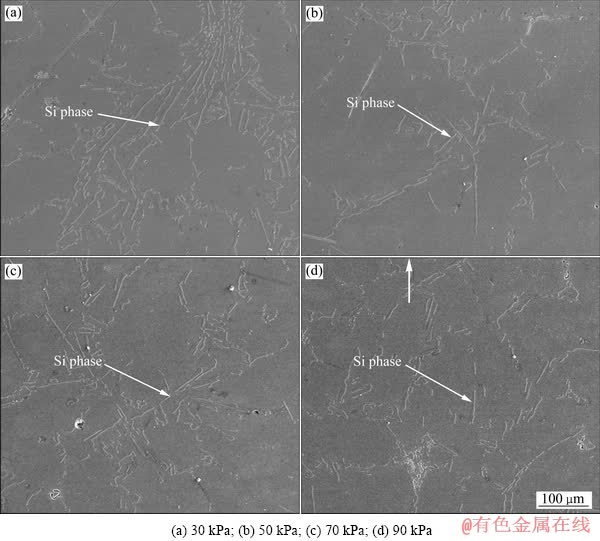

2.2 凝固压差对真空差压铸造ZL114A合金共晶硅形貌的影响

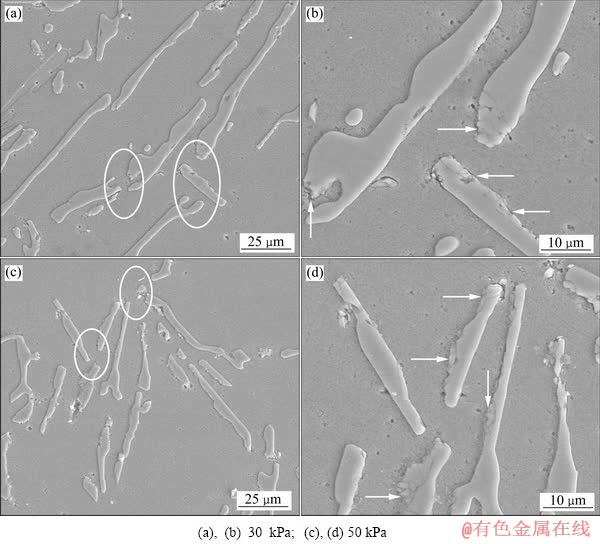

图5所示为不同凝固压差下真空差压铸造ZL114A合金的共晶硅形貌。图5(a)所示为凝固压差为30 kPa时合金的共晶硅形貌,共晶硅组织主要以粗大的针状存在于基体中;图5(b)和(c)所示分别为凝固压差为50 kPa和70 kPa时的共晶硅形貌。可以发现,尽管存在少量针状共晶硅,但是共晶硅组织已经得到了充分细化,大部分以短棒状的形式存在;图5(d)所示为凝固压差为90 kPa时的共晶硅形貌,可以发现,针状的共晶硅组织几乎已经消失,共晶硅组织主要以短棒状的形式存在,且颗粒状共晶硅趋于细小圆整。

在真空差压铸造过程中,凝固压差对ZL114A合金共晶硅形貌影响显著,随着凝固压差不断增加,共晶组织由粗大的针状向短棒或颗粒状转变。当凝固压差为30 kPa进行真空差压铸造时,此时金属液挤滤的压力差较低,挤滤能力较弱,枝晶间的补缩力还很小,对共晶硅的破碎效果很弱,基体中的共晶硅主要为粗大的针状;当凝固压差为50 kPa进行真空差压铸造时,金属液挤滤的压力差升高,挤滤效果增强,在补缩力的作用下,少量针状共晶硅组织受力产生弯曲,甚至被折断,从而以短棒状的形式存在;当凝固压差为70 kPa进行真空差压铸造时,金属液的补缩作用进一步加强,补缩作用驱使共晶硅组织随金属液在枝晶间流动,细小的共晶硅在渗流的过程会形成非均质形核核心,增大共晶硅的非枝晶生长趋势,此时组织中的共晶硅大部分以短棒状形式存在;当凝固压差为90 kPa进行真空差压铸造时,凝固补缩作用显著增强,强有力的补缩作用导致共晶硅几乎以短棒状形式存在,且颗粒状共晶硅趋于细小圆整。

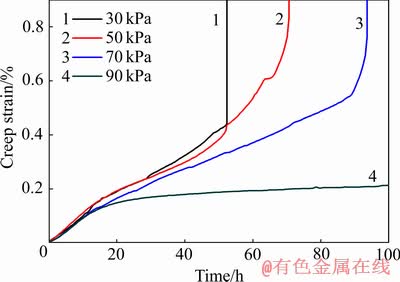

2.3 凝固压差对真空差压铸造ZL114A合金高温蠕变性能的影响

图5 不同凝固压差下真空差压铸造铝合金共晶硅SEM 像

Fig. 5 SEM images of aluminum alloy eutectic silicon under vacuum counter-pressure casting at different solidification pressure differences

图6 凝固压差对真空差压铸造ZL114A合金高温蠕变性能的影响

Fig. 6 Effect of solidification pressure difference on high temperature creep properties of vacuum differential pressure casting ZL114A alloy

蠕变变形过程有3个特征阶段,即减速蠕变、稳态蠕变和加速蠕变阶段[23]。蠕变温度为200 ℃,蠕变应力为120 MPa条件下,凝固压差对真空差压铸造ZL114A合金高温蠕变性能的影响规律如图6所示。

从图6可以看出,凝固压差对真空差压铸造ZL114A合金的高温蠕变性能具有明显的影响。当凝固压差为30 kPa时,ZL114A合金的高温蠕变速率较快,在蠕变过程中不存在稳态蠕变阶段,因此试样在变形量高达11.73%时发生断裂的时间仅为52 h;当凝固压差为50 kPa时,蠕变断裂时间延长到71 h,此时蠕变断裂时间更长,蠕变变化趋势更为平缓,且存在稳态蠕变阶段,但稳态蠕变阶段时间较短,发生蠕变断裂时的变形量相比凝固压差为30 kPa时减小近50%,变形量仅为5.56%;当凝固压差为70 kPa时,蠕变断裂时间为94 h,此时的蠕变变化趋势并没有明显变化,但稳态蠕变时间更长,高温蠕变性能有了较大的改善;当凝固压差为90 kPa时,高温蠕变曲线中存在明显的稳态蠕变阶段,蠕变时间达到100 h后合金试样仍未见断裂,此时的试样变形量仅为0.21%。可以得出,凝固压差的提高并没有改变真空差压铸造ZL114A合金的3个阶段蠕变特点,但降低了稳态蠕变速率,增加了蠕变变形第二阶段的时间,使得蠕变断裂时间延长,从而显著改善了ZL114A合金的高温蠕变性能。

相关研究学者发现,共晶硅颗粒受外力发生断裂时存在临界应力,该临界应力可由式(2)表示[24]:

(2)

(2)

式中: 为单位面积需要的自由表面能;

为单位面积需要的自由表面能; 为泊松比;R为硅颗粒半径。由式(2)可知,硅颗粒半径R与其受外力发生断裂时的临界应力成反比,硅颗粒半径越小,使其发生断裂需要的应力就越大。因此,改善共晶硅的形貌及尺寸是提高铝合金高温蠕变性能行之有效的方法。当采用90 kPa的凝固压差进行真空差压铸造时,铝合金的微观组织中存在大量细小圆整的初生α(Al)晶粒,使得晶界对位错运动的阻碍作用大幅提高,从而改善了铝合金的高温蠕变性能。另外,细小圆整的共晶硅数量越多,硅颗粒半径必然减小,导致铝合金断裂所需应力增大,而共晶硅对基体的割裂作用会随之减弱,合金的塑性得到提高,从而提高了铝合金的高温蠕变性能。

为泊松比;R为硅颗粒半径。由式(2)可知,硅颗粒半径R与其受外力发生断裂时的临界应力成反比,硅颗粒半径越小,使其发生断裂需要的应力就越大。因此,改善共晶硅的形貌及尺寸是提高铝合金高温蠕变性能行之有效的方法。当采用90 kPa的凝固压差进行真空差压铸造时,铝合金的微观组织中存在大量细小圆整的初生α(Al)晶粒,使得晶界对位错运动的阻碍作用大幅提高,从而改善了铝合金的高温蠕变性能。另外,细小圆整的共晶硅数量越多,硅颗粒半径必然减小,导致铝合金断裂所需应力增大,而共晶硅对基体的割裂作用会随之减弱,合金的塑性得到提高,从而提高了铝合金的高温蠕变性能。

ZL114A合金的蠕变断裂机制通常为微裂纹聚合型断裂,由于其断裂机制与共晶硅的形貌息息相关,为了进一步研究凝固压差对真空差压铸造ZL114A合金的高温蠕变行为的影响机理,以凝固压差为30 kPa和50 kPa铝合金试样断后共晶硅形貌为例进行讨论分析。蠕变断裂后真空差压铸造ZL114A合金试样的共晶硅形貌如图7所示。

从图7可以看出,ZL114A合金在经过高温蠕变实验后,组织中存在数量较多的断裂共晶硅,并在共晶硅边缘处萌生大量微裂纹,这些微裂纹沿着共晶硅与基体接触面方向生长扩散,分布在裂纹扩展方向上的共晶硅,由于阻碍了裂纹的生长会被截断,这在基体中尺寸较大和分布不均匀的共晶硅中更容易发生;而细小圆整的的共晶硅则更不容易发生断裂,当细小圆整的共晶硅处在裂纹生长扩散的方向上时,由于无法截断共晶硅阻止,裂纹的生长扩散将会绕开这些细小的共晶硅,从而降低裂纹的生长速率。通过对比压差分别为30 kPa和50 kPa真空差压铸造ZL114A合金蠕变断裂后的共晶硅形貌可知,凝固压差越高,细小圆整的共晶硅数量越多,阻碍合金微裂纹生长扩散的能力越强,高温蠕变性能越好。

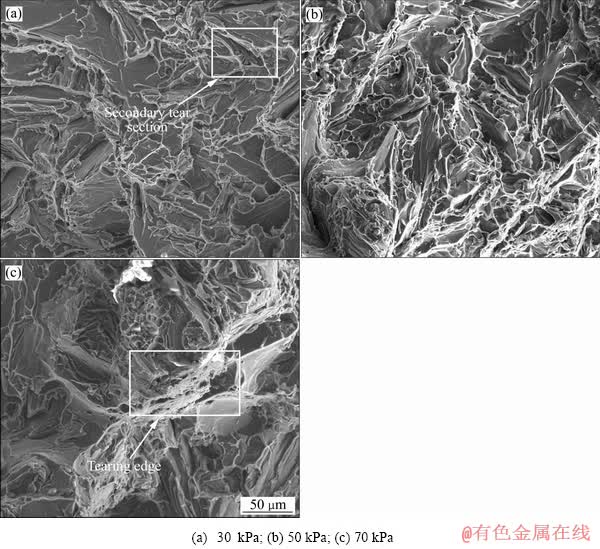

在研究分析ZL114A合金高温蠕变性能的时候,观察合金试样断裂时的断口形貌是对材料断裂机制进行分析的一种重要的方式。通过SEM观察ZL114A合金的断口形貌,分析其蠕变行为,以便更好地研究凝固压差对真空差压铸造ZL114A合金高温蠕变性能的影响。图8所示为不同凝固压差下真空差压铸造ZL114A合金的断口形貌。

通过对比可以发现,凝固压差对真空差压铸造ZL114A合金的断口形貌影响显著。当凝固压差为30 kPa时,解理面和解理台阶数量较多,并存在明显的分叉裂纹及二次裂纹断面;当凝固压差为50 kPa时,断口形貌中的解理面和解理台阶数量明显减少,出现少量形状大小规则的韧窝,但韧窝尺寸较大;当凝固压差为70 kPa时,断口形貌中出现较多的断口韧窝,此时韧窝的形状更圆,尺寸更小,并存在一定数量的纤维状撕裂棱,说明此时ZL114A合金试样以塑性断裂为主,韧性断裂程度有所增加,当凝固压差达到90 kPa时,断口形貌达到最佳,其高温蠕变性能也达到最佳值。

图7 蠕变断裂后真空差压铸造ZL114A合金的共晶硅形貌

Fig. 7 Eutectic silicon morphologies of vacuum counter-pressure casting ZL114A alloy after creep rupture

图8 不同凝固压差下真空差压铸造ZL114A合金试样蠕变断口形貌

Fig. 8 Creep fracture morphologies of vacuum differential pressure casting ZL114A alloy sample under different solidification pressure differences

3 结论

1) 在真空差压铸造过程中,凝固压差对真空差压铸造ZL114A合金的初生相组织和共晶硅形貌均具有显著影响,随着凝固压差的增大,金属液的挤滤渗流作用变强,合金初生相组织发生显著变化,由部分粗大的树枝晶转变为细小的等轴晶,共晶硅形貌发生了明显转变,由粗大的针状转变为短棒或颗粒状。

2) 凝固压差对真空差压铸造ZL114A合金的高温蠕变性能影响显著。随着凝固压差的增加,ZL114A合金的蠕变断裂时间显著延长,变形量显著下降,高温蠕变性能得到极大的改善;当凝固压差为90 kPa时,蠕变时间达到100 h后ZL114A合金试样仍未见断裂,此时的试样变形量仅为0.21%。

REFERENCES

[1] 赵玉华, 满佳乐, 刘玉林, 陆皖皖. 凝固速度及热处理工艺对Al-8Ca组织性能的影响[J]. 机械工程学报, 2018, 54(18): 62-67.

ZHAO Yu-hua, MAN Jia-le, LIU Yu-lin, LU Wan-wan. Effect of solidification rate and heat treatment process on microstructure and properties of Al-8Ca[J]. Journal of Mechanical Engineering, 2018, 54(18): 62-67.

[2] 王 罡, 任珂, 胡毅森, 叶 茂, 王淑青, 融亦鸣. 基于微观组织特征的航天铝铜合金力学行为研究[J]. 机械工程学报, 2018, 54(9): 77-85.

WANG Gang, REN Ke, HU Yi-sen, YE Mao, WANG Shu-qing, RONG Yi-ming. Study on mechanical behavior of aerospace aluminum-copper alloy based on microstructure characteristics[J]. Journal of Mechanical Engineering, 2018, 54(9): 77-85.

[3] 李培杰, 杜满昌, 陈玉勇, 贾 均, 朱 键. 新型高强耐热铸造铝硅合金及其强化耐热机理的研究[J]. 机械工程学报, 1995, 31(2): 88-92, 83.

LI Pei-jie, DU Man-chang, CHEN Yu-yong, JIA Jun, ZHU Jian. Study on a new high-strength heat-resistant cast aluminum-silicon alloy and its enhanced heat resistance mechanism[J]. Journal of Mechanical Engineering, 1995, 31(2): 88-92, 83.

[4] SHAJI M C, RAVIKUMAR K K, RAVI M, SUKUMARAN K. Development of a high strength cast aluminium alloy for possible automotive applications[J]. Materials Science Forum, 2013, 765: 54-58.

[5] 刘 慧. 凝固压差和压力对真空差压铸造ZL114A合金微观组织和高温蠕变性能的影响[D]. 南昌: 南昌航空大学, 2018.

LIU Hui. Effect of coagulation pressure difference and pressure on microstructure and high temperature creep properties of vacuum differential pressure casting ZL114A alloy[D]. Nanchang: Nanchang Hangkong University, 2018.

[6] SRIVATSAN T S, ANAND S, VEERAGHAVAN D, VASUDEVAN V K. The tensile response and fracture behavior of an Al-Zn-Mg-Cu alloy: Influence of temperature[J]. Journal of Materials Engineering and Performance, 1997, 6(3): 349-358.

[7] CHANG-YEOL J. High temperature mechanical properties of Al-Si-Mg-(Cu) alloys for automotive cylinder heads[J]. Materials Transactions,2013,54(4): 588-594.

[8] GARAT M, LASLAZ G. Improved aluminum alloys for common rail diesel cylinder heads[J]. AFS Transactions, 2007, 115: 89-96.

[9] LIU X Y, PAN Q L, ZHANG X L, LIANG S X, GAO F, ZHENG L Y, LI M X. Creep behavior and microstructural evolution of deformed Al-Cu-Mg-Ag heat resistant alloy[J]. Materials Science and Engineering A, 2014, 599: 160-165.

[10] 王珊玲, 沈保罗, 高升吉. ZL107合金的高温静态蠕变和循环蠕变[J]. 中国有色金属学报, 2001, 11(8): 626-630.

WANG Shan-ling, SHEN Paul, GAO Sheng-ji. High temperature static creep and cyclic creep of ZL107 alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(8): 626-630.

[11] 韩玉科, 杨 琦. 铸造ZL205A合金的变质处理与蠕变性能研究[J]. 特种铸造及有色合金, 2017, 37(8): 921-924.

HAN Yu-ke, YANG Qi. Study on modification and creep properties of cast ZL205A alloy[J]. Special Casting & Nonferrous Alloys, 2017, 37(8): 921-924.

[12] 康福伟, 张继敏, 樊德智, 王珊珊. ZL114A合金热变形本构方程[J]. 哈尔滨理工大学学报, 2018, 23(2): 134-139.

KANG Fu-wei, ZHANG Ji-min, FAN De-zhi, WANG Shan-shan. The constitutive equation of thermal deformation of ZL114A alloy[J]. Journal of Harbin University of Science and Technology, 2018, 23(2): 134-139.

[13] HEGDE S, PRABHU K N. Modification of eutectic silicon in Al-Si alloys[J]. Journal of Materials Science, 2008, 43(9): 3009-3027.

[14] 熊博文, 余 欢, 严青松, 徐志峰, 蔡长春, 王嘉辉, 杨 振. 真空差压铸造薄壁铸件的研究进展[J]. 特种铸造及有色合金, 2012, 32(3): 238-242.

XIONG Bo-wen, YU Huan, YAN Qing-song, XU Zhi-feng, CAI Chang-chun, WANG Jia-hui, YANG Zhen. Research progress of vacuum differential pressure casting thin wall castings[J]. Special Casting and Nonferrous Alloys, 2012, 32(3): 238-242.

[15] 董选普, 黄乃瑜, 吴树森. 真空差压铸造法金属液流动形态的研究[J]. 铸造, 2002, 51(7): 415-419.

DONG Xuan-pu, HUANG Nai-yu, WU Shu-sen. Study on the flow pattern of metal liquid in vacuum differential pressure casting[J]. Casting, 2002, 51(7): 415-419.

[16] 严青松, 余 欢, 魏伯康, 徐志峰, 蔡长春. 真空差压铸造工艺的凝固补缩特性与模型[J]. 中国有色金属学报, 2008, 18(6): 1051-1057.

YAN Qing-song, YU Huan, WEI Bo-kang, XU Zhi-feng, CAI Chang-chun. Coagulation and shrinkage characteristics and model of vacuum differential pressure casting process[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1051-1057.

[17] 杨普超, 严青松, 芦 刚, 王 清, 段勇标. 超声功率对差压铸造ZL114A铝合金硬度的影响[J]. 特种铸造及有色合金, 2017, 37(10): 1084-1087.

YANG Pu-chao, YAN Qing-song, LU Gang, WANG Qing, DUAN Yong-biao. Effect of ultrasonic power on the hardness of differential pressure casting ZL114A aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2017, 37(10): 1084-1087.

[18] YAN Q S, YU H, LU G, XIONG B W, XU S. Density and solidification feeding model of vacuum counter-pressure cast aluminum alloy under grade-pressuring conditions[J]. China Foundry, 2016, 13(2): 133-138.

[19] 严青松, 王 芳, 芦 刚, 熊博文, 卢百平, 徐 帅. 凝固压力对真空差压铸造ZL114A合金中Si分布的影响[J].特种铸造及有色合金, 2013, 33(11): 989-992.

YAN Qing-song, WANG Fang, LU Gang, XIONG Bo-wen, LU Bai-ping, XU Shuai. Effect of solidification pressure on Si distribution in vacuum differential pressure casting ZL114A alloy[J]. Special Casting & Nonferrous Alloys, 2013, 33(11): 989-992.

[20] 董选普, 黄乃瑜, 樊自田. 真空压差铸造法工艺参数的研究[J]. 热加工工艺, 2003(5): 15-17.

DONG Xuan-pu, HUANG Nai-yu, FAN Zi-tian. Study on process parameters of vacuum differential pressure casting method[J]. Hot Working Technology, 2003(5): 15-17.

[21] YAN Qing-song, CAI Qi-zhou, WEI Bo-kang. Simulation of fuzzy control systems for nonferrous alloy vacuum counter- pressure casting[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(4): 873-877.

[22] 严青松, 潘 飞, 芦 刚, 杨普超, 王 清. 施振温度对超声振动-真空差压协同作用下铝合金微观组织及力学性能的影响[J]. 稀有金属材料与工程, 2018, 47(6): 1842-1847.

YAN Qing-song, PAN Fei, LU Gang, YANG Pu-chao, WANG Qing. Effect of vibration temperature on microstructure and mechanical properties of aluminum alloy under ultrasonic vibration-vacuum differential pressure[J]. Rare Metal Materials and Engineering, 2018, 47(6): 1842-1847.

[23] 张诗昌, 朱 明, 赵 刚, 陈长军. AZ31镁合金中Zn含量对其高温蠕变性能的影响[J]. 中国有色金属学报, 2008, 18(7): 1205-1210.

ZHANG Shi-chang, ZHU Ming, ZHAO Gang, CHEN Chang-jun. Effect of Zn content on the high temperature creep properties of AZ31 magnesium alloy[J]. Chinese Journal of Nonferrous Metals, 2008, 18(7): 1205-1210.

[24] CURRY D A, KNOTT J F. Effect of microstructure on cleavage fracture toughness of quenched and tempered steels[J]. Metal Science, 1979, 13(6): 341-345.

Effect of solidification pressure differences on microstructure and high temperature creep properties of vacuum counter-pressure casting ZL114A alloy

HUANG Peng-peng, LU Gang, YAN Qing-song, LIU Hui, YAN Yu-ping

(School of Aeronautic Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: ZL114A alloy samples were prepared by vacuum counter-pressure casting technique under different solidification pressure differences. The effects of solidification pressure difference on the primary phase structure, eutectic silicon morphology and high temperature creep properties of vacuum counter-pressure casting ZL114A alloy were investigated by metallography, SEM and high temperature creep performance tests. The results show that as the solidification pressure difference increases, the primary phase structure of the alloy is remarkably refined from coarse dendrites to fine equiaxed crystals, and the eutectic silicon is also transformed from a coarse needle shape to a small short rod or granular shape. At the same time, the high temperature creep property of ZL114A alloy is significantly improved. When the solidification pressure difference is 90 kPa, the alloy sample still has no fracture after the creep time reaches 100 h. At this time, the deformation of the sample is only 0.21%.

Key words: ZL114A alloy; vacuum counter-pressure casting; solidification pressure differences; microstructure; high temperature creep

Foundation item: Project(51861027) supported by the National Natural Science Foundation of China; Project (20181BCB19001) supported by the Project for Jiangxi Advantageous Scientific and Technological Innovation Team, China

Received date: 2019-09-07; Accepted date: 2019-12-18

Corresponding author: LU Gang; Tel: +86-791-86453167; E-mail: aimulalg@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51861027);江西省优势科技创新团队重点项目(20181BCB19001)

收稿日期:2019-09-07;修订日期:2019-12-18

通信作者:芦 刚,副教授,博士;电话:0791-86453167;E-mail:aimulalg@163.com