DOI: 10.11817/j.issn.1672-7207.2015.11.029

废石破碎胶结充填配比优选及在寒冷气候条件下的应用

韩斌,刘超,孙伟,姚松,吴建勋

(北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083)

摘要:为解决金英金矿外购铁矿尾砂在寒冷气候条件下充填存在充填体强度低、稳定性差以及井下产出废石大量堆积的难题,开展废石破碎用于井下充填的室内实验。研究结果表明:在充填倍线为2.0~6.0的前提下,废石充填料浆质量分数可达75%以上;当废石与尾砂的质量比为3~6时,对充填料浆流动性和充填体强度无明显影响;粒径d≤5 mm废石+压滤尾砂的充填骨料可获得最大充填体强度,充填骨料的充填体强度从大到小依次为d≤5 mm废石、d≤8 mm废石+压滤尾砂、d≤5 mm废石+铁矿尾砂、铁矿尾砂和d≤8 mm废石+铁矿尾砂;料浆质量分数是确保充填体强度和降低水泥掺量的关键,采用d≤5 mm废石+水泥充填时,料浆质量分数每提高1%,水泥掺量可降低1.2%;当养护温度由10 ℃提升至15 ℃时,充填体充填时间为7 d及28 d强度分别提高109.52%和58.46%;经现场工业试验,推荐采用的d≤5 mm废石胶结充填料浆实际质量分数为75%,水泥掺量为11%,充填能力为110 m3/h,充填成本降低15%~18%。

关键词:废石胶结充填;寒冷气候;配比优化;工业试验

中图分类号:TD853.3 文献标志码:A 文章编号:1672-7207(2015)11-4195-09

Optimized mix ratio of crushed waste rocks in cementing backfill and its application in extreme cold weather

HAN Bin, LIU Chao, SUN Wei, YAO Song, WU Jianxun

(Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to solve the problems of out-sourced backfilling material in Jinying gold deposit under cold weather, such as low strength of backfilling, poor stability and accumulation of waste rock produced underground, a lab experiment was conducted using crushed waste rock for underground backfill. The results show that when the stowing gradient is 2.0-6.0, the mass fraction of waste backfill slurry can reach above 75%. When the mix ratio of crushed waste to tailings is 3-6, it has no significant effect on backfill slurry fluidity or backfill strength. The filling slurry with waste rock of d≤5 mm + pressed tailings obtains the maximum backfill strength, and other types of slurry have lower strength, so the strength levels are the crushed waste rock of d≤5 mm, waste rock of d≤8mm + pressed tailings, waste rock of d≤ 5 mm + iron tailings, iron tailings and waste rock of d≤8 mm + iron tailings in turn from high level to low level. Slurry density is the key factor for backfill strength and for reducing cement dosage. When the waste rock of d≤5 mm + cement is used for backfill, every 1% increase of slurry mass fraction can reduce 1.2% of cement dosage. When the curing temperature rises from 10 ℃ to 15 ℃, the backfill time of 7 d and 28 d backfill strength increase 109.52% and 58.46%, respectively. After the field industrial tests, it is recommended to the backfill with d≤5 mm waste rock cemented slurry with a mass fraction of 75% and cement dosage of 11%. The backfill capacity can reach 110 m3/h, and the cost of backfilling can be reduced by 15%-18%.

Key words: waste rock cementing backfill; extreme cold weather; mix ratio optimization; industrial experiment

在地下矿产资源被采出的同时,大量废石会随之采出并堆积于地表。1949年至2005年间,我国各类矿山共产出废石162亿t以上,其中金矿废石达4.6亿t[1-5]。废石堆存不仅占用大量土地资源,而且会带来一系列环境问题。与此同时,地下开采导致的采空区坍塌事故成为金属矿山的首要灾害。废石胶结充填以矿山掘进或开采过程中产生的废石(或破碎后)为集料,以水泥为胶结剂,采用合理的配比混合后输送到井下空区,起到充填的目的[6-9],废石充填技术不仅可以消耗地表堆积废石、保护环境,而且可以提高资源利用率、降低采矿成本。目前,充填技术研究的核心是料浆的流动性及充填体的强度,即确定合理的充填料浆配比及创造良好的养护条件。Wang等[10-12]对充填料浆配比及其输送特征进行大量研究,料浆质量浓度、灰砂比(即水泥与尾砂的质量比)和粒级组成等因素对充填体强度特征及泵送特性有较大影响。Pokharel等[13-16]对不同养护温度下充填体强度特征进行了大量实验,研究结果表明低温抑制了水泥水化反应的进行,从而导致充填体水化产物质量分数和强度下降等,提高养护温度,有利于增强充填体力学性能。刘志祥等[17]分别对灰砂比为1:4,1:8,1:10和1:12的4种尾砂胶结充填体进行了力学试验,得出其应力-应变曲线,结果表明充填体与岩体的匹配系数与原岩应力、岩体弹性模量、充填体弹性模量及充填体损伤参数相关。赵国彦等[18-19]通过灰色关联分析法探究低温高寒环境下充填体强度对灰砂比料浆质量分数和养护时间等因素变化的敏感程度,结果表明:在低温高寒环境下,充填体强度随着灰砂比和养护时间的增大而增大,影响充填体强度的最主要因素为灰砂比,其次为养护时间,再次为料浆质量浓度。吉林省白山市金英金矿目前采用铁矿尾砂+水泥胶结充填自流输送工艺,所用尾砂全部来自外购,充填原料成本较高;铁矿尾砂质量大,制备的充填料浆易沉淀、堵管,只能通过降低充填料浆质量浓度以实现自流输送,造成充填体强度偏低,且该矿冬季平均气温低于-21 ℃,充填料浆温度低,低温养护环境进一步制约了充填体强度的增长,导致回采过程中多次发生充填体垮塌事故。另一方面,吉林金英金矿目前地表堆场存有近70万t井下产出的废石,且规模还在不断扩大。废石长期堆放在地表,不仅占用有限的工业场地,而且造成矿山环境的破坏,同时该矿仍有约10万m3的空区待充填,要通过增加其充填能力来满足充填要求。为此,本文作者对金英金矿废石破碎胶结充填技术进行尝试性试验,对6种不同材料展开配比试验,测定充填料浆流动性及充填体强度变化规律,对推荐的充填配比进行不同温度养护试验,并开展现场工业试验。

1 充填骨料优选试验

1.1 实验方案

根据国内外同类矿山的成功经验,确定废石胶结充填、废石+铁矿尾砂胶结充填以及废石+矿山自产压滤尾砂胶结充填共3种配比模式,综合兼顾废石破碎成本以及满足高充填倍线下的自流胶结充填需求,选取粒径d≤8 mm和d≤5 mm这2种不同粒级级配的骨料;为考察新、旧充填配比的差异,开展铁矿尾砂胶结充填配比对照实验。确定如下6种充填配比实验方案:

1) d≤5 mm废石+水泥;

2) d≤5 mm废石+铁矿尾砂+水泥;

3) d≤5 mm废石+压滤尾砂+水泥;

4) d≤8 mm废石+铁矿尾砂+水泥;

5) d≤8 mm废石+压滤尾砂+水泥;

6) 铁矿尾砂+水泥。

金英金矿主要回采区域的充填倍线为2.5~6.0(倍线大于6.0则采用泵送充填),根据相关经验和初期实验,确定如下关键参数:

1) 料浆扩散度应大于1 m,本次试验充填料浆质量分数为74%~75%;

2) 为考察尾砂对充填料浆流动性及充填体强度的影响,废石与尾砂的质量比选用了3,4,5,6这4种不同的值。

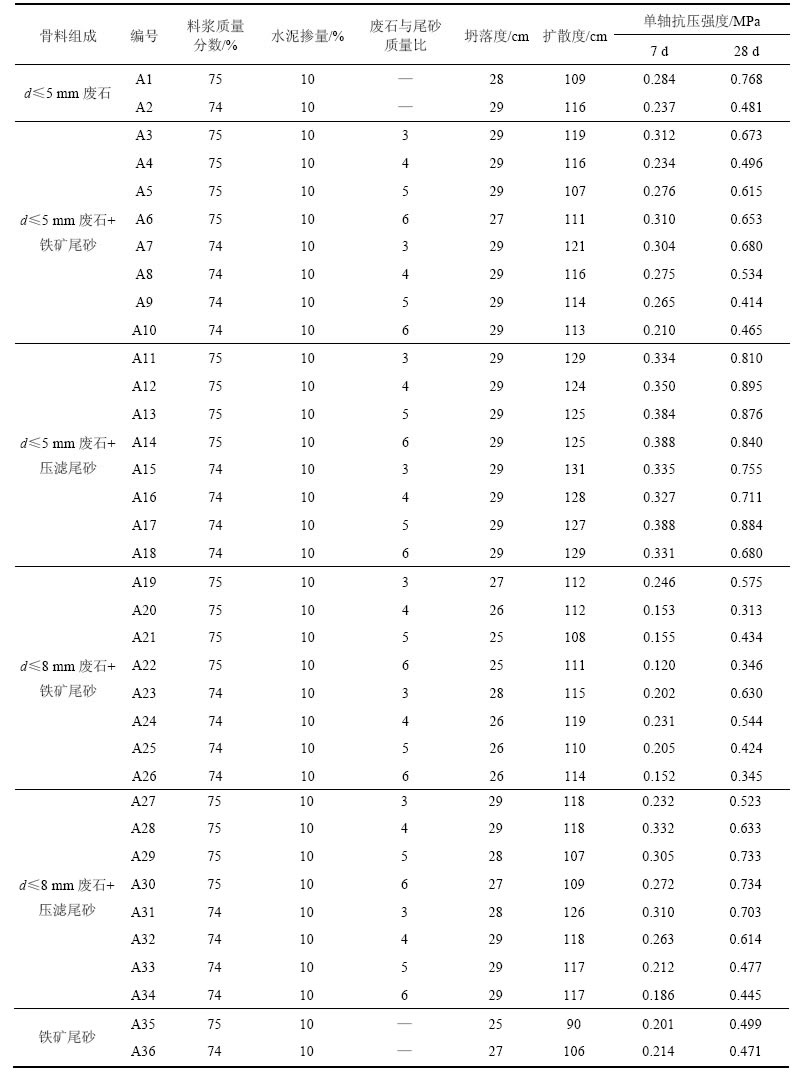

根据上述分析,确定实验方案如表1所示。

1.2 实验材料

1) 水:取自充填搅拌站供水仓,主要源自地下水及选场废水;

2) 废石骨料:实验用原料取自废石堆场,经随机取样后烘干,采用颚式破碎机破碎、筛分后获得d≤5 mm和d≤8 mm骨料;

3) 水泥:采用32.5级复合硅酸盐水泥;

4) 铁矿尾砂:采用该矿外购的铁矿尾砂;

5) 压滤尾砂:金英金矿自产尾砂。

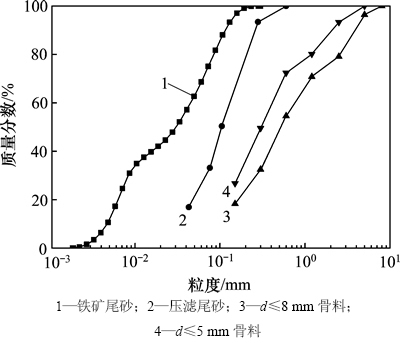

各充填骨料粒级组成见图1。

图1 充填骨料粒级组成

Fig. 1 Granular compositions of aggregates

1.3 待测参数

1) 充填料浆流动性指标:扩散度和坍落度;

2) 充填体试块强度指标:充填时间为7 d和28 d单轴抗压强度,各龄期测定3个试块,取平均值。

1.4 实验过程

首先将称好质量的水(精度为10 g)加入搅拌桶,之后将各物料组分准确称质量后装入搅拌桶,用JS-8型手持式搅拌机搅拌均匀,测定料浆坍落度、扩散度后,装入80 mm×200 mm(直径×长度)的试模(见图2)。由于浇筑的充填试块在养护初期强度较低,为避免往井下运输过程中试块受损,将浇筑好的试块在试验室先养护48 h(养护温度约为16 ℃),待其达到一定强度后再搬运至井下养护室(养护室温度约为10 ℃,湿度约为85%)。当试块养护至预定龄期后,拉运至地表切割为80 mm×160 mm(直径×长度)的标准试块,采用100 kN的万能压力机测定充填体充填时间为7 d和28 d单轴抗压强度,试验结果见表1。

1.5 试验结果分析

1.5.1 料浆流动性分析

由表1可知:对不同料浆质量分数、水泥掺量(即掺入水泥的质量分数)及废石与尾砂质量比,实测塌落度并没有明显变化(25~29 cm),表明塌落度与本次试验参数没有明显的关系,扩散度变化趋势见图2。

根据表1、图2及现场试验,可得出如下结论:

1) 当充填料浆质量分数为75%时,除现有铁矿尾砂料浆外,各配比扩散度均大于105 cm,据金川镍矿、锦丰金矿等矿山的充填经验,推断金英金矿采用废石充填时,充填料浆的质量分数可达75%或以上。

2) 当充填料浆质量分数为75%时,除用d≤8 mm废石+水泥的充填配比具有较明显的离析现象外,其他各配比物料和易性均较好,不易沉底、板结,且不易造成堵管。

3) 从扩散度来看,随着废石与尾砂质量比的增加,充填料浆的流动性有变差的趋势,但该变化幅度不小于9.3%,即当废石和尾砂质量比为3~6时,充填料浆的流动性无明显变化。

4) 对适用于自流充填的料浆,不同流动性料浆的坍落度指标变化较小(36组配比实验中占81%的坍落度为27~29 cm),同时坍落度不能真实反映料浆的离析情况,因此,以坍落度作为衡量料浆流动性的评价指标并不适用于高流动性料浆。

1.5.2 骨料类型对充填体强度影响

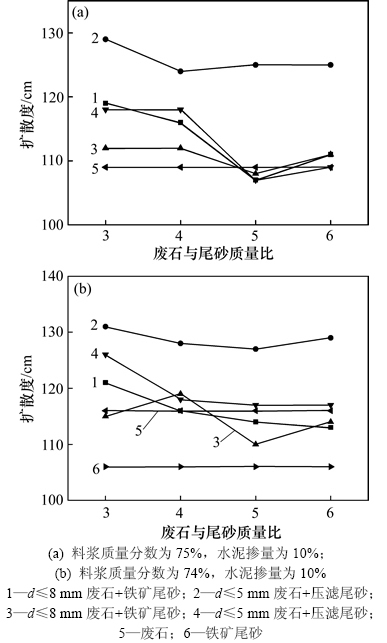

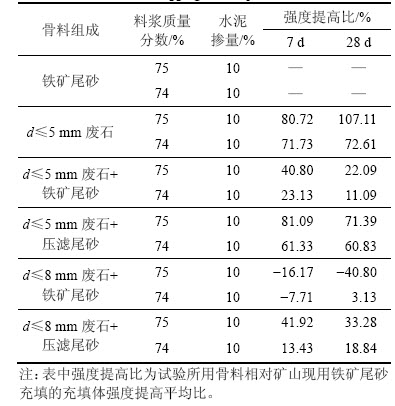

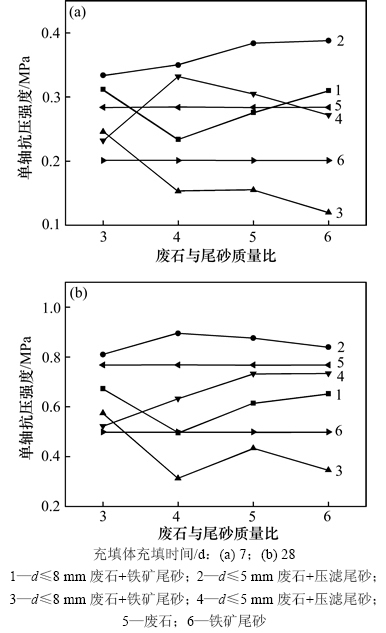

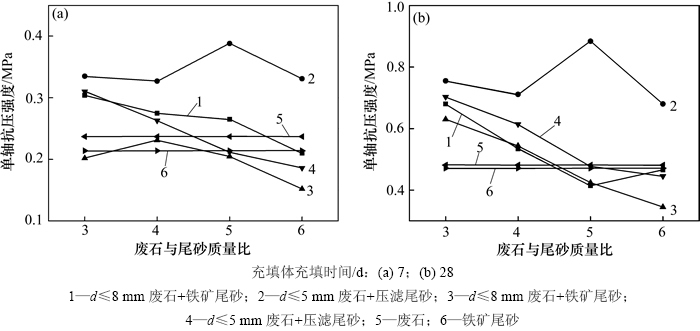

根据表1可得到不同类型骨料的充填体强度,以及相对于现用铁矿尾砂充填的强度提高比,分别如表2、图3及图4所示。

由表2、图3和图4可得:

1) 与目前铁矿尾砂+水泥充填相比,除d≤8 mm废石+铁矿尾砂为骨料的充填体充填时间为7 d单轴抗压强度降低外,其余强度测试结果均有一定提高,表明采用废石充填更有利于提高充填体强度。

2) 采用d≤5 mm废石+压滤尾砂的充填骨料可获得最大充填体强度,d≤5 mm废石充填骨料可获得次优的充填体强度,其次的充填骨料充填强度从大到小顺序依次为d≤8 mm废石+压滤尾砂、d≤5 mm废石+铁矿尾砂、铁矿尾砂及d≤8 mm废石+铁矿尾砂。

1.5.3 尾砂掺量对充填体强度影响

由表1、图3及图4可知:

1) 当充填料浆质量分数为75%时,废石与尾砂质量比对充填体强度影响不显著,当充填料浆质量分数降低至74%时,废石与尾砂质量比与充填体强度呈负增长特性,因此,在实际充填过程中提高料浆质量分数非常有利于保证充填体质量;但当充填料浆质量分数低于75%时,废石尾砂比应大于4。

表1 不同类型骨料试验结果

Table 1 Test results of different aggregates

图2 不同料浆扩散度变化规律

Fig. 2 Slurry diffusance changing rules at different densities

表2 不同类型骨料充填体强度提高比

Table 2 Percentage of backfill strength increasing with different aggregate compositions

图3 不同配比的充填体单轴抗压强度变化曲线(质量分数为75%,水泥掺量为10%)

Fig. 3 Uniaxial compressive strength changing curves with different mix ratios (mass fraction of 75% and cement dosage of 10%)

2) 合理的充填料浆粒级级组成是影响充填体强度的重要原因。金英金矿铁矿尾砂中粒径小于74 μm颗粒的质量分数占75%以上,是导致充填体强度较低的一个重要原因。

2 料浆质量分数及水泥掺量对废石充填体强度影响

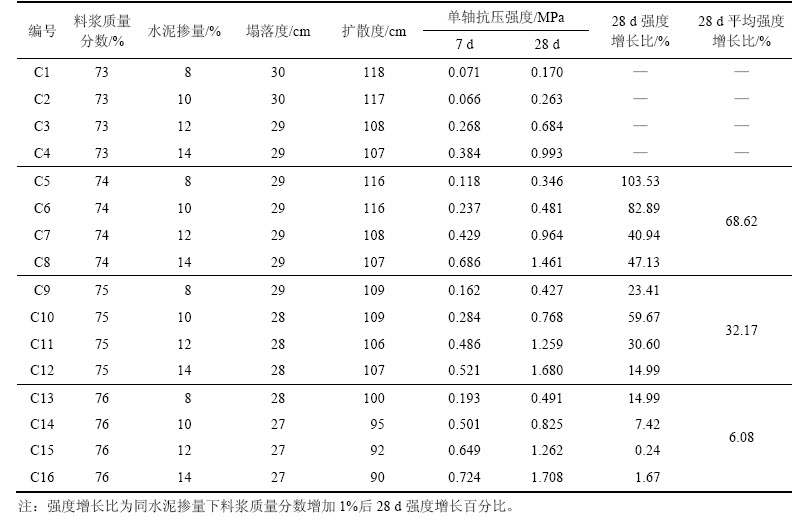

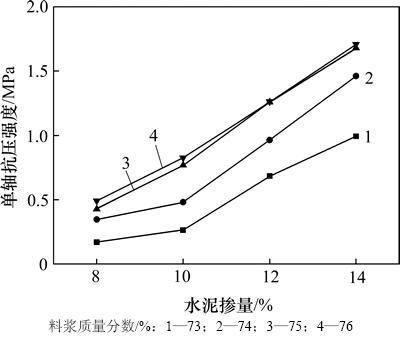

为验证实验的可重复性,并探讨不同料浆质量分数和水泥掺量对充填体强度的影响,开展了d≤5 mm废石+水泥充填料浆质量分数实验,结果分别如表3、图5和图6所示。

图4 不同配比的充填体单轴抗压强度变化曲线(质量分数为74%,水泥掺量为10%)

Fig. 4 Uniaxial compressive strength changing curves with different mix ratios (mass fraction of 74% and cement dosage of 10%)

表3 不同质量分数d≤5 mm废石+水泥充填料浆实验结果

Table 3 Test results of waste rock of d≤5 mm + cement with different mass fractions

根据表3、图5和图6可得出如下结论:

1) 采用d≤5 mm废石+水泥充填时,每提高1%的充填料浆质量分数,在充填时间达到28 d相同强度的前提下,充填用水泥掺量可降低1.2%;

2) 提高料浆质量分数是提高充填体强度非常关键的环节。当质量分数超过75%后,充填体强度提高趋于缓慢,且扩散度急剧降至100 cm以下,对于高充填倍线的采场较难实现自流输送。因此,推荐料浆质量分数为75%。

3) 充填体强度随水泥添加量增加而增大,当料浆质量分数为75%,水泥掺量为11%~12%时,充填体强度可以达到1.0 MPa。根据井下设计要求,推荐水泥掺量为11%。

图5 d≤5 mm废石+水泥充填时不同料浆质量分数充填体28 d单轴抗压强度

Fig. 5 Backfill uniaxial compressive strength at 28 d with waste rock at d≤5 mm + cement with different mass fractions

图6 d≤5 mm废石+水泥充填时不同水泥掺量充填体28 d单轴抗压强度

Fig. 6 Backfill uniaxial compressive strength at 28 d with waste rock at d≤5 mm + cement with different cement dosages

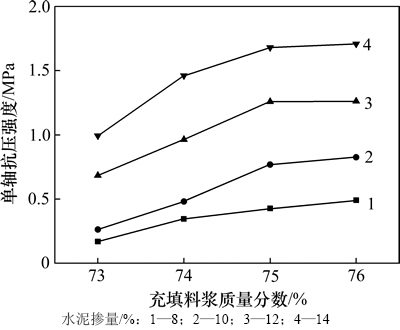

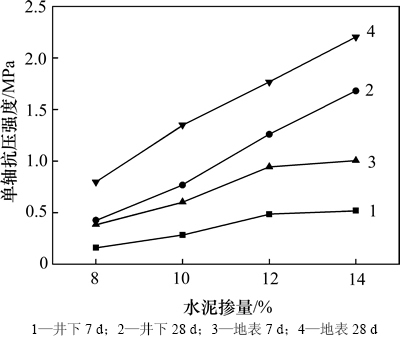

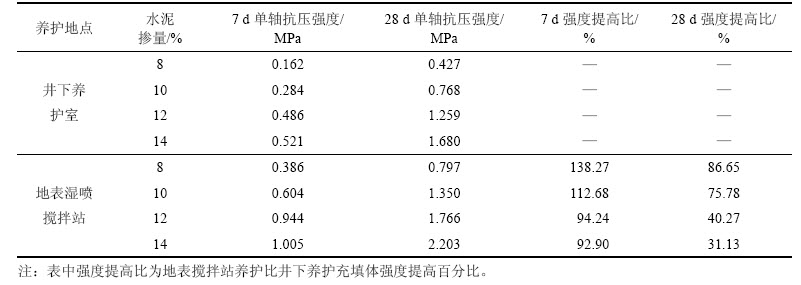

3 养护温度对充填体强度影响

金英金矿所在地全年温度较低,冬季地表温度达到-30 ℃以下,井下温度约为5 ℃。为探究养护温度对充填体强度的影响,进行不同养护温度下的废石胶结充填配比对比实验。其中一组试块(共计24个)养护于井下养护室(平均温度约为10 ℃),另一组试块养护于地表湿喷搅拌站机房(平均温度约为15 ℃),浆料质量分数为75%,充填体强度测试结果见表4和图7。

由表4和图7可以看出:

1) 废石充填试块的养护温度对其强度增长具有显著影响,地表高温养护比井下低温养护下充填体强度有明显提升。

2) 当养护温度由10 ℃提升至15 ℃,水泥添加量由8%增加至12%时,充填体充填7 d单轴抗压强度增量由138.27%降低为92.90%,充填28 d强度增量由86.65%降低为31.13%。上述结果表明:温度对低水泥掺量充填体强度影响较为明显;随着水泥添加量的增加,温度对废石充填体强度的影响程度有所下降,且充填7 d强度下降趋势要比28 d的趋势更为显著。

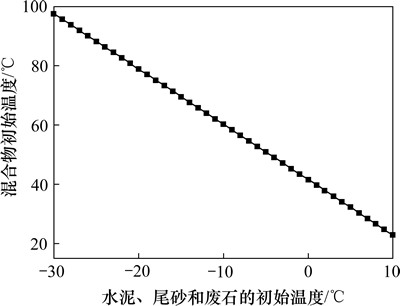

3) 充填搅拌站在冬季提高充填拌合水温度及加强充填废石骨料与水泥保温工作具有重要作用。

将拌合水预加温,与低温状态的水泥、废石、尾砂混合,制备出预定温度的充填料浆。忽略制备过程中热量损失,基于热量守恒定律,拌合水降温释放的热量、水泥水化反应释放的热量Qr与水泥、废石、尾砂吸收的热量Qa应近似相等,即

(1)

(1)

(2)

(2)

(3)

(3)

其中:t为混合物的总温度,℃;tw,tc,tg和tt分别为拌合水、水泥、废石和尾砂的初始温度,℃;mw,mc,mg和mt分别为拌合水、水泥、废石和尾砂的质量,kg/m3;cw为拌合水的比热容,4.2 kJ/(kg·℃);cc为水泥的比热容,0.75 kJ/(kg·℃),选取水泥在0 ℃左右比热容;cg为废石的比热容,0.79 kJ/(kg·℃);ct为尾砂的比热容,0.79 kJ/(kg·℃);Qc为水泥水化放热量,10 kJ/kg,选取水泥在一个小时左右放出的热量;Qr为拌合水降温和水泥水化反应放热热量,kJ;Qa为水泥、废石和尾砂升温吸收的热量,kJ。

图7 养护温度对充填体强度的影响

Fig. 7 Impaction of curing temperature on backfill strength

表4 养护温度对充填体强度的影响表

Table 4 Impaction of curing temperature to backfill strength

综合考虑技术、经济因素,确定充填料浆目标温度为15 ℃,则可获得不同环境温度下要求的拌合水温度如图8所示。

图8 拌合水预热温度与充填材料初始温度关系

Fig. 8 Relationship between pre-heat temperature of mixing water and backfill initial temperature

4 工业应用

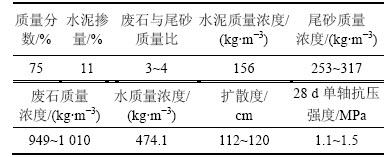

金英金矿空区大规模充填设计强度为1.0 MPa,根据前述试验和矿山现场实际条件,推荐采用d≤5 mm废石+铁矿尾砂的胶结充填形式。生产工艺如下:将建设于废石堆场一侧2段闭路式废石破碎系统产出的d≤5 mm废石通过卡车运至尾砂仓,由前装机将尾砂与废石混合后(废石与尾砂质量比为3~4),由天车抓斗装入提升箕斗装载系统,运至充填搅拌站后与水泥浆混合,经两段卧式搅拌后通过充填钻孔自流输送至井下。现场试验充填配比如表5所示。

由表5可知:料浆质量分数可达到75%,未发生堵管、离析等现象,充填能力可达到110 m3/h,充填体充填28 d单轴抗压强度大于1.1 MPa、相邻采场开采未发生充填体塌方等事故。充填综合成本降低了15%~18%,日消耗废石约1 600 t;当室外温度为-10 ℃时,当充填拌合水加热至60 ℃,充填料浆温度可达到15 ℃,有效促进了充填体强度的增大。

表5 现场工业试验充填配比

Table 5 Mix ratio of in site industrial experimented backfill

5 结论

1) 在充填倍线为2.0~6.0的前提下,d≤5 mm破碎废石的充填料浆质量分数可达75%以上。

2) 与目前铁矿尾砂+水泥充填相比,采用废石充填更有利于提高充填体强度。d≤5 mm废石+压滤尾砂的充填骨料可获得最大充填体强度,充填体强度次高的充填骨料依次为d≤5 mm废石、d≤8 mm废石+压滤尾砂、d≤5 mm废石+铁矿尾砂、铁矿尾砂和d≤8 mm废石+铁矿尾砂。

3) 当充填料浆质量分数为75%时,废石与尾砂质量比对充填体强度影响不显著,当充填料浆质量分数降低至74%时,废石与尾砂质量比与充填体强度呈现负增长特性,因此,在实际充填过程中,提高料浆质量分数有利于保证充填体质量;但当充填料浆质量分数低于75%时,废石与尾砂质量比应大于4;料浆质量分数是确保充填体强度和降低水泥掺量的关键;采用d≤5 mm废石+水泥充填时,在充填时间达到28 d相同强度的前提下,每提高1%料浆质量分数,水泥掺量可降低1.2%。

4) 提高养护温度对提高充填体强度具有重要作用。当养护温度由10 ℃提升至15 ℃时,充填体充填时间为7 d及28 d强度分别提高109.52%和58.46%,在实际生产中应重视充填搅拌站在冬季提高充填拌合水温以及加强充填废石及水泥保温工作。

5) 经现场工业试验,推荐采用d≤5 mm废石+铁矿尾砂胶结充填,料浆实际质量分数为75%,水泥掺量为11%,充填能力为110 m3/h,充填成本降低15%~ 18%,具有良好的综合效益。

参考文献:

[1] 蔡嗣经. 矿山充填力学基础[M]. 北京: 冶金工业出版社, 2009: 3-12.

CAI Sijing. Mine filling mechanics foundation[M]. Beijing: Metallurgical Industry Press, 2009: 3-12.

[2] HU Ruiling, YUE Zhongqi, WANG Lichao, et al. Review on current status and challenging issues of land subsidence of China[J]. Engineering Geology, 2004, 76(1/2): 65-77.

[3] 王贤来, 姚维信, 王虎, 等. 矿山废石全尾砂充填研究现状与发展趋势[J]. 中国矿业, 2011, 20(9): 76-79.

WANG Xianlai, YAO Weixin, WANG Hu, et al. The directions of R&D on backfill with waste rock and total tailings in underground mine[J]. China Mining Magazine, 2011, 20(9): 76-79.

[4] WU Aixiang, HAN Bin, LIU Tongyou. Backfill technical-economic analysis of underhand drift cut-and-fill stoping based on reliability theory[C]// Proceeding of the 8th International Symposium on Mining with Backfill. Beijing, China: The Nonferrous Metals Society of China, 2004: 41-44.

[5] Tikov B, Mostafa B. Design and application of underground mine paste backfill technology[J]. Geotechnical and Geological Engineering, 2008, 26(2): 147-174.

[6] 贺桂成, 刘永, 丁德馨, 等.废石胶结充填体强度特性及其应用研究[J]. 采矿与安全工程学报, 2013, 30(1): 74-79.

HE Guicheng, LIU Yong, DING Dexin, et al. Strength characteristic of cemented waste rock backfills and its application[J]. Journal of Mining & Safety Engineering, 2013, 30(1): 74-79.

[7] Hassani F P, Mortazavi A, Shabani M. An investigation of mechanisms involved in backfill-rock mass behavior in narrow vein mining[J]. Journal of the South African Institute of Mining and Metallurgy, 2008, 108(8): 463-472

[8] Rankine R, Pacheco M, Sivakugan N. Underground mining with backfills[J]. Soils and Rocks, 2007, 30(2): 93-101.

[9] Mamadou F, Belem T, Samb S, et al. Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression[J]. Journal of Materials Science, 2007, 42(11): 3914-3922.

[10] WANG Xinming, ZHANG Qinli. Cemented backfilling technology with unclassified tailings based on vertical sand silo[J]. Journal of Central South University of Technology, 2008, 15(6): 801-807.

[11] ZHANG Qinli, WANG Xinming. Hydraulic calculation of gravity transportation pipeline system for backfill slurry[J]. Journal of Central South University of Technology, 2008, 15(5): 645-649.

[12] 张钦礼, 谢盛青, 郑晶晶, 等. 充填料浆沉降规律研究及输送可行性分析[J]. 重庆大学学报, 2011, 34(1): 105-109.

ZHANG Qinli, XIE Shengqing, ZHENG Jingjing, et al. Sedimentation law research and transportation feasibility study of backfilling slurry[J]. Journal of Chongqing University, 2011, 34(1): 105-109.

[13] Pokharel M, Fall M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill[J]. Cement and Concrete Composites, 2013, 38(4): 21-28.

[14] Fall M, Benzaazoua M, Saa E G. Mix proportioning of underground cemented tailings backfill[J]. Tunnelling and Underground Space Technology, 2008, 23(1): 80-90.

[15] Fall M, Benzaazoua M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization[J]. Cement and Concrete Research, 2005, 35(2): 301-314.

[16] Fall M, Celestin J C, Pokharel M, et al. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill[J]. Engineering Geology, 2010, 114(3): 397-413.

[17] 刘志祥, 李夕兵, 戴塔根, 等. 尾砂胶结充填体损伤模型及与岩体的匹配分析[J]. 岩土力学, 2006, 27(9): 1442-1446.

LIU Zhixiang, LI Xibing, DAI Tagen, et al. On damage model of cemented tailings backfill and its match with rock mass[J]. Rock and Soil Mechanics, 2006, 27(9): 1442-1446.

[18] 赵国彦, 周礼, 马举, 等. 低温高寒环境下尾砂胶结充填体强度特性研究[J].矿冶工程, 2013, 33(3): 24-26.

ZHAO Guoyan, ZHOU Li, MA Ju, et al. Study on strength properties of cemented tailings backfill under low temperature condition[J]. Mining and Metallurgical Engineering, 2013, 33(3): 24-26.

[19] 赵国彦, 马举, 彭康, 等. 基于响应面法的高寒矿山充填配比优化[J]. 北京科技大学学报, 2013, 35(5): 559-565.

ZHAO Guoyan, MA Ju, PENG Kang, et al. Mix ratio optimization of alpine mine backfill based on the response surface method[J]. Journal of University of Science and Technology Beijing, 2013,35(5): 559-565.

(编辑 刘锦伟)

收稿日期:2014-12-13;修回日期:2015-02-25

基金项目(Foundation item):国家“十二五”科技支撑计划项目(2012BAB08B02);新世纪优秀人才支持计划项目(NECT-13-0669);国家自然科学基金资助项目(50774011) (Project(2012BAB08B02) supported by the National “Twelfth Five Year” Science and Technology Support Program; Project(NECT-13-0669) supported by New Century Excellent Talents Supporting Plan; Project(50774011) supported by the National Science Foundation of China)

通信作者:刘超,博士,从事采矿与岩石力学研究;E-mail: lchdaizi@163.com