文章编号:1004-0609(2016)-04-0707-08

复合场作用下Al-5.0Cu-1.0Fe合金的显微组织和力学性能

罗 执,张 杨,赵愈亮,张卫文

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:

将压力场和超声场复合作用于铝合金的凝固过程,并对比分析无外场、单一外场(压力场、超声场)和复合场的作用效果。采用定量金相分析、扫描电镜、电子探针等手段研究压力场、超声场以及压力和超声复合场作用下Al-5.0Cu-1.0Fe合金的显微组织和显微硬度。结果表明:分别施加50 MPa压力场和800 W超声场均能减少α(Al)二次枝晶间距,细化并分散富铁相和θ(Al2Cu)相,同时改变富铁相的形貌,使针状的Al7Cu2Fe相转变成汉字状的富铁相Al6(CuFe);同时复合场比单一外场能更大程度地细化α(Al)二次枝晶间距、富铁相和θ(Al2Cu)相;单独施加压力50 MPa比单独施加800 W的超声更能够有效减少缩松,但同时施加压力和超声时效果最佳;同时施加压力和超声场时可获得最高的α(Al)基体显微硬度。对复合场的作用效果进行初步探讨,这是超声场的空化效应以及声流效应和压力场的压力效应共同作用的结果。

关键词:

Al-5.0Cu-1.0Fe合金;超声场;压力场;富铁相;显微组织;显微硬度;

中图分类号:TG292 文献标志码:A

Al-Cu系合金由于Cu的固溶作用而具有较好的强韧性,同时具有较高的比强度和硬度、良好的耐腐蚀性、易于加工等优点而被广泛应用于汽车、军事、航空航天工业[1-3]。但是,由于Al-Cu系合金的结晶温度范围宽、流动性差、铸造性能较差,同时由于杂质元素Fe在铝合金中难以避免,会形成α-富Fe相,β-富Fe相以及固溶少量Mn、Cu原子的AlmFe、Al3Fe与Al6Fe,降低了基体中有效Cu的含量,恶化了铸造Al-Cu合金的力学性能,限制了其应用[4-7]。在这几种富铁相中,β-富Fe相组成多为β-Al5FeSi、Al9Fe2Si2、Al7Cu2Fe和Al7Cu2(FeMn)等,常以针片状的形貌出现,此形貌易形成应力集中,割裂基体,脆性较大,α-富Fe相组成多为α-Al8Fe2Si、Al12Fe3Si2和Al15(FeMn)3- (SiCu)2等,通常为汉字状或骨骼状,排布紧密,末端呈球状。而Al6Fe与AlmFe作为非平衡铁相,易在较高的冷却速率下形成,通常为汉字状、鱼骨状或是块状,应力集中小[7]。因此,β-富Fe相对合金性能危害更大[8-11]。而且,当Fe量较大时,粗大的针片状富铁相会阻碍枝晶间液态金属的流动,降低Al-Cu熔体的流动性和充型能力。所以,通过优化工艺来减少杂质Fe的有害影响对于开发高性能低成本的Al-Cu合金材料具有重要的指导意义。

目前,国内外通过减小Fe在合金中含量和改变富铁相形貌的方法来降低铝合金熔体中Fe的危害作用[4, 12],利用诸如压力场、超声场等外加场[13-27]成为一种重要的途径。挤压铸造作为一种优质、高效、节能的近净成形技术,其工艺流程简单,能获得组织致密、力学性能优异的合金铸件[28-29]。DONG等[13]研究了挤压铸造Al-7Si-0.3Mg合金,发现挤压铸造能细化富铁相,并且提高合金的力学性能。ARHAMI等[14]对挤压铸造Al-8Fe-1.4V-8Si合金进行了研究,能使β-富Fe相转变成危害性较小的α-富Fe相。本课题组的前期研究[4, 15-18]表明,当挤压压力从0 MPa增大到75 MPa时,Al-5.0Cu合金中针状β-富Fe相转变为汉字状的α-富Fe相,强度和伸长率增加。

超声熔体处理通过空化效应、声流效应和热效应等多种效应的综合作用,改变金属的凝固过程,最终改善和控制金属的凝固行为。张勇等[19]采用受控凝固和受控振动相结合的实验装置和方法,在Al-Fe合金中引入不同功率的超声振动,揭示了超声可以显著细化铁相,大幅提高了抗拉强度。吴树森课题组[20-24]和OSAWA等[25]则对高硅高铁铝合金熔体施加超声振动后浇注,富铁相细化和其形态发生改变,块状和短条状δ-富Fe相增多,而针状β-富Fe相减少。李廷举等[26]对Al-12%Si-2%Fe合金进行超声处理,发现随超声时间增长,α-富Fe相逐渐增多,而β-富Fe相逐渐减少。同时,KHALIFA等[27]对含铁量为0.78%的ADC12铝合金施加超声振动,同样得到富铁相形貌改变和强度提高的结论。由此可知,超声处理能细化铝合金的富铁相,但超声处理多用于Al-Si系合金中,而对Al-Cu系合金的研究则较少。

当前,国内外通常单独利用挤压铸造压力场或超声场来改善铝合金中的富铁相,然而,THIRUMAL等[30]研究了AA6061合金挤压铸造和超声振动的作用,两者均能提高合金性能。DAI等[31]也尝试用两种外场来改变AlCuMnTi合金的组织和性能,同样效果明显。上述研究均是将合金熔体先超声处理再进行不同工艺参数的挤压铸造,而本文作者则是首次使超声场和挤压铸造压力场同时作用于合金熔体,相对前者本研究组织细化效果更加明显,组织缺陷较少,实验流程更短。本文作者选择一种成分简单、含铁量较高Al-5.0Cu-1.0Fe合金为研究对象,研究不同条件下该合金的显微组织和力学性能,一方面填补超声处理Al-Cu系合金研究的空白,另一方面开创一种新型复合场,为开发高性能低成本的Al-Cu系合金提供理论指导和实验支撑。

1 实验

本试验中所用原材料为高纯铝锭(99.95%,质量分数)、Al-50Cu、Al-5Fe中间合金,在7.5 kW坩埚井式电阻炉中熔炼合金,完全熔化后使用商用固体精炼剂进行精炼除气除渣,控制熔体温度在710 ℃左右,利用d 80 mm×100 mm大小的浇勺快速浇注,合金通过光谱仪分析,成分如表1所列。

复合场装置如图1所示,装置由两部分构成:超声振动系统和挤压铸造系统。超声振动系统由空冷的频率为20 kHz的发生器、PZT合金制成的换能器和一个工作杆组成。实验中使用的超声功率为800 W,频率为19.3 kHz,超声的时间为30 s。挤压铸造系统中的压机液压力为100 t,铸造模具材料为H13钢,尺寸为75 mm×75 mm×100 mm。模具的预热温度为200 ℃,挤压压力分别为0、50 MPa,挤压速度为10~ 20 mm/s,保压时间为30 s,获得铸锭尺寸为75 mm× 75 mm×70 mm。在复合场下,超声功率为800 W,挤压压力50 MPa,共同作用时间为30 s。

图1 复合场装置示意图

Fig. 1 Schematic diagram of compound field system

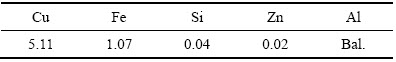

表1 合金的化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

在超声杆尖端处截取d 10 mm×12 mm的金相试样,抛光后采用质量分数为0.5%的HF溶液腐蚀,在LEICA/DMI 5000M型金相显微镜下进行显微组织观察,并利用Image-Pro Plus 6.0图像分析软件进行第二相比例分数的定量分析,在放大500倍下选取不少于30个视场,每个视场选取不少于10条截线。采用定量立体测量学中所公认的公式AA=VV[32],即第二相的面积分数(AA)等于体积分数(VV),将软件计算出的面积分数转换为体积分数。金相中的孔洞以及第二相具体成分在Quanta 2000型扫描电子显微镜下进行。在维氏硬度计上测α(Al)基体的显微硬度,其中载荷为0.49 N,保压时间为15 s,试验结果是10个测试点的平均值。采用EPMA-1600型波谱仪分析了不同条件下铸态合金α(Al)基体中Cu的成分,探究合金的硬度变化原因。同时,为更清晰地观察富铁相的三维立体形貌,将抛光后的金相样品倒置于浓度为10 g/mL的碘甲醇溶液中4~5 h,然后用酒精和超声波清洗后,采用Nova Nano SEM 430型扫描电子显微镜观察合金的显微组织。

2 结果与分析

2.1 合金的显微组织

不同条件下的铸态合金的显微组织如图2所示。由图2可知,合金铸态组织为典型的枝晶结构,主要由α(Al)枝晶及分布在枝晶之间的各种第二相组成。在图2(a)中,在无外场的作用下,合金在富铁相周围出现大量的缩松,根据Al-Cu-Fe三元合金相图[33]看出,富铁相在金属熔液降温过程中逐渐形成,无液态金属补缩,而形成缩松。在图2(b)中,50 MPa挤压压力下的组织得到细化,缩松大幅减少,并且出现明显的双峰组织。在图2(c)中,相对图2(a)而言,缩松减少,晶粒细化,并且富铁相也较分散。图2(d)中枝晶的细化程度更加明显,同时富铁相尺寸也减小。由此可见,压力场和超声场的共同作用使得对枝晶的作用更明显,但却并不是简单意义上的加成。

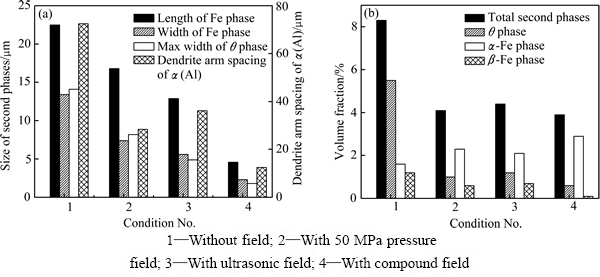

不同方法下相的体积分数与α(Al)基体的二次枝晶间距的大小如图3所示。可以看出,当施加复合场时,α(Al)的二次枝晶间距相对于无外场作用的72.5 mm减小到12.5 mm,减小了80%,富铁相的平均长度由22.5 mm减小到4.6 mm,平均宽度由13.4 mm减小到2.3 mm,θ(Al2Cu)相的最大宽度也由14.1 mm减小到1.8 mm。复合场的作用也使得θ(Al2Cu)相的体积分数由5.5%减小到0.6%,β-富Fe相的体积分数由1.2%减小到0.1%,Al6(CuFe)的体积分数由1.6%增加到2.9%。因此,复合场的引入,不仅能细化第二相,而且使得针状富铁相减少,汉字状富铁相增多。

图2 不同条件下的铸态合金的显微组织

Fig. 2 Microstructures of as-cast alloys under different conditions

图3 不同条件下合金的相尺寸和体积分数

Fig. 3 Sizes(a) and volume fraction(b) of phases in alloys under different conditions

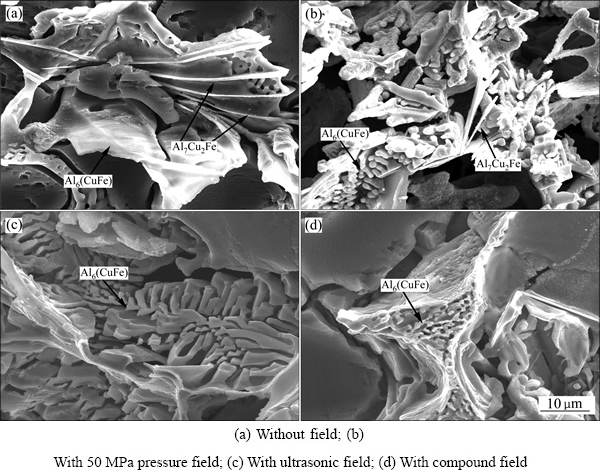

图4所示为不同条件下铸态合金富铁相的3D形貌。可以看出,在无外场下,针片状Al7Cu2Fe较细长,同时贯穿于骨骼状Al6(CuFe),而Al6(CuFe)则较粗大,呈块状。当施加压力场时,铁相变短小,骨骼状的Al6(CuFe)更加细小,且更分散,而施加超声场时,针片状铁相几乎看不到。当复合场作用时,富铁相的细化效果更明显,主要出现椭圆花纹状铁相,而没有针状铁相。

2.2 缩松

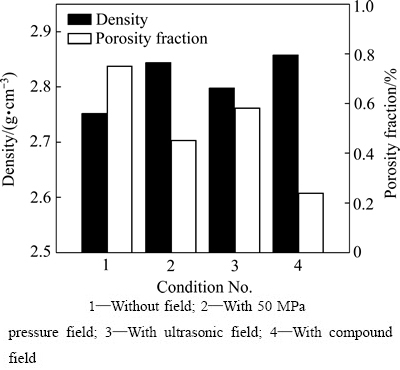

图5所示为不同铁相附近的缩松。缩松周围出现的相也是合金中存在的相,其能谱分析结果如表2所列。其所对应的相分别为黑色汉字状富铁相Al6(CuFe),针片状富铁相Al7Cu2Fe,灰色花纹状相Al2Cu,与相关文献[10, 17, 34]的报道一致。由于宽的结晶温度范围,所以Al-Cu合金中较易形成缩松。合金的实际密度采用阿基米德排水法测得,缩松体积分数采用定量金相分析软件IPP算得,不同条件下的实际密度与缩松体积分数如图6所示,外场的作用使得合金的密度上升,缩松体积分数减少,尤其是复合场作用下,相对无外场作用时而言,密度上升3.85%,缩松体积分数减少68.0%。

图4 不同条件下的铸态合金富铁相的3D形貌

Fig. 4 Three-dimensional morphology of Fe-rich intermetallics of as-cast alloys under different conditions

图5 合金中紧挨富铁相的孔洞

Fig. 5 Porosity in alloy associated with Al7Cu2Fe phase without field (a) and Al6(CuFe) phase with ultrasonic field (b)

表2 图5中各点的EDS能谱分析结果

Table 2 EDS analysis results of locations in Fig. 5

图6 不同条件下合金的密度和缩松体积分数

Fig. 6 Density and volume fraction of porosity of alloys under different conditions

2.3 显微硬度

不同条件下铸态合金的显微硬度如图7所示,从图7中可以看出,在施加压力场、超声场或压力超声复合场时,显微硬度都较无外场时大,且复合场时合金的显微硬度最大。与无外场相比,当施加50 MPa压力场时,铸态下显微硬度从32 HV增大到39 HV,增幅为21.9%;当施加超声场时,显微硬度从32 HV增大到37 HV,增幅为15.6%;当施加复合场时,显微硬度从32 HV增大到50 HV,增幅为56.3%。复合场时性能的提高并非两种外场的简单叠加,铸态合金复合场作用下相对无外场显微硬度的增幅大于单一外场作用增幅的加和。通过EPMA测试铝合金基体中Cu的含量,如图8所示,在外场的作用下,合金元素Cu在基体中的溶解度增大,合理地解释了复合场下显微硬度最大这一现象。这是由于Cu在α(Al)中的溶解度较大(达到4.5%),随着压力的增加,Cu在α(Al)中的溶解度增大,这与本课题组的前期研究[17]是一致的。

图7 不同条件下α(Al)基体的显微硬度

Fig. 7 Micro-hardness of α(Al) matrix in alloys under different conditions

图8 不同条件下铸态合金α(Al)基体的Cu含量

Fig. 8 Cu content in α(Al) matrix in cast alloys under different conditions

3 讨论

试验结果表明,在施加外场的作用时,晶粒的二次枝晶间距减小,针状β-富Fe相与缩松体积分数减少。针对压力场而言,一方面,由克拉佩龙方程可知,压力能使凝固点升高,使原本过热的金属液出现过冷的状态,增大形核率,单位体积的晶核数目越多,长成的晶粒越细小,同时压力缩小结晶温度区间,更快的形核也使铸件缩松、孔洞减少[35]。另一方面,由于金属的散热速率快于气体的,而压力使铸件与模具接触更为紧密,提高了二者之间的热传递效率,导致铸件的冷却速率升高,铸件的凝固时间缩短[36]。LIU等[7]和KAMGA等[37]分别对Al-4.6Cu-0.5Fe和B206合金的研究表明,提高冷却速率能促使针片状β-富Fe相转变汉字状Al6(CuFe),这是由于,一方面凝固点升高使得Al6(CuFe)的形核、生长的温度区间增大,另一方面过冷度的增大也促进了Al6(CuFe)的形核。此外,正交晶格Al6(CuFe)的形核动力能大于四方晶格β-Fe的,冷却速度很快时,Fe原子更易成长为Al6(CuFe)。

对超声场而言,超声波在熔体中传播时会产生空化效应和声流效应,空化效应一方面使气泡破裂产生瞬时高压,使液态金属局部压力过大,造成过冷度的增加,从而提高了形核率;另一方面气泡在长大、上升、破灭的过程中,吸收了一部分的热量,导致气泡周围的金属熔液过冷,也使得形核率增大。声流效应是超声波在介质中衰减而使沿超声波传播方向的声压减小的现象,声压梯度使得液体介质高速流动,大量的早期形成的枝晶被打断、富铁相受到冲击,最终富铁相均匀分布,晶粒细化,缩松等缺陷减少[38-39]。而根据SALAS等[40]的研究表明,在AlCu合金中,冷却速度越快,二次枝晶间距越小,也解释了合金在受到外场的作用下,二次枝晶间距减小的现象。

在这两种外场单独作用时,合金中的缩松都有一定程度的减少,单独施加压力50 MPa比单独施加800 W的超声更能够有效减少缩松。在合金液降温过程中,富铁相首先形成,不同形貌、尺寸的富铁相阻碍了金属液的流动通道,从而产生缩松,同时缩松也较易紧挨富铁相形成。随着外场的加入,合金中的缩松体积分数减少,这是由于在压力场下,压力提高了金属液的流动速度;在超声场下,声流效应加剧了液体的对流,也使得缩松减少。

由于两种外场各自对合金显微组织的影响,所以试验首次将两种外场结合起来应用于铸造Al-Cu系合金的研究中,初步探讨了复合场对合金组织与力学性能的影响。在复合场中,超声场的空化效应和压力场的共同作用使合金的冷却速度增加,因此合金的晶粒尺寸和二次枝晶间距变得细小,第二相由稳定的Al7Cu2Fe相向亚稳的Al6(CuFe)相转变。同时在超声场声流效应的作用下,合金中的第二相细小均匀地分布在基体上,并且在挤压铸造中经常出现的双峰组织也明显减轻。同时复合场的外场的效应使得晶粒形核增多,晶粒明显细化,且缩松随之减少,Cu元素在基体溶解度的提高也使得合金的显微硬度得到提高。但是,复合场共同作用机制仍未被深入研究清楚。作为一种新颖的方法,更多的研究有待进一步的开展。

4 结论

1) 压力场和超声场组成的复合场较单一外场而言,更大程度地细化二次枝晶,缩松、孔洞减少,SDAS由72.5 mm减小到12.5 mm,减小了80%,孔洞体积分数减少了68%。

2) 复合场下细化、减少以及分散了第二相,使得合金富铁相从针片状Al7Cu2Fe相大量地向危害性较小的汉字状Al6(CuFe)相转变,同时促进了Cu元素在基体中的溶解,提高了合金的显微硬度。

3) 复合场的作用机制在试验中得到了初步探讨,压力场和超声场均提高合金的冷却速率,同时超声场的空化效应和声流效应提高了形核率,细化了晶粒,促进了第二相的形核、生长。

REFERENCES

[1] 王瑞红, 王永俊, 王艳红. 微量钪添加对Al-Cu合金时效析出及电化学腐蚀行为的影响[J]. 中国稀土学报, 2014, 4, 32(2): 190-196.

WANG Rui-hong, WANG Yong-jun, WANG Yan-hong. Effect of minor scandium addition on precipitation and electrochemical corrosion of Al-Cu alloy[J]. Journal of the Chinese Rare Earth Society, 2014, 4, 32(2): 190-196.

[2] 陈子勇, 舒 群, 陈玉勇. 高强铸造铝铜合金显微组织和力学性能的研究[J]. 材料科学与工艺, 2007, 10, 15(5): 718-722.

CHEN Zi-yong, SHU Qun, CHEN Yu-yong. The study of microstructure and mechanical properties of high strength and toughness casting Al-Cu alloy[J]. Materials Science and Technology, 2007, 10, 15(5): 718-722.

[3] GUO Hong-min, ZHANG Ai-sheng, YANG Xiang-jie, YAN Ming-ming. Grain refinement of Al-5%Cu aluminum alloy under mechanical vibration using meltable vibrating probe[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2489-2496.

[4] 林 波, 张卫文, 程 佩, 汪先送, 李元元. 挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金的显微组织和力学性能[J]. 中国有色金属学报, 2013, 23(5): 1195-1201.

LIN Bo, ZHANG Wei-wen, CHENG Pei, WANG Xian-song, LI Yuan-yuan. Microstructure and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1195-1201.

[5] COUTURE A. Iron in aluminum casting alloys-a literature survey[J]. American Foundry Society International Cast Metal Journal, 1981(6): 9-17.

[6] TSENG C J, LEE S L, WU T F. Effect of Fe content on microstructure and mechanical properties of A206 alloy[J]. Materials Transactions, 2000, 41(10): 708-713.

[7] LIU K, CAO X, CHEN X G. Formation and phase selection of iron-rich intermetallics in Al-4.6Cu-0.5Fe cast alloy[J]. Metallurgical and Materials Transaction A, 2013, 44(2): 682-695.

[8] SALEM S, STEN J, INGVAR L S. The influence of cooling rate and manganese content on the α-Al5FeSi phase formation and mechanical properties of Al-Si-based alloys[J]. Materials Science and Engineering A, 2008, 490: 385-390.

[9] SHABESTARI S G. The effect of iron and manganese on the formation of intermetallic compounds in aluminum-silicon alloys[J]. Materials Science and Engineering A, 2004, 383: 289-298.

[10] SREEJA KUMARI S S, PILLAI R M, RAJAN T P D, PAI B C. Effects of individual and combined additions of Be, Mn, Ca and Sr on the solidification behaviour, structure and mechanical properties of Al-7Si-0.3Mg-0.8Fe alloy[J]. Materials Science and Engineering A, 2007, 460/461: 561-573.

[11] LIU K, CAO X, CHEN X G. Effect of Mn, Si, and cooling rate on the formation of iron-rich intermetallics in 206 Al-Cu cast alloys[J]. Metallurgical and Materials Transactions B, 2012, 43: 1231-1240.

[12] 孙常明, 史志铭, 李志芳. 利用富铈混合稀土改善工业纯铝中富铁相形貌的研究[J]. 中国稀土学报, 2007, 25(3): 318-322.

SUN Chang-ming, SHI Zhi-ming, LI Zhi-fang. Improvement of morphology of Fe-riched phase in commercial pure aluminum by Ce-riched rare earth modification[J]. Journal of the Chinese Rare Earth Society, 2007, 25(3): 318-322.

[13] DONG J X , KARNEZIS P A , DURRANT G, CANTOR B.The effect of Sr and Fe additions on the microstructure and mechanical properties of a direct squeeze cast Al-7Si-0.3Mg alloy[J]. Metallurgical and Materials Transactions A, 1999, 10: 1341-1356.

[14] ARHAMI M, SARIOGLU F, KALKANLI A, HASHEMIPOUR M. Microstructural characterization of squeeze-cast Al-8Fe- 1.4V-8Si[J]. Materials Science and Engineering A, 2008, 405: 218-223.

[15] ZHANG W W, LIN B, FAN J L, ZHANG D T, LI Y Y. Microstructures and mechanical properties of heat-treated Al-5.0Cu-0.5Fe squeeze cast alloys with different Mn/Fe ratio[J]. Materials Science and Engineering A, 2013, 588: 366-375.

[16] ZHANG W W, LIN B, CHENG P, ZHANG D T, LI Y Y. Effects of Mn content on microstructures and mechanical properties of Al-5.0Cu-0.5Fe alloys prepared by squeeze casting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1525-1531.

[17] ZHANG W W, LIN B, ZHANG D T, LI Y Y. Microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.6Mn alloys with different Fe content[J]. Materials and Design, 2013, 52: 225-233.

[18] LIN B, ZHANG W W, LOU Z H, ZHANG D T, LI Y Y. Comparative study on microstructures and mechanical properties of the heat-treated Al-5.0Cu-0.6Mn-xFe alloys prepared by gravity die casting and squeeze casting[J]. Materials and Design, 2014, 59: 10-18.

[19] 张 勇, 何德坪, 陈 峰. 超声振动细化Al-Fe合金的研究[J]. 兵器材料科学与工程, 1992, 15(9): 1-5.

ZHANG Yong, HE De-ping, CHEN Feng. The research of the microstructure of Al-Fe alloy treated by ultrasonic vibration[J]. Ordnance Material Science and Engineering, 1992, 15(9): 1-5.

[20] 林 冲, 吴树森, 钟 鼓, 戴 维. 超声振动对Al-17Si-xFe合金富铁相形貌的影响[J]. 特种铸造及有色合金, 2011, 31(11): 1012-1017.

LIN Chong, WU Shu-sen, ZHONG Gu, DAI Wei. Effects of ultrasonic vibration on morphology of iron-containing intermetallic compounds in Al-17Si-xFe alloys[J]. Special Casting and Nonferrous Alloys, 2011, 31(11): 1012-1017.

[21] LIN C, WU S S, LU S L, AN P, WAN L. Effects of ultrasonic vibration and manganese on microstructure and mechanical properties of hypereutectic Al-Si alloys with 2%Fe[J]. Intermetallics, 2013, 32: 176-183.

[22] LIN C, WU S S, LU S L, AN P, WAN L. Microstructure and mechanical properties of rheo-diecast hypereutectic Al-Si alloy with 2%Fe assisted with ultrasonic vibration process[J]. Journal of Alloy and Compounds, 2013, 568: 42-48.

[23] LIN C, WU S S, ZHONG G, WAN L, AN P. Effect of ultrasonic vibration on Fe-containing intermetallic compounds of hypereutectic Al-Si alloys with high Fe content[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1245-1252.

[24] ZHONG G, WU S S, JIANG H W, AN P. Effects of ultrasonic vibration on the iron-containing intermetallic compounds of high silicon aluminum alloy with 2% Fe[J]. Journal of Alloy and Compounds, 2010, 492: 482-487.

[25] OSAWA Y, TAKAMORI S, KIMURA T, MINAGAWA K, KAKISAWA H. Morphology of intermetallic compounds in Al-Si-Fe alloy and its control by ultrasonic vibration[J]. Materials Transactions, 2007, 48(9): 2467-2475.

[26] ZHANG Y B, JIE J C, GAO Y, LU Y P, LI T J. Effects of ultrasonic treatment on the formation of iron-containing intermetallic compounds in Al-12%Si-2%Fe alloys[J]. Intermetallics, 2013, 42: 120-125.

[27] KHALIFA W, TSUNEKAWA Y, OKUMIYA M. Effect of ultrasonic treatment on the Fe-intermetallic phases in ADC12 die cast alloy[J]. Journal of Materials Processing Technology, 2010, 210: 2178-2187.

[28] ZHANG M, ZHANG W W, ZHAO H D, ZHANG D T, LI Y Y. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(3): 496-501.

[29] ZHANG M L, XING S M, XIAO L M. Design of process parameters for direct squeeze casting[J]. Journal of University of Science and Technology Beijing, 2008, 15(3): 339-343.

[30] THIRUMAL A M, MOHAN B, RAJADURAI A. Comparative study of squeeze casting of AA6061 with and without employing ultrasonic cavitations[J]. Applied Mechanics and Materials, 2014, 541/542: 349-353.

[31] DAI W, WU S S, LU S L, LIN C. Effects of rheo-squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy[J]. Materials Science and Engineering A, 2012, 538: 320-326.

[32] RUSS J C. Practical stereology[M]. New York: Plenum Press, 1986.

[33] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butterworths, 1976.

[34] 范建磊, 郑成坤, 罗宗强, 张卫文. 压力对铸造Al-Li-Cu合金组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(9): 2307-2314.

FAN Jian-lei, ZHENG Cheng-kun, LUO Zong-qiang, ZHANG Wei-wen. Effect of pressure on macro-/micro- structures and mechanical properties of Al-Li-Cu cast alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2307-2314.

[35] GHOMASHCHI M R, VIKHROV A. Squeeze casting: An overview[J]. Journal of Materials Processing Technology, 2000, 101: 1-9.

[36] 罗守靖, 陈炳光, 齐丕骧. 液态模锻与挤压铸造技术[M]. 北京: 化学工业出版社, 2006.

LUO Shou-jing, CHEN Bing-guang, QI Pei-xiang. The technology of liquid forging and squeeze casting[M]. Beijing: Chemical Industry Press, 2006.

[37] KAMGA H K, LAROUCHE D, BOURNANE M, RAHEM A. Solidification of aluminum-copper B206 alloys with iron and solid additions[J]. Metallurgical and Materials Transactions A, 2010, 41(11): 2845-2855.

[38] 刘清梅. 超声波对金属凝固特性及组织影响的研究[D]. 上海:上海大学, 2007.

LIU Qing-mei. Research of ultrasonic treatment on solidfication characteristics and structure of metals[D]. Shanghai: Shanghai University, 2007.

[39] JIANA X, XUA H, MEEKA T T, HAN Q. Effect of power ultrasound on solidification of aluminum A356 alloy[J]. Materials Letters, 2005, 59: 190-193.

[40] SALAS G F, NOGUEZ M E, RAMIREZ J G. Application of secondary dendrite arm spacing-cooling rate equation for cast alloys[J]. Transactions of the American Foundry Society, 2000, 108: 593-597.

Microstructure and mechanical property of Al-5.0Cu-1.0Fe alloy treated by compound field

LUO Zhi, ZHANG Yang, ZHAO Yu-liang, ZHANG Wei-wen

(School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: Compound field was firstly used to influence the solidification of Al alloy, and the effect of different field on the microstructure and mechanical properties was investigated. The microstructure and micro-hardness of Al-5.0Cu-1.0Fe alloy treated by compound field (combination of 50 MPa pressure field and 800 W ultrasonic field) were studied by image analysis, scanning electron microscopy and electron probe micro-analysis. The results show that both 50 MPa pressure field and ultrasonic field decrease the second dendritic arm spacing, thin and spread the second intermetallics. Meanwhile, large amounts of iron-rich phases transform from acicular shape to Chinese script morphology. Compared with the single field, the microstructure of the alloy treated by compound field is refined and modified more obviously. The casting defects, such as porosity, are reduced more efficiently when 50 MPa pressure field is applied, and the alloy applied compound field has the highest micro-hardness with the smallest volume percentage of porosity. The mechanism of compound field was also preliminarily discussed, which results from ultrasonically-induced cavitation and acoustic streaming effect and pressurely-induced pressure effect.

Key words: Al-5.0Cu-1.0Fe alloy; ultrasonic field; pressure field; iron-rich phases; microstructure; micro-hardness

Foundation item: Project(51374110) supported by the National Natural Science Foundation of China; Project (2015A030312003) supported by the Natural Science Foundation of Guangdong Province, China

Received date: 2015-04-19; Accepted date: 2015-11-30

Corresponding author: ZHANG Wei-wen; Tel: +86-20-87112933; E-mail: mewzhang@scut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51374110);广东省自然科学基金团队项目(2015A030312003)

收稿日期:2015-04-19;修订日期:2015-11-30

通信作者:张卫文,教授,博士;电话:020-87112933;E-mail: mewzhang@scut.edu.cn

摘 要:将压力场和超声场复合作用于铝合金的凝固过程,并对比分析无外场、单一外场(压力场、超声场)和复合场的作用效果。采用定量金相分析、扫描电镜、电子探针等手段研究压力场、超声场以及压力和超声复合场作用下Al-5.0Cu-1.0Fe合金的显微组织和显微硬度。结果表明:分别施加50 MPa压力场和800 W超声场均能减少α(Al)二次枝晶间距,细化并分散富铁相和θ(Al2Cu)相,同时改变富铁相的形貌,使针状的Al7Cu2Fe相转变成汉字状的富铁相Al6(CuFe);同时复合场比单一外场能更大程度地细化α(Al)二次枝晶间距、富铁相和θ(Al2Cu)相;单独施加压力50 MPa比单独施加800 W的超声更能够有效减少缩松,但同时施加压力和超声时效果最佳;同时施加压力和超声场时可获得最高的α(Al)基体显微硬度。对复合场的作用效果进行初步探讨,这是超声场的空化效应以及声流效应和压力场的压力效应共同作用的结果。

[1] 王瑞红, 王永俊, 王艳红. 微量钪添加对Al-Cu合金时效析出及电化学腐蚀行为的影响[J]. 中国稀土学报, 2014, 4, 32(2): 190-196.

[2] 陈子勇, 舒 群, 陈玉勇. 高强铸造铝铜合金显微组织和力学性能的研究[J]. 材料科学与工艺, 2007, 10, 15(5): 718-722.

[12] 孙常明, 史志铭, 李志芳. 利用富铈混合稀土改善工业纯铝中富铁相形貌的研究[J]. 中国稀土学报, 2007, 25(3): 318-322.

[19] 张 勇, 何德坪, 陈 峰. 超声振动细化Al-Fe合金的研究[J]. 兵器材料科学与工程, 1992, 15(9): 1-5.

[20] 林 冲, 吴树森, 钟 鼓, 戴 维. 超声振动对Al-17Si-xFe合金富铁相形貌的影响[J]. 特种铸造及有色合金, 2011, 31(11): 1012-1017.

[32] RUSS J C. Practical stereology[M]. New York: Plenum Press, 1986.

[33] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butterworths, 1976.

[34] 范建磊, 郑成坤, 罗宗强, 张卫文. 压力对铸造Al-Li-Cu合金组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(9): 2307-2314.

[36] 罗守靖, 陈炳光, 齐丕骧. 液态模锻与挤压铸造技术[M]. 北京: 化学工业出版社, 2006.