DOI:10.11817/j.jsxb.1004.0609.2020-37720

不锈钢基板上CMT电弧增材制造铝青铜的组织及性能

陈茂爱, 张建华, 余雄兵

(山东大学 材料液固结构演变与加工教育部重点实验室 材料连接技术研究所,济南 250061)

摘要:本文研究了工艺参数对不锈钢表面增材制造铝青铜薄壁试样组织和性能的影响。结果表明,基材与熔敷层之间形成了一层Fe基固溶体层,附近熔敷层中离散分布Fe基固溶体粒子和FeAl3相;随着送丝速度的增大,Fe基固溶体层的厚度增大,粒子大小、数量及分布范围均增大。剪切时断裂并未一直沿着结合界面层,而是主要从熔敷层断裂;剪切强度随着送丝速度增大而增大。第二层以上每道熔敷层的组织分为三部分,垂直于交界线的粗大柱状晶、偏离垂直方向生长的细小柱状晶以及由等轴晶和水平生长的柱状晶组成的混合区。送丝速度对薄壁试样强度的影响较小,横向拉伸强度为390MPa左右,纵向为360MPa左右,断裂形式均为韧性断裂。

关键词:CMT;增材制造;显微组织;力学性能

中图分类号:TG 455 文献标志码:A

CMT(Cold Metal Transfer)电弧,具有热输入低、飞溅小、熔敷金属层成形美观、稀释率低等优点,不但适合于异种材料的连接,也适合在基体材料上增材制造异种金属[1-5],能保证各自的优异性能,在铝合金和高温合金的增材制造上获得了较广泛的应用[6-11]。

铜及铜合金具有良好的导电性、导热性和抗氧化性性[12-14],目前,铜合金增材制造主要利用激光和电子束增材制造技术。ONUIKE B等人[15]利用选区激光熔化技术(SLM),以Cu-10Sn粉末为原材料进行增材制造,比较增材制造试样和铸造试样的微观组织及力学性能。发现增材制造试样的晶粒更加细小,力学性能提高。SZEMKUS等人[16]以75%Cu-25%Cr为原材料,采用激光增材制造Cu-Cr电接触产品,利用OM和SEM检测制造的Cu-Cr产品的孔隙率,发现最低孔隙率为3.3%。GUSCHLBAUER R等人[17]以纯度为 99.95%的铜粉作为原材料,采用电子束选区熔化技术增材制造铜构件,结果表明,提高电子束能量有利于避免铜粉未熔化、气孔、裂纹等缺陷。

尽管利用激光和电子束进行铜合金的增材制造已经取得了一些研究成果,但由于铜合金对激光折射率较高,增材制造过程中激光利用率低、成本高,且气孔率较高;电子束增材制造要求真空密闭环境,对零件尺寸有严格的限制,所以需要开拓其他工艺的铜合金增材制造。目前基于CMT技术的增材制造主要用于铝合金的增材制造,关于铜合金的CMT电弧增材制造研究尚未见报道,在异种材料上进行增材制造的研究也未见报道。钢铁材料具有强度高、塑性韧性好、价格低等优点,但也存在导电、导热性能差和耐蚀性不足等缺点,铜合金和钢的复合零部件因克服了这两种材料各自的缺点,实现性能和经济上的优势互补[18-20],具有较为广阔的应用前景。例如在航空航天、兵器制造业和海洋工程等领域,要求导热性好、强度高、耐蚀性强的部件广泛采用铜钢复合件[21]。在不锈钢基体上打印铝青铜有利于提高这些部件的性能、加快研制过程。

本实验以CMT电弧为热源,在304不锈钢基板上熔敷铝青铜焊丝,进行增材制造,研究工艺参数对熔敷层-基材界面和增材制造薄壁试样组织和性能的影响。

1 实验

实验采用250mm×70mm×3mm的304不锈钢作为基板,采用 1.2mm的铝青铜作为焊丝。采用Transplus Synergic 2700 CMT电源及三维工作台进行熔敷。熔敷过程中,层间温度为室温,喷嘴到熔敷层表面的距离始终保持15mm,保护气的流量为15 L·min-1。

1.2mm的铝青铜作为焊丝。采用Transplus Synergic 2700 CMT电源及三维工作台进行熔敷。熔敷过程中,层间温度为室温,喷嘴到熔敷层表面的距离始终保持15mm,保护气的流量为15 L·min-1。

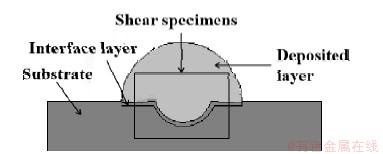

利用剪切实验测量第一道熔敷层和基体之间的结合强度,试样截取位置如图1所示;沿熔敷层与基体之间的结合界面进行剪切。从增材制造的薄壁试样上沿纵、横向各取三个拉伸试样。利用MT5015电子万能试验机进行剪切和拉伸性能实验;截取金相试样,经过粗磨、细磨、抛光和腐蚀后,利用XJP-6A金相显微镜观察显微组织;利用DHV-100显微硬度计进行显微硬度测试。图2为纵、横向拉伸试样及显微组织试样示意图。

图1 熔敷层剪切示意图

Fig.1 Schematic of taking of extraction of shear specimen

图2 纵、横向拉伸试样及显微组织试样示意图

Fig.2 Schematic diagram of extraction of longitudinal and transverse tensile specimens and microstructure specimens

2 结果与讨论

2.1 第一道熔敷层成形

首先研究了送丝速度和行走速度对第一道熔敷层成形的影响,根据熔敷层形貌可分为四个区域,如图3所示。送丝速度在3~10m/min的范围内,匹配合适的行走速度,可获得表面光滑的熔敷层。送丝速度较小而行走速度较大时(A区),由于熔敷过程中热输入较小,熔敷层高度大、宽度小且边缘处有未熔合现象,熔敷层铺展不均匀;送丝速度和行走速度都较大时(B区),容易发生异常短路,电弧频繁熄灭,焊丝粘连在熔池前沿不能回抽,发生瞬时粘丝现象,致使熔敷层不连续;C区为熔敷过程稳定的成形良好区,熔敷层表面光滑、润湿角较小、无咬边;行走速度小而送丝速度大时(D区),由于熔敷过程中热输入过大,导致熔池内部过热,增加了熔池凝固时间,使尾部熔池表面接触空气而被氧化,也会使熔池在凝固过程中由于熔滴进入熔池而产生的后推力使其表面变褶皱。

图3 熔敷工艺参数对熔敷层成形质量的影响

Fig.3 Deposition parameter effect on appearance of the first deposit

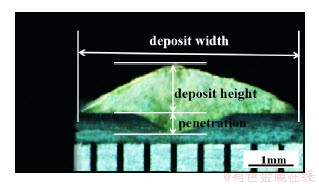

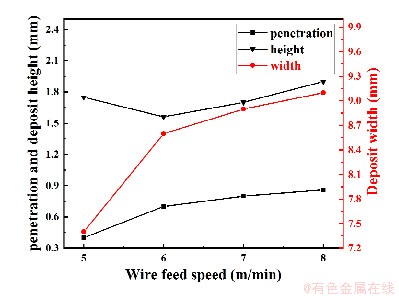

在0.6m/min的行走速度下,研究送丝速度对熔熔敷层成形尺寸的影响。图4示出了第一道熔敷层的宏观形貌及形状尺寸。图5所示为送丝速度对基材熔深、熔敷层宽度及高度的影响。送丝速度较小(5m/min)时,热输入较小,液态熔池冷却过快,铺展不开,导致熔敷层宽度较小而高度较大,当送丝速度提高到6m/min,热输入增大,液态熔池流动性变好,导致熔敷层高度下降,而熔敷层宽度则明显增大,继续增大送丝速度,基材熔深、熔敷层宽度和高度均增大,但增大幅度明显降低。

图4 第一道熔敷层的宏观形貌及形状尺寸

Fig.4 Cross-sectional Morphology of the first deposit

图5 送丝速度对基材熔深、熔敷层宽度和高度的影响

Fig. 5 Effect of wire feed speed on substrate penetration, deposit width and height

2.2 显微组织

2.2.1 基材-熔敷层界面附近显微组织

图6示出了行走速度为0.6m/min时不同送丝速度下熔敷层-基材界面附近的显微组织。基材与熔敷层之间形成了一层连续的界面层。线扫描分析表明,该界面层含有Fe、Cu、Cr、Al等元素,如图7所示。该界面层的形态和成分随着离基体表面距离的变化而变化,该界面层与基体的交界线是一条光滑的曲线,而与熔敷层之间的界面呈锯齿状。两侧界面形貌的差异说明Cu元素向不锈钢中的扩散不均匀,有些部位扩散快,有些部位扩散慢;扩散快的部位出现短棒状凸起。随着送丝速度从5.0 m/min 增大到8.0 m/min,结合界面层厚度从5.7μm增加到8.5μm。该界面层附近的熔敷层中还离散分布着富铁相粒子,其数量及尺寸也随送丝速度的提高而增大,而且,这些粒子的分布范围也随着送丝速度的增大而增大,如图8所示。

图6 送丝速度对基材-熔敷层界面组织的影响

Fig. 6 Effect of wire feed speed on the microstructure around the substrate/deposit interface

图7 基材-熔敷层界面的线扫描成分分析(WFS=6m/min)

Fig.7 EDS line scan analysis across the substrate/deposit interface (WFS=6m/min)

图8 熔敷层中富铁相的分布

Fig. 8 Distribution of isolated iron-rich phases in the deposit

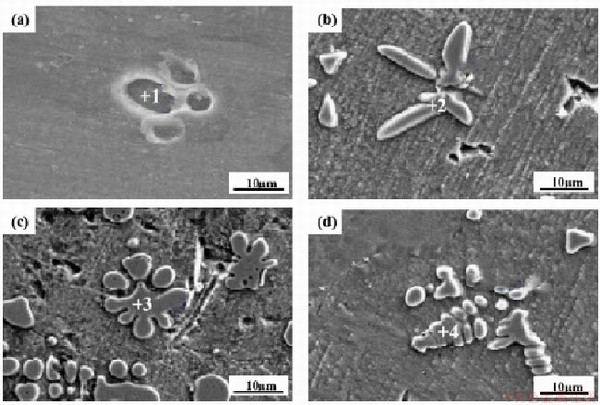

图9为界面附近第二相粒子的SEM形貌。利用EDS分析了4个粒子的成分,结果如表1所示。粒子中主要元素是Fe,另外还含有少量的Cu、Cr和Al和Ni等。Fe和Cu之间互溶度很低,且两组元间不生成任何金属间化合物,因此这些粒子不可能是单一的固溶体,很可能是Fe基固溶体和其他物相的混合物。熔敷层X射线衍射分析结果表明,熔敷层中含有Fe基固溶体、Cu基固溶体和少量FeAl3相,如图10所示。铜基固溶体来自于基体,说明这些粒子是含有Cr、Cu、Al和Ni的铁基固溶体和少量FeAl3相的混合物。EDS分析中发现的Cu含量远高于Cu在Fe中的固溶度,是因为入射电子束打到Cu基体上引起的。其1号粒子和2号粒子的Cu含量高正好说明了这一点,因为这两个粒子的半径小,EDS分析时入射电子束容易打到Cu基体上。

图9 富铁相的SEM-BSE显微照片(WFS=6m/min)

Fig.9 SEM/BSE micrographs of iron-rich phases(WFS=6m/min)

表 1 不同形貌富铁相的元素含量(摩尔分数,%)

Table 1 Element content of iron-rich phases with different morphologies (molar fraction,%)

图10 第一道熔敷层的X射线衍射谱

Fig.10 XRD pattern of the first deposited layer

2.2.2 薄壁试样显微组织

图11(a)所示为熔敷了16层的薄壁试样横截面宏观形貌,各层之间有明显的分界线。图11(b)为第15层和16层重合部分的微观形貌,可看出15层被重熔之前的原始轮廓和被16层重熔之后的熔合线均清晰可见。前后层结晶方向不同导致显微组织有较大差别而形成层带。分析发现,第二层及其以上各层的组织形貌基本类似,而每层又有三个貌不同的部分构成。图12示出了第十六层从下至上的

图11 增材制造试样的横截面形貌

Fig.11 The profile of the cross section of the additive manufactured sample

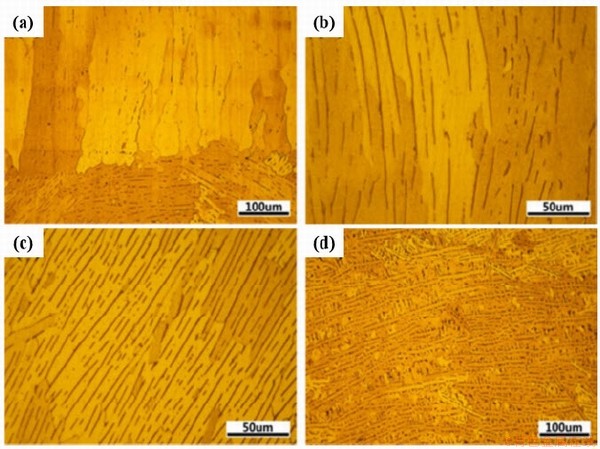

各个部分的显微组织,图12(a)为该层底部组织,该区域为粗大的柱状晶,生长方向垂直于层间的交界面,随着离交界面距离的增大,柱状晶明显减小,如图12(b)所示;图12(c)为过渡区,铜基体亦呈柱状晶生长,但晶粒较细小,生长方向严重偏离交界面法相方向,向左右两侧偏离(图中仅仅示出了偏向右边的组织);图12(d)为该层的顶部组织,柱状晶和等轴晶共存,柱状晶几乎平行于交界面方向生长。

图12 增材试样第十六层从下至上的微观组织

Fig.12 Microstructures of different region in the 16th deposit in additive manufactured sample

2.3 力学性能

2.3.1 基材-熔敷层间的剪切强度

图13 熔敷层剪切断口横截面的宏观金相图

Fig.13 Macroscopic morphology of cross section of the sheared specimen

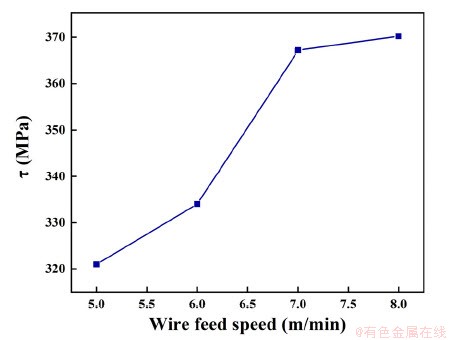

图13为熔敷层剪切断口横截面的宏观金相图。可看出,断裂路径与基体表面基本平行,并非一直沿着熔敷界面层。图14为剪切强度随送丝速度的变化趋势,随着送丝速度的增加,剪切强度增大,这是因为热输入增大,熔敷层中的富铁相增多,起到了第二相强化的作用,提高了其剪切强度。图15示出了断口边缘部位及断口中心部位的断口形貌。由于边缘部位沿着界面Fe基固溶体层断裂,断口呈现出脆性特征,而中心部位则存在明显的韧窝,表现为韧性断裂。

图14 送丝速度对剪切强度的影响

Fig.14 Influence of wire feed speed on shear strength

图15 第一道熔敷层不同位置剪切断口微观形貌(WFS=6m/min)

Fig.15 SEM images near the edge (a) and at the center of the shear fracture surface

2.3.2 薄壁试样硬度分布

图15为不同送丝速度下沿薄壁试样中心线的硬度分布。由图15可看出,在距离界面较近2.5mm的范围内硬度较大,且随着离开界面距离的增大而显著下降,造成这种现象的原因是增材制造过程中熔化的基材进入熔敷层,形成富铁相,富铁相的存在提高了试样的硬度,使近界面区硬度大大提高。距界面的距离超过2.5mm时,当送丝速度增大,硬度略微降低,原因是送丝速度的增大致使热输入增加,层间散热变慢,组织变得粗大,硬度降低。同一送丝速度下,薄壁试样不同部位的硬度也有微小波动,这可能是因为每一熔敷层各个部位的组织不同引起的,垂直于界面的粗大柱状晶、偏向的细小柱状晶和水平柱状晶-等轴晶混合组织的硬度稍有不同。

图16 薄壁试样的硬度分布

Fig.16 Hardness distribution of thin-walled samples

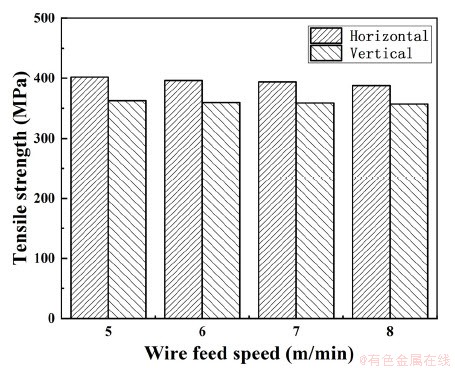

2.3.3 送丝速度对薄壁试样拉伸性能的影响

为探究工艺参数对铝青铜增材制造薄壁试样拉伸性能的影响,在熔敷试样的纵、横向各取三个样。图17为纵、横向增材制造薄壁试样拉伸试验的结果,由图17可知,送丝速度对薄壁试样纵、横向拉伸强度基本没有影响。薄壁试样横向拉伸时拉应力垂直于晶粒生长方向,拉伸强度在390MPa左右,纵向拉伸时应力沿着晶粒生长方向,拉伸强度在360MPa左右,横向拉伸强度大于纵向,表现出各向异性。

图17 送丝速度对纵、横向薄壁试样拉伸强度的影响

Fig.17 Effect of wire feed speed on tensile strength of longitudinal and transverse thin-walled samples

选取送丝速度为6m/min的拉伸断口形貌进行观察,图18(a)为送丝速度6m/min的纵向拉伸断口形貌,图18(b)为送丝速度6m/min的横向拉伸断口形貌,对比两图可以发现,断裂方式均为韧性断裂,纵向断口韧窝尺寸较横向断口韧窝尺寸稍大。

图18 纵、横向拉伸断口形貌(WFS=6m/min)

Fig.18 Fracture morphology of longitudinal tensile specimen (a) and transverse tensile specimen (b) (WFS=6m/min)

3 结论

1)送丝速度在3~10m/min的范围内,匹配合适的行走速度,可获得表面光滑、润湿角较小、无咬边的打印层。

2)熔敷层与基材的之间形成了一层连续的富Fe相,界面层与熔敷层之间的界面呈锯齿状,而与不锈钢之间的界面为圆滑的曲线,第二相粒子均为铁基固溶体和少量FeAl3相的混合物。

3)第二道及以上的熔敷层的组织从下到上依次为垂直于交界线的粗大柱状晶、偏离垂直方向生长的细小柱状晶以及由等轴晶和水平生长的柱状晶组成的混合区。

4)熔敷层与基体的剪切断裂路径与基体表面平行,主要分布在熔敷层中,随着送丝速度的增大,剪切强度增大;薄壁试样横向拉伸强度在390MPa左右,纵向在360MPa左右,基本不受送丝速度的影响,断裂方式均为韧性断裂。

REFERENCES

[1] ZHANG Chen, LI Yu-fei, GAO Ming, ZENG Xiao-yan. Wire Arc Additive Manufacturing of Al-6Mg Alloy using Variable Polarity Cold Metal Transfer Arc as Power Source[J]. Materials Science and Engineering: A, 2018, 711: 415-423.

[2] SCUDINO S, UNTERDORFER C, PRASHANTH K G, ATTAR H, ELLENDT N, UHLENWINKEL V, ECKERT J. Additive manufacturing of Cu–10Sn bronze[J]. Materials Letters, 2015, 156: 202-204.

[3] 姜云禄. 基于冷金属过渡技术的铝合金快速成形技术及工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.

JIANG Yun-lu. Research on the Rapid Prototyping Technology and Forming Process of Aluminum Alloy Based on the CMT[D]. Harbin: Harbin Institute of Technology, 2013.

[4] BEYTULLAH G, KALUC E, TABAN E, AYDIN SIK S S. Mechanical and Microstructural Properties of Robotic Cold Metal Transfer(CMT) Welded 5083-H111 and 6082-T651 Aluminum Alloys[J]. Materials & Design (1980-2015), 2014, 54: 207-211.

[5] PICKIN C G, WILLIAMS S W, LUNT M. Characterisation of theCold Metal Transfer (CMT) Process and its Application for Low Dilution Cladding[J]. Journal of Materials Processing Tech, 2011, 211(3): 496-502.

[6] FANG Xue-wei, ZHANG Li-juan, LI Hui, LI Chao-long, HUANG Ke, LU Bing-hang. Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process[J]. Materials (Basel, Switzerland), 2018, 11(5): 812.

[7] SU Chuan-chu, CHEN Xi-zhang, GAO Chuang, WANG Yan-fang. Effect of Heat Input on Microstructure and Mechanical Properties of Al-Mg Alloys Fabricated by WAAM[J]. Applied Surface Science, 2019, 486: 431-440.

[8] NIE Yun-peng, ZHANG Pei-lei, WU Xi, LI Guo-jin, YAN Hua, YU Zhi-shui. Rapid Prototyping of 4043 Al-Alloy Parts by Cold Metal Transfer[J]. Science and Technology of Welding and Joining, 2018, 23(6): 527-535.

[9] 陈树君, 赵 昀, 肖 珺, 田宏宇. 铝合金电弧熔积成形机器人增材制造系统[J]. 焊接, 2016(4): 9-12.

CHEN Shu-jun, ZHAO Yun, XIAO Qun, TIAN Hong-yu. Aluminum Alloy Arc Deposition Robot Additive Manufacturing System[J]. Weld, 2016(4): 9-12.

[10] CONG Bao-qiang, DING Jia-luo, WILLIAMS S. Effect of Arc Mode in Cold Metal Transfer Process on Porosity of Additively Manufactured Al-6.3%Cu Alloy[J].The International Journal of Advanced Manufacturing Technology, 2015, 76(9): 1593-1606.

[11] GOMEZ O A, CORONA G L, DESCHAUS-BEAUME F, MEZRAG B, ROUQUETTE S. Effect of Process Parameters on the Quality of Aluminium Alloy Al5Si Deposits in Wire and Arc Additive Manufacturing using a Cold Metal Transfer Process[J]. Science and Technology of Welding and Joining, 2018, 23(4): 316-332.

[12] LOUREIRO A, MENDES R, RIBEIRO J B, LEAL R M, GALVAO I. Effect of Explosive Mixture on Quality of Explosive Welds of Copper to Aluminium[J]. Materials & Design, 2016, 95: 256-267.

[13] FINDIK F. Recent developments in explosive welding[J]. Materials & Design, 2011, 32(3): 1081-1093.

[14] ZHANG Min, ZHANG Tao, CAI Jun-qing, LIU Juan-juan, LI Ji-hong. Effect of heat treatment on microstucture and properties of explosive welding clad plate of TA1/Q345[J]. China Welding, 2018, 27(01): 26-31.

[15] ONUIKE B, HEER B, BANDYOPADHYAY A. Additive Manufacturing of Inconel 718—Copper Alloy Bimetallic Structure using Laser Engineered Net Shaping (LENSTM)[J]. Additive Manufacturing, 2018, 21: 133-140.

[16] SZEMKUS S, KEMPF B, JAHN S, WIEHL G, HERINGHAUS F, RETTENMAYR M. Laser Additive Manufacturing of Contact Materials[J]. Journal of Materials Processing Tech, 2018, 252: 612-617.

[17] GUSCHLBAUER R, MOMENI S, OSMANLIC F, KORNER C. Process development of 99.95% pure copper processed via selective electron beam melting and its mechanical and physical properties[J]. Materials Characterization, 2018, 143: 163-170.

[18] TATSUYA F, YUKI W, YASUYUKI M, FUMIO K. Brazing of copper to stainless steel with a low-silver-content brazing filler metal[J]. IOP Conference Series: Materials Science and Engineering, 2014, 61: 012016.

[19] MAHDI M, EKRAMI A. Microstructure and mechanical properties of pure Cu interlayer TLP joints of 304 stainless steel to dual phase steel[J]. Journal of Materials Processing Tech, 2020, 275: 116276.

[20] CHEN R B, SHIUE R K. The microstructural observation and wettability study of active brazing beryllium copper and 304 stainless steel[J]. Journal of Materials Science Letters, 2001, 20(15): 1435-1437.

[21] 黄湘湘, 冯 凯, 何利杰, 龚 剑, 陈 江, 李铸国. 碳钢表面激光熔覆铝青铜涂层的组织及铜渗透现象[J]. 激光与 光电子学进展, 2019, 56(05): 153-160.

HUANG Xiang-xiang, FENG Kai, HE Li-jie, GONG Jian, CHEN Jiang, LI Zhu-guo. Microstructure and copper penetration phenomenon of laser cladding aluminum bronze coating on carbon steel surface[J]. Progress in Laser and Optoelectronics, 2019, 56(05): 153-160.

Microstructure and properties of additive manufactured Cu-Al bronze alloy on St-St substrate using CMT arc as heat source

CHEN Mao-ai, ZHANG Jian-hua, YU Xiong-bing

(MOE key Laboratory for Liquid-Solid Structure Evolution and Materials Processing,Institute for Materials Joining, Shandong University, Jinan 250061, China)

Abstract: The effect of process parameters on microstructure and properties of additive manufactured Cu-Al bronze on St-St substrate was studied. The results show that a continuous layer of Fe-based solid solution forms between the substrate and the deposit. In addition, isolated particles composed of Fe-based solid solution and FeAl3 distribute in the additive manufactured Cu-Al Cu matrix. The thickness of the Fe-based solid solution layer and the particle size and number increase with increasing wire feed speed. The shear strength between the substrate and deposit increases with the increase of wire feed speed. The shear fracture does not propagate along the Fe-based solid solution layer, but goes through the deposited metal near the substrata. The microstructure of each deposited pass above the second layer was divided into three zones, i.e. coarse columnar grain zone, fine columnar grain zone and mixed zone consisting of equiaxed and horizontal columnar grains. The wire feeding speed has little effect on the mechanical strength of thin-walled specimen. The transverse tensile strength is about 390 MPa and the longitudinal one is about 360 MPa. All the fracture surfaces exhibit dimple structure.

Key words: CMT; additive manufacturing; microstructure; mechanical properties

Corresponding author: CHEN Mao-ai; Tel: +86-15562491928; E-mail: chenmaoai@sdu.edu.cn