Trans. Nonferrous Met. Soc. China 22(2012) 2593-2603

Tuning mechanical properties for β(B2)-containing TiAl intermetallics

QIU Cong-zhang, LIU Yong, HUANG Lan, LIU bin, ZHANG Wei, HE Yue-hui, HUANG Bai-yun

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 9 July 2012; accepted 8 October 2012

Abstract:

Based on the analyses of the microstructures and phase diagrams of the TiAl-based alloy, the relationship among the composition, structure and mechanical properties of the B2-containing γ-TiAl alloys was reviewed. The refinement of microstructures and improvement of mechanical properties of TiAl alloy through stabilization of the β/B2 phase were reviewed. The mechanism of the superplastic behavior of the B2-containing γ-TiAl alloys was discussed. With a reasonable addition of β-stabilizer, metastable B2 phase can be maintained, which is favorable for fine-grained structure and better high-temperature deformation behaviors. The mechanical properties of the B2-containing TiAl alloy, including the deformability and elevated temperature properties, can also be improved with doping elements and subsequent hot-working processes. The above mentioned researches discuss a new way for developing TiAl alloys with comprehensive properties, including good deformability and creep resistance.

Key words:

β-stabilizing elements; B2 phase; TiAl-based alloys; phase diagram; grain refinement; thermal processing; superplastic deformation;

1 Introduction

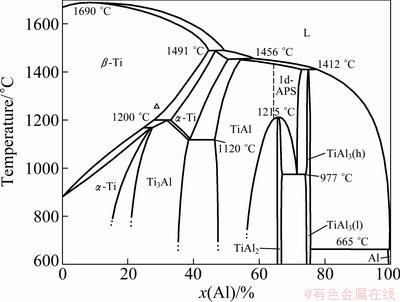

With the fast development of modern industry, especially the aerospace industry, how to enable materials to efficiently serve at high temperatures is very essential. It is potential to use lightweight materials to reduce consumption of energy and achieve a sustained development of society. Gamma-TiAl alloy has continued to attract much attention from scientists for its properties of low density, high specific strength and moduli, good resistance against creep, oxidation and corrosion at elevated temperatures. In the last 30 years, the alloy based on γ(TiAl) phase with a tetragonal L10 structure has been extensively studied. It also contains a certain amount of α2(Ti3Al) phase with a close-packed hexagonal D019 structure. Gamma-based TiAl alloy, with about half of density of traditional Ni-based alloy, can also be in service durably at elevated temperatures [1-5].

However, its inherent ductility still maintains a problem affecting the forming processes, even at high temperatures. By being alloyed with some strong β(B2)- stabilizing elements, such as refractory metals (Cr, Nb, W and Mo), the γ-TiAl alloy with a fine-grained structure may maintain a metastable B2 phase (the ordered phase of β at low-temperature) in γ phase, and have favorable high-temperature deformation ability [2,6-8]. Consequently, the B2-containing TiAl alloy (the γ-based TiAl alloy contains a certain amount of β(B2) phase) has arisen much concerns.

It is also important to know why and how the β(B2) phase can be formed in γ-based TiAl alloy, and what is the effect of B2 phase on microstructure and properties. Thus most of researches on the B2-containing TiAl alloy focused on the development of new TiAl alloy which possessed excellent mechanical properties and favourable workability.

In this work, the authors will summarize the recent progresses on the investigation of B2-containing TiAl alloy, including the composition-structure-property relationship, the effect of β(B2) phase, the deformation and superplastic behaviors, and the applications. The authors aim to provide useful reference for designing and tuning mechanical properties for the new B2-containing intermetallics.

2 B2-containing TiAl alloy

In the early 1980s, scientists [9,10] have already begun to pay much attention to the existence of B2 phase in TiAl alloys. Similar phenomena have been observed in a certain amount of ordered β phase (B2(CsCl) type structure) occurring in refractory metal-containing TiAl alloy system. KIMURA et al [11] investigated the effect of additional elements X(including V, Cr, Mn, Nb, and Mo) on γ-based titanium aluminides. The β phase is stabilized due to phase equilibria among γ(TiAl), α2(Ti3Al) and B2 (B.C.C. Ti) [7,12] phases.

The B2-containing TiAl alloys usually have Al concentrations of 44%-48% in mole fraction. INKSON et al have studied some B2-containing TiAl alloys, such as Ti-45.5Al-1.6Fe-1.1V-0.7B [13] and Ti-47Al-4(Cr, Nb, Mo, B) [14]. The existence of β(B2) grains is beneficial for grain refinement and high-temperature deformation. Compared with other TiAl alloys of γ+α2 phase, although their strength has not been enhanced definitely, their plastic deformation properties at elevated temperatures have been improved remarkably. Researchers [1,15-20] identified the superplastic behaviors, which are partially attributed to the existence of B2 grains in B2-containing TiAl alloys.

Several applications, i.e. turbine blades and engine-valves made of B2-containing TiAl alloys, have been announced by CLEMENS [21], TETSUI [22] and GE company [23,24]. Most of the components possess satisfactory properties for the applications.

In order to better understand the effect of β(B2) phase, the following aspects for B2-containing TiAl alloy were concerned: 1) Relationship between composition and microstructure, to understand how to control the contents of phases and microstructures through alloying and succedent thermal processing(es); 2) Relationship between structure and properties, to reveal the mechanism of strengthening-toughening, creep and oxidation processes, and to clarify the influence of B2 phase on performances at elevated temperatures; 3) mechanism of deformation and superplastic behavior, to study how to improve the thermal deformation ability and performance by controlling the composition and structure, and to develop a new B2-containing TiAl alloy with proper properties which can be used as a high-temperature lightweight material for industrial applications.

3 Composition-structure-property relation- ship

3.1 Composition and structure

Phase structure, equilibria and characteristics of B2-containing TiAl alloy should be clearly identified for designing compositions and thermal processing procedures.

3.1.1 Structure and characteristics

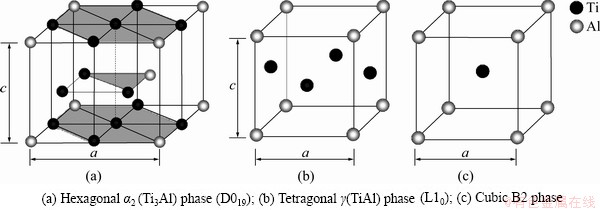

According to the Ti-Al binary phase diagram, the β phase hardly occurs as an ordered B2 variant in Al-rich compositions. However, it can appear in Al-lean section, which contains some refractory metal stabilizers.

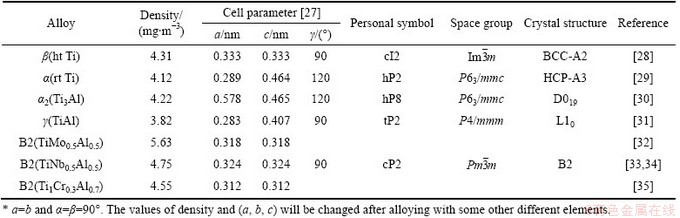

The crystallographic data of some stable and metastable phases occurring in the Ti-Al-X system are given in Table 1, and the crystal structures of phases present in the B2-containing TiAl alloy are shown in Fig. 1. It has been reported that the position substituted by different β-stabilizing elements in the lattice of B2 phase is varied. Usually, alloys (such as Cr, V and Nb) are easy to substitute the Ti sublattice [25]. Molybdenum appears to substitute either Ti or Al sublattice. CHEN and JONES [26] have shown that when the titanium or aluminium content drops, Mo substitutes the titanium or aluminium sublattice, respectively. The substitution will induce the change of lattice parameters and density of B2 phase.

3.1.2 Phase equilibria and phase diagram

Phase diagrams, including Ti-Al multi-component systems, are useful for the graphical representations of the phase changes, design and control of heat treatment procedures.

Table 1 Crystal data for Ti-Al-X system

Fig. 1 Crystal structures of phases in B2-contaned TiAl alloy [3]

The thorough assessment of the binary Ti-Al phase diagram by MURRAY [36] in 1987 has been considered a standard reference, and also reassessed in a comprehensive study using all available experimental data by SCHUSTER et al [6] in 2006 (shown in Fig. 2). γ(TiAl) phase with Al concentrations of 44% to 48% in mole fraction, according to the phase diagram (Fig. 2), will follow the phase transformation path: L→L+β→ α+β(or α)→α→α+γ→α2+γ on solidification process from high temperature to room temperature. KAINUMA et al [37,38] confirmed the existence of the β(A2)/β2(B2) order-disorder transition in the B.C.C. phase nearby “△” region, as shown in Fig. 2.

Fig. 2 Ti-Al system according to assessment of SCHUSTER and PALM [6]

JIN [39] and ZHAO et al [40] have used the approach based on high-throughput diffusion multiples and electron probe microanalysis(EPMA) to map simple binary or complex ternary phase diagrams. Whereafter, there is an order-of-magnitude increase in efficiency to establish ternary phase diagrams. The ASM alloy phase diagrams center [27] collected more than 1000 ternary phase diagrams of Ti-Al-X systems, which X includes the element C, Co, Cr, Cu, Fe, H, Mn, Mo, N, Nb, Nd, O, Sn, Si, Y, V and W, involving some Ti-(42-49)Al- (0.1-10)X (mole fraction, %) partial composition systems [25]. However, there is still uncertainty in the phase diagram, such as in Ti-Al-Mo system (<900 °C) and the TiAl-rich vertical section of Ti-Al-Fe system.

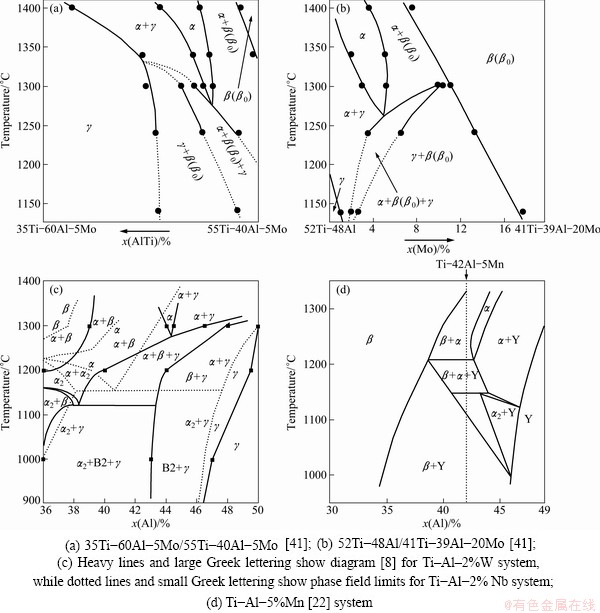

Ternary TiAl-Mo vertical section of phase diagrams shows that [41], α2+γ+B2(β0) or γ+B2(β0) phase field exists with increasing the content of Mo (Figs. 3(a) and (b)); as indicated by MARIA et al [8], the existence of ordered β(B2) phase in the Ti-Al-2%W system has also been identified (Fig. 3(c)); and TETSUI et al [22] have also reported the presence of the β(B2) phase in Ti-Al-5%Mn system (Fig. 3(d)).

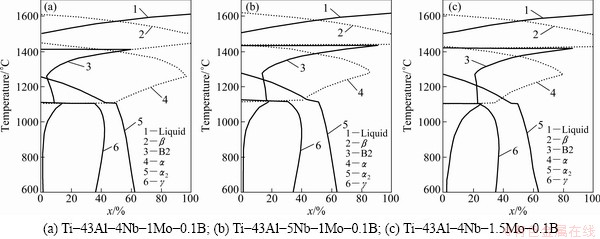

Thermodynamic calculations based on the CALPHAD method can be used to predict the constituent phases and the related transition temperatures when a new TiAl alloy is designed. CLEMENS et al [21] applied ThermoCalc  and MatCalc software packages to calculating phase fractions as a function of temperature for three different β-stabilized γ-TiAl based alloys as shown in Fig. 4. Meanwhile, the calculations were applied to correlating the phases developed in the design of B2-containing TiAl alloy.

and MatCalc software packages to calculating phase fractions as a function of temperature for three different β-stabilized γ-TiAl based alloys as shown in Fig. 4. Meanwhile, the calculations were applied to correlating the phases developed in the design of B2-containing TiAl alloy.

A study on the constitution of ternary alloy systems in relevant composition ranges has been reported by KAINUMA et al [42]. The partitioning tendency of the alloying elements, in order of their preference to concentrate into different phases at 1200 °C, can be grouped under three categories: (i) Cu, Ni and Nb, β>γ>α; (ii) Zr, γ>β>α; and (iii) Cr, Mn, Fe, Co, Mo and W, β>α>γ. On the basis of the regular solution model, the expression for the partition coefficient k(i/j) (=xi/xj) of alloying element X between i and j phases in the section  with a fixed ratio of xTi/xAl, can be given by

with a fixed ratio of xTi/xAl, can be given by

(1)

(1)

where T is the temperature; R is the mole gas constant,  is the lattice stability difference and

is the lattice stability difference and  is the difference in interaction parameters between j and i phases [43]. For example,

is the difference in interaction parameters between j and i phases [43]. For example,  for B2 phase in TiAl alloy is defined as

for B2 phase in TiAl alloy is defined as  where

where  is the interaction energy of the B2 phase in the A-B binary system.

is the interaction energy of the B2 phase in the A-B binary system.

Fig. 3 Isothermal section in equilibrium diagram of TiAl-X (Mo, Nb, W) systems [8,22,41]

Fig. 4 Calculated phase fractions as function of temperature for three different β-stabilized γ-TiAl based alloys [21]. All three alloys show an adjustable β/B2-phase fraction

3.1.3 Alloy design

The changes of alloying elements and thermal process produce varieties of microstructures and properties (characteristics).

Aluminium is an important α-stabilizing element for γ-TiAl alloys. As shown in Ti-Al binary phase diagram (Fig. 2), it is clear that at a low Al content, the high temperature β phase is extended. The Al-content required is close to 45% for most B2-containing TiAl alloys to improve the hot working ability. In some cases, the Al content is as low as 42%-43% [22,44,45]. Due to the presence of the β(B2) phase, the thermal deformability of the alloy is much greater than that of the conventional TiAl alloy.

Other elements have also been added to the TiAl alloy in order to modify the microstructures and improve the properties and/or deformability. The alloying elements are classified into 2 types according to the different influence on B2-containing TiAl alloys:

1) β stabilizers

As β-stabilizing elements, some transition metals, such as Cr, Fe, Mn, Mo, Nb, Ta, V and W [4,24,46-50], shift the β transition to lower temperatures and extend the β phase field. The β-isomorphous elements, e.g. Mo, V, and Ta, have high solubility in titanium; while the β-eutectic elements, e.g. Cr, Co, Cu, Fe, Mn, Ni, Si and W, can lead to the formation of intermetallic compounds [3]. The β/B2 phase can be retained at room temperature after alloying β-stabilizers in TiAl-based alloys. A small amount of addition of Mo, Fe or W [1,51,52] (about 2%) to binary TiAl can lead to the formation of β/B2 phase, while a very large amount of Nb (>10%-15%) is required for the same effect [8]. For some Nb-containing TiAl alloy, the β/B2 phase is only found at high temperatures or in a low Al contents [53].

2) Low-Z elements

Belonging to α-stabilizers, some interstitial elements dissolve in TiAl alloys, and extend α phase field. These low-Z elements (such as B, C, N, O and Si) also form rather stable compounds, which disperse in B2-containing TiAl alloys.

Boron (B or TiB2) can be used for grain refinement of cast alloys. During the solidification, the formation of borides can partially hinder the migration of α grain boundaries [54-56]. GOSSLAR et al [57] and RAO et al [58] have reported that primary TiB2 (formed prior to β and peritectic α phase) are stable in the melt and may serve as potential nucleation sites for the primary β phase; while secondary TiB2 precipitates (formed after the β phase but before the formation of the α phase) promote the nucleation and growth of α grains. Hence, during the solidification of TiAl-based alloys, the nucleation of TiB2 particles can result in grain refinement.

PARK et al [59] have pointed out that after introducing carbon in TiAl alloy, Ti3AlC phase can be formed and affect the growth of the lamellar microstructure significantly. It is evident that carbon addition markedly decreases the interlamellar spacing. Improvements in high temperature strength and creep resistance have also been obtained by the fine dispersions of Ti3AlC precipitates [60-62]. The precipitates in carbon-doped TiAl alloys can provide high glide resistance and show strong bowing-out of dislocation segments [60]. In nitrogen-doped TiAl alloys, nitride has similar precipitation hardening effect [63].

For silicon, fine precipitation of a titanium silicide, Ti5Si3, has been found [64,65] as effective obstacle of dislocation motion and is beneficial to improve the creep resistance without sacrificing tensile properties.

Therefore, during the design of B2-containing TiAl alloy, some low-Z additions (such as B, C, N and Si) should be considered for the solid solution and dispersion strengthening. But the content of such elements should be controlled to prevent the coarsening of their particles and the decrease of the ductility and so on [66].

3.2 Microstructures

3.2.1 Phase transformations

A comprehensive explanation that fine-grained cast TiAl alloys can be produced by utilizing β stabilizers have been given by JIN et al [17]. The hexagonal α phase in TiAl alloy has a sixfold symmetry with a 60° angle between secondary arm and primary dendrite spine, and the cubic β phase has a dendrite shape with a four-symmetry, in which the secondary arms are oriented 90° to the primary dendrite spine at the solid/liquid interface. For the most commonly investigated alloys, due to the fact that the preferential α crystal growth is parallel to the C axis, the α crystals tend to form columnar grains along the direction (C axis) of heat extraction. During cooling subsequent to solidification, γ lamellae grows in each of columnar grains to form the γ+α2 lamellar structure. By alloying β stabilizers and reducing the aluminum content, the primary solidification can be shifted from the α case to the β case. There are three equivalent preferential directions of β crystal growth during solidification along <100>, namely [100], [010] and [001]. The transformation of β→α most likely takes place by following the orientation relationship of  and

and

, and then twelve variants of α with different orientations form. This may be the reason of the fine cast microstructure after alloying β stabilizers [67,68].

, and then twelve variants of α with different orientations form. This may be the reason of the fine cast microstructure after alloying β stabilizers [67,68].

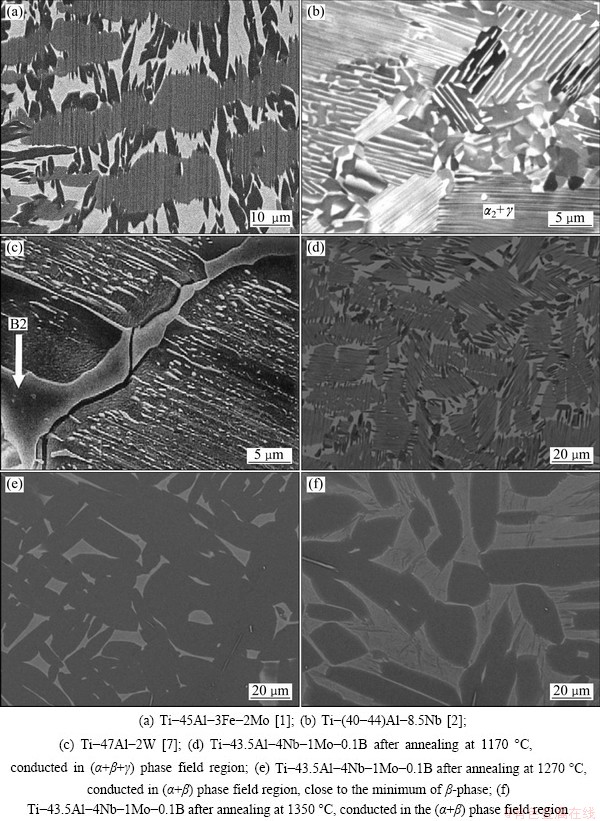

The fine as-cast microstructure, with B2+α2+γ or B2+γ grains (shown in Fig. 5), and excellent hot workability make these B2-containing TiAl alloys attract significant interests [1,2,7]. The following transformation sequence for some B2-containing TiAl alloys at continuous cooling conditions has been proposed by SCHMOELZER et al [12]: L→L+β→β→ α+β→α(+βm)→α+γ(+βm)→α+B2+γ→α2+B2+γ, where βm denotes the metastable β-phase. And the microstructure can be modified by different heat-treatment processes (shown in Figs. 5(d, e, f)).

Fig. 5 Typical microstructures of B2-containings TiAl alloy [1,2,7,12]

3.2.2 Thermal processing

Microstructural optimization of B2-containing TiAl alloy is of particular concern with respect to balanced properties. Thus, thermal processing has been widely used to modify the microstructures and to improve the mechanical properties.

Normally, γ(TiAl)-based alloys can be altered over a wide range by heat-treatments to form different types of microstructures: 1) a near-gamma microstructure (annealing slightly above the eutectoid temperature), 2) a duplex microstructure composed of γ grains and γ/α2 colonies (heat-treatments in the middle of the (α+γ) region), and 3) nearly lamellar or 4) fully lamellar microstructures (generated upon cooling when wrought γ(TiAl)-based alloys are heat-treated about 10 °C below or 10-20 °C above the α-transus temperature, respectively).

Except for the annealing temperature, the holding time and cooling rate also have effects on the microstructures of B2-containing TiAl alloys. NOVOSELOVA et al [69] have found that the grain size of the lamellar structure can be refined with increasing the cooling rate and decreasing the holding time.

The stress during thermal processing is favorable for removing the β/B2 phases. It has been reported that in some B2-containing TiAl alloys, the transformations of β→γ [70] or β→α2 [71] can be induced which are beneficial for stress relaxation during deformation. In as-cast B2-containing TiAl alloy, the effects of heat treatments and hot-isostatic pressing on the phase transformation and microstructures have been studied by ZHANG et al [72]. The β/B2 phase can not be eliminated by long-term annealing at 1150 °C or above the α-transus temperature (1400 °C). However, a significant decrease of volume fraction of β/B2 phase occurs during hot-isostatic pressing.

Hence, the microstructures, such as (α2+γ) lamellar+B2+γ, (α2+γ) lamellar, or near duplex B2+γ microstructure, can be presented in B2-containing TiAl alloy by different thermo-mechanical processing [12,46,73-77].

4 Deformation and superplasticity

4.1 Mechanical properties

SUN et al [78] reported that the B2 phase should be controlled strictly since it is hard and brittle at room temperature. Nevertheless, a fine-grained structure can easily be formed upon alloying β/B2 stablizers and the existence of B2 phase makes it possible to reach high mechanical properties as pointed out by IMAEV et al [79,80]. The B2 phase has been used to improve the workability and superplasticity of the TiAl alloys [1,15,16,18]. Precipitation of B2 phase from α2 lamellae, which retards dislocation motion, is considered intrinsic toughening mechanism and can enhance the fracture toughness, as reported by CHEN et al [81]. It has also been found [82] that bands of β/B2 particles can reduce the minimum creep rate and extend the rupture life. IMAYEV et al [83] suggested that, considering the balance between the room temperature ductility/strength properties and the high temperature long-term strength, it is promising to design a B2-containing TiAl alloy with a refined lamellar microstructure by β/B2 stablizers, and to achieve a high thermal deformability and good machinability.

4.2 Deformation

The deformation characteristics of γ-based TiAl alloy include [25]: 1) the ductility has strong anisotropy; 2) the yield strength increases abnormally with the temperatures in a certain range; 3) the fracture model obeys SCHMID’S rule [84]; and 4) there are a small number of independent slip and dislocation systems. The TiAl-based alloy possesses hard-to-move dislocations, and some obstacles, such as superdislocations, Roof barriers, Kear-Wilsdorf locks, and Lomer-Cotrell locks. It presents a very low ductility till the intergranular brittle fracture occurs [85]. In order to improve the deformability, it is necessary to increase the movability of dislocations and decrease the obstacles.

At room temperature, the ductility of TiAl alloy has been related to the active deformation modes corresponding to different phases, as reported by MORRIS et al [86]. The γ phase is very deformable, with large densities of ordinary 1/2<110> dislocations and deformation twins and a low number of <101> superdislocations after slight plastic deformation. With sufficient independent slip systems, the <100> and dissociated <111> superdislocations on {110} planes increase the deformability of the B2 phase. And the presence of “ω precipitates” [10] leads to considerable friction forces that decrease dislocation mobility and enhance the strength of B2-containing TiAl alloy. The α2 phase is the least deformable due to the limited slip systems  [87], which require a large resolved shear stress to propagate.

[87], which require a large resolved shear stress to propagate.

At elevated temperatures (below 800 °C), the deformation modes corresponding to different phases have been studied. The glide systems of γ phase are similar to those occurring at room temperature. The partial independent slip systems should be relaxed following climb processes [88] and the activation of mechanical twinning within the γ phase should be enhanced [89]. Due to the emergence of homogeneous activation of prismatic glide and a relatively dense population of 1/3 dislocations on pyramidal planes

dislocations on pyramidal planes  , the α2 phase seems to be more ductile [90,91]. The changes of the deformation mechanisms coincide with the transition from brittle to ductile fracture, which typically occurs (γ+α2) alloys. The B2 phase can be deformed more easily than α2 or γ phase because the dislocation climb or glide is easier in B2 grains. On one hand, the presence of soft β/B2 precipitates at (α2+γ) lamellar interfaces is better for creep resistance, since the β/B2 phase could pin the moving dislocations and strengthen the materials [92]. On the other hand, the presence of B2 grains is also beneficial for reducing the stress concentration at triple junctions, which delays the cavitation and fracture process [16]. So good deformation and superplasticity have been observed in the B2-containing TiAl alloys [1,15,16,18].

, the α2 phase seems to be more ductile [90,91]. The changes of the deformation mechanisms coincide with the transition from brittle to ductile fracture, which typically occurs (γ+α2) alloys. The B2 phase can be deformed more easily than α2 or γ phase because the dislocation climb or glide is easier in B2 grains. On one hand, the presence of soft β/B2 precipitates at (α2+γ) lamellar interfaces is better for creep resistance, since the β/B2 phase could pin the moving dislocations and strengthen the materials [92]. On the other hand, the presence of B2 grains is also beneficial for reducing the stress concentration at triple junctions, which delays the cavitation and fracture process [16]. So good deformation and superplasticity have been observed in the B2-containing TiAl alloys [1,15,16,18].

4.3 Superplasticity

Superplasticity is the ability of a polycrystalline material to exhibit very high tensile elongations prior to failure. VANDERSCHUEREN et al [15] reported that a B2-containing TiAl alloy shows superplastic behavior with the elongation of 580 % under the test condition of 3×10-4 s-1 and 1420 K. Superplasticity has been observed in many other B2-containing TiAl alloys.

The effects of B2 phase on the superplastic behavior can be summarized as follows:

1) Microstructural refinement. The β/B2 phase can serve as a grain-refining component in TiAl alloys and fine grains promote grain boundary sliding and rotating during superplastic deformation.

2) Lubrication effect. A promoted grain slide lubricant for the γ phase and the enhanced grain boundary cohesion can be induced by the presence of β/B2 phase [15], and thus the cavitation and fracture processes can be delayed [18].

3) Coordination effect. At elevated temperatures, dislocation climb or glide is easier in B2 grains due to the open BCC structure. The fine B2 grains accommodate sliding strains to reduce the propensity of cavitation at grain triple junctions and thus delay the cavitation and fracture process [16].

4) Transformation superplasticity. Grain boundary sliding (GBS) might also be partly accommodated by the deformation-enhanced  transformation during the superplastic deformation of an α2-rich TiAl alloy, as reported by YANG et al [71]. The phase transformation of β→γ, which also takes place in a B2-containing TiAl alloy during superplastic deformation, can result in the relaxation of the concentrated stress at phase boundaries and make the grain boundaries favorable for sliding without inducing cavitation [70].

transformation during the superplastic deformation of an α2-rich TiAl alloy, as reported by YANG et al [71]. The phase transformation of β→γ, which also takes place in a B2-containing TiAl alloy during superplastic deformation, can result in the relaxation of the concentrated stress at phase boundaries and make the grain boundaries favorable for sliding without inducing cavitation [70].

5) Dynamic recrystallization. The dynamic recrystallization preferentially takes place in the ductile β(B2) phase, which significantly reduces the stress concentration during superplastic deformation [1].

The superplastic deformation, as a complex process, includes the dislocation movement, diffusion and grain boundary sliding. And the processes are interacted and interdependent with each other. Hence, the mechanism of superplastic deformation of B2-containing TiAl alloys still needs further study.

5 Conclusions and prospects

Extensive developments in the metallurgy and manufacture of B2-containing TiAl alloys have been made in the past years. The B2-containing TiAl alloys are potential to provide excellent comprehensive properties, including good workability and high-temperature performance. These alloys can be fabricated through proper alloying and thermal processing.

Admittedly, it still needs more detailed understanding of the relationship among the composition, microstructure and properties for the applications of the B2-containing TiAl alloys, including: 1) developing more comprehensive Ti-Al multi-content phase diagram system, understanding the influence of alloying elements on the formation of phases and microstructures; 2) extensively studying the formation and evolvement of β/B2 phase, and the method to control the content of phases and microstructures, and optimizing the mechanical properties; 3) further exploring the effects of β/B2 phase on thermal deformability, such as the superplastic behavior and hot forming.

References

[1] QIU C Z, LIU Y, ZHANG W, LIU B, LIANG X P. Development of a Nb-free TiAl-based intermetallics with a low-temperature superplasticity [J]. Intermetallics, 2012, 27: 46-51.

[2] APPEL F, OEHRING M, PAUL J D H. Nano-scale design of TiAl alloys based on β-phase decomposition [J]. Advanced Engineering Materials, 2006, 8: 371-376.

[3] LEYENS C, PETERS M. Titanium and titanium alloys—Fundamentals and applications [M]. Weinheim: Wiley-VCH, 2003.

[4] CHEN G L. Research and development status and prospect on the ordered structural intermetallics [J]. Materials Review, 2000, 14: 51-56.

[5] LI B H, KONG F T, CHEN Y Y, CHEN Z Y, ZHANG J W. Alloying design of titanium aluminum intermetallics and research progress [J]. Journal of Aeronautical Meterials, 2006, 26: 72-78.

[6] SCHUSTER J C, PALM M. Reassessment of the binary aluminum-titanium phase diagram [J]. Journal of Phase Equilibria and Diffusion, 2006, 27: 255-277.

[7] JUNG I S, JANG H S, OH M H, LEE J H, WEE D M. Microstructure control of TiAl alloys containing beta stabilizers by directional solidification [J]. Materials Science and Engineering A, 2002, 329: 13-18.

[8] MARIA A M, GIL I, MORRIS D G. Microstructural stability of γ-based TiAl intermetallics containing β phase [J]. Intermetallics, 2005, 13: 929-936.

[9] BANERJEE D, GOGIA A K, NANDY T K. Deformation structure in a Ti-24Al-11Nb alloy [J]. Metallurgical Transactions A, 1990, 21: 627-639.

[10] STRYCHOR R, WILLIAMS J C, SOFFA W A. Phase- transformations and modulated microstructures in Ti-Al-Nb alloys [J]. Metallurgical Transactions A, 1988, 19: 225-234.

[11] KIMURA M, HASHIMOTO K, MORIKAWA H. Study on phase-stability in Ti-Al-X systems at high-temperatures [J]. Materials Science and Engineering A, 1992, 152: 54-59.

[12] SCHMOELZER T, LISS K D, ZICKLER G A, WATSON I J, DROESSLER L M, WALLGRAM W, BUSLAPS T, STUDER A, CLEMENS H. Phase fractions, transition and ordering temperatures in TiAl-Nb-Mo alloys: An in- and ex-situ study [J]. Intermetallics, 2010, 18: 1544-1552.

[13] INKSON B J, BOOTHROYD C B, HUMPHREYS C J. Microstructure of a gamma alpha-2 beta Ti-Al alloy containing iron and vanadium [J]. Acta Metallurgica et Materialia, 1993, 41: 2867-2876.

[14] INKSON B J, CLEMENS H, MARIEN J. Gamma+alpha(2)+B2 lamellar domains in rolled TiAl [J]. Scripta Materialia, 1998, 38: 1377-1382.

[15] VANDERSCHUEREN D, NOBUKI M, NAKAMURA M. Superplasticity in a vanadium alloyed gamma plus beta phased Ti-Al intermetallic [J]. Scripta Metallurgica et Materialia, 1993, 28: 605-610.

[16] NIEH T G, HSIUNG L M, WADSWORTH J. Superplastic behavior of a powder metallurgy TiAl alloy with a metastable microstructure [J]. Intermetallics, 1999, 7: 163-170.

[17] JIN Y, WANG J N, YANG J, WANG Y. Microstructure refinement of cast TiAl alloys by β solidification [J]. Scripta Materialia, 2004, 51: 113-117.

[18] MASAHASHI N, MIZUHARA Y, MATSUO M, HANAMURA T, KIMURA M, HASHIMOTO K. High temperature deformation behavior of titanium-aluminide based gamma plus beta microduplex alloy [J]. ISIJ International, 1991, 31: 728-737.

[19] NIU H Z, KONG F T, CHEN Y Y, ZHANG C J. Low-temperature superplasticity of forged Ti-43Al-4Nb-2Mo-0.5B alloy [J]. Journal of Alloys and Compounds, 2012, 543: 19-25.

[20] ZHANG B, WANG J N, YANG J. Superplastic behavior of a TiAl alloy in its as-cast state original research article [J]. Materials Research Bulletin, 2002, 37: 2315-2320.

[21] CLEMENS H, WALLGRAM W, KREMMER S, G THER V, OTTO A, BARTELS A. Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot-workability [J]. Advanced Engineering Materials, 2008, 10: 707-713.

[22] TETSUI T, SHINDO K, KAJI S, KOBAYASHI S, TAKEYAMA M. Fabrication of TiAl components by means of hot forging and machining [J]. Intermetallics, 2005, 13: 971-978.

[23] WEIMER M J, KELLY T J. Overview of TiAl implementation at GE aviation [R]//Seattle: 17th AeroMat Conference & Exposition, 2006.

[24] BEWLAY B P, HURON E, KELLY T J, PERETTI M W, WEIMER M J. TiAl application status at GE aviation [R]//Houston: Materials Science & Technology, 2010.

[25] APPEL F, PAUL J D H., OEHRING M. Gamma titanium aluminide alloys [M]. Weinheim: Wiley-VCH, 2011.

[26] CHEN Z, JONES I P. Sublattice occupancy in 3Ti-Al-Mo B2 phases [J]. Scripta Metallurgica et Materialia, 1995, 32: 553-557.

[27] VILLARS P, OKAMOTO H, CENZUA K. A-B-C phase diagram[EB/OL]. [2012] http://www1.asminternational.org/ AsmEnterprise/APD, 2006.

[28] TAYLOR A, FLOYD R W. The constitution of nickel-rich alloys of the nickel-chromium-titanium system [J]. J Inst Met, 1951, 80: 577-587.

[29] CLARK D, JEPSON K S, LEWIS G I. A study of the titanium-aluminium system up to 40 at% aluminium [J]. J Inst Met, 1962, 91: 197-203.

[30] PENALOZA V A, HOUSKA C R. Refinements on the X-ray internsities from Ti3Al [J]. An Congr Nac Metal, 1983, 3: A55-A59.

[31] SRIDHARAN S, NOWOTNY H, WAYNE S F. Investigations within the quaternary system titanium-nickel-aluminium-carbon [J]. Monatsh Chem, 1983, 114: 127-135.

[32] SINGH A K, KUMAR S, BANUMATHY S, MANDAL R K. Structure of the B2 phase in Ti-25Al-25Mo alloy [J]. Philosophical Magazine, 2007, 87: 5435-5445.

[33] KAZANTSEVA N V, MUSHNIKOV N V, POPOV A G., SAZONOVA V A, TERENT'EV P B. Use of mechanoactivation for obtaining hydrides of titanium aluminides [J]. Physics of Metals and Metallography, 2008, 105: 460-470.

[34] BENDERSKY L A, BOETTINGER W J, ROYTBURD A. Coherent precipitates in the B.C.C./orthorhombic two-phase field of the Ti-Al-Nb system [J]. Acta Metall Mater, 1991, 39: 1959-1969.

[35] RAMAN A, SCHUBERT K. The occurrence of Zr2Cu and Cr2Al-type intermetallic compounds [J]. Z Metallkd, 1964, 55: 798-804. (in German)

[36] MURRAY J L. The Al-Ti (aluminum-titanium) system [J]. Phase Diagrams of Binary Titanium Alloys, 1987, 44: 12-24.

[37] KAINUMA R, PALM M, INDEN G. Solid-phase equilibria in the Ti-rich part of the Ti-Al system [J]. Intermetallics, 1994, 2: 321-332.

[38] OHNUMA I, FUJITA Y, MITSUI H, ISHIKAWA K, KAINUMA R, ISHIDA K. Phase equilibria in the Ti-Al binary system [J]. Acta Materialia, 2000, 48: 3113-3123.

[39] JIN Z P. A study of the range of stability of σ phase in some ternary systems [J]. Scand J Metall, 1981, 10: 279-287.

[40] ZHAO J C. Combinatorial approaches as effective tools in the study of phase diagrams and composition-structure-property relationships [J]. Progress in Materials Science, 2006, 51: 557-631.

[41] YI S. Phase equilibria and development of β0+γ two phase microstructures in gamma-based Ti-Al-Mo ternary alloys [D]. Madison: The University of Wisconsin, 1997.

[42] KAINUMA R, FUJITA Y, MITSUI H, OHNUMA I, ISHIDA K. Phase equilibria among alpha (hcp), beta (bcc) and gamma (Ll(0)) phases in Ti-Al base ternary alloys [J]. Intermetallics, 2000, 8(8): 855-867.

[43] HILLERT M. Phase equilibria, phase diagrams and phase transformations [M]. London: Cambridge University Press, 1998.

[44] TETSUI T, SHINDO K, KOBAYASHI S, TAKEYAMA M. Strengthening a high-strength TiAl alloy by hot-forging [J]. Intermetallics, 2003, 11: 299-306.

[45] TETSUI T, SHINDO K, KOBAYASHI S, TAKEYAMA M. A newly developed hot worked TiAl alloy for blades and structural components [J]. Scripta Materialia, 2002, 47: 399-403.

[46] HUANG L, LIAW P K, LIU C T, LIU Y, HUANG J S. Microstructural evolution of(TiAl)+Nb+W+B alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 2192-2198.

[47] ZHENG Y R, WANG X P. β2 phase in TiAl-Cr alloy [J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 1-6. (in Chinese)

[48] LIU Ci-cheng, LI Shu-jiang, ZHANG Wei-jun, LIN Jun-ping, CHEN Guo-liang, KIM Y W. Effects of Al and Nb on high temperature strength of gamma-TiAl based alloys [J]. The Chinese Journal of Nonferrous Metals, 2000, 10(4): 470-475. (in Chinese)

[49] HUANG Bai-yun, QU Xian-hui, NEI Chang-ming, XIONG Qing. Effects of additions on dislocation configuration and ductility of TiAl intermetallics [J]. The Chinese Journal of Nonferrous Metals, 1993, 3(4): 38-41. (in Chinese)

[50] HUANG J S, LIU Y, HE Y H, ZHANG Y H, LIU B, ZHANG W, HE X Y, HUANG B Y. Distribution of Nb, W and B in TiAl alloy and their effect on microstructure [J]. Materials Science and Engineering of Power Metallurgy, 2006, 11: 32-37.

[51] QIU C Z, LIU Y, HUANG L, ZHANG W, LIU B, LU B. Effect of Fe and Mo additions on microstructure and mechanical properties of TiAl intermetallics [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 521-527.

[52] SCHMOELZER T, MAYER S, SAILER C, HAUPT F, GUTHER V, STARON P, LISS K D, CLEMENS H. In situ diffraction experiments for the investigation of phase fractions and ordering temperatures in Ti-44 at% Al-(3-7) at% Mo alloys [J]. Advanced Engineering Materials, 2011, 13: 306-311.

[53] WU H L, ZHANG W, GONG S K. Effect of Nb on the bonding characteristics of TiAl intermetallic compounds: A first-principle study [J]. Acta Chimica Sinica, 2008, 66: 1669-1675.

[54] HU D, WU X, LORETTO M H. Advances in optimisation of mechanical properties in cast TiAl alloys [J]. Intermetallics, 2005, 13: 914-919.

[55] IMAYEV R M, IMAYEV V M, OEHRING M, APPEL F. Alloy design concepts for refined gamma titanium aluminide based alloys [J]. Intermetallics, 2007, 15: 451-460.

[56] YANG Guang-yu, LIU Yong, WANG Yan, LI Jian-bo, TANG Bai, LI Hui-zhong. Effects of trace B and Y elements on microstructures of cast Ti-Al-Nb-W alloy [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 777-783. (in Chinese)

[57] GOSSLAR D G, NTHER R, HECHT U, HARTIG C, BORMANN R. Grain refinement of TiAl-based alloys: The role of TiB2 crystallography and growth [J]. Acta Materialia, 2010, 58: 6744-6751.

[58] RAO Guang-bin, LIU Kui, HAN En-hou, KE Wei. Mechanism of grain refinement effect of boron addition on γ-TiAl based alloys [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 225-271. (in Chinese)

[59] PARK H S, NAM S W, KIM N J, HWANG S K. Refinement of the lamellar structure in TiAl-based intermetallic compound by addition of carbon [J]. Scripta Materialia, 1999, 41: 1197-1203.

[60] APPEL F, BROSSMANN U, CHRISTOPH U, EGGERT S, JANSCHEK P, LORENZ U, MULLAUER J, OEHRING M, PAUL J D H. Recent progress in the development of gamma titanium aluminide alloys [J]. Advanced Engineering Materials, 2000, 2: 699-720.

[61] HUANG Bai-yun, QU Xian-hui, HE Yue-hui, KONG Gao-ling. Carbonization treatment on TiAl alloys [J]. The Chinese Journal of Nonferrous Metals, 1994, 4(4): 53-55. (in Chinese)

[62] DONG L M, CUI Y Y, YANG R. Effects of B or C on the macro- and micro- structures of cast near gamma TiAl alloys [J]. Acta Metallurgica Sinica, 2002, 38: 643-646.

[63] TIAN W H, NEMOTO M. Precipitation behavior of nitrides in L10-ordered TiAl[J]. Intermetallics, 2005, 13: 1030-1037.

[64] NODA T, OKABE M, ISOBE S, SAYASHI M. Silicide precipitation strengthened TiAl [J]. Materials Science and Engineering A, 1995, 192-193: 774-779.

[65] XIAO W H, ZHANG L, JIANG H R. Effects of Si on high temperature oxidation resistance of TiAl alloy [J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(3): 365-369. (in Chinese)

[66] PENG C Q, HUANG B Y, HE Y H. Effects of alloying on properties of TiAl-based alloys and mechanisms [J]. Transactions of Nonferrous Metals Society of China, 1998, 8: 11-17.

[67] WANG J N, XIE K. Refining of coarse lamellar microstructure of TiAl alloys by rapid heat treatment [J]. Intermetallics, 2000, 8: 545-548.

[68] CHENG Yu-yong, ZHANG Shu-zhi, KONG Fan-tao, LIU Zu-yan, LIN Jun-pin. Progress in β-solidifying γ-TiM based alloys [J]. Chinese Journal of Rare Metals, 2012, 36(1): 154-160. (in Chinese)

[69] NOVOSELOVA T, MALINOV S, SHA W. Experimental study of the effects of heat treatment on microstructure and grain size of a gamma TiAl alloy [J]. Intermetallics, 2003, 11: 491-499.

[70] WANG J N, WANG Y. An investigation of the origin of the superplasticity of cast TiAl alloys [J]. International Journal of Plasticity, 2006, 22: 1530-1548.

[71] YANG K L, HUANG J C, WANG Y N. Phase transformation in the β phase of super α2 Ti3Al base alloys during static annealing and superplastic deformation at 700-1000 °C [J]. Acta Materialia, 2003, 51: 2577-2594.

[72] ZHANG D, DEHM G, CLEMENS H. Effect of heat-treatments and hot-isostatic pressing on phase transformation and microstructure in a beta/B2 containing gamma-TiAl based alloy [J]. Scripta Materialia, 2000, 42: 1065-1070.

[73] JEWETT T J, AHRENS B, DAHMS M. Stability of TiAl in the Ti-Al-Cr system [J]. Materials Science and Engineering A, 1997, 225: 29-37.

[74] WANG Y, LIU Y, YANG G Y, LI H Z, TANG B. Microstructure of cast γ-TiAl based alloy solidified from β phase region [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 215-222.

[75] HUANG J S, LIU Y, HE Y H, ZHANG Y H, LIU B, REN B, HUNG B Y. Effect of heat treatment on microstructure of Ti-45Al-7Nb-0.15B-0.4W [J]. Transactions of Nonferrous Metals Society of China, 2005, 15: 344-351.

[76] HUANGL,LIAWPK,LIUY,HUANGJS.Effectofhot-deformationonthemicrostructureoftheTi-Al-Nb-W-Balloy[J].Intermetallics,2012,28:11-15.

[77] HUANG L, LIAW P K, LIU C T, LIU Y, HUANG J S. Microstructural evolution of (TiAl) plus Nb plus W plus B alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 2192-2198.

[78] SUN F S, CAO C X, KIM S E, LEE Y T, YAN M G. Alloying mechanism of beta stabilizers in a TiAl alloy[J]. Metallurgical and Materials Transactions A, 2001, 32: 1573-1589.

[79] IMAEV V M, IMAEV R M, OLENEVA T I, KHISMATULLIN T. G. Microstructure and mechanical properties of the intermeallic alloy Ti-45Al-6(Nb,Mo)-0.2B [J]. Physics of Metals and Metallography, 2008, 106: 641-648.

[80] IMAYEV V, KHISMATULLIN T, IMAYEV R. Microstructure and technological plasticity of cast intermetallic alloys on the basis of gamma-TiAl [J]. Physics of Metals and Metallography, 2010, 109: 402-410.

[81] CHEN Y Y, NIU H Z, KONG F T, XIAO S L. Microstructure and fracture toughness of a beta phase containing TiAl alloy [J]. Intermetallics, 2011, 19: 1405-1410.

[82] ZHU H, SEO D Y, MARUYAMA K. Strengthening of lamellar TiAl alloys by precipitation bands of βo particles [J]. Materials Science and Engineering A, 2009, 510-511: 14-19.

[83] IMAYEV V, OLENEVA T, IMAYEV R, CHRIST H J, FECHT H J. Microstructure and mechanical properties of low and heavy alloyed γ-TiAl+α2-Ti3Al based alloys subjected to different treatments [J]. Intermetallics, 2012, 26: 91-97.

[84] NG K S, NGAN A H W. Breakdown of Schmid's law in micropillars [J]. Scripta Materialia, 2008, 59: 796-799.

[85] TANG Jian-cheng. Research on microstructural evolution and deformation mechanism of TiAl-based alloy [D]. Changsha: Central South University, 2000. (in Chinese)

[86] MORRIS M A, LI Y G. Deformation mechanisms and slip transfer in a Ti-44Al-2Mo alloy [J]. Materials Science and Engineering A, 1995, 197: 133-145.

[87] COURT S A, LOFVANDER J P A, LORETTO M H, FRASER H L. The influence of temperature and alloying additions on the mechanisms of plastic-deformation of Ti3Al [J]. Philosophical Magazine A, 1990, 61: 109-139.

[88] KAD B K, FRASER H L. On the contribution of climb to high-temperature deformation in single-phase gamma-tial [J]. Philosophical Magazine A, 1994, 69: 689-699.

[89] APPEL F. An electron microscope study of mechanical twinning and fracture in TiAl alloys [J]. Philosophical Magazine, 2005, 85: 205-231.

[90] WIEZOREK J M K., DELUCA P M, MILLS M J, FRASER H L. Deformation mechanisms in a binary Ti-48at.%Al alloy with lamellar microstructure [J]. Philosophical Magazine Letters, 1997, 75: 271-280.

[91] GODFREY A, HU D, LORETTO M H. The role of the alpha(2) phase in the transmission of slip in lamellar TiAl-based alloys[J]. Philosophical Magazine A, 1998, 77: 287-297.

[92] ZHU H L, SEO D Y, MARUYAMA K. Strengthening behavior of beta phase in lamellar microstructure of TiAl alloys [J]. JOM, 2010, 62: 64-69.

含β相的TiAl基金属间化合物组织与性能的优化

邱从章,刘 咏,黄 岚,刘 彬,张 伟,贺跃辉,黄伯云

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:从合金相的结构与相图入手,探讨了B2型TiAl基合金(以γ相为基、含β/B2相的TiAl合金)成分、结构、组织与性能的相关性,分析了β/B2相细化合金的组织和提高材料的高温变形能力的原因,并阐述了B2型TiAl基合金超塑性变形的机理。在TiAl基合金中添加适量的β稳定型元素,形成较稳定的B2结构的有序相,有利于细化晶粒和提高材料的高温变形能力。这种B2型TiAl基合金可通过掺杂微量低序数元素以及随后的热加工工艺提高其综合性能,包括变形能力和高温性能。

关键词:β稳定型元素;B2相;TiAl基合金;相图;晶粒细化;热加工;超塑性变形

(Edited by YANG Hua)

Foundation item: Project (2011CB605505) supported by the National Basic Research Program of China; Project (2011JQ002) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: LIU Yong; Tel: +86-731-88836939; E-mail: yonliu@csu.edu.cn

DOI: 10.1016/S1003-6326(11)61505-7

Abstract: Based on the analyses of the microstructures and phase diagrams of the TiAl-based alloy, the relationship among the composition, structure and mechanical properties of the B2-containing γ-TiAl alloys was reviewed. The refinement of microstructures and improvement of mechanical properties of TiAl alloy through stabilization of the β/B2 phase were reviewed. The mechanism of the superplastic behavior of the B2-containing γ-TiAl alloys was discussed. With a reasonable addition of β-stabilizer, metastable B2 phase can be maintained, which is favorable for fine-grained structure and better high-temperature deformation behaviors. The mechanical properties of the B2-containing TiAl alloy, including the deformability and elevated temperature properties, can also be improved with doping elements and subsequent hot-working processes. The above mentioned researches discuss a new way for developing TiAl alloys with comprehensive properties, including good deformability and creep resistance.