Trans. Nonferrous Met. Soc. China 31(2021) 3405-3415

Investigation of mechanical and diffusion properties in bcc Ti-Nb-Zr-Sn alloys viaa high-throughput method

Zhu-hao WEN1, Yao WANG2, Wei-min CHEN1, Li-jun ZHANG3, Yong DU3

1. Institute of Advanced Wear & Corrosion Resistant and Functional Materials, Jinan University, Guangzhou510632, China;

2. Centre of Excellence for Advanced Materials, Dongguan523808, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha410083, China

Received 22July 2021; accepted 2November 2021

Abstract:

he mechanical and diffusion properties of bcc Ti-Nb-Zr-Sn alloys in the Ti-rich corner were analyzed through a high-throughput method with the combinationof nanoindentation and diffusion couple techniques. Nine groups of quaternary Ti-Nb-Zr-Sn diffusion couples were prepared after annealing at 1273 K for 25 h. The composition-dependent mechanical properties were determined by nanoindentation and electron probe microanalysis (EPMA) techniques. Moreover, the corresponding interdiffusion coefficients were confirmed from the composition gradients of the quaternary diffusion couples using a pragmatic numerical inverse method. A composition-dependent database on the mechanical and diffusion properties was utilized to discuss the processability during the hot working. The results reveal that the solute elements Nb and Sn are strictlycontrolled to increase the hardness and wear resistance of Ti-Nb-Zr-Sn alloys, and the additional element Zr is mainly useful to improve the processability during the hot working.

Key words:

mechanical properties; interdiffusion coefficient; Ti-Nb-Zr-Sn alloys; diffusion couple; nanoindentation;

1 Introduction

Sn-containing Ti alloys have attracted more and more attention due to their low Young’s modulus and superior corrosion resistance [1-3]. The alloy with the composition of Ti-24Nb-4Zr-8Sn (wt.%) was found with a modulus of 33 GPa [1], consequently several Ti-Nb-Zr-Sn alloys with a single bcc structure were prepared through experimental approaches and their mechanical properties were measured via the stress-strain curves of tensile tests or the load-displacement curves of nanoindentation tests [4-6]. However, systematic studies on the composition-dependent mechanical and diffusion properties of quaternary alloys are still missing. An in-depth understanding on the mechanical and diffusion properties in the Ti-Nb-Zr-Sn alloys is a prerequisite for the design of novel bio-alloys.

Young’s modulus, hardness and interdiffusion coefficient refer to the important mechanical and diffusion properties of the materials, which are necessarily considered during the design of the novel metallic implant biomaterials [7-9]. The traditional method, using repeated compositional adjustments and experimental testing, merely provides the limited experimental data, which seriously blocks the development of the mechanical property database. For the sake of more experimental Young’s modulus and hardness of the alloys, ZHAO [10] proposed a high-throughput method by combining the nanoindentation tests with the diffusion couple technique and it was conducted for several Ti-Nb-Zr-based alloy systems [11-15]. In addition, interdiffusion coefficients can be calculated from the composition gradient of diffusion couples by using a pragmatic numerical inverse method [16-18]. Since they are related to the steady-state rate atintermediatetemperature, the diffusion information and Young’s modulus are generally used to judge the difficulty of processing [14].

In this work, the combination of diffusion couple and nanoindentation techniques was selected to explore the mechanical and diffusion properties in the Ti-rich Ti-Nb-Zr-Sn system over a wide composition range at 1273 K. Firstly, 9 groups ofTi-Nb-Zr-Sn diffusion couples were annealed at the selected temperature to ensure the alloys within a single bcc phase. Secondly, a nanoindentation test on the diffusion couples was carried out to measure Young’s modulus, hardness, and elastic recovery varied with the indentation positions, and the field emission electron probe microanalysis (Fe-EPMA) was adopted to determine the compositions of the indentations. Subsequently, the composition-dependent mechanical properties of the Ti-based alloys were obtained. As for the interdiffusion coefficients at 1273 K, a pragmatic numerical inverse method was taken in the Ti-Nb-Zr-Sn alloys. Finally, the composition-dependent mechanical and diffusion properties of Ti-rich Ti-Nb-Zr-Sn alloys were discussed.

2 Experimental

2.1 Material preparation and characterization

The slugs of Nb (purity: 99.95 wt.%), Sn (purity: 99.95 wt.%), Ti (purity: 99.999 wt.%), and Zr (purity: 99.9 wt.%) from Zhongnuo Advanced Material (Beijing) Technology Co., Ltd., were used for the fabrication of the Ti-Nb-Zr-Sn diffusion couples. The compositions of couples C1-C9 in the Ti-rich Ti-Nb-Zr-Sn system are presented in Table 1. Up to 18 ternary alloys prepared by arc melting under an Ar atmosphere using a non- reactive W electrode (WKDHL-1, Opto-electronics Co., Ltd., Beijing, China) were cut into blocks with the size of 7 mm × 7 mm × 2 mm. The ground blocks sealed into vacuum quartz tubes were homogenized at (1273±2) K for 7 d. After the homogenization annealing, the ground blocks with any two components were bound by Mo clamps, sealed into vacuum quartz tubes, and annealed at (1273±2) K for 25 h in an ELF1106-type furnace (CarboliteGero Co., Ltd., United Kingdom). After the annealing, the Ti-Nb-Zr-Sn diffusion couples were quenched in the flowing water. Cross-sections of the diffusion couples were ground and polished by SiC papers and diamond pastes, respectively. The alloy compositions along the composition gradient direction of nine quaternary Ti-Nb-Zr-Sn diffusion couples were determined with the support of Fe-EPMA (JXA-8530, JEOL, Japan). Young’s moduli (E) and hardness (H) were measured by the nanoindenter (Keysight G200, Agilent Technology, USA) with an in-depth control (2000 nm) according to the Oliver-Pharr analysis [19]. Moreover, the corresponding energy was obtained from the load-displacement curve, and ratio of the elastic indentation energy to the total deformation energy (Uel/Utot) was calculated as the elastic recovery [14].

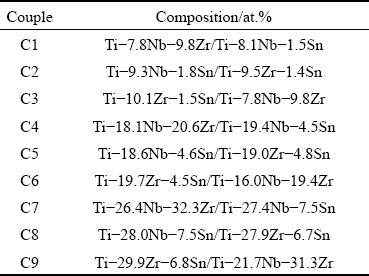

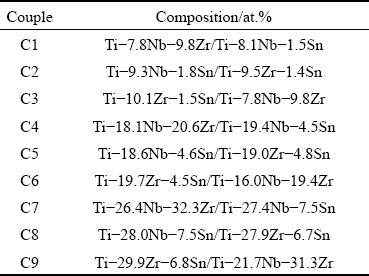

Table 1 Alloy compositions for Ti-Nb-Zr-Sn diffusion couples

2.2 Determination of interdiffusion coefficients

Based on the Fick’s second law, a pragmatic numerical inverse method was proposed to determine the interdiffusion coefficients along with the composition variations of the binary or multicomponent diffusion couples, which can be related with the mobility according to the Manning’s random alloy model [16,17]. The composition-dependent interdiffusion coefficients of Ti-rich Ti-Nb-Zr-Sn system were calculated with the support of a high-throughput determination of interdiffusion coefficients (HitDIC) code [20]. In the present work, the thermodynamic parameters presented in Refs. [21-23] were utilized,and the used mobility parameters on the self and impurity diffusion coefficients were reported in Refs. [24,25].

3 Results and discussion

3.1 Mechanical and wear properties of Ti-Nb-Zr-Sn alloys

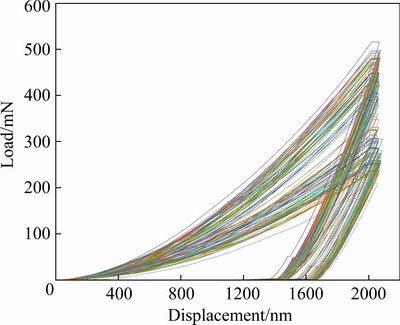

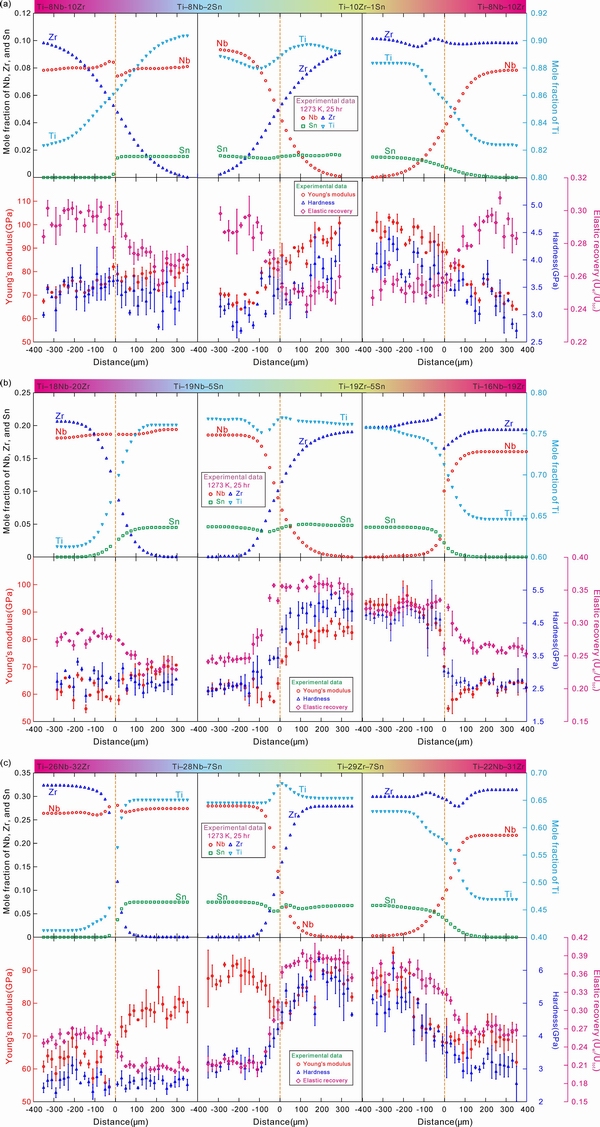

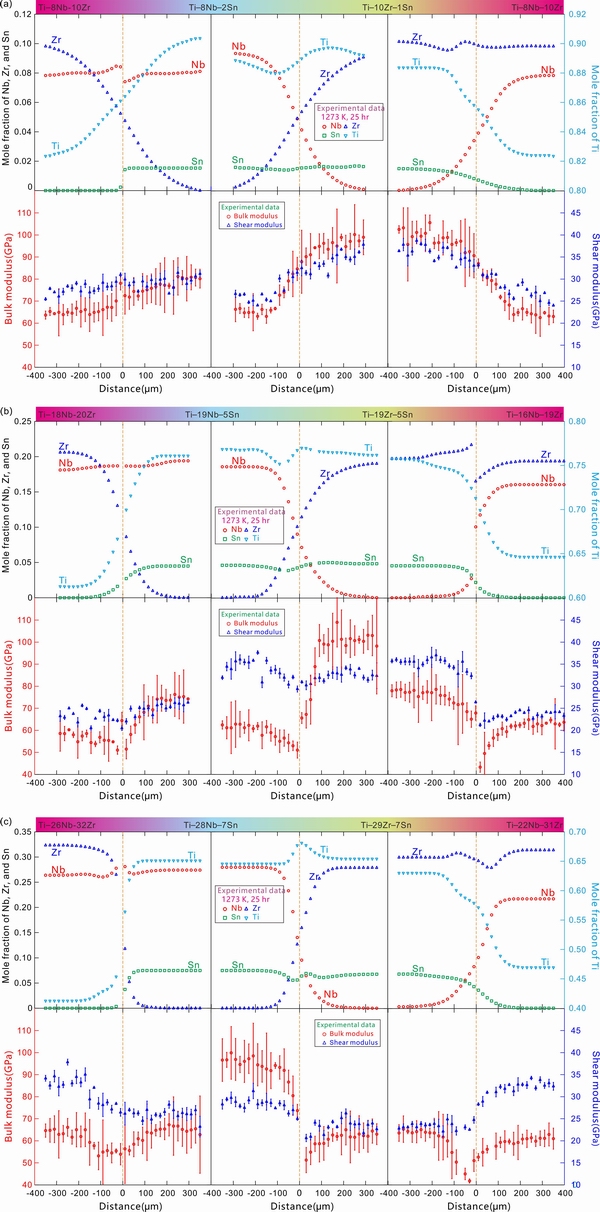

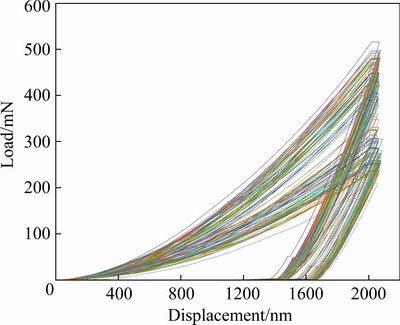

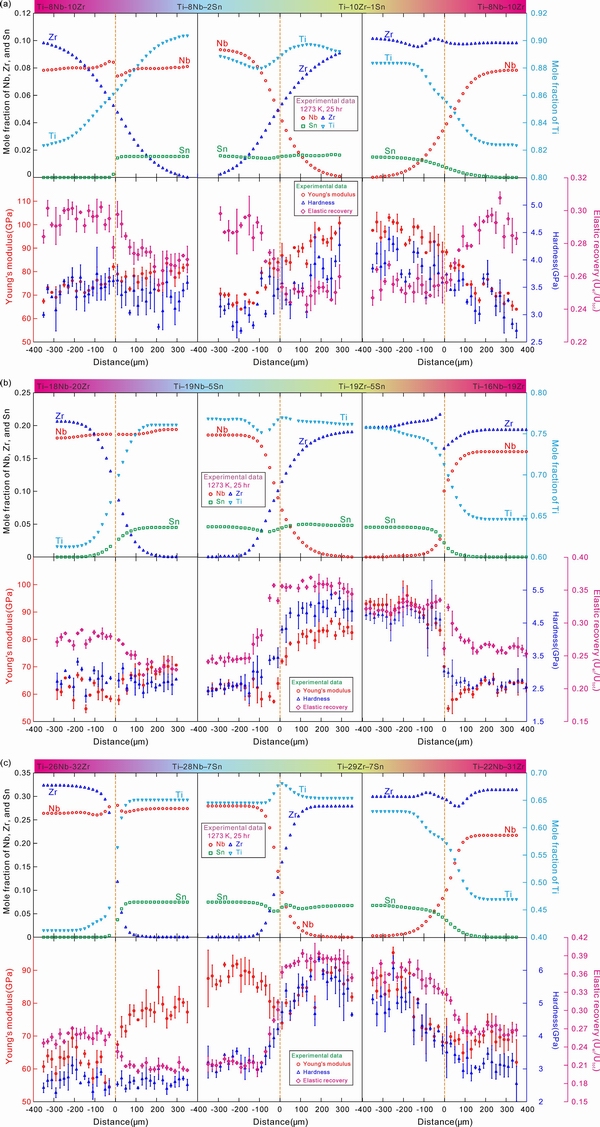

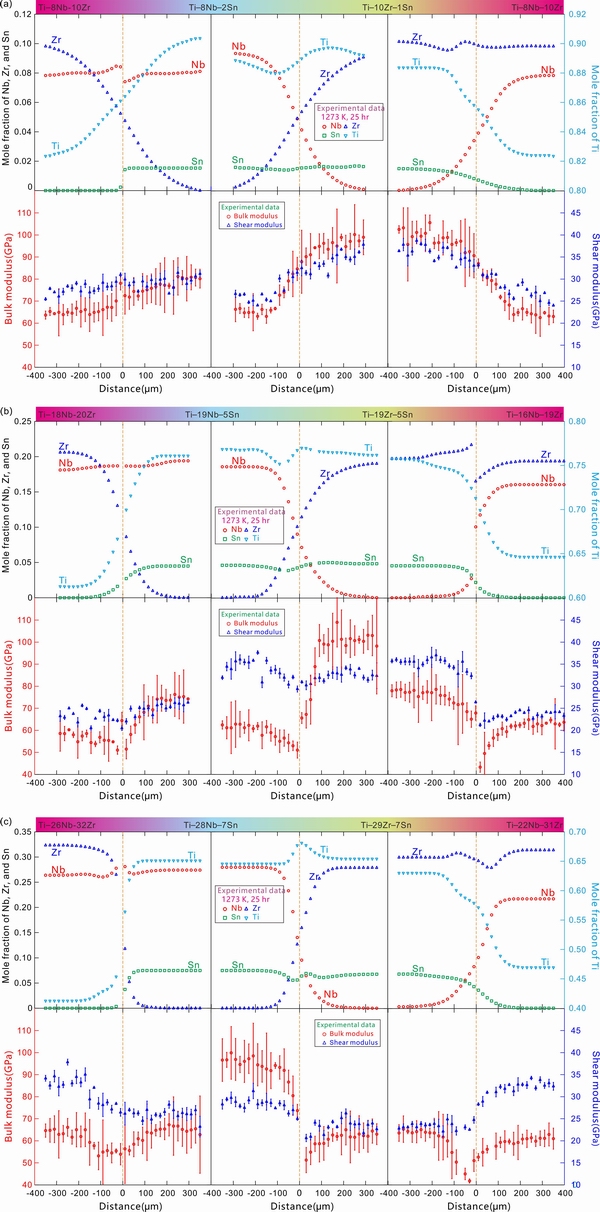

Figure 1 shows the load-displacement curves of C9 annealed at 1273 K for 25 h, indicating that the mechanical properties are dependent on the alloy compositions. Using the contact boundary of the end-members as the reference position, mechanical properties including Young’s modulus, hardness, and elastic recovery as a function of composition can be obtained by correlating the fitted composition vs position curves with the nanoindentation results vs position, which has been performed in Ref. [26]. Figure 2 illustrates the composition-dependent mechanical properties (i.e., Young’s modulus, hardness, and elastic recovery) in the Ti-Nb-Zr-Sn diffusion couples, accompanied with the corresponding experimental errors. Obviously, the measured results are composition-dependent. As shown in Fig. 2, the variations of the experimental Young’s modulus, hardness, and elastic recovery are within the range of 53-103 GPa, 2-6 GPa, and 0.2-0.39, respectively. It can be seen from Fig. 2(a) that the experimental Young’smodulus and hardness from the side of Ti-8Nb-10Zr to those of Ti-8Nb-2Sn do not vary significantly, and then rapidly increase to those in the side of Ti-10Zr-1Sn. However, the elastic recovery decreases from the side of Ti-8Nb-10Zr to that of Ti-8Nb-2Sn, and then continues to decrease to that in the side of Ti-10Zr-1Sn. The experimental hardness variations from Ti-Nb-Zr to Ti-Zr-Sn in Figs. 2(b) and 2(c) are similar to the trend in Fig. 2(a). In Figs. 2(b) and 2(c), the elastic recovery of the bcc Ti alloys decreases from the side of Ti-Nb-Zr to that of Ti-Nb-Sn, and then increases to that in the side of Ti-Zr-Sn. Moreover, the results also show an inverse relationship between the hardness and Nb concentration, which is similar to the previous investigation on the Ti-Nb-Zr-Hf system [14].

Fig. 1 Load-displacement curves of C9 annealed at 1273 K for 25 h

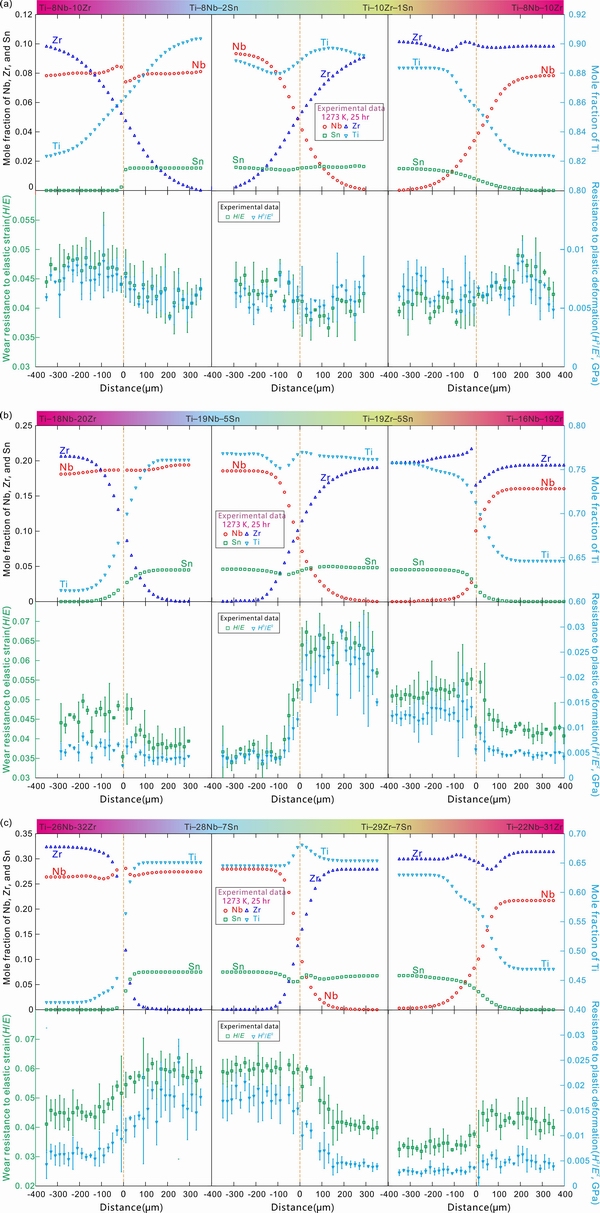

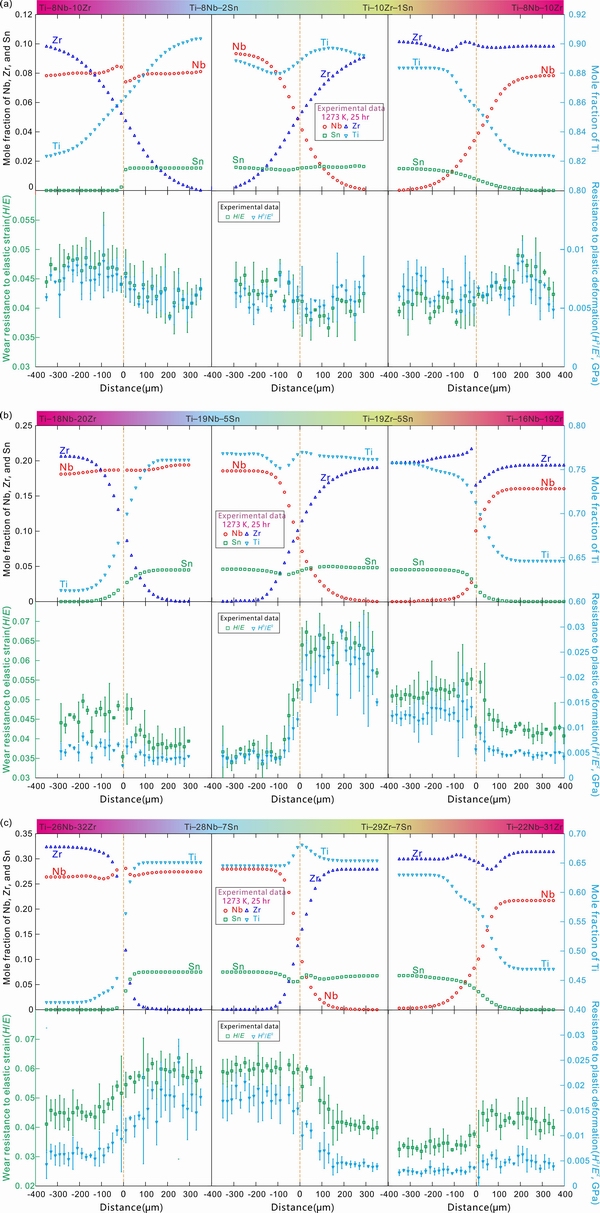

In general, high wear resistance can prolong the service life of the materials [27,28]. According to the wear theory [29], wear resistance can be represented by using the ratios of hardness toYoung’s modulus including H/E and H 3/E2, which separately represents the ability to resist elastic deformation and plastic deformation in loaded contact. Based on the above-mentioned Young’s modulus and hardness, these two ratios are presented to evaluate the wear resistance of the bcc-Ti alloys, and the calculations are presented in Fig. 3. The values 0.04 and 0.009 recommended in Ref. [13] are accepted as the reference states of H/E and H 3/E2 for comparison. In Fig. 3, theH/Eratioof most composition points in the Ti-Nb-Zr-Sn diffusion couples is larger than 0.04, while the H 3/E2value of several points is larger than 0.009 GPa. It indicates that Ti-Nb-Zr-Sn alloys have high ability to resist elastic deformation, but limited wear resistance during the plastic deformation.

The relationship between Young’s modulus and hardness for Ti-Nb-Zr-Sn alloys is consistent with the expression of isotropic crystal presented in Ref. [30]:

(1)

(1)

wherev is the Poisson ratio. In addition, the Young’s modulus and Poisson ratio can be related with the bulk modulus B and shear modulus G [31]:

(2)

(2)

(3)

(3)

And then, the following expressions can be given by

(4)

(4)

(5)

(5)

Fig. 2 Experimental composition profiles, Young’s modulus, hardness, and elastic recovery of bcc Ti-based alloys in couples of C1-C3(a), C4-C6(b), and C7-C9 (c) annealed at 1273 K for 25 h

Fig. 3 Ratios H/E and H3/E2 of bcc Ti-based alloys in C1-C3(a), C4-C6(b), and C7-C9 (c) diffusion couples annealed at 1273 K for 25 h

Thus, the approximate bulk and shear moduli can be deduced from the measured Young’s modulus and hardness of nanoindentation tests, and the composition-dependent bulk and shear moduli in the Ti-Nb-Zr-Sn diffusion couples are shown in Fig. 4. It is seen that the bulk modulus variation is similar to the variation of Young’s modulus, resulting from the fact that bulk modulus is mainly dominated by Young’s modulus. In Figs. 4(a) and (b), shear modulus increases from Ti-Nb-Zr to Ti-Nb-Sn, and then rapidly increases to Ti-Zr-Sn. While shear modulus increases from Ti-Nb-Zr to Ti-Nb-Sn, and then decreases to Ti-Zr-Sn.

Fig. 4 Predicted bulk and shear moduli of bcc Ti-based alloys in C1-C3(a), C4-C6(b), and C7-C9 (c) diffusion couples annealed at 1273 K for 25 h

3.2 Diffusion properties of Ti-Nb-Zr-Sn alloys

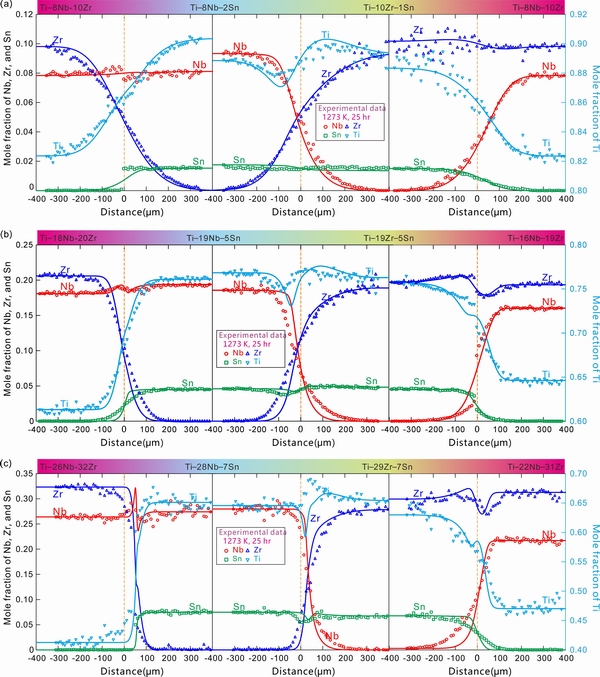

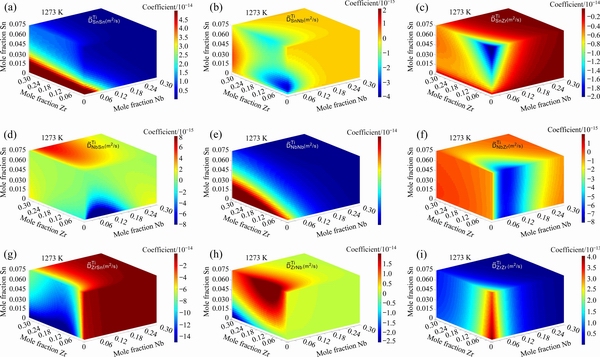

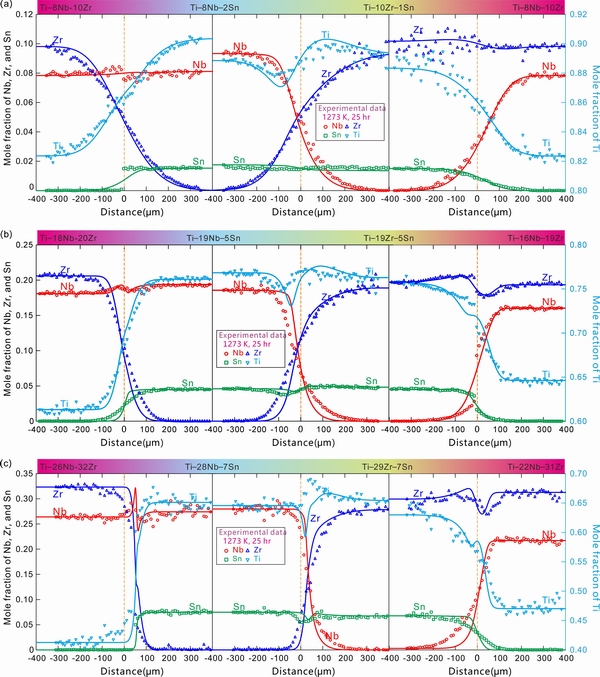

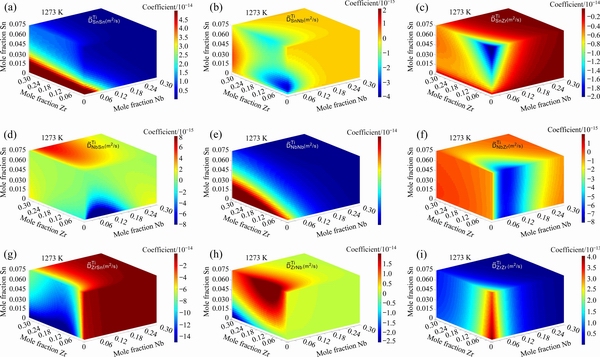

Figure 5 displays the model-predicted composition profiles of Ti-Nb-Zr-Sn diffusion couples at 1273 K, compared with the measured data. Most of the experimental profiles are in good agreement with the model-predicted composition profiles, meaning that the modeling parameters are reliable and can be utilized to provide accurate interdiffusion coefficients. The constructed interdiffusion coefficients of Ti-rich Ti-Nb-Zr-Sn system at 1273 K are demonstrated by using the color variations in the composition space of a quaternary system in Fig. 6. The figure shows that the main and cross interdiffusion coefficients using pragmatic numerical inverse method vary with the Nb, Zr, and Sn concentrations. Among them main interdiffusion coefficients,

and

and  are all positive, decreasing with theincreasing concentrations of Nb and Sn in the Ti-Nb-Zr-Sn system.

are all positive, decreasing with theincreasing concentrations of Nb and Sn in the Ti-Nb-Zr-Sn system.  and

and slightly increase with the increasing Zr concentration, while

slightly increase with the increasing Zr concentration, while  decreases with the increase of Zr. Compared with the main interdiffusion coefficients, the cross interdiffusion coefficients show more complex variations with the concentrations of Nb, Zr, and Sn.

decreases with the increase of Zr. Compared with the main interdiffusion coefficients, the cross interdiffusion coefficients show more complex variations with the concentrations of Nb, Zr, and Sn.

Fig. 5 Measured and model-predicated composition profiles in couples of C1-C3(a), C4-C6(b), and C7-C9 (c) annealed at 1273 K for 25 h

Fig. 6 Main and cross interdiffusion coefficients of Ti-rich Ti-Nb-Zr-Sn system at 1273 K determined by using pragmatic numerical inverse method

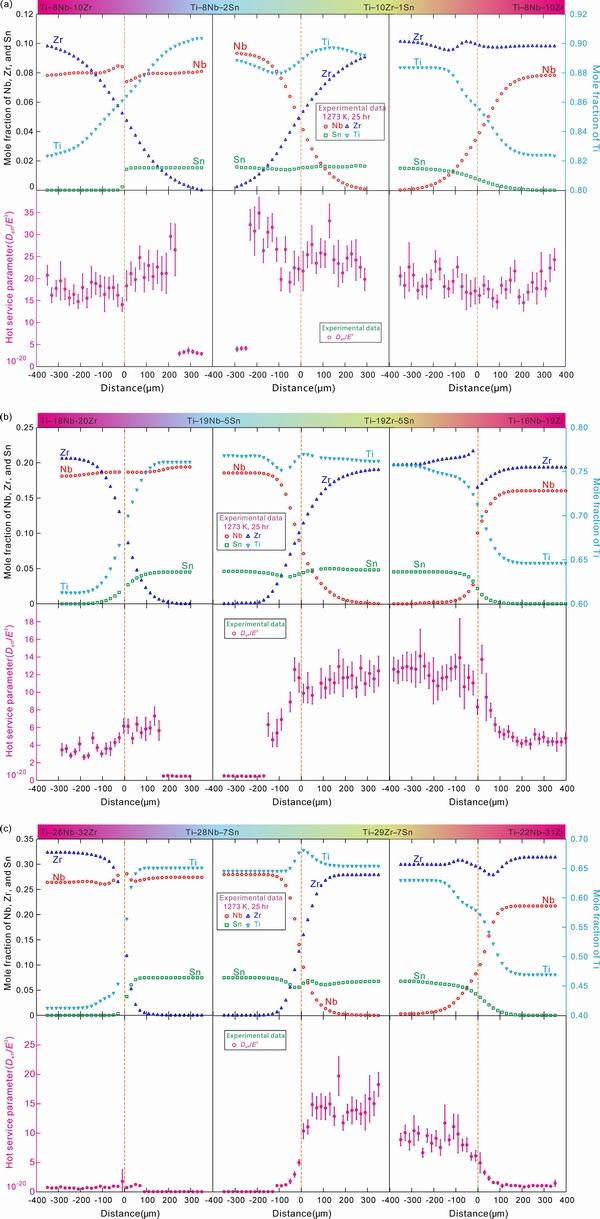

3.3 Hot processability prediction of Ti-Nb-Zr-Sn alloys

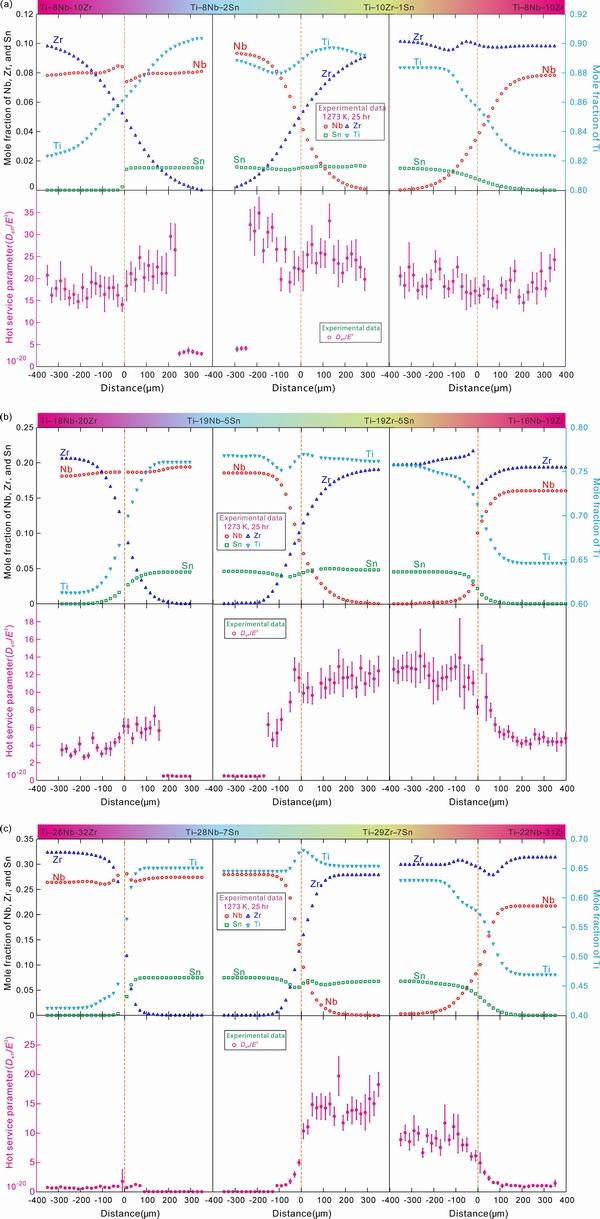

Very recently, the ratio of effective diffusion coefficient to cube of Young’s modulus (Deff/E3) was proposed as a hot working parameter to characterize the processability during the hot working [14]. It is noted that the effective diffusion coefficient is equivalent to the main interdiffusion coefficient of the solute element with large atomic radius, which is consistent with the experimental investigations in Ref. [32]. The hot working parameters(Deff/E3) at each composition point of Ti-Nb-Zr-Sn diffusion couples can be obtained from the experimental Young’s moduli and the main interdiffusion coefficients at 1273 K, which areshown in Fig. 7. Due to the atomic radii of three solute elements Nb, Sn, and Zr, the effective diffusion coefficient (Deff) of Ti-Nb-Zr-Sn, Ti-Nb(-Sn), and Ti-Sn alloys and pure Ti are the interdiffusion coefficients

and

and  and self-diffusion coefficient

and self-diffusion coefficient  , respectively. In Ref. [14], a value of 7.25×10-20 m2/(s·GPa3) is recommended as the reference data of Ti-6Al-4V alloy for comparison. In Fig. 7(a), the hot working parameter of Ti-8Nb-2Sn alloy is lower than the recommended value, but those of other Ti alloys in the Ti-Nb-Zr-Sn diffusion couples are larger than the recommended value. It is seen from Figs. 7(b) and (c) that the ternary and quaternary alloys which are adjacent to Ti-19Zr-5Sn and Ti-29Zr-7Sn have a high hot working parameter. The results indicate that Ti alloys with high concentrations of solute elements Nb and Sn may not perform the nice processability at intermediate temperatures. The addition of Zr is helpful for the increase of effective diffusion coefficient and then the increase of hot working parameter, which is expected for the thermomechanical treatment of bio-Ti alloys.

, respectively. In Ref. [14], a value of 7.25×10-20 m2/(s·GPa3) is recommended as the reference data of Ti-6Al-4V alloy for comparison. In Fig. 7(a), the hot working parameter of Ti-8Nb-2Sn alloy is lower than the recommended value, but those of other Ti alloys in the Ti-Nb-Zr-Sn diffusion couples are larger than the recommended value. It is seen from Figs. 7(b) and (c) that the ternary and quaternary alloys which are adjacent to Ti-19Zr-5Sn and Ti-29Zr-7Sn have a high hot working parameter. The results indicate that Ti alloys with high concentrations of solute elements Nb and Sn may not perform the nice processability at intermediate temperatures. The addition of Zr is helpful for the increase of effective diffusion coefficient and then the increase of hot working parameter, which is expected for the thermomechanical treatment of bio-Ti alloys.

Fig. 7 Hot working parameters of bcc Ti-based alloys in C1-C3(a), C4-C6(b), and C7-C9 (c) diffusion couples annealed at 1273 K for 25 h

4 Conclusions

(1) The experimental mechanical properties of the bcc Ti-Nb-Zr-Sn alloys are composition-dependent, which is urgently needed for the alloy design. The experimental Young’s moduli, hardness, and elastic recovery of the Ti-Nb-Zr-Sn alloys are in the range of 53-103 GPa, 2-6 GPa, and 0.2-0.39, respectively.

(2) The high H/E and low H3/E2ratios indicate that Ti-Nb-Zr-Sn alloys have high wear resistance during the elastic deformation, but limited wear resistance during the plastic deformation. The bulk and shear moduli of Ti-Nb-Zr-Sn alloys over a wide composition range are estimated from the experimental Young’s modulus and hardness.

(3) The composition-dependent interdiffusion coefficients of the bcc Ti-Nb-Zr-Sn alloys are determined by using the pragmatic numerical inverse method from the experimental composition profiles of quaternary diffusion couples. Hot working parameters in the Ti-rich Ti-Nb-Zr-Sn system are presented. This work reveals that additive concentrations of the solute elements Nb and Sn are strictlycontrolled to increase the hardness of Ti alloys, and the addition of element Zr is useful for improving the processability during the hot working.

Acknowledgments

This work is supported bythe National Natural Science Foundation for Youth of China (No. 51701083), the Guangzhou Science and Technology Association Young Talent Lifting Project, China (No. X20210201054), the Guangdong Provincial Natural Science Foundation for Doctoral Research Project, China (No. 2017A030310519), and the Open Fund of National Joint Engineering Research Center for Abrasion Control and Molding of MetalMaterials, China (No. HKDNM201903). Yao WANG acknowledges the financial support from the Guangdong Basic and Applied Basic Research Foundation, China (No. 2019A1515110095).

References

[1] HAO Y L, LISJ,SUNSY,ZHENGCY,HUQ M, YANG R.Super-elastictitaniumalloywithunstableplasticdeformation[J].AppliedPhysicsLetters,2005,87:091906.

[2] GUO S, MENG Q K, CHENG X N, ZHAO X Q. Deformation behavior of metastable β-type Ti-25Nb-2Mo-4Sn alloy for biomedical applications [J]. Journal of theMechanicalBehaviorof Biomedical Materials, 2014, 38: 26-32.

[3] HASHMI M L, WADOOD A. Microstructural, mechanical and shape memory characterizations of Ti-Mo-Sn alloys [J]. Transactions of Nonferrous Metals Society of China, 2020, 30: 688-700.

[4] HAO Y L, LISJ,SUNS Y, YANG RYL. Effect of Zr and Sn on Young’s modulus and superelasticity of Ti-Nb-based alloys [J]. Materials Science andEngineeringA, 2006, 441: 112-118.

[5] ZHANG Y W, LIS J, HAO Y L, YANG R. Nanoindentation study on Ti-24Nb-4Zr-8Sn single crystals [J]. Chinese Journal of Nonferrous Metals, 2010, 20: s528-s532.

[6] LAN C B, WU Y, GUO LL, CHEN H J, CHEN F. Microstructure, texture evolution and mechanical properties of cold rolled Ti-32.5Nb-6.8Zr-2.7Sn biomedical beta titanium alloy [J]. Journal of Materials Science and Technology, 2018, 34: 788-792.

[7] CHEN W M, ZENG D H, REN P, HU B, LI W. Effects of Sc addition on the diffusion kinetics and mechanical properties of bcc Ti Alloys [J]. Metallurgical and Materials Transactions A, 2019, 50: 2576-2579.

[8] FANTON L, de LIMA N B, ENCINAS E R, BORR?S V A, AFONSO C R M, FOGAGNOLO J B. Effects of laser surface melting on crystallographic texture, microstructure, elastic modulus and hardness of Ti-30Nb-4Sn alloy [J]. Transactions of Nonferrous Metals Society of China, 2020, 30: 392-404.

[9] LIU Y, TANG H C, HUANG Q L, ZHAO D P, HE J Y, CAO Y K, SONG M, LIU B, OUYANG S H. Strong-yet-ductile Ti-Zr alloys through high concentration of oxygen strengthening [J]. Transactions of Nonferrous Metals Society of China, 2021, 30: 2449-2458.

[10] ZHAO J C. Combinatorial approaches as effective tools in the study of phase diagrams and composition-structure-property relationships [J]. Progress in Materials Science, 2006, 51: 557-631.

[11] CHEN W M, ZHANG L J. Experimental investigations on the quaternary interdiffusion coefficients, Young’s modulus and hardness in bcc Ti-Nb-Ta-Zr quaternary alloys [J]. Journal ofPhaseEquilibriaand Diffusion, 2019, 40: 138-147.

[12] LING J F, CHEN W M, SHENG YY, LI W, ZHANG LL, DU Y. A MGI-oriented investigation of the Young’s modulus and its application to the development of a novel Ti–Nb–Zr–Cr bio-alloy [J]. Materials Science andEngineeringC, 2020, 106: 110265.

[13] LING J F, HUANG DD, BAI K W, LI W, YU Z T, CHEN W M. High-throughput development and applications of the compositional mechanical property map of theβtitanium alloys [J]. Journal of Materials Science and Technology, 2021, 71: 201-210.

[14] WEN Z H, WANG Y Z, LING J F, CHEN W M, ZHANG L J, DU Y. High-throughput determination of the composition-dependent mechanical and diffusion properties in βTi–Nb–Zr-Hf refractory alloys [J]. Journal ofAlloysand Compounds, 2021, 876: 160150.

[15] LING J F, WEN Z H, YANG G M, WANG Y, CHEN W M. A CALPHAD-type Young’s modulus database of Ti-rich Ti-Nb-Zr-Mo system [J]. Calphad, 2021, 73: 102255.

[16] CHEN W M, ZHANG L J, DU Y, TANG C Y, HUANG B Y. A pragmatic method to determine the composition-dependent interdiffusivities in ternary systems by using a single diffusion couple [J]. ScriptaMaterialia, 2014, 90-91: 53-56.

[17] CHEN W M, ZHONG J, ZHANG L J. An augmented numerical inverse method for determining the composition-dependent interdiffusivities in alloy systems by using a single diffusion couple [J]. MRSCommunications, 2016, 6: 295-300.

[18] CHEN W M, ZHANG L J. High-throughput determination of interdiffusion coefficients for Co-Cr-Fe-Mn-Ni high-entropy alloys [J]. Journal of Phase Equilibria and Diffusion, 2017, 38: 457-465.

[19] OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. Journal of Materials Research, 1992, 7: 1564-1583.

[20] ZHONG J, CHEN W M, ZHANG L J. HitDIC: A free-accessible code for high-throughput determination of interdiffusion coefficients in single solution phase [J]. Calphad, 2018, 60: 177-190.

[21] PENG Y B, DU Y, ZHOU P, ZHANG W B, CHEN W M, CHEN L, WANG S, WEN G, XIE W. CSUTDCC1—A thermodynamic database for multicomponent cemented carbides [J]. International Journal of Refractory Metals &HardMaterials, 2014, 42: 57-70.

[22] LAFAYE P, TOFFOLON-MASCLET C, CRIVELLO J C, JOUBERT J M. Experimental investigations and thermodynamic modelling of the Cr-Nb-Sn-Zr system [J]. Calphad, 2019, 64: 43-54.

[23] PENG Y B, HUANG G Z, LONG L D, YAN L W, LONG J Z, HE S W, XU T. Thermodynamic modeling of the Ti-Nb-Sn system and its preliminary applications in aging precipitation and solidification simulations [J]. Materials ResearchExpress, 2021, 8: 036516.

[24] WANG J L, LIU L B, TUO B Y, BAI W M, WANG X, LI X, HU X P. Computational study of mobilities and diffusion in Ti-Sn alloy [J]. Journal of Phase Equilibria and Diffusion, 2015, 36: 248-253.

[25] CHEN W M. Interdiffusion and atomic mobility in bcc Ti-rich Ti-Nb-Zr system [J]. Calphad, 2018, 60: 98-105.

[26] ZHOU L, MEHTA A, CHO K, SOHN Y H. Composition-dependent interdiffusion coefficient, reduced elastic modulus and hardness in γ-, γ′- and β-phases in the Ni-Al system [J]. Journal ofAlloysand Compounds, 2017, 727: 153-162.

[27] WEI S Z, XU L J. Review on research progress of steel and iron wear-resistant materials [J]. ActaMetallurgicaSinica, 2020, 56: 523-538.

[28] XU L J, SONG W L, MA S Q, ZHOU Y C, PAN K M, WEI S Z. Effect of slippage rate on frictional wear behaviors of high-speed steel with dual-scale tungsten carbides (M6C) under high-pressure sliding-rolling condition [J]. Tribology International, 2021, 154: 106719.

[29] LEYLAND A, MATTHEWS A. On the significance of theH/Eratio in wear control: A nanocomposite coating approach to optimisedtribological behavior [J]. Wear, 2000, 246: 1-11.

[30] QIU S, MIAO N H, ZHOU J, GUO Z L, SUN Z M. Strengthening mechanism of aluminum on elastic properties of NbVTiZr high-entropy alloys [J]. Intermetallics, 2018, 92: 7-14.

[31] TAN Y K, ZHUANG R J, YANG G J, TAO X M, CHEN H M, OUYANG Y F, DU Y. Diffusional behaviors and mechanical properties of Ni-Zn system [J]. Journal ofAlloysand Compounds, 2021, 881: 160581.

[32] MONMA K, SUTO H, OIKAWA H. Relation between high-temperature creep and diffusion in alloys (On the relation between high-temperature creep and diffusion in nickel-base solid solutions. VII) [J]. Journal of Japan Institute of Metals, 1964, 28: 308-312.

体心立方Ti-Nb-Zr-Sn合金力学和扩散性能的高通量研究

闻祝浩1,王瑶2,陈伟民1,张利军3,杜勇3

1. 暨南大学 先进耐磨蚀及功能材料研究院,广州 510632;

2. 东莞材料基因高等理工研究院,东莞 523808;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:采用纳米压痕和扩散偶相耦合的方法对体心立方富Ti端Ti-Nb-Zr-Sn合金力学和扩散性能开展高通量检测。通过在1273K固溶退火25h制备9组四元Ti-Nb-Zr-Sn扩散偶。借助纳米压痕和电子探针等技术实验确定随成分变化的力学性能,并且利用实用高效数值回归方法从四元扩散偶的成分梯度中获取相应的互扩散系数。这套Ti-Nb-Zr-Sn合金随成分变化的力学和扩散性能数据库可用于热加工过程中的加工变形性能分析。结果显示,控制Nb和Sn等溶质元素含量可提高Ti-Nb-Zr-Sn 合金的硬度和耐磨性能,而另一种溶质元素Zr能够有效提升合金的热加工变形能力。

关键词:力学性能;互扩散系数;Ti-Nb-Zr-Sn合金;扩散偶;纳米压痕

(Edited by Xiang-qun LI)

1003-6326/  2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

Abstract:The mechanical and diffusion properties of bcc Ti-Nb-Zr-Sn alloys in the Ti-rich corner were analyzed through a high-throughput method with the combinationof nanoindentation and diffusion couple techniques. Nine groups of quaternary Ti-Nb-Zr-Sn diffusion couples were prepared after annealing at 1273 K for 25 h. The composition-dependent mechanical properties were determined by nanoindentation and electron probe microanalysis (EPMA) techniques. Moreover, the corresponding interdiffusion coefficients were confirmed from the composition gradients of the quaternary diffusion couples using a pragmatic numerical inverse method. A composition-dependent database on the mechanical and diffusion properties was utilized to discuss the processability during the hot working. The results reveal that the solute elements Nb and Sn are strictlycontrolled to increase the hardness and wear resistance of Ti-Nb-Zr-Sn alloys, and the additional element Zr is mainly useful to improve the processability during the hot working.

(1)

(1) (2)

(2) (3)

(3) (4)

(4) (5)

(5)

and

and  are all positive, decreasing with theincreasing concentrations of Nb and Sn in the Ti-Nb-Zr-Sn system.

are all positive, decreasing with theincreasing concentrations of Nb and Sn in the Ti-Nb-Zr-Sn system.  and

and

, respectively. In Ref. [14], a value of 7.25×10-20 m2/(s·GPa3) is recommended as the reference data of Ti-6Al-4V alloy for comparison. In Fig. 7(a), the hot working parameter of Ti-8Nb-2Sn alloy is lower than the recommended value, but those of other Ti alloys in the Ti-Nb-Zr-Sn diffusion couples are larger than the recommended value. It is seen from Figs. 7(b) and (c) that the ternary and quaternary alloys which are adjacent to Ti-19Zr-5Sn and Ti-29Zr-7Sn have a high hot working parameter. The results indicate that Ti alloys with high concentrations of solute elements Nb and Sn may not perform the nice processability at intermediate temperatures. The addition of Zr is helpful for the increase of effective diffusion coefficient and then the increase of hot working parameter, which is expected for the thermomechanical treatment of bio-Ti alloys.

, respectively. In Ref. [14], a value of 7.25×10-20 m2/(s·GPa3) is recommended as the reference data of Ti-6Al-4V alloy for comparison. In Fig. 7(a), the hot working parameter of Ti-8Nb-2Sn alloy is lower than the recommended value, but those of other Ti alloys in the Ti-Nb-Zr-Sn diffusion couples are larger than the recommended value. It is seen from Figs. 7(b) and (c) that the ternary and quaternary alloys which are adjacent to Ti-19Zr-5Sn and Ti-29Zr-7Sn have a high hot working parameter. The results indicate that Ti alloys with high concentrations of solute elements Nb and Sn may not perform the nice processability at intermediate temperatures. The addition of Zr is helpful for the increase of effective diffusion coefficient and then the increase of hot working parameter, which is expected for the thermomechanical treatment of bio-Ti alloys.

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press