Plastic deformation mechanisms of AZ31 magnesium alloy under

high strain rate compression

YANG Yong-biao(杨勇彪)1, 2, WANG Fu-chi(王富耻)1, TAN Cheng-wen(谭成文)1,

WU Yuan-yuan(吴园园)1, CAI Hong-nian(才鸿年)1

1. School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China;

2. School of Information and Communication Engineering, North University of China, Taiyuan 030051, China

Abstract:

The twinning and slip activities of AZ31 magnesium alloy sheet at a strain rate of 1 200 s-1 were investigated. Dynamically mechanical properties of various oriented samples were measured using Split Hopkinson Pressure Bar(SHPB). Optical microscope observations reveal that the dominant deformation mechanism is twinning for 90? oriented sample, and is slip for 45? and 0? oriented samples. TEM analysis for samples at a strain of 0.3% shows that the main deformation mechanisms for 90?, 45? and 0? oriented sample are ![]() and

and ![]() twinning, basal slip and non basal slip, respectively. The main features of the true stress—true strain curves can be explained based on deformation mechanism analysis.

twinning, basal slip and non basal slip, respectively. The main features of the true stress—true strain curves can be explained based on deformation mechanism analysis.

Key words:

AZ31 magnesium alloy; twinning; basal slip, non basal slip;

1 Introduction

The increasing demand for better fuel economy, higher operating efficiency and related reduction of exhaust gases in automotive applications have prompted intensive research into lightweight structural materials. Magnesium alloy offers great potential for automobile construction and further technical applications in aeronautics, electronics and other fields due to its low density, high specific strength and high specific stiffness[1-2]. However, the limited ductility and poor formability of magnesium alloys at room temperature are often attributed to the difficulty in activating a sufficient number of independent slip and twinning systems. During deformation, plastic strain is accommodated mostly by basal slip and tension twinning ![]() , resulting from compression in final textures, in which most of the c-axes are approximately aligned with the compression direction[3]. The mechanical properties anisotropy of magnesium alloy plate under quasi static loading condition has been investigated extensively. However, most researches were carried out on tensile properties along transverse and rolling direction due to the limited dimension of normal direction[4-6]. The dynamic mechanical properties of magnesium alloy has aroused the interests of several research groups due to its potential application in military field[7-9]. Nevertheless, the vast majority of investigations only touch upon the effects of the second phase and grain refinement, and seldom studies have focused on the dynamic mechanical property anisotropy of magnesium alloy sheet. Therefore, an experiment has been designed, where the angle between the loading direction and normal direction of AZ31 magnesium alloy sheet can be varied for understanding the operation of different slip systems, twinning modes and dynamic mechanical properties under compressive loading.

, resulting from compression in final textures, in which most of the c-axes are approximately aligned with the compression direction[3]. The mechanical properties anisotropy of magnesium alloy plate under quasi static loading condition has been investigated extensively. However, most researches were carried out on tensile properties along transverse and rolling direction due to the limited dimension of normal direction[4-6]. The dynamic mechanical properties of magnesium alloy has aroused the interests of several research groups due to its potential application in military field[7-9]. Nevertheless, the vast majority of investigations only touch upon the effects of the second phase and grain refinement, and seldom studies have focused on the dynamic mechanical property anisotropy of magnesium alloy sheet. Therefore, an experiment has been designed, where the angle between the loading direction and normal direction of AZ31 magnesium alloy sheet can be varied for understanding the operation of different slip systems, twinning modes and dynamic mechanical properties under compressive loading.

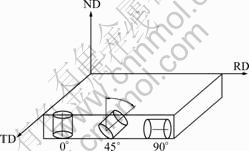

The material was a commercially available AZ31 (Mg-3Al-1Zn-0.3%Mn (mass fraction)) hot rolled sheet, which was homogenized at 600 K for 1 h. Basal planes were aligned almost parallel to rolling plane, as shown in Fig.1. Cylinders (d7 mm×7 mm) were cut from this sheet for compression testing with the cylinder axis 0?, 45? and 90? from ND (Fig.2). The high strain rate compression tests were carried out using Split Hopkinson Pressure Bar(SHPB). Samples at different strains (0.3%, 2%, 4% and 6%) were obtained by using titanium alloy stopper ring of different heights under dynamic compressive loading. The inner diameter of the stopper ring is 7.5 mm and its outer diameter is 14.5 mm. Postmortem observations were carried out on the cross section of the samples using optical microscopy(OM), and on the section with its normal direction 90?, 45? and 0? from cylinder axis using transmission electron microscopy(TEM). TEM specimens were prepared in the following steps. 2 mm×2 mm×0.5 mm slices were cut off, and mechanically ground to 0.03-0.05 mm. Then the thin foils were ion milled at room temperature in a Gatan Model 691 with a small incident angle till perforation. All the thin foils were examined in a JEOL-JEM-200CX TEM operated at 160 kV.

Fig.1 {0002} pole figures of AZ31 magnesium sheet

Fig.2 Schematic illustration of AZ31 alloy sample orientations for dynamic compression testing

3 Results and discussion

3.1 Dynamic mechanical anisotropy

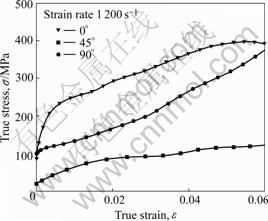

The true stress—true strain curves of 90?, 45? and 0? samples at a strain rate of 1 200 s-1 are presented in Fig.3. The strain hardening rate increases with increasing strain for 90? sample, and decreases for 45? and 0?samples, exhibiting different trends approximately. The flow stress of 90? sample is higher than that of 45? sample and lower than that of 0? sample with the stresses at a strain of 0.3% for 90?, 45? and 0? samples being 120 MPa, 40 MPa, and 200 MPa, respectively. The dynamic mechanical properties of AZ31 magnesium sheet are anisotropic.

Fig.3 Dynamic compressive properties of various oriented AZ31 alloy samples at strain rate of 1 200 s-1

3.2 Microstructure analysis

Fig.4 presents the microstructure evolution of 90?,

45? and 0? samples, respectively. Twinning platelets can be seen at a strain of 0.3%, as shown in Fig.4(a1); and twinned area fraction increases with increasing strain for 90? sample, as shown in Figs.4(a2)-(a4). Twinning platelets can hardly be seen both for 45? (Figs.4(b1)-(b4)) and 0? samples with increasing strain (Figs.4(c1)-(c4)).

For insight understanding of slip and twinning activities, TEM observations were also carried out for samples at a strain of 0.3% and at a strain rate of 1 200 s-1. Fig.5 displays typical TEM micrographs showing deformation twin and selected area diffraction pattern for 90°sample. Twin boundary(TB) and basal plane (0001) are also marked. The selected area diffraction pattern in Fig.5(a) shows that the twin system is ![]() , while the selected area diffraction pattern in Fig.5(b) shows that the twin system is

, while the selected area diffraction pattern in Fig.5(b) shows that the twin system is ![]() . Due to the limited slip system at room temperature in HCP Mg alloys, twinning has been theoretically and experimentally proven to be the dominant model that is responsible for plastic deformation. Although several twinning systems have been experimentally observed contributing to plastic deformation in magnesium alloy [10-11],

. Due to the limited slip system at room temperature in HCP Mg alloys, twinning has been theoretically and experimentally proven to be the dominant model that is responsible for plastic deformation. Although several twinning systems have been experimentally observed contributing to plastic deformation in magnesium alloy [10-11],![]() and

and![]() twins are the two major twinning systems,

twins are the two major twinning systems, ![]() twin in particular. Due to the smallest twinning shear strain (ε=0.130 2),

twin in particular. Due to the smallest twinning shear strain (ε=0.130 2), ![]() governs the deformation in equal channel angular extrusion(ECAE), severe plastic deformation(SPD) and other compression processes, while

governs the deformation in equal channel angular extrusion(ECAE), severe plastic deformation(SPD) and other compression processes, while ![]() twin usually appears at later stage of plastic deformation, followed by fractures[12-14]. In the present work, both

twin usually appears at later stage of plastic deformation, followed by fractures[12-14]. In the present work, both ![]() and

and ![]() twins are found in TEM observations at a strain of 0.3%, therefore, it is sobering to conclude that at the initial stage of plastic deformation of AZ31 alloy under high strain rate loading, the dominant mechanisms of plastic deformation

twins are found in TEM observations at a strain of 0.3%, therefore, it is sobering to conclude that at the initial stage of plastic deformation of AZ31 alloy under high strain rate loading, the dominant mechanisms of plastic deformation

are ![]() and

and ![]() twins, which are different from the plastic deformation mechanisms in quasi static loading conditions.

twins, which are different from the plastic deformation mechanisms in quasi static loading conditions.

Fig.4 Microstructure evolution of AZ31 sheet at strain rate of 1 200 s-1: (a) 90?-oriented sample, 1 ε=0.3%, 2 ε=2.0%, 3 ε=4.0%, 4 ε=6.0%; (b) 45?-oriented sample, 1 ε=0.3%, 2 ε=2.0 %, 3 ε=4.0%, 4 ε=6.0%; (c) 0?-oriented sample, 1 ε=0.3%, 2 ε=2%, 3 ε=4%, 4 ε=6.0%

Fig.5 TEM micrographs of 90?-oriented AZ31 sample (![]() =1 200 s-1 , ε=0.3%): (a)

=1 200 s-1 , ε=0.3%): (a) ![]() deformation twin; (b)

deformation twin; (b) ![]() deformation twin

deformation twin ![]()

Another feature of the microstructure within Fig.5(b) is the dislocations both inside and outside the deformation twining. These dislocations marked by little arrow lie either on the basal plane or on the non-basal planes, which can be either the prismatic planes or the pyramidal planes.

Since twinned area fraction increases with increasing strain for 90? sample according to OM analysis and the main deformation mechanism at the initial stage of plastic deformation has also been proven to be twinning, twinning should be the predominant deformation mechanism.

Fig.6 presents the TEM micrograph showing the dislocations and its selected area diffraction pattern of 45? sample. Extensive dislocation tangles can be found on the basal plane, while few dislocations can be seen on non basal plane for 45? sample.

Fig.6 TEM micrograph and selected area diffraction pattern ![]() of 45?-oriented sample (

of 45?-oriented sample (![]() =1 200 s-1, ε=0.3%)

=1 200 s-1, ε=0.3%)

Fig.7 presents the TEM micrographs showing the microstructure of 0? sample. The dislocation density on basal plane is much lower (Fig.7(a)) than that of 45? sample, and the dislocation density on non basal plane is much higher than that of 45? sample (Fig.7(b)). Therefore, basal slip is the main deformation mechanism for 45? sample, while non basal slip is the main deformation mechanism for 90? sample, which is similar to the plastic deformation mechanism under quasi static loading conditions[15].

Fig.7 TEM micrographs of 0?-oriented sample (![]() =1 200 s-1, ε=0.3%): (a) B//[0001]; (b)

=1 200 s-1, ε=0.3%): (a) B//[0001]; (b)![]()

However, the dislocation tangles on basal plane are not easy to form under low strain rate loading[16]. Different plastic mechanisms are the reasons for different stress level at a strain of 0.3% for different oriented samples. Since not much twin platelets can be seen during plastic deformation for 45? and 0? samples according to OM analysis and dislocation slip is the main deformation mechanism at the initial stage of plastic deformation, dislocation slip is the predominant deformation mechanism. Dislocation slip is the main deformation mechanism both for 45? sample and 0? sample resulting in the decrease of strain hardening rate with increasing strain. Twinning is the main plastic deformation mechanism for 90? sample leading to increase of strain hardening rate.

4 Conclusions1) Dynamic mechanical property anisotropy at a strain rate of 1 200 s-1 of AZ31 sheet can be explained based on different plastic deformation mechanisms of samples with compression axis 90?, 45? and 0? from normal direction(ND) of the sheet.

2) Twinning is the dominant deformation mechanism for 90? sample with ![]() twinning and

twinning and ![]() twinning at a strain of 0.3%.

twinning at a strain of 0.3%.

3) Slip is the controlling deformation mechanism for 45? and 0? samples with basal slip and non basal slip being the main deformation mechanisms at a strain of 0.3%, respectively.

References

[1] CHEN Zhen-hua. Magnesium alloy [M]. Beijing: Chemical Industry Press, 2004: 1-5. (in Chinese)

[2] CHEN Zhen-hua. Wrought magnesium alloy [M]. Beijing: Chemical Industry Press, 2005: 1-10. (in Chinese)

[3] PHILIPPE M J. Texture formation in hexagonal materials [J]. Mater Sci Forum, 1994, 157(2): 1337-1350.

[4] BARNETT M R, NAVE M D, BETTLES C J. Deformation micro- structures and textures of some cold rolled Mg alloys [J]. Mater Sci Eng A, 2004, 386(1/2): 205-211.

[5] BARNETT M R. Twinning and the ductility of magnesium alloys (Part I): “Tension” twins [J]. Mater Sci Eng A, 2007, 464(1/2): 1-7.

[6] LAN Jiang, JONAS J J. Influence of  extension twinning on the flow behavior of AZ31 Mg alloy [J]. Mater Sci Eng A, 2007, 445(1): 302-309.

extension twinning on the flow behavior of AZ31 Mg alloy [J]. Mater Sci Eng A, 2007, 445(1): 302-309.

[7] MUKAI T, YAMANOI M. Effect of grain refinement on tensile ductility in ZK60 magnesium under dynamic loading [J]. Mater Trans, 2001, 42(7): 1177-1181.

[8] YOKOYAMA T. Impact tensile stress–strain characteristics of wrought magnesium alloys [J]. Strain, 2003, 39(4): 167-175.

[9] KLIMANEK P. Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates [J]. Material Sci Eng A, 2002, 324(1): 145-150.

[10] YOO M H. Interactions of slip dislocations with twins in HCP metal [J]. Trans Met Soc of AIME, 1969, 245(9): 2051-2060.

[11] KITAHARA T, ANDO S, TSUSHIDA M, KITAHARA H, TONDA H. Deformation behavior of magnesium single crystals in c-axis compression [J]. Key Engineering Materials, 2007, 345/346: 129-132.

[12] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP [J]. Acta Mater, 2003, 51(11): 3073-3084.

[13] NAVE M D, BARNETT M R. Microstructures and textures of pure magnesium deformed in plane-strain compression [J]. Script Mater, 2004, 51(9): 881-885.

[14] BARNETT M R. Twinning and the ductility of magnesium alloys (Part II): “Contraction” twins [J]. Mater Sci Eng A, 2007, 464(1/2): 8-16.

[15] JAIN A, AGNEW S R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet [J]. Mater Sci Eng A, 2007, 462(1/2): 29-36.

[16] SUN H Q, SHI Y N, ZHANG M P. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy [J]. Acta Mater, 2007, 55(3): 975-982.

Corresponding author: TAN Cheng-wen; Tel: +86-10-68912712-001; E-mail: tanchengwen@126.com

Abstract: The twinning and slip activities of AZ31 magnesium alloy sheet at a strain rate of 1 200 s-1 were investigated. Dynamically mechanical properties of various oriented samples were measured using Split Hopkinson Pressure Bar(SHPB). Optical microscope observations reveal that the dominant deformation mechanism is twinning for 90? oriented sample, and is slip for 45? and 0? oriented samples. TEM analysis for samples at a strain of 0.3% shows that the main deformation mechanisms for 90?, 45? and 0? oriented sample are ![]() and

and ![]() twinning, basal slip and non basal slip, respectively. The main features of the true stress—true strain curves can be explained based on deformation mechanism analysis.

twinning, basal slip and non basal slip, respectively. The main features of the true stress—true strain curves can be explained based on deformation mechanism analysis.