DOI:10.19476/j.ysxb.1004.0609.2019.08.05

金属箔片阻隔Mg/Al超声波焊接界面反应的有效性

李铭锋1,王官明1,朱政强1,张义福1,胡清华2,肖乾坤1

(1. 南昌大学 机电工程学院,南昌 330031;

2. 桂林理工大学 材料科学与工程学院,桂林 541004)

摘 要:

本文以AZ31B Mg/6061-T6Al为研究对象,对界面添加锌、铜和银箔并采用超声波点焊进行焊接来考察接头性能。采用金相显微镜、SEM、XRD和拉伸试验机等研究了接头的显微组织和力学性能。结果表明: Mg/Al接头在焊接时间为1.1 s时接头温度达358.6 ℃,界面形成由Al12Mg17和Al3Mg2组成的连续IMC脆性层,降低了接头力学性能,断口为脆性解离断裂;添加锌箔能降低获得可靠接头的焊接时间,0.5 s时接头最大拉剪力为1154.4 N、撕裂力为146.9 N,断口表现出韧性断裂特征,随焊接时间延长锌箔的有效性降低;添加铜箔可有效阻隔Mg-Al系IMC的形成,但由于Mg/Cu焊接性差,导致接头力学性能较低;添加银箔亦能有效阻隔Mg-Al系IMC的形成,1.1 s时接头拉剪力达到最大值为1141.4 N,但撕裂力较小(72.2 N),Mg/Ag界面断口呈现脆性断裂特征。

关键词:

超声波点焊;Mg/Al异质合金;金属间化合物(IMC);金属箔片;力学性能;

文章编号:1004-0609(2019)-08-1606-10 中图分类号:TG453.9 文献标志码:A

目前汽车工业应汽车轻量化发展理念要求,正越来越广泛地采用具有密度低、比强度和比刚度高等优点的铝合金和镁合金来代替钢材以实现车身轻量化,进而实现提升汽车的燃油效率和节能减排的目的[1-4]。为了充分利用镁合金与铝合金的优异性能,将两种材料进行焊接而获得可靠的连接构件已成为必然趋势[5]。但是镁和铝之间的物理性质存在较大的差异,并且都具有较活泼化学性质,对Mg/Al采用常规焊接方法焊接时,焊缝容易夹杂氧化物、形成气孔和裂纹等缺陷[6-7];而焊缝中极容易形成大量脆性Mg-Al系IMC是Mg/Al焊接的技术难点[8-10]。为实现镁铝异质合金的可靠连接,人们应用了包括熔化焊、固相焊中的先进连接技术,如激光焊接[11]、钨极氩弧焊[12],搅拌摩擦焊[13]、超声波焊[8, 14]和扩散焊[15]等方法,但不管应用何种方法,焊缝中均会形成大量的脆性IMC而降低焊接接头性能。

为了减少镁/铝焊缝中的IMC,研究者采用添加中间层的方法来阻隔其出现以提升接头性能[16-17]。如PANTELI等[8]在AZ31/ AA6111超声波焊接中,分别采用物理气相沉积法和冷喷涂法在镁板表面制作1 μm锰层和100 μm铝层,发现两种涂层均可降低IMC层的平均厚度,且铝层能有效地改善接头的断裂能。崔庆波等[18]在铝合金表面采用化学镀法涂覆一层3 μm锡层,采用超声波点焊对其与镁合金焊接发现,锡层能有效地阻止镁和铝的相互扩散,抑制了Mg-Al系IMC的形成,镀锡层的接头拉剪强度提升了19.6%。徐光晨等[15]在镁合金中添加稀土镧元素,分析在Mg/Al扩散焊中镧对组织及性能的影响,结果表明镧能减少界面处的β-Mg17Al12形成,与铝形成高熔点、高热稳定性Al11La3相,当加入1% 稀土镧时接头抗剪强度提高54%。DAI等[19]采用电弧辅助超声波焊接系统焊接添加0.3 mm锡夹层的镁铝异种金属,发现在界面中Mg2Sn和锡基固溶体取代Mg-Al系的IMC的形成,并且极大地提升了接头峰值荷载。GAO等[12]在6061铝合金和AZ31B镁合金TIG焊中,研究不同厚度的锌箔对接头性能的影响,发现适当的锌过渡层能有效改善Mg/Al接头的微观结构,减少了接头中的Mg-Al系的IMC。

在Mg/Al焊接时采用不同方法添加中间层能有效抑制IMC的形成并提升接头性能,其中直接添加箔片是为最简便的一种方法。虽然有相关文献报道了在Mg/Al焊接中添加锌、铜和银中间夹层[12, 20-21],但尚未发现应用在超声波焊接中的研究报道。本文采用锌、铜和银箔片作为中间层进行镁铝异质合金超声波焊接,分析界面连接行为和接头的力学性能,对接头的显微结构、元素分布及断口形貌进行了研究。

1 实验

采用厚度为0.5 mm的AZ31B镁和6061-T6Al合金板进行超声波搭接点焊试验,样品规格为100 mm×20 mm×0.5 mm,搭接量为40 mm;采用厚度均为100 μm的锌、铜和银箔片(纯度≥99.99%)作为中间夹层。试验使用的超声波点焊设备型号为 NC-2020A (见图1),超声振动频率为20 kHz,最大输出功率为2 kW,焊点面积为 15 mm×6 mm。

母材与箔片分别采用1200#和5000#砂纸打磨表面氧化膜,用酒精擦除表面然后采用丙酮去除油脂;固定焊接压力(F)和焊接功率(P)分别为1145 N和1.4 kW,焊接时间(t)为0.5、0.7、0.9和1.1 s;每组试验分别焊接3个试样进行拉剪力和撕裂力测试,分别参照国标GB/T 7124—1986和GB/T 2790—1995进行,拉剪和撕裂试验加载速度分别为1和2 mm/min。首先,把箔片点焊到镁合金表面进行添加中间夹层,点焊参数为F=344 N、P=0.3 kW;t=0.3 s。其次,采用SEM分析接头界面的反应行为;采用EDS和XRD分析接头的生成相和元素分布;采用WDW3050万能试验机对接头进行拉剪力和撕裂力试验。再次,采用型号为AT4508多路测温仪和直径为0.2 mm的K型热电偶测量界面温度,测量时设置采集间隔为0.1 s。

2 结果与分析

2.1 界面反应行为

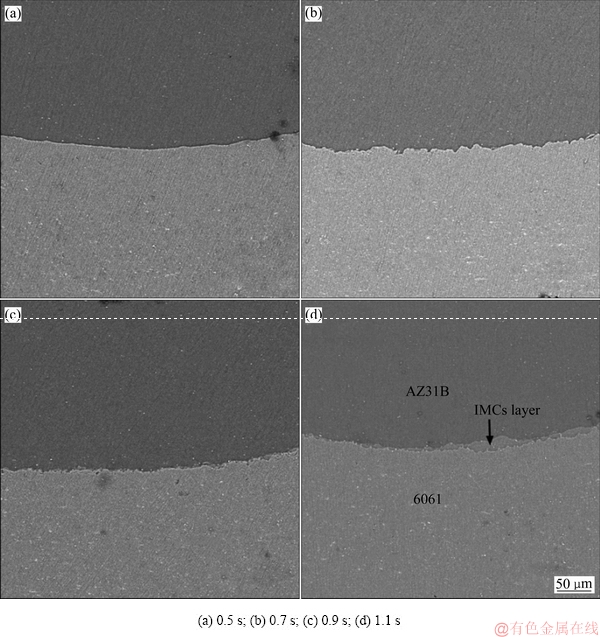

图2所示为在不同焊接时间下Mg/Al超声波点焊接头截面BSE像。由图2可见,焊接界面紧密结合,未出现裂纹、虚焊等缺陷;随着焊接时间增加,接头结合面呈现锯齿状,这是由于超声波焊接为固相连接技术,在焊接过程中,焊极对相互接触的母材施加横向剪切力和纵向的压力,在高频声波的振动和高应变率作用下迫使表面氧化膜破碎、表面升温和局部软化而产生塑性变形,从而产生机械互锁而实现有效连接。

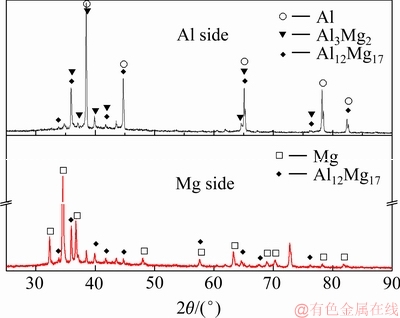

焊接时间为0.5和0.7 s时界面均未出现脆性的IMC层;而当焊接时间为0.9 s时,界面出现了细微不连续的IMC岛;焊接时间增加到1.1 s时,界面形成了约15 μm厚且连续的IMC层。对焊接时间为1.1 s的接头断口进行XRD扫描,结果如图3所示,可知接头界面形成的脆性IMC层由靠近Mg侧的Al12Mg17和靠近铝侧的Al3Mg2组成。对于IMC层的固态生长规律一般遵循抛物线规律,因此IMC 层厚度可以采用下列抛物线方程来计算[22]:

(1)

(1)

式中:X是IMC层的厚度;t和K分别是加热时间和生长速率常数,而生长速率常数K是在给定温度下通过Arrhenius方程计算

(2)

(2)

式中:K0是指前因子;Q是活化能;R是玻尔兹曼常数;T是热力学温度。采用PANTELI等[22]通过线性回归拟合出来的K0 (5×104 μm2/s)和Q (65 kJ/mol)值,结合本工作测量的峰值温度,计算1.1 s时IMC层的厚度为0.33 μm,这与实际焊接中形成的IMC层厚度差别非常大。这是由于IMC的形成和增厚通过扩散进行,在超声波焊接中,高应变率变形下能迅速增加空位浓度,促进位错增值和细化晶粒等,进而提升了元素扩散系数[23],因此IMC层在很小的焊接时间内迅速增厚。由于镁在铝中的扩散率更大,因此Al12Mg17 在界面率先成核并长大,随着时间推移形成连续反应层;随后连续的Al12Mg17反应层阻碍了镁向继续铝侧扩散,此时Al3Mg2在Al12Mg17/Al界面成核并以更快的速度长大,最终IMC层由Al12Mg17和Al3Mg2组成[24]。

图1 超声波焊机及焊点形貌

Fig. 1 Ultrasonic welding equipment and sonotrode shape

图2 不同焊接时间下Mg/Al接头的BSE像

Fig. 2 BSE images of Mg/Al joint with different welding time

图3 焊接时间为1.1 s的镁/铝接头断口XRD谱

Fig. 3 XRD patterns of Mg/Al joint fracture with welding time of 1.1 s

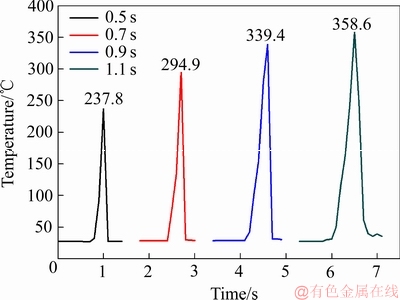

随着焊接时间延长,接头界面温度改变如图4所示,当焊接时间为1.1 s时界面峰值温度为358.6 ℃,这也表明超声波焊接为固相连接技术,界面温度尚未达到母材金属的熔点,而是通过界面元素扩散和形成机械嵌合实现有效连接;但本次温度测量与PANTELI等[22]测量Mg/Al接头温度存在异同,其测量焊接时间大于0.512 s时,Mg/Al接头温度均大于400 ℃,造成这种差异的原因可能与材料厚度、焊接设备及测温设备的采集精度等因素相关。

图4 Mg/Al接头的温度测量结果

Fig. 4 Temperature measurement results of Mg/Al joints

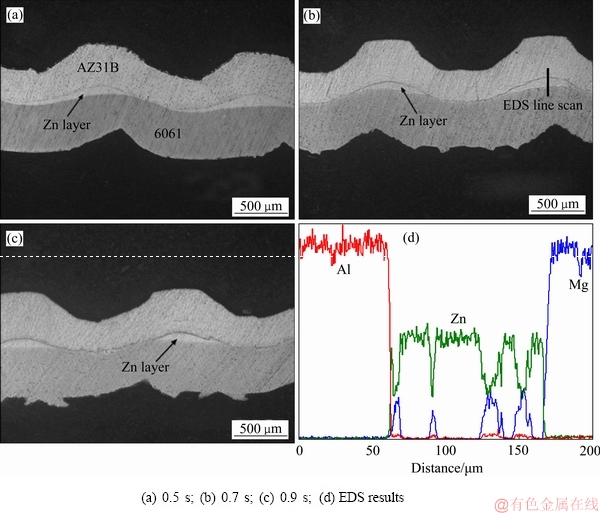

图5所示为添加锌箔接头显微组织和EDS扫描结果。由图5可见,在不同焊接时间下均能形成无缺陷的有效接头,当焊接时间为0.5 s时锌层呈连续状态,随焊接时间持续延长界面锌层的连续性降低;这是由于锌为较软的金属且熔点(419.53 ℃)很低,在界面摩擦力学作用下锌箔受高温软化,大部分锌箔被挤出焊缝,界面只形成部分岛状锌层;但由于锌箔起到缓冲作用,减缓了Mg/Al界面直接接触进而推迟了Mg-Al系IMC形成,当焊接时间达到1.1 s时,接头界面温度较高而导致锌熔化并把镁板挤裂而导致焊缝失效。从EDS线扫描显示在锌层中存在镁元素,表明在焊接时间为0.7 s时锌层就已经破裂成不连续的锌块,导致镁元素迅速扩散而填充到锌块之间。

图5 不同焊接时间下的Mg/Zn/Al接头显微组织和EDS线扫描结果

Fig. 5 Microstructure and EDS line scan results of Mg/Zn/Al joint with different welding time

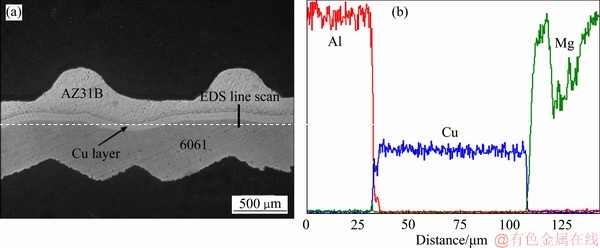

图6 焊接时间为1.1 s的Mg/Cu/Al接头显微组织和EDS线扫描结果

Fig. 6 Microstructure(a) and EDS line scan results(b) of Mg/Cu/Al joint with welding time of 1.1 s

图6所示为焊接时间为1.1 s的Mg/Cu/Al接头显微组织和EDS线扫描结果。由图6可见,当焊接时间为 1.1 s时添加铜箔的接头界面结合良好,连续均匀分布的铜层有效阻隔了Mg-Al系IMC形成。从EDS分析结果可以看出,Al/Cu界面形成厚度约为6 μm的扩散层,由于Al/Cu超声波焊接时扩散系数(1.4×103 m2/s[25])很大,因此Al/Cu界面形成较厚扩散层。由于铜与镁的物、化性质和晶体结构差异较大而焊接性较差,因此Mg/Cu界面仅形成约1 μm的扩散层。

焊接时间为1.1 s的添加银箔的接头显微组织如图7所示。由图7可见,界面中银层呈连续状态并实现无缺陷的可靠连接,成功地阻隔镁和铝互扩散从而阻止Mg-Al系的IMC的形成。EDS线扫描结果显示在键合区元素的浓度分布,从EDS结果可以获得Al/Ag和Mg/Ag之间元素扩散层厚度分别约为2 μm和6 μm,造成这种差异是由于银在镁中的扩散速率(D0=3.65×10-4 m2/s)比银在铝中的扩散速率(D0= 1.18×10-5 m2/s)大[21]。

2.2 力学性能分析

图7 焊接时间为1.1 s的Mg/Ag/Al接头显微结构和EDS线扫描结果

Fig. 7 Microstructure and EDS line scan results of Mg/Ag/Al joint with welding time of 1.1 s

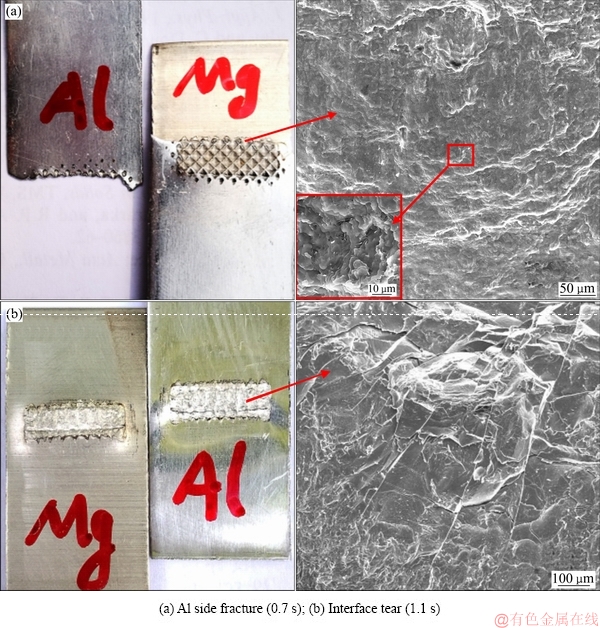

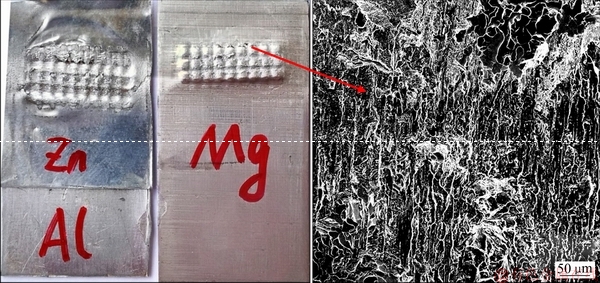

图8 Al/Mg接头撕裂试验的断裂形式及断口形貌

Fig. 8 Fracture form and fracture morphology of Al/Mg joint tear test

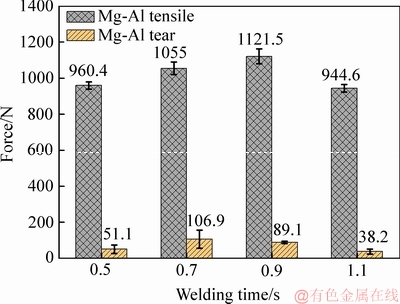

对Mg/Ag接头进行拉剪和撕裂实验时,接头失效形式主要有铝侧断裂和界面撕裂,如图8所示。由图8 可知,当焊接时间为0.7 s时,断口由大量平滑小平面组成,呈现韧性断裂特征,这是由于焊缝界面通过机械嵌合达到有效连接且尚未形成脆性IMC,此时接头的撕裂力达到最大(106.9 N)。当焊接时间为1.1 s时,接头失效形式为界面撕裂且断口表面呈现大平面解离断裂特征,且断口存在大量的二次裂纹,表明接头失效迅速发生。结合图2分析结果可知,由于界面形成连续IMC层导致接头力学性能迅速下降,此时接头的拉剪力和撕裂力达到最低值分别为944.6 N和38.2 N。如图9所示,Mg/Al接头的拉剪和撕裂力均随着焊接时间增大而先增大后减小。当焊极时间为0.9 s时,拉剪力达到最大值为1121.5 N,但撕裂力较0.7 s时的小,这由于在0.9 s时界面局部区域出现了细小的岛状IMC,接头在撕裂力作用下裂纹率先从IMC岛边缘萌生扩展导致断裂失效。

图9 Mg/Al接头拉剪力和撕裂力

Fig. 9 Tensile and tearing force of Mg/Al joint

图10所示为Mg/Zn/Al接头拉剪和撕裂力试验结果。由图10可知,随着焊接时间延长,拉剪力减小而撕裂力先减小后增加;当焊接时间为0.5 s时,拉剪力最大为1154.4 N。这由于在0.5 s 时绝大部分锌箔能保留在焊缝界面且锌质地较软能快速实现塑性变形而形成机械嵌合连接。如图11所示,接头的撕裂断口微观形貌显示大部分区域呈现出韧性断裂特征。当焊接时间延长到0.7 s时,由于部分锌层在高应变率变形和高温作用下软化而挤出焊缝,且降低了Mg/Al界面直接接触时间,因而界面结合较差导致拉剪力和撕裂力下降。0.9 s时焊缝界面结合提升,但由于局部锌箔的熔化对镁板的影响和接头横截面厚度削减,降低了焊缝承受的拉剪力。

图10 Mg/Zn/Al接头拉剪力和撕裂力

Fig. 10 Tensile and tearing force of Mg/Zn/Al joint

图11 焊接时间为0.5 s 的Mg/Zn/Al接头撕裂试验的断裂形式及断口形貌

Fig. 11 Fracture form and fracture morphology of Mg/Zn/Al joint tear test with welding time of 0.5 s

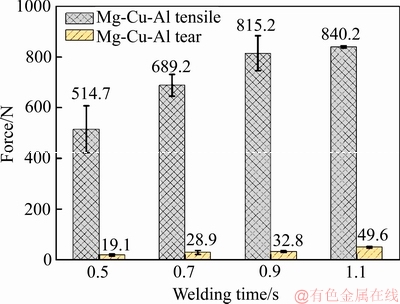

图12 Mg/Cu/Al接头拉剪力和撕裂力

Fig. 12 Tensile and tearing force of Mg/Cu/Al joint

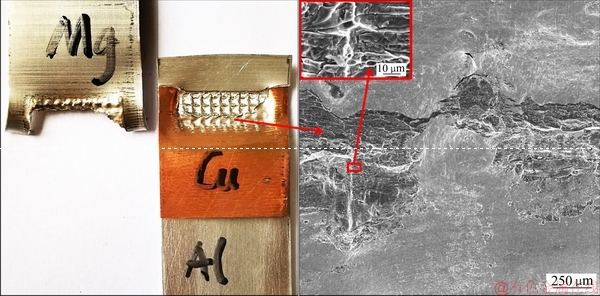

图12所示为接头添加铜箔后的拉剪和撕裂力测试结果。由图12可知,焊接时间延长时,拉剪力和撕裂力均增加,最大值分别为840.2 N和49.6 N,这比Mg/Al接头的力学性能更低。由于铜箔加入增加了焊接界面,铜的熔点(1086 ℃)较Mg(650 ℃)的高,因此需要增加焊接时间才能形成有效连接。但随着焊接时间提升导致镁板首先软化变形和横截面厚度削减严重,在焊缝受拉剪力和撕裂作用时均从镁板侧断裂失效(见图13),这是力学性能很小的原因之一。由于铜与镁性质差异大而焊接性能较差,从Mg/Cu/Al接头的撕裂断口形貌图(见图13)可以看出,1.1 s时Mg/Cu大部分断口面光滑而未能牢固连接,形成牢固结合局部区域断口呈脆性断裂,且存在大量二次裂纹。有研究表明[26]在大的焊接能量下Mg/Cu界面会形成脆、硬的Mg2Cu,这也是局部区域存在脆断和接头力学性能低的原因。因此铜箔不适合作中间夹层来提升Mg/Al接头性能。

图13 焊接时间为1.1 s 的Mg/Cu/Al接头撕裂试验的断裂形式及断口形貌

Fig. 13 Fracture form and fracture morphology of Mg/Cu/Al joint tear test with welding time of 1.1 s

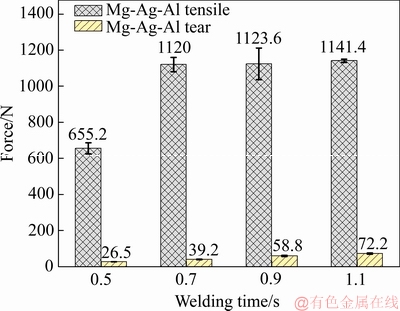

接头添加银箔的拉剪和撕裂力测试结果如图14所示。由图14可知,焊接时间为0.5 s时,接头拉剪力和撕裂力分别为655.2 N和26.5 N,这由于焊接时间短界面未充分软化接触而形成有效连接;在0.7~1.1 s时接头承受拉剪力较0.5 s迅速增大后并几乎保持稳定,1.1 s时接头达到最大拉剪力为1141.4 N。撕裂力随焊接时间提升而缓慢增加,最大值仅为72.2 N。Mg/Ag界面撕裂如图15所示,表明添加银箔接头虽然提升了拉剪力,但仍存在Mg/Ag性能较薄弱界面;由断口形貌图(见图15)可以看出,接头断口呈现脆性断裂特征,且存在大量二次裂纹。

图14 Mg/Ag/Al接头拉剪力和撕裂力

Fig. 14 Tensile and tearing force of Mg/Ag/Al joint

图15 焊接时间为1.1 s 的Mg/Ag/Al接头撕裂试验的断裂形式及断口形貌

Fig. 15 Fracture form and fracture morphology of Mg/Ag/Al joint tear test with welding time of 1.1 s

3 结论

1) 采用超声波点焊可以成功实现镁铝异质合金焊接,在焊接时间为0.9 s时达到最大的拉剪力为1121.5 N和较大的撕裂力为89.1 N;当焊接时间为1.1 s时接头界面出现由Al12Mg17和Al3Mg2组成的连续脆性IMC层,这严重降低了接头的力学性能,接头为脆性断裂;接头温度随着焊接时间延长而增大,在1.1 s时界面温度最大值为358.6 ℃。

2) 界面添加锌箔能降低焊接时间而实现可靠连接,0.5 s时接头拉剪力和撕裂力分别为1154.4 N和146.9 N,断口为表现出韧性占优特征;随着焊接时间延长,存留在焊缝的锌层减少,当焊接时间达1.1 s时由于锌层熔化而挤裂镁板导致接头失效。

3) 界面添加铜箔能有效阻隔Mg-Al系IMC的形成,但由于铜的硬度较大且熔点高,焊接时间延长时镁板横截面削减严重,且由于镁与铜焊接性极差,接头受力时首先从镁板断裂失效;Mg/Cu断口面大部分表面光滑,部分牢固连接区域为脆性断裂且存在大量二次裂纹,因此铜箔不适合作为中间层来提升Mg/Al接头性能。

4) 加入银箔亦能有效阻隔Mg-Al系IMC的形成,1.1 s接头拉剪力达到最大为1141.4 N较Mg/Al接头的高,但撕裂力较小(72.2 N),Mg/Ag界面为接头键合的薄弱面,其断口呈现脆性断裂特征。

REFERENCES

[1] 张丽娟, 周惦武, 刘金水, 徐少华, 乔小杰, 李 升. 钢/铝异种金属添加粉末的激光焊接[J]. 中国有色金属学报, 2013, 23(12): 3401-3409.

ZHANG Li-juan, ZHOU Dian-wu, LIU Jin-shui, XU Shao-hua, QIAO Xiao-jie, LI Sheng. Laser welding of steel/aluminum dissimilar metal with powder addition[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3401-3409.

[2] PENNER P, LIU L, GERLICH A, ZHOU Y. Feasibility study of resistance spot welding of dissimilar Al/Mg combinations with Ni based interlayers[J]. Science & Technology of Welding & Joining, 2013, 18(7): 541-550.

[3] AZIZI A, ALIMARDAN H. Effect of welding temperature and duration on properties of 7075 Al to AZ31B Mg diffusion bonded joint[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 85-92.

[4] 帅 朋, 吴志生, 赵 菲, 贾登峰. 镁/铝异种材料焊接研究现状[J]. 焊接技术, 2017(2): 1-4.

PENG Shuai, WU Zhi-sheng, ZHAO Fei, JIA Deng-feng. Research status of magnesium/aluminum dissimilar materials welding[J]. Welding Technology, 2017(2): 1-4.

[5] 陈 影, 沈长斌, 葛继平. Mg/Al异种金属焊接的研究现状[J]. 稀有金属材料与工程, 2012, 41(s2): 109-112.

Chen Ying, Shen Changbin, Ge Jiping. Research progress on the welding of Mg/Al dissimilar metals[J]. Rare Metal Materials and Engineering, 2012, 41(s2): 109-112.

[6] 马运柱, 伍 镭, 龙路平, 刘文胜, 刘 超. Mg/Al真空扩散焊接头界面的显微组织和力学性能[J]. 中国有色金属学报, 2017, 27(6): 1083-1090.

MA Yun-zhu, WU Lei, LONG Lu-ping, LIU Wen-sheng, LIU Chao. Microstructure and mechanic property of Mg/Al joints obtained by vacuum diffusion bondings[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1083-1090.

[7] 宋友宝, 杨新岐, 崔 雷, 中志康, 晓 鹏. 异种高强铝合金搅拌摩擦焊搭接接头的缺陷和拉伸性能[J]. 中国有色金属学报, 2014, 24(5): 1167-1174.

SONG You-bao, YANG Xin-qi, CUI Lei, ZHONG Zhi-kang, XIAO Peng. Defects and tensile properties of friction stir welded lap joints for dissimilar high-strength aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1167-1174.

[8] PANTELI A, ROBSON J D, CHEN Y C, PRANGNELL P B. The effectiveness of surface coatings on preventing interfacial reaction during ultrasonic welding of aluminum to magnesium[J]. Metallurgical & Materials Transactions A, 2013, 44(13): 5773-5781.

[9] DAI Xiang-yu, ZHANG Hong-tao, LIU Ji-hou, FENG Ji-cai. Microstructure and properties of Mg/Al joint welded by gas tungsten arc welding-assisted hybrid ultrasonic seam welding[J]. Materials & Design, 2015, 77: 65-71.

[10] POOYAP,ABBASIM. Materials flow and phase transformation in friction stir welding of Al6013/Mg[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1253-1261.

[11] OGURA T, NETSU S, YOKOCHI T, SAIDA K. Dissimilar metal joining of A5052 aluminum alloy and AZ31 magnesium alloy using laser brazing[J]. Materials Science Forum, 2016, 879: 2532-2536.

[12] 刘积厚. TIG电弧预热辅助下的Mg/Al异种金属超声波滚焊工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.

LIU Ji-hou. Research on ultrasonic seam welding process of dissimilar metals of Mg/Al with the preheating of TIG arc[D]. Harbin:Harbin Institute of Technology, 2014.

[13] LEE K J, KWON E P. Microstructure of stir zone in dissimilar friction stir welds ofAA6061-T6 and AZ31 alloy sheets-TNMSC[J]. Transactions of Nonferrous Metals Society of China, 2015, 24(7): 2374-2379.

[14] PANTELI A, CHEN Y C, STRONG D, ZHANG X, PRANGNELL P B. Optimization of aluminium-to- magnesium ultrasonic spot welding[J]. JOM, 2012, 64(3): 414-420.

[15] 徐光晨, 陈翌庆, 刘丽华, Alan LUO, 马立坤. La对镁/铝液固扩散连接界面组织及性能的影响[J]. 中国有色金属学报, 2014, 24(11): 2743-2748.

XU Guang-chen, CHEN Yi-qing, LIU Li-hua, Alan LUO, MA Li-kun. Effect of La on structures and properties of the liquid-solid diffusion bonding interface of magnesium/ aluminum[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2743-2748.

[16] GAO Qiong, WANG Ke-hong. Influence of Zn interlayer on interfacial microstructure and mechanical properties of TIG lap-welded Mg/Al joints[J]. Journal of Materials Engineering & Performance, 2016, 25(3): 756-763.

[17] PATEL V K, BHOLE S D, CHEN D L. Improving weld strength of magnesium to aluminium dissimilar joints via tin interlayer during ultrasonic spot welding[J]. Science & Technology of Welding & Joining, 2013, 17(5): 342-347.

[18] 崔庆波, 李玉龙, 杨 瑾, 王裕波, 余 啸. 化学镀锡层对镁铝异种金属超声波焊接的影响[J]. 材料科学与工艺, 2017, 25(2): 35-38.

CUI Qing-bo, LI Yu-long, YANG Jin, WANG Yu-bo, YU Xiao. Effects of chemical plating Sn coating on the ultrasonic spot welding of Mg/Al dissimilar metals[J]. Meterials Science & Technology, 2017, 25(2): 35-38.

[19] DAI Xiang-yu, ZHANG Hong-tao, WANG Bo, JI Ang, LIU Ji-hou, Feng Ji-cai. Improving weld strength of arc-assisted ultrasonic seam welded Mg/Al joint with Sn interlayer[J]. Materials and Design, 2016, 98: 262-271.

[20] 罗国强, 尹 凯, 王仪宇. 铜薄膜作中间层的镁铝扩散焊接[J]. 武汉工程大学学报, 2012, 34(8): 62-66.

LUO Guo-qiang, YI Kai, WANG Yi-yu. Diffusion bonding of magnesium alloy and aluminum alloy using copper film as interlayer[J]. Journal of Wuhan Institute of Technology, 2012, 34(8): 62-66.

[21] WANG Yi-yu, LUO Guo-qiang, ZHANG Jian, SHEN Qiang, ZHANG Lian-meng. Effect of silver interlayer on microstructure and mechanical properties of diffusion- bonded Mg-Al joints[J]. Journal of Alloys & Compounds, 2012, 541(30): 458-461.

[22] PANTELI A, ROBSON J D, BROUGH I, PRANGNELL PB. The effect of high strain rate deformation on intermetallic reaction during ultrasonic welding aluminium to magnesium[J]. Materials Science and Engineering A, 2012, 556: 31-42.

[23] PATEL V K, BHOLE S D, CHEN D L. Characterization of ultrasonic spot welded joints of Mg-to-galvanized and ungalvanized steel with a tin interlayer[J]. Journal of Materials Processing Technology, 2014, 214(4): 811-817.

[24] LI Wang, YIN Wang, PRANGNELL P, ROBSON J. Modeling of intermetallic compounds growth between dissimilar metals[J]. Metallurgical & Materials Transactions A, 2015, 46(9): 4106-4114.

[25] KULEMIN A V, KHOLOPOV Y V. The diffusion processes taking place during the ultrasonic welding of copper to aluminum (translation)[J]. Automat Weld, 1980, 33(6): 11-13.

[26] 李彩霞, 杨艳, 赵晓. 镁合金/铜超声波点焊接头界面组织及性能[J]. 热加工工艺, 2016(17): 192-196.

LI Cai-xia, YANG Yan, ZHAO Xiao. Interfacial microstructure and mechanical properties of magnesium alloy/Cu ultrasonic spot welded joints[J]. Hot Working Technology, 2016(17): 192-196.

Effectiveness of metal foil barrier interfacial reaction during ultrasonic welding of Mg/Al

LI Ming-feng1, WANG Guan-ming1, ZHU Zheng-qiang1, ZHANG Yi-fu1, HU Qing-hua2, XIAO Qian-kun1

(1. School of Mechanical & Electrical Engineering, Nanchang University, Nanchang 330031, China;

2. School of materials science and Engineering, Guilin University of Technology, Guilin 541004, China)

Abstract: In this paper, AZ31B Mg/6061-T6 Al was used as the research object. The foils of Zn, Cu and Ag were added to the interface, respectively, and ultrasonic spot welding was used to inspect the joint performance. The microstructure and mechanical properties of the joints were investigated by metallographic microscope, SEM, XRD and tensile tester. The results show that when the welding time is 1.1 s, the joint temperature reaches 358.6 °C, and the interface forms a continuous IMC brittle layer composed of Al12Mg17 and Al3Mg2, which reduces the mechanical properties of the joint and the fracture is brittle dissociative fracture. Adding Zn foil to the interface can reduce the welding time for obtaining reliable joints. The maximum tensile shear force is 1154.4 N and the tear force is 146.9 N at 0.5 s. The fracture shows the characteristics of toughness, and the effectiveness of Zn foil decreases with the increase of welding time. The addition of Cu foil effectively blocks the formation of Mg-Al IMC, however, due to the poor weldability of Mg/Cu, the mechanical properties of the joint are very poor. The addition of Ag foil can also effectively block the formation of Mg-Al IMC. The tensile shear force of the joint reaches a maximum of 1141.4 N at 1.1 s, but the tearing force is small (72.2 N). The fracture of the Mg/Ag interface exhibits brittle fracture characteristics.

Key words: ultrasonic spot welding; Mg/Al heteroalloy; intermetallic compounds; metal foil; mechanical property

Foundation item: Project(51365039) supported by the National Natural Science Foundation of China; Project(U1731118) supported by the Joint Research Fund in Astronomy under Cooperative Agreement between the National Natural Science Foundation of China (NSFC) and Chinese Academy of Sciences (CAS)

Received date: 2018-08-22; Accepted date: 2019-01-21

Corresponding author: WANG Guan-ming; Tel: +86-13767058021; E-mail: zgwangguanming@126.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51365039);国家自然科学基金委员会-中国科学院天文联合基金资助项目(U1731118)

收稿日期:2018-08-22;修订日期:2019-01-21

通信作者:王官明,高级工程师;电话:13767058021;E-mail:zgwangguanming@126.com

摘 要:本文以AZ31B Mg/6061-T6Al为研究对象,对界面添加锌、铜和银箔并采用超声波点焊进行焊接来考察接头性能。采用金相显微镜、SEM、XRD和拉伸试验机等研究了接头的显微组织和力学性能。结果表明: Mg/Al接头在焊接时间为1.1 s时接头温度达358.6 ℃,界面形成由Al12Mg17和Al3Mg2组成的连续IMC脆性层,降低了接头力学性能,断口为脆性解离断裂;添加锌箔能降低获得可靠接头的焊接时间,0.5 s时接头最大拉剪力为1154.4 N、撕裂力为146.9 N,断口表现出韧性断裂特征,随焊接时间延长锌箔的有效性降低;添加铜箔可有效阻隔Mg-Al系IMC的形成,但由于Mg/Cu焊接性差,导致接头力学性能较低;添加银箔亦能有效阻隔Mg-Al系IMC的形成,1.1 s时接头拉剪力达到最大值为1141.4 N,但撕裂力较小(72.2 N),Mg/Ag界面断口呈现脆性断裂特征。

[1] 张丽娟, 周惦武, 刘金水, 徐少华, 乔小杰, 李 升. 钢/铝异种金属添加粉末的激光焊接[J]. 中国有色金属学报, 2013, 23(12): 3401-3409.

[4] 帅 朋, 吴志生, 赵 菲, 贾登峰. 镁/铝异种材料焊接研究现状[J]. 焊接技术, 2017(2): 1-4.

[5] 陈 影, 沈长斌, 葛继平. Mg/Al异种金属焊接的研究现状[J]. 稀有金属材料与工程, 2012, 41(s2): 109-112.

[6] 马运柱, 伍 镭, 龙路平, 刘文胜, 刘 超. Mg/Al真空扩散焊接头界面的显微组织和力学性能[J]. 中国有色金属学报, 2017, 27(6): 1083-1090.

[7] 宋友宝, 杨新岐, 崔 雷, 中志康, 晓 鹏. 异种高强铝合金搅拌摩擦焊搭接接头的缺陷和拉伸性能[J]. 中国有色金属学报, 2014, 24(5): 1167-1174.

[12] 刘积厚. TIG电弧预热辅助下的Mg/Al异种金属超声波滚焊工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.

[15] 徐光晨, 陈翌庆, 刘丽华, Alan LUO, 马立坤. La对镁/铝液固扩散连接界面组织及性能的影响[J]. 中国有色金属学报, 2014, 24(11): 2743-2748.

[18] 崔庆波, 李玉龙, 杨 瑾, 王裕波, 余 啸. 化学镀锡层对镁铝异种金属超声波焊接的影响[J]. 材料科学与工艺, 2017, 25(2): 35-38.

[20] 罗国强, 尹 凯, 王仪宇. 铜薄膜作中间层的镁铝扩散焊接[J]. 武汉工程大学学报, 2012, 34(8): 62-66.

[26] 李彩霞, 杨艳, 赵晓. 镁合金/铜超声波点焊接头界面组织及性能[J]. 热加工工艺, 2016(17): 192-196.