DOI: 10.11817/j.issn.1672-7207.2020.11.010

选区激光熔化AlSi10Mg合金镜的表面性能

韩潇1, 2,康楠3,焦建超1, 2,王超1, 2

(1. 北京空间机电研究所,北京,100094;

2. 先进光学遥感技术北京市重点实验室,北京,100094;

3. 西北工业大学 凝固技术国家重点实验室,陕西 西安,710072)

摘 要:

造技术适用于复杂轻量化结构光学元件的快速成形,且采用同种材料一体化光机结构能够降低空间光学成像系统的温度敏感性,提高稳定性,利用选区激光熔化(SLM)技术制备全铝空间光学相机用AlSi10Mg铝合金反射镜。研究结果表明:采用SLM制备的AlSi10Mg铝合金组织致密(相对密度大于99.5%),且退火后力学性能优异;通过单点金刚石车削(SPDT)获得光学级表面,表面粗糙度达8~13 nm,面形精度达到0.28λ(λ为波长,λ=632 nm)。该研究结果可以应用于空间光学反射镜的设计与制造。

关键词:

增材制造;选区激光熔化;铝镜;空间光学;表面性能;金刚石车削;

中图分类号:TB34;TG113 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3088-05

Surface characteristics of selective laser melted AlSi10Mg mirrors

HAN Xiao1, 2, KANG Nan3, JIAO Jianchao1, 2, WANG Chao1, 2

(1. Beijing Institute of Space Mechanics and Electricity, Beijing 100094, China;

2. Beijing Key Laboratory of Advanced Optical Remote Sensing Technology, Beijing 100094, China;

3. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi'an 710072, China)

Abstract: Considering that additive manufacturing(AM) technologies is adapted for the optical components with complex lightweight structure, using the opto-mechanical structure with the same material can reduce temperature sensitivity,selective laser melting(SLM) technology was utilized to fabricate the AlSi10Mg mirror for aluminum alloy space optical sensor. The results show that the relative density of as-fabricated AlSi10Mg sample is above 99.5%, and the tensile strength and the ductility are excellent. The single point diamond turning(SPDT) is applied to deliver the optical surface with thoughness of 8-13 nm and accuracy of 0.28λ(λ=632 nm). The results can be used to manufacture the lightweight space optical mirrors.

Key words: additive manufacturing; selective laser melting; aluminum mirror; space optical; surface characteristics; diamond turning

随着空间光学遥感技术的迅速发展,高分辨率轻质空间光学相机已成为各国研究热点。光学反射镜是决定空间相机的地面分辨率和其他光学特性的关键部件,对材料及加工制造工艺的要求极为苛刻[1]。由于铝合金易于加工制造且成本较低,已成为空间相机结构及光学反射镜较为常用的材料。对于铝合金反射镜,制备工艺和性能是首要考虑的关键问题[2-3]。增材制造(additive manufacturing,AM)技术使得复杂结构成形成为可能,利用金属增材制造技术制备铝合金镜坯及其支撑结构,能够大幅度提升光机结构轻量化程度。同时,光学元件与支撑结构采用同种材料也可以降低光学镜头对温度变化的敏感性[4]。近年来,AlSi10Mg合金因其具有良好的粉末流动性、优异的气密性且成形过程不易产生热裂纹的优点,已经成为一种继TC4钛合金后被广泛研究与应用的增材制造金属材料。作为一种高精度金属增材制造成形方法,选区激光熔化(selective laser melting,SLM)在复杂零件制造方面越来越受到关注[5]。本文利用SLM技术直接通过镜坯的CAD模型成形AlSi10Mg铝合金反射镜镜坯,并进一步表征其显微组织结构、力学和表面性能。

1 试验方法

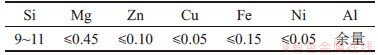

本研究中使用的金属粉末为江西宝航有限责任公司(BAM LTD)生产的气体雾化AlSi10Mg粉末,粉末组分见表1。图1所示为粉末形貌的SEM照片,可见粉末球形态较均匀,平均粒径为30.26 μm(在20~60 μm范围内)。所有试样均利用FS271M选区激光沉积系统制备,该系统采用Yb光纤激光器,激光功率为500 W,激光光斑直径为70 μm,成形过程均在Ar气氛中进行,氧气质量分数低于0.1%。SLM工艺参数如下:激光功率为200 W,扫描速度为1 000 mm/s,铺粉层厚度为30 μm。试样成形后,从基板移除零件之前,进行300 ℃/2 h退火处理,消除成形过程中由于快速凝固导致的内应力。

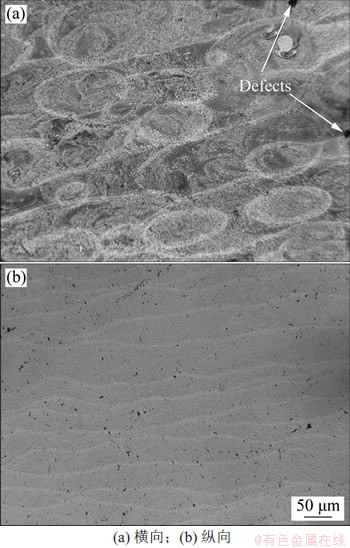

表1 AlSi10Mg 粉末组分(质量分数)

Table 1 Chemical composition of AlSi10Mg powder %

图1 AlSi10Mg粉末SEM 照片

Fig. 1 SEM micrograph of AlSi10Mg powder

利用光学显微镜(OM,型号为Keyence VH-Z50L)和场发射扫描电子显微镜(SEM,型号为 Zeiss Gmini500)观察成形样品的显微组织结构。利用阿基米德排水法测定试样相对密度。拉伸样品尺寸参考GB/T 228.1—2010,通过室温下的拉伸试验(Instron-3382 万能力学试验机)测试热处理前后的样品力学性能,拉伸速率为1 mm/min。通过显微硬度计测量样品的维氏硬度,正四棱锥金刚石压头的面夹角为136°,在压头施加10 N压力并在室温下保持10 s,对每个样品测量5个不同位置的维氏硬度,取平均值。

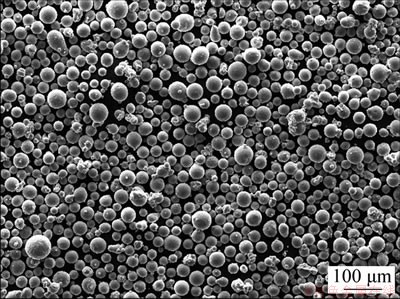

铝合金反射镜原型基于RC光学系统设计。图2所示为反射镜CAD模型,直径为58 mm,光学表面为非球面,镜体背面为轻质结构。在SLM成形过程中,CAD模型转化成STL格式。沿图2中x方向成形镜坯,激光扫描方向则平行于y-z平面。

图2 反射镜三维模型

Fig. 2 3D models of mirror

利用单点金刚石车削(SPDT)对反射镜光学表面进行超精密加工,工艺参数如下:刀具转速为1 200 r/min,切削深度为2 μm,进给量为2 μm/r。采用Zygo白光干涉仪和LuphoScan非接触式轮廓仪对光学加工后镜面粗糙度和面形进行检测。

2 结果与讨论

2.1 显微组织与相对密度

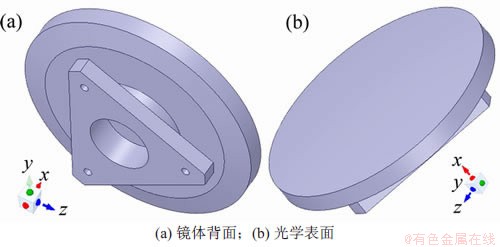

图3所示为经SLM成形试样的横向和纵向显微组织。从图3可以看出:反射镜光学表面具有高致密度和低孔隙率;在SLM加工过程中,由于冷却速率高而形成了细小的等轴晶粒微观结构[6];从横向组织照片可见熔池形貌,从纵向组织照片可见典型的“鱼鳞”形态[7]。观察横向组织可知,熔池宽度超过激光光斑直径(约70 μm)。此外,从沿着成形方向的“鱼鳞”状组织形态最大厚度可知熔池深度为50~150 μm,与30 μm的铺粉层厚度并不完全一致,表明在SLM成形过程中存在重新熔融的新层[8]。

图3 SLM AlSi10Mg的横向与纵向典型组织形貌光学显微照片

Fig. 3 OM micrographs of typical etched microstructure,cross section and longitudinal section of SLM AlSi10Mg

通过排水法测定成形样品的相对密度,设备为赛多利斯BS2245电子天平,其称量精度可达0.1 mg。选择3个长×宽×高均为10 mm×10 mm×10 mm的随炉样品,每个样品测量3次,并取平均值,所得相对密度分别为99.74%,99.43%和99.56%,平均值达99.58%。

2.2 力学性能

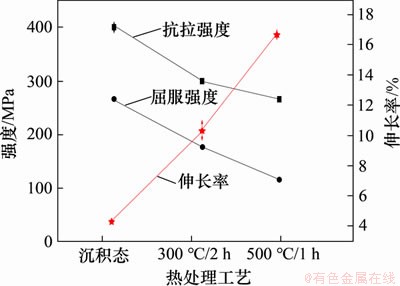

SLM成形的金属零件通常需要经退火处理,以消除残余应力,但可能导致变形和微裂纹[9]。图4所示为不同热处理工艺下经SLM成形的AlSi10Mg试样拉伸性能。沉积态样品的抗拉强度和屈服强度约为400 MPa和270 MPa,优于铸造成形样品的拉伸性能。在经过300 ℃退火2 h后,试样的抗拉强度降低为287.0 MPa,屈服强度降低为176.5 MPa,与沉积态相比分别降低28%和33%。这主要是由于在300 ℃时,Al基体中过饱和的Si被析出,导致拉伸强度降低[10]。同时,其伸长率升高到约10%。随着退火温度进一步升高到500 ℃,在短时间内(约1 h),样品的抗拉强度和屈服强度分别降低33%和45%,分别为250 MPa和100 MPa。反之,随着退火温度升高,伸长率进一步增大。这主要是由于退火温度进一步升高,析出的Si相显著长大。在沉积态或于300 ℃退火处理的样品中,Si相可以起到显著的Orowan强化作用,但当退火温度升高、Si相显著长大时,该强化机制消失,导致拉伸强度显著降低[11]。

图4 SLM AlSi10Mg不同退火条件力学性能

Fig. 4 Tensile properties of SLM AlSi10Mg with different heat treatments

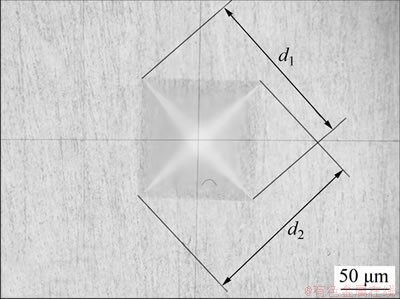

硬度也是表征材料抵抗塑性变形能力的重要指标。LI等[12]研究了热处理对SLM成形的AlSi10Mg试样硬度的影响,发现随着热处理温度和持续时间增加,会出现持续软化的现象。图5所示为经镜坯退火处理(300 ℃/2 h)后表面四棱锥的压痕光学显微照片,经测试,压痕的对角线长度d1≈d2=145 μm,退火前后的维氏硬度(HV)分别为110±10和99±5。

图5 表面压痕光学显微照片

Fig. 5 Optical micrographs of indentation on tested surfaces

2.3 铝镜加工与表面特性测量

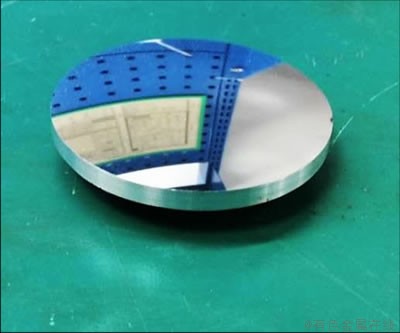

直径为58 mm的镜坯经SLM成形后,采用喷砂处理清理工件表面上的残留粉末,SLM成形镜坯尺寸误差为±0.1 mm。利用超精密金刚石加工方法直接对反射镜光学表面进行车削,表面总切削量约为0.1 mm。图6所示为金刚石单点车削后的铝镜实物照片。

图6 SLM铝合金表面光学加工后实物照片

Fig. 6 Aluminum mirror produced by SLM after diamond point machining

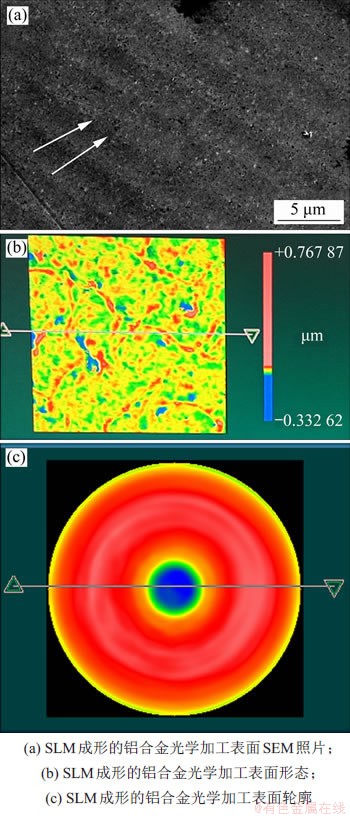

SLM铝合金光学加工表面SEM照片、光学加工表面形态和光学加工表面轮廓如图7所示。从图7(a)可见步长为2 μm的切削痕迹。测得光学加工表面形态(见图7(b))的表面粗糙度为8~13 nm,非接触式轮廓仪测量的表面轮廓(见图7(c))的面形精度约为0.28λ(λ为波长,λ=632 nm)。然而,这种加工的表面粗糙度尚不足以满足高质量的光学成像系统要求,通常还需对铝合金反射镜表面镀制镍(Ni)金属膜层,再进行金刚石精密加工,以提高表面粗糙度[13]。有研究表明,热等静压(HIP)工艺对增材制造铝合金的致密化非常有效,能够去除镜坯体内的所有孔隙,提高表面精密抛光质量[14]。

图7 SLM成形的铝合金光学加工表面SEM照片、光学加工表面形态和光学加工表面轮廓

Fig. 7 SEM images of the turning surface,turning surface morphology detected by interferometer and surface profile of the mirror of SLM aluminum alloy

3 结论

1) 选区激光熔化技术(SLM)可以应用于制造精密光学元件,有助于复杂轻量化结构的金属反射镜镜坯研制。

2) 采用 SLM制造的铝合金非球面镜具有优良的微观结构和优异的力学性能。反射镜表面经超精密金刚石加工后,其表面粗糙度为8~13 nm,面形精度为0.28λ(λ=632 nm),能够满足光学成像应用要求。

参考文献:

[1] 张博文, 王小勇, 赵野, 等. 天基大口径反射镜支撑技术的发展[J]. 红外与激光工程, 2018, 47(11): 1113001.

ZHANG Bowen, WANG Xiaoyong, ZHAO Ye, et a1. Progress on support technique of space-based large aperture mirror[J]. Infrared and Laser Engineering, 2018, 47(11): 113001.

[2] NEWSWANDERA T, CROWTHERA B, GUBBELSB G, et al. Aluminum alloy AA-6061 and RSA-6061 heat treatment for large mirror applications[C]// Proceeding of SPIE. San Diego, California, United States, 2013: 883704-1-15.

[3] 张东阁, 傅雨田. 铝合金反射镜的发展与应用[J]. 红外技术, 2015, 37(10): 814-823.

ZHANG Dongge, FU Yutian. Development and application of aluminum mirrors in optical system[J]. Infrared Technology, 2015, 37(10): 814-823.

[4] AZAM F I, ABDUL RANI A M, ALTAF K, et al. An indepth review on direct additive manufacturing of metals[C]// IOP Conference Series: Materials Science and Engineering, 3rd International Conference on Mechanical, Manufacturing and Process Plant Engineering(ICMMPE 2017) .Batu Ferringhi, Penang, Malaysia, 2017: 012005.

[5] WEI Pei, WEI Zhengying, CHEN Zhen, et al. The AlSi10Mg samples produced by selective laser melting:single track, densification, microstructure and mechanical behavior[J].Applied Surface Science, 2017, 408(30): 38-50.

[6] JAVIDANI M, ARREGUIN-ZAVALA J, DANOVITCH J, et al. Additive manufacturing of AlSi10Mg alloy using direct energy deposition: microstructure and hardness characterization[J]. Journal of Thermal Spray Technology, 2017, 26(4): 587-597.

[7] 赵晓明, 齐元昊, 于全成, 等. AlSil0Mg铝合金3D打印组织与性能研究[J] . 铸造技术, 2016, 37(11): 2402-2404.

ZHAO Xiaoming, QI Yuanhao, YU Quancheng, et a1. Study on microstructure and mechanical properties of AlSi10Mg alloy produced by 3D printing[J]. Foundry Technology, 2016, 37(11): 2402-2404.

[8] TRADOWSKY U, WHITE J, WARD R M, et al. Selective laser melting of AlSi10Mg: influence of post-processing on the microstructural and tensile properties development[J].Materials & Design, 2016, 105(5): 212-222.

[9] FIOCCHI J, TUISSI A, BASSANI P, et al. Low temperature annealing dedicated to AlSi10Mg selective laser melting products[J]. Journal of Alloys and Compounds, 2017, 695: 3402-3409.

[10] CAO Y, LIN X, WANG Q Z, et al. Microstructure evolution and mechanical properties at high temperature of selective laser melted AlSi10Mg[J]. Journal of Materials Science & Technology, 2021, 62: 162-172.

[11] CHEN B, MOON S K, YAO X, et al. Strength and strain hardening of a selective laser melted AlSi10Mg alloy[J]. Scripta Materialia, 2017, 141: 45-49.

[12] LI Wei, LI Shuai, LIU Jie, et al. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: microstructure evolution, mechanical properties and fracture mechanism[J]. Materials Science and Engineering: A, 2016, 663: 116-125.

[13] HILPERT E, HARTUNG J, RISSE S, et al. Precision manufacturing of a lightweight mirror body made by selective laser melting[J]. Precision Engineering, 2018, 53: 310-317.

[14] HERZOG H, SEGAL J, SMITH J, et al. Optical fabrication of lightweighted 3D printed mirrors[C]// Proc of SPIE, 2015: 957308.

(编辑 陈灿华)

收稿日期: 2020 -08 -26; 修回日期: 2020 -09 -22

基金项目(Foundation item):国家自然科学基金资助项目(U1537105) (Project(U1537105) supported by the Natural National Science Foundation of China)

通信作者:韩潇,博士,高级工程师,从事空间光学遥感器先进制造及其材料性能评价技术研究;E-mail:hanxiao1998@126.com

摘要:基于激光增材制造技术适用于复杂轻量化结构光学元件的快速成形,且采用同种材料一体化光机结构能够降低空间光学成像系统的温度敏感性,提高稳定性,利用选区激光熔化(SLM)技术制备全铝空间光学相机用AlSi10Mg铝合金反射镜。研究结果表明:采用SLM制备的AlSi10Mg铝合金组织致密(相对密度大于99.5%),且退火后力学性能优异;通过单点金刚石车削(SPDT)获得光学级表面,表面粗糙度达8~13 nm,面形精度达到0.28λ(λ为波长,λ=632 nm)。该研究结果可以应用于空间光学反射镜的设计与制造。