DOI: 10.11817/j.issn.1672-7207.2018.01.031

基于GA-BP神经网络的柴油喷雾贯穿距预测

陈征1, 2,黎青青1, 2,肖乃松1, 2,吴诚1, 2,徐广辉3,郝勇刚3,刘长振3

(1. 汽车车身先进设计制造国家重点实验室,湖南 长沙,410082;

2. 湖南大学 机械与运载工程学院,湖南 长沙,410082;

3. 中国北方发动机研究所,天津,300380)

摘 要:

贯穿距测量的问题,提出一种基于GA-BP神经网络的预测方法。首先通过实验得到30组柴油在定容弹中不同环境背压、喷油压力和喷油脉宽等条件下的喷雾贯穿距,然后将前20组数据作为训练样本,后10组数据作为测试样本,最后分别通过BP神经网络和GA-BP神经网络建立喷雾贯穿距的预测模型。研究结果表明:GA-BP神经网络预测模型的平均相对误差和相对误差方差均比BP神经网络预测模型的低,并且其达到收敛时所需的迭代次数比BP神经网络预测模型的少。基于GA-BP神经网络的柴油喷雾贯穿距预测模型具有较高精度和适用性,为喷雾贯穿距的测量提供了一种低成本、高效率的方法。

关键词:

中图分类号:TK428.9 文献标志码:A 文章编号:1672-7207(2018)01-0247-06

Prediction of diesel spray penetration length based on GA-BP neural network

CHEN Zheng1, 2, LI Qingqing1, 2, XIAO Naisong1, 2, WU Cheng1, 2, XU Guanghui3, HAO Yonggang3, LIU Changzhen3

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China;

3. North China Institute of Engine, Tianjin 300380, China)

Abstract: In order to solve the problem about measuring the penetration length of diesel spray, a prediction method based on GA-BP neural network was proposed in this work. Firstly, 30 sets of diesel spray penetration length were obtained by experiments under various environmental back pressures, injection pressures and injection pulse widths in a constant volume bomb. Then the first 20 sets and the last 10 sets were treated as training samples and test samples, respectively. Finally, BP and GA-BP neural network models were built and compared for the prediction of spray penetration length. The results show that the mean relative error and relative error variance of GA-BP neural network model are lower than those of the BP neural network model, and the number of iterations required for convergence is less than that of BP neural network model. The prediction model of diesel spray penetration length based on GA-BP neural network has higher accuracy and better performance, providing a low cost and high efficient method for measuring spray penetration length.

Key words: BP neural network; diesel spray; penetration length; prediction

燃油的喷射、雾化、蒸发以及与空气的混合等过程对发动机的燃烧和排放特性有重要影响[1-2],因此,许多研究者对柴油喷雾特性进行了研究,以了解柴油喷雾的性能。PARK等[3]研究了燃油温度对喷雾的影响,结果表明当燃油温度较低时,喷雾贯穿距增大,喷雾锥角减小,这会导致冷启动时燃料空气混合变 差。WANG等[4]研究了室温和低温下的柴油喷雾特性,结果表明,与室温相比,低温下增大黏度导致燃料喷射量减少,喷雾质量下降。WANG等[5]研究了喷射压力震荡对喷雾的影响,结果表明喷射压力震荡越剧 烈,喷雾场中液相和气相运动被强烈的干扰,喷射压力震荡能够强化燃料和空气的混合。YIN等[6]研究了柴油喷嘴中空腔对喷雾的影响,结果显示空腔在高压下使喷雾锥角增大、贯穿距减小。HUANG等[7]研究了乙醇柴油混合物在低温燃烧条件下的喷雾燃烧过程,发现蒸发对喷雾贯穿距没什么影响,但是增大了喷雾的传播锥角和投影面积。EMBERSON等[8]研究了柴油和水的乳化物,发现乳化物对喷雾锥角影响很大,但是对贯穿距几乎没有什么影响。YU等[9]比较研究了煤油和柴油的喷雾特性,结果表明煤油具有更短的喷雾贯穿距和更大的喷雾锥角。WANG等[10-12]研究了多次喷射和单次喷射对柴油喷雾的影响,结果表明,与单次喷射相比,多次喷射的液滴更大。并且由于柴油喷雾的初始发展阶段对喷雾的最终形成有很大影响,为此有许多研究者在这方面进行了大量研究,提出了不同的数值模拟方法如欧拉多相流、大涡模拟以及微显微实验技术等[13-16],实现了喷嘴附近柴油雾化初始阶段的观察和测量,并且结果得到了良好的验证。LI等[17]还研究了喷射压力和环境压力对初始阶段柴油喷雾贯穿距和末端速度的影响,提出了喷雾贯穿距的预测经验公式。以上研究表明:燃油喷雾特性的研究主要是基于大量喷雾实验数据的基础上,少有应用神经网络算法(一种由大量处理单元互联组成的非线性、自适应信息处理算法)对喷雾贯穿距进行预测研究。GA-BP神经网络能够不通过实验或少量实验,就可以得到喷雾贯穿距,将大大降低开展喷雾实验的成本。该方法主要是利用GA(genetic algorithm)算法的全局搜索能力,以得到BP(back propagation)神经网络初始权值和阈值的最佳值,从而避免陷入局部最优和提高神经网络训练速度。为此,本文作者拟开展BP和GA-BP神经网络算法对柴油喷雾贯穿距的预测研究,以了解上述2种算法对柴油喷雾贯穿距的预测能力和精度。

1 GA-BP神经网络预测模型

1.1 BP神经网络

BP(back propagation)神经网络是一种按误差逆传播算法训练的多层前馈网络,是目前应用最广泛的神经网络模型之一[18]。BP神经网络由输入层、隐层和输出层组成,假设输入向量为X,输出向量为Y,输入层到隐层的权值矩阵和偏差矩阵分别为W1和B1,隐层到输出层的权值矩阵和偏差矩阵分别为W2和B2,隐层和输出层的神经元传输函数分别为f1和f2,则BP神经网络的输出为

(1)

(1)

BP神经网络的基本原理是采用梯度下降法调整权值和阈值使得网络的实际输出值和期望输出值的均方误差最小,其目标函数为

(2)

(2)

式中:yi为期望输出值; 为实际输出值;N为训练样本数目。

为实际输出值;N为训练样本数目。

1.2 遗传算法

BP神经网络对于输入层与隐含层、隐含层与输出层神经元之间初始连接权值,隐含层和输出层初始阈值非常敏感,若这些参数的初始值设置不合理,则减慢网络收敛速度,甚至陷入局部最优解。而遗传算法(genetic algorithm,GA)具有全局搜索的能力,能够通过生物进化中遗传过程的选择、交叉和变异对个体进行筛选,保留适应度值好的个体,淘汰适应度差的个体,反复循环,最终得到满足条件的个体[19]。因此,本文作者将GA和BP神经网络相结合,利用GA来优化BP神经网络初始权值和阈值,提高BP神经网络的收敛速度,减小BP算法陷入局部最优的可能性。其具体步骤如下[20]。

Step 1:随机初始化种群。个体编码采用实数编码方式,每个个体由输入层与隐含层连接权值、隐含层阈值、隐含层与输出层连接权值以及输出层阈值构成实数串。

Step 2:确定适应度函数。适应度函数F的表达式如下:

(3)

(3)

式中:yi为期望输出; 为预测输出。

为预测输出。

Step 3:选择操作。从种群中选择若干个体作为双亲用于繁殖后代。每个个体i被选择的概率pi为

(4)

(4)

式中:c为种群个体数目;Fi为个体i适应度。

Step 4:交叉操作。2个配对的个体以交叉概率pc交换其中部分基因,从而形成2个新个体。则第k1和第k2个个体在第j位基因交叉操作方法如下:

(5)

(5)

式中:gk1,j和gk2,j分别为第k1和第k2个体在第j位的基因;r为[0,1]之间的随机数。

Step 5:变异操作。以1个比较小的变异概率pv选择第i个个体的第j个基因gij进行变异从而增加种群的多样性,变异操作方法如下:

(6)

(6)

式中:gmax和gmin分别为基因gij的上界和下界;r1为1个随机数;s为当前迭代次数;smax为最大进化次数;r2为[0,1]间的随机数。

Step 6:计算适应度函数值。若适应度函数值达到最大值,则输出优化的权值和阈值,若没有达到最大值,则返回Step 3。

Step 7:将优化的权值和阈值作为 BP神经网络的初始权值和阈值,然后用训练样本对 BP神经网络进行训练,得到柴油喷雾贯穿距预测模型。

Step 8:用测试样本检验预测模型的精度。

2 GA-BP神经网络模型应用

2.1 喷雾贯穿距数据采集

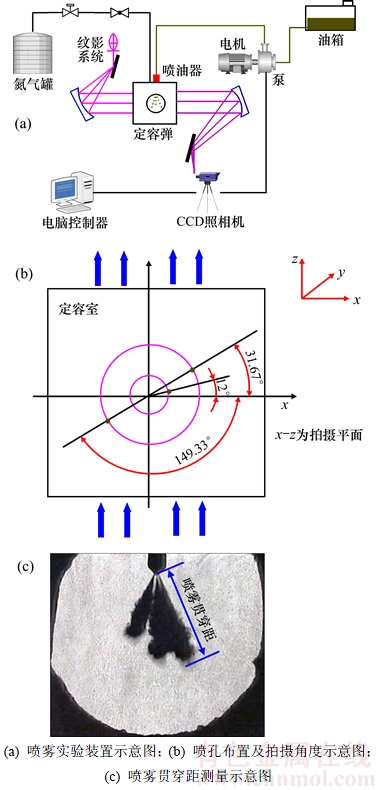

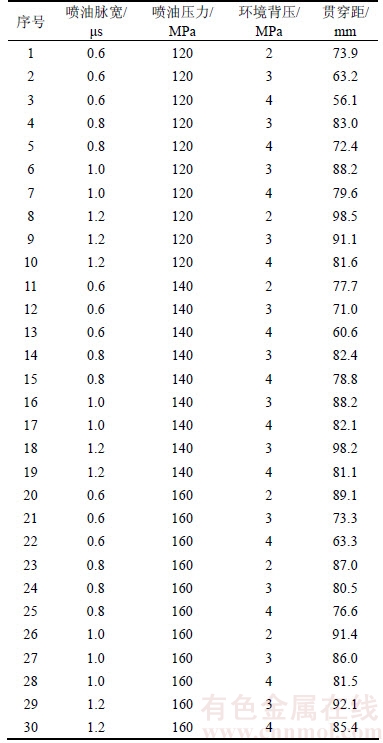

图1所示为柴油喷雾定容弹实验装置示意图,实验装置主要包括燃油单次喷射测量仪、纹影光学系统、高压定容容器、燃油供给系统以及数据采集系统。实验所选用的喷油器为3孔直喷喷油器,燃料为市售5号柴油。实验采用纹影法成像技术测得喷雾形态及贯穿距。待测喷油器安装在测试压力容器顶端,容器内部压力通过氮气瓶(配减压阀)和真空泵在0.1~7.0 MPa之间进行调节,容弹内的温度在整个实验中控制在20 ℃,容器侧壁上安装有2块石英玻璃为高速摄像机提供光路。实验采用高压共轨供油系统提供最大可达160 MPa的喷射压力。采用同步控制电路来实现喷雾图片的高效准确采集。通过不同环境背压、喷油压力和喷油脉宽等工况下的实验,得到的柴油喷雾贯穿距实验结果如表1所示。

图1 柴油喷雾定容弹实验装置示意图

Fig. 1 Experimental schematic of diesel spray in constant volume bomb

2.2 喷雾贯穿距预测结果

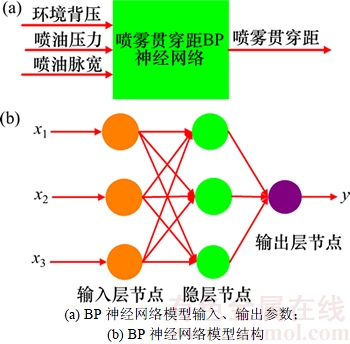

基于不同实验工况下的喷雾贯穿距结果,以环境背压x1、喷油压力x2和喷油脉宽x3为输入向量,喷雾贯穿距y为输出向量,建立如图2所示的喷雾贯穿距BP神经网络预测模型。本文以前20组数据作为训练样本,后10组作为测试样本。由于输入变量为不同量纲的变量,因此,需要对样本进行归一化处理,即将输入层和输出层的数据映射到[0,1]之间,训练结束后,将模型输出反映射到原来的数据范围,则可以得到实际预测结果。遗传算法参数对预测结果有很大影响,需要合理选择其参数范围,以实现快速收敛和求取全局最优解,因此本文中遗传算法的参数如表2所示。根据喷雾贯穿距预测需要,BP神经网络的输入层、隐层和输出层节点的数目分别选择为3,5和1,训练目标误差为0.01,最大训练步数为100,学习速率为0.1。

表1 不同实验条件下的喷雾贯穿距

Table 1 Spray penetration length under various conditions

图2 喷雾贯穿距BP神经网络预测模型

Fig. 2 BP neural network prediction model of spray penetration length

表2 遗传算法参数

Table 2 Parameters of genetic algorithm

为验证GA-BP神经网络预测模型的有效性,将其结果与BP神经网络预测模型的结果进行比较,以平均相对误差(EMR)和相对误差方差(VRE)这2个指标来定量评判模型的性能。

(7)

(7)

(8)

(8)

式中:yi为测试样本值;f(xi)为预测值。

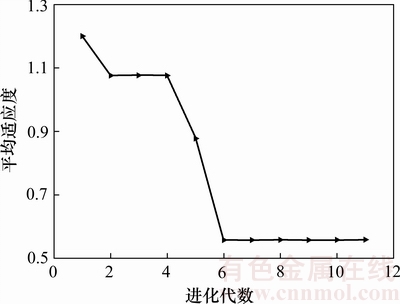

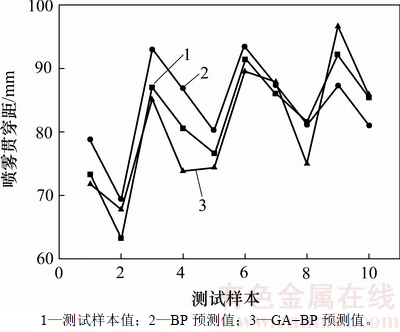

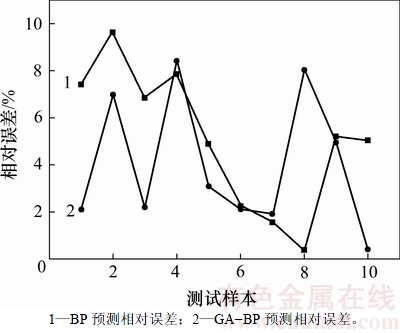

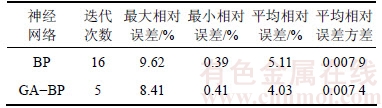

采用BP神经网络和GA-BP神经网络的预测结果如图3~5所示。从图3可知:平均适应度经过6代进化,其值不再发生变化,平均适应度经过6代进化得到了最佳值。从图4可以看出:BP神经网络的预测值和GA-BP神经网络的预测值都很接近实验测量值,某些测试样本表明BP神经网络的预测效果好,而某些测试样本表明GA-BP神经网络的预测效果好。为全面比较2种神经网络的预测性能,本文从迭代次数和平均相对误差方面进行比较。如表3所示,GA-BP神经网络预测模型的平均相对误差和相对误差方差均比BP神经网络预测模型的低,并且其达到收敛时所需的迭代次数比BP神经网络预测模型的少,结果表明经过遗传算法优化后的BP神经网络初始权值和阈值位置比较合理,其经过训练后的性能比BP神经网络的优。

图3 平均适应度随进化代数变化曲线

Fig. 3 Changing curve of mean fitness with evolution generations

图4 BP神经网络和GA-BP神经网络预测值比较

Fig. 4 Comparison of prediction value of BP and GA-BP neural networks

图5 BP神经网络和GA-BP神经网络预测相对误差比较

Fig. 5 Comparison of prediction relative errors of BP and GA-BP neural networks

表3 BP神经网络和GA-BP神经网络预测性能比较

Table 3 Comparison of prediction performance of BP and GA-BP neural networks

3 结论

1) BP神经网络和GA-BP神经网络均能实现柴油喷雾贯穿距的预测。

2) GA-BP神经网络预测模型的平均相对误差和相对误差方差分别为4.03%和0.007 4,均比BP神经网络预测模型的低,并且其达到收敛时的迭代次数为5,远远少于BP神经网络预测模型的迭代次数。

3) 基于GA-BP神经网络的柴油喷雾贯穿距预测模型具有较高精度和适用性,为喷雾贯穿距测量提供了一种低成本、高效率的方法。

参考文献:

[1] PAYRI R, VIERA J P, WANG H, et al. Velocity field analysis of the high density, high pressure diesel spray[J]. International Journal of Multiphase Flow, 2016, 80: 69-78.

[2] POS R, CRACKNELL R, GANIPPA L. Transient characteristics of diesel sprays from a deposit rich injector[J]. Fuel, 2015, 153: 183-191.

[3] PARK Y, HWANG J, BAE C, et al. Effects of diesel fuel temperature on fuel flow and spray characteristics[J]. Fuel, 2015, 162: 1-7.

[4] WANG Z, JIANG C, XU H, et al. Macroscopic and microscopic characterization of diesel spray under room temperature and low temperature with split injection[J]. Fuel Processing Technology, 2016, 142: 71-85.

[5] WANG X, HAN Z, SU W. A numerical study of the effects of pressure fluctuations inside injection nozzle on high-pressure and evaporating diesel spray characteristics[J]. Applied Mathematical Modelling, 2016, 40(5/6): 4032-4043.

[6] YIN B, YU S, JIA H, et al. Numerical research of diesel spray and atomization coupled cavitation by large eddy simulation (LES) under high injection pressure[J]. International Journal of Heat and Fluid Flow, 2016, 59: 1-9.

[7] HUANG S, DENG P, HUANG R, et al. Visualization research on spray atomization, evaporation and combustion processes of ethanol-diesel blend under LTC conditions[J]. Energy Conversion & Management, 2015, 106: 911-920.

[8] EMBERSON D R, IHRACSKA B, IMRAN S, et al. Optical characterization of Diesel and water emulsion fuel injection sprays using shadowgraphy[J]. Fuel, 2016, 172: 253-262.

[9] YU W, YANG W, TAY K, et al. Macroscopic spray characteristics of kerosene and diesel based on two different piezoelectric and solenoid injectors[J]. Experimental Thermal and Fluid Science, 2016, 76: 12-23.

[10] WANG Z, DING H, MA X, et al. Ultra-high speed imaging study of the diesel spray close to the injector tip at the initial opening stage with split injection[J]. Applied Energy, 2016, 163: 105-117.

[11] WANG Z, DING H, MA X, et al. Ultra-high speed imaging study of the diesel spray close to the injector tip at the initial opening stage with single injection[J]. Applied Energy, 2016, 165: 335-344.

[12] WANG Z, XU H, JIANG C, et al. Experimental study on microscopic and macroscopic characteristics of diesel spray with split injection[J]. Fuel, 2016, 174: 140-152.

[13] VUJANOVI M, PETRANOVI

M, PETRANOVI Z, EDELBAUER W, et al. Numerical modelling of diesel spray using the Eulerian multiphase approach[J]. Energy Conversion & Management, 2015, 104: 160-169.

Z, EDELBAUER W, et al. Numerical modelling of diesel spray using the Eulerian multiphase approach[J]. Energy Conversion & Management, 2015, 104: 160-169.

[14] JANGI M, SOLSJO R, JOHANSSON B, et al. On large eddy simulation of diesel spray for internal combustion engines[J]. International Journal of Heat & Fluid Flow, 2015, 53: 68-80.

[15] CRUA C, HEIKAL M R, GOLD M R. Microscopic imaging of the initial stage of diesel spray formation[J]. Fuel, 2015, 157: 140-150.

[16] SALVADOR F J, ROMERO J V, ROSELL M D, et al. Numerical simulation of primary atomization in diesel spray at low injection pressure[J]. Journal of Computational & Applied Mathematics, 2016, 291: 94-102.

M D, et al. Numerical simulation of primary atomization in diesel spray at low injection pressure[J]. Journal of Computational & Applied Mathematics, 2016, 291: 94-102.

[17] LI Y, XU H. Experimental study of temporal evolution of initial stage diesel spray under varied conditions[J]. Fuel, 2015, 171: 44-53.

[18] CHENG C, CHENG X, DAI N, et al. Prediction of facial deformation after complete denture prosthesis using BP neural network[J]. Computers in biology and medicine, 2015, 66: 103-112.

[19] TSOUKALAS V D, FRAGIADAKIS N G. Prediction of occupational risk in the shipbuilding industry using multivariable linear regression and genetic algorithm analysis[J]. Safety Science, 2016, 83: 12-22.

[20] FU X, RICCI S, BISAGNI C. Minimum-weight design for three dimensional woven composite stiffened panels using neural networks and genetic algorithms[J]. Composite Structures, 2015, 134: 708-715.

(编辑 杨幼平)

收稿日期:2017-01-11;修回日期:2017-04-08

基金项目(Foundation item):中央高校基本科研业务费资助项目(227201401189);内燃机燃烧学国家重点实验室开放基金资助项目(K2015-01) (Project(227201401189) supported by the Fundamental Research Funds for the Central Universities; Project(K2015-01) supported by State Key Laboratory of Engines, Tianjin University)

通信作者:陈征,博士,副教授,从事代用燃料燃烧和数值模拟研究;E-mail: chen.zheng@126.com

摘要:为解决柴油喷雾贯穿距测量的问题,提出一种基于GA-BP神经网络的预测方法。首先通过实验得到30组柴油在定容弹中不同环境背压、喷油压力和喷油脉宽等条件下的喷雾贯穿距,然后将前20组数据作为训练样本,后10组数据作为测试样本,最后分别通过BP神经网络和GA-BP神经网络建立喷雾贯穿距的预测模型。研究结果表明:GA-BP神经网络预测模型的平均相对误差和相对误差方差均比BP神经网络预测模型的低,并且其达到收敛时所需的迭代次数比BP神经网络预测模型的少。基于GA-BP神经网络的柴油喷雾贯穿距预测模型具有较高精度和适用性,为喷雾贯穿距的测量提供了一种低成本、高效率的方法。