黄铁矿超细粉磨过程的氧化

来源期刊:中南大学学报(自然科学版)2003年第3期

论文作者:张清岑 刘建平 肖奇

文章页码:235 - 237

关键词:黄铁矿;超细粉磨;氧化动力学;钝化

Key words:FeS2; ultra-fine grinding; oxidation dynamics; passivation

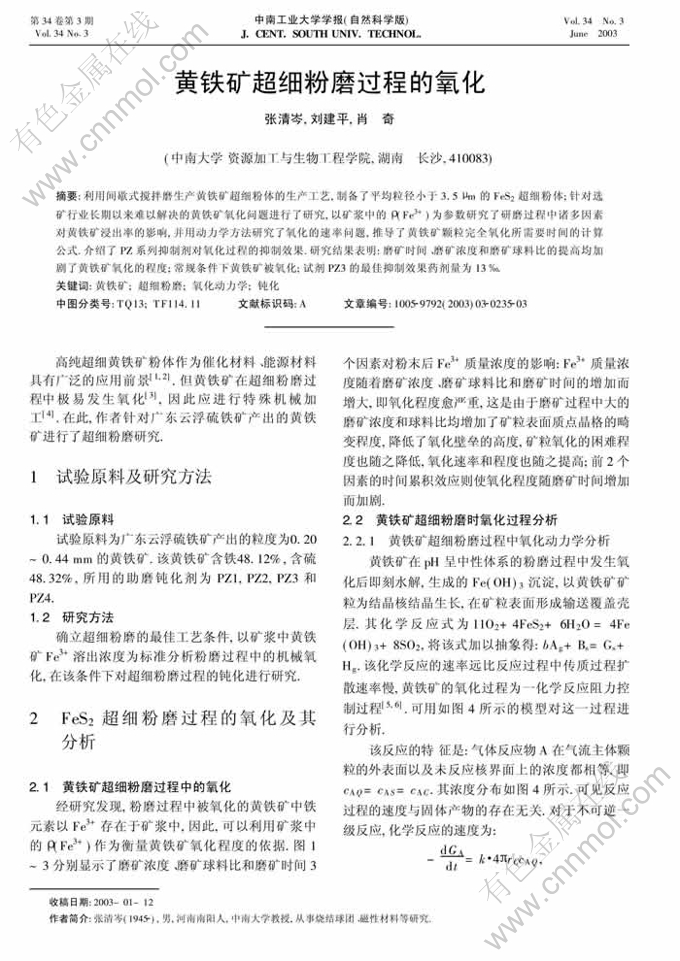

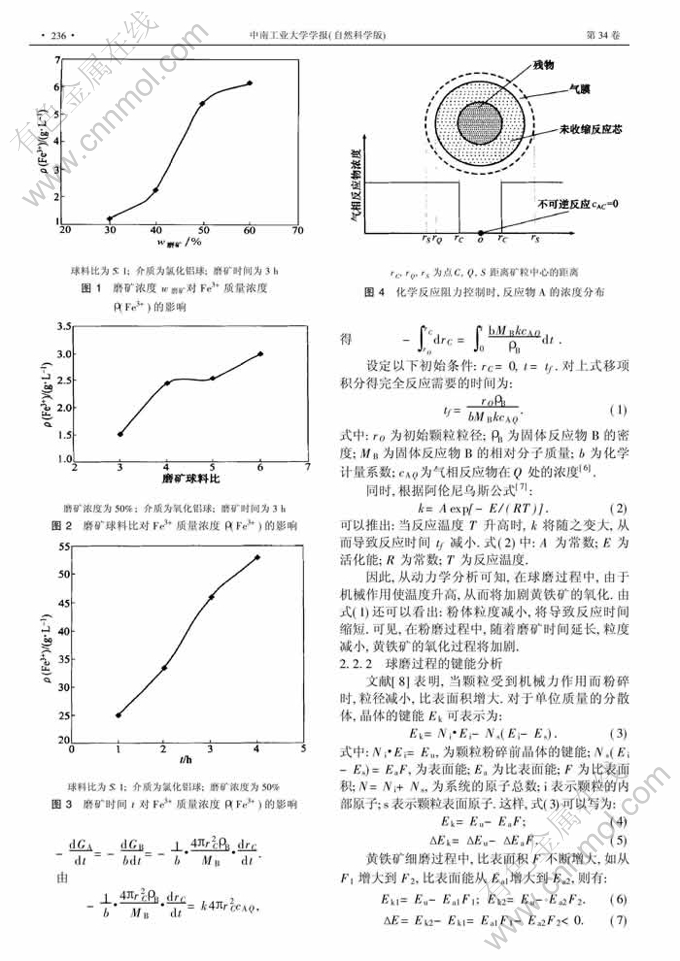

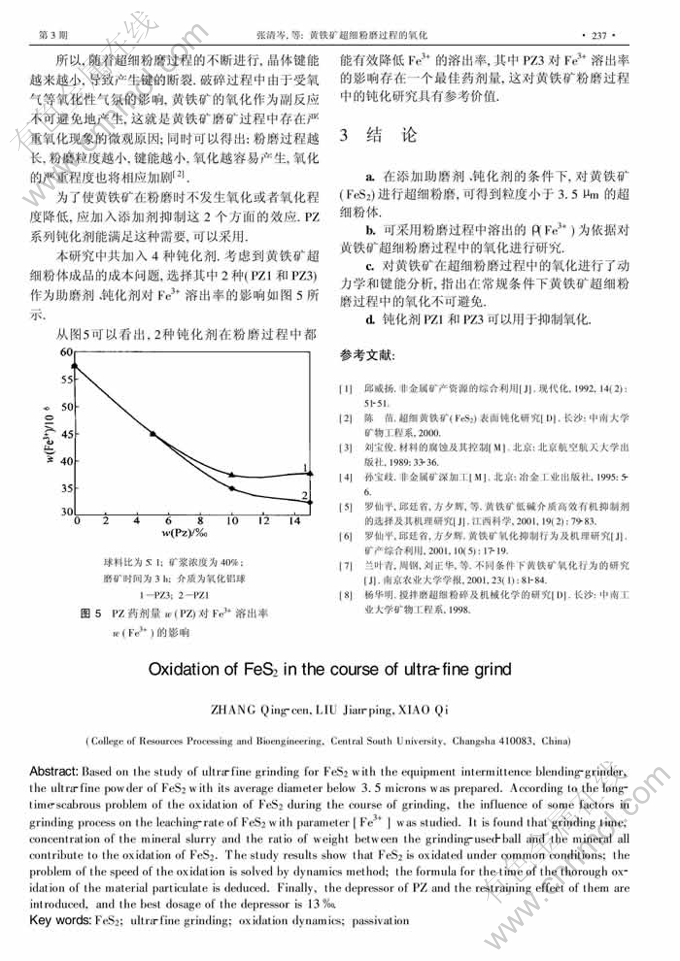

摘 要:利用间歇式搅拌磨生产黄铁矿超细粉体的生产工艺,制备了平均粒径小于3.5μm的FeS2超细粉体;针对选矿行业长期以来难以解决的黄铁矿氧化问题进行了研究,以矿浆中的ρ(Fe3+)为参数研究了研磨过程中诸多因素对黄铁矿浸出率的影响,并用动力学方法研究了氧化的速率问题,推导了黄铁矿颗粒完全氧化所需要时间的计算公式.介绍了PZ系列抑制剂对氧化过程的抑制效果.研究结果表明:磨矿时间、磨矿浓度和磨矿球料比的提高均加剧了黄铁矿氧化的程度;常规条件下黄铁矿被氧化;试剂PZ3的最佳抑制效果药剂量为13‰.

Abstract: Based on the study of ultra-fine grinding for FeS2 with the equipment intermittence blending-grinder,the ultra-fine powder of FeS2 with its average diameter below 3.5 microns was prepared. According to the longtime-scabrous problem of the oxidation of FeS2 during the course of grinding, the influence of some factors in grinding process on the leaching-rate of FeS2with parameter [Fe3+] was studied. It is found that grinding time,concentration of the mineral slurry and the ratio of weight between the grinding-used-ball and the mineral all contribute to the oxidation of FeS2. The study results show that FeS2is oxidated under common conditions; the problem of the speed of the oxidation is solved by dynamics method; the formula for the time of the thorough oxidation of the material particulate is deduced. Finally, the depressor of PZ and the restraining effect of them are introduced, and the best dosage of the depressor is 13‰.