Variable universe fuzzy expert system for aluminum electrolysis

CAO Dan-yang1, ZENG Shui-ping2, LI Jin-hong1

1. College of Information Engineering, North China University of Technology, Beijing 100144, China;

2. College of Mechanical and Electrical Engineering, North China University of Technology, Beijing 100144, China

Received 4 March 2010; accepted 28 June 2010

Abstract:

In aluminum electrolytic process, the variables affect the current efficiency and the stability of electrolysis cells. AlF3 addition and aluminum tapping volume are two important factors that affect economic benefits of aluminum electrolytic production. Fuzzy logic provides a suitable mechanism to describe the relationship between the process variables and the current efficiency. Fuzzy expert system based on Mamdani fuzzy inference process for aluminum electrolysis was adopted to adjust AlF3 addition and aluminum tapping volume. A novel variable universe approach was applied in the system to solve the problem that different electrolysis cells have different universes of variables. The system was applied to 300 kA aluminum electrolysis cells in a aluminum plant. Experimental results showed that the electrolyte temperature was kept stably between 945 and 955 °C, the current efficiency reached 93.5%, and the DC power consumption was 13 000 kW?h per ton aluminum.

Key words:

variable universe; fuzzy expert system; aluminum electrolysis;

1 Introduction

In the aluminum electrolysis production, alumina is usually dissolved into molten cryolite, which reduces its melting temperature significantly. Objectives of the workers are to maximize the current efficiency, and to maintain the stability of the electrolytic cells during aluminum electrolysis. However, the process of aluminum electrolysis production is a nonlinear, multivariable, and strong coupling process due to the influence of process parameters and environmental factors. The relationship between the current efficiency and process parameters is very complex and difficult to describe through a mathematical model. However, the relationship can be constructed using fuzzy logic approach[1].

As a qualitative approach, fuzzy logic provides a methodology to mimic human expert and allow the use of data and information from expert knowledge. Fuzzy expert system has been widely used in the production process control and optimization since MAMDANI and ASSILIAN developed fuzzy logic controller model for a steam engine[2]. Mamdani fuzzy expert system has been applied in the field of production control in many industries, for example, the application of fuzzy expert system for the early warning of accidents due to driver hypo-vigilance[3], the determination of coronary heart disease risk[4], and operating room air condition control systems[5]. Despite the wide application of fuzzy expert system, the technique hasn’t been applied in aluminum electrolysis production still.

Each electrolytic cell has its own unique range of universe of parameters. So, for different electrolytic cells, we can’t get very good results even if we use the fuzzy logic control. To settle this question, the variable universe fuzzy controller was presented in Refs.[6-10]. In the premise that the number of control rules is fixed, the universe is changed with the changing error. Thus, the contraction of universe is equal to the control rules added, and the precision of the controlled system will be improved. So it was widely used in various controlled fields.

Recently, low cryolite ratio and low temperature technology are regarded as the main process operation conditions in the aluminum electrolysis process. Modern control theory and new method to control the alumina concentration are widely used, and a fuzzy expert control method has been developed based on on-line intelligent identification[11-14]. However, the research on other parameters such as temperature, aluminum tapping volume and AlF3 is very limited. So in this work a variable universe fuzzy expert system was developed for aluminum electrolysis to control aluminum tapping volume and AlF3.

2 Aluminum electrolysis process

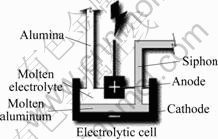

Aluminum is produced from alumina by an electrolysis process that uses large quantities of electrical energy to separate aluminum from oxygen in the alumina. For this process, in a modern smelter about 13 500 kW?h of electricity is required to produce 1 t aluminum. The schematic of aluminum electrolytic cell is shown in Fig.1[15].

Fig.1 Aluminum electrolytic cell

Alumina is a compound of aluminum and oxygen. To obtain metal Al from alumina, oxygen must be separated by electricity in the smelting process. This reaction takes place in large, carbon-lined steel cells, or pots, through which a direct electrical current is passed. The bottom of each pot acts as a cathode, or negative electrode. Carbon blocks are suspended in the pot to serve as an anode, or positive electrode. Inside the pot, alumina is dissolved in a molten electrolyte composed mainly of the cryolite. The electrical current passing from the anode to the cathode causes oxygen in the compound to react with the carbon anode to form carbon dioxide, while the produced aluminum settles to the bottom of the pot to be siphoned off to casting and fabricating.

In aluminum electrolysis production, aluminum tapping volume and AlF3 addition are two important factors that affect the current efficiency and the stability of the electrolytic cell[16]. Meanwhile, aluminum tapping volume and AlF3 addition are influenced by electrolyte temperature and superheat degree and aluminum level.

3 Variable universe fuzzy logic control

Fuzzy system consists of few inputs, outputs, set of predefined rules and a defuzzification method with respect to the selected fuzzy inference system.

3.1 Variable universe

Let Xi=![]() (i=1, 2, …, n) be the universe of the input variable xi (i=1, 2, …, n) and let Y=[Umin, Umax] be the universe of output variable y. Ψi={Aij} (j=1, 2, …, m) stand for the fuzzy sets Xi and Φj ={Bj} stand for the fuzzy sets Y. Ψi and Φj are regarded as the linguistic variables, so that {Rs} (s=1, 2, …, p), fuzzy inference rule set, is formed as follows:

(i=1, 2, …, n) be the universe of the input variable xi (i=1, 2, …, n) and let Y=[Umin, Umax] be the universe of output variable y. Ψi={Aij} (j=1, 2, …, m) stand for the fuzzy sets Xi and Φj ={Bj} stand for the fuzzy sets Y. Ψi and Φj are regarded as the linguistic variables, so that {Rs} (s=1, 2, …, p), fuzzy inference rule set, is formed as follows:

Rs: If x1 is A1j, …, and xn is Anj then y is Bj (1)

The so-called variable universe means that some universes, such as Xi and Y, can change along with changing variables xi and y. In Refs.[6-10], the details of variable universe method were described. However, the method is not appropriate to multiple electrolysis cells in aluminum electrolysis. So we present a novel variable universe approach for aluminum electrolysis. In the novel

approach, Eq.(1) is still used. In addition, let ![]()

![]() (i=1, 2, …, n; k=1, 2, …, t) be the

(i=1, 2, …, n; k=1, 2, …, t) be the

universe of the input variable xi(k) (i=1, 2, …, n) of the

kth electrolytic cell and let ![]() be the

be the

universe of output variable y(k) of the kth electrolytic cell. In order to use the same set of rules {Rs} in fuzzy expert system, xi(k) and y(k) will be converted into Xi and Y respectively:

![]() (2)

(2)

![]() (3)

(3)

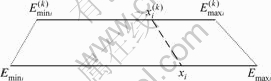

The relationship between xi and xi(k) is shown in Fig.2.

Fig.2 Relationship between xi and xi(k)

3.2 Fuzzy inference system

The most commonly used fuzzy inference technique is the so-called Mamdani method. The Mamdani-style fuzzy inference process is performed in three steps:

1) Fuzzification of the input variables;

2) Fuzzy inference;

3) Defuzzification of the output variables.

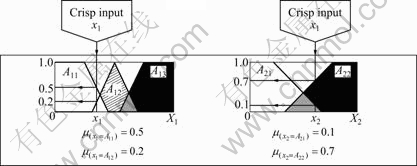

The structure of the fuzzy inference system is shown in Fig.3.

Fig.3 Structure of fuzzy inference system

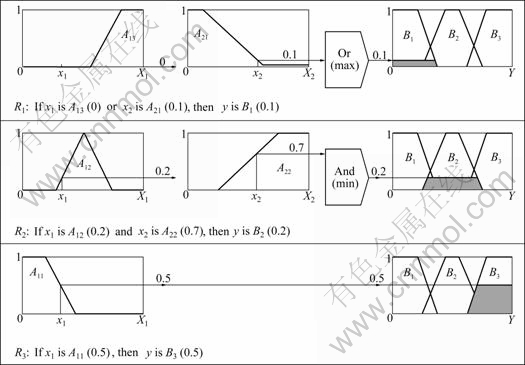

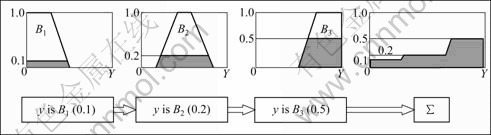

For example, a simple two-input and one-output problem includes three rules:

R1: if x1 is A13 or x2 is A21, then y is B1;

R2: if x1 is A12 and x2 is A22, then y is B2;

R3: if x1 is A11, then y is B3.

The first step is to take the inputs, x1 and x2, and determine the degree to which these inputs belong to each of the appropriate fuzzy sets, as shown in Fig.4.

In the second step, the system is to take the fuzzified inputs, and apply them to the antecedents of the fuzzy rules. If a given fuzzy rule has multiple antecedents, the fuzzy operator (AND or OR) is used to obtain a single number that represents the result of the antecedent evaluation, as shown in Fig.5.

![]() (4)

(4)

![]() (5)

(5)

Now, the result of the antecedent evaluation can be applied to the membership function of the consequent. Then, aggregation is the process of unification of the

Fig.4 Membership function and fuzzy sets

Fig.5 Rule evaluation

outputs of all rules. We take the membership functions of all rule consequents and combine them into a single fuzzy set. The input of the aggregation process is the list of consequent membership functions, and the output is one fuzzy set for each output variable, as shown in Fig.6.

The last step in the fuzzy inference process is defuzzification. Fuzziness helps us to evaluate the rules, but the final output of a fuzzy system has to be a crisp number. The input for the defuzzification process is the aggregate output fuzzy set and the output is a single number. There are several defuzzification methods, but the most popular one is the centroid technique. It finds the point where a vertical line would slice the aggregate set into two equal masses. Mathematically this centre of gravity (COG) can be expressed as:

(6)

(6)

4 Design of variable universe fuzzy expert system for aluminum electrolysis

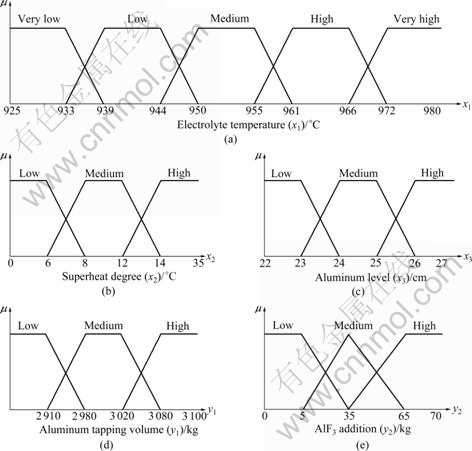

4.1 Fuzzification

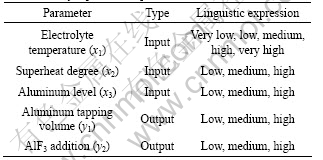

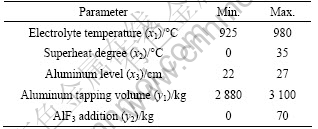

In the variable universe fuzzy expert system, four parameters were chosen as input, two parameters were chosen as output, and the linguistic expressions are given in Table 1. The system assesses electrolyte temperature (x1), superheat degree (x2), and aluminum level (x3) all together in the electrolytic cell and adjusts aluminum tapping volume (y1) and AlF3 addition (y2) in order to enhance the current efficiency and the stability of the electrolytic cell [16]. The universes of the input and output variables are listed in Table 2.

The development of membership functions is also based on discussion with the aluminum electrolytic production experts in the aluminum electrolytic plants. All the membership functions of fuzzy input and output variables are of linear form, such as triangular and trapezium. The linear membership functions are simple, easy to calculate and appropriate in describing the fuzzy input and output variables in the aluminum electrolytic production. As the membership functions of parameters are taken in triangle and trapezium, their mathematical

Table 1 Fuzzy input and output variables

Table 2 Universe of input and output variables

formulas are gathered in a suitable way. The memberships of input and output are shown in Fig.7.

For electrolyte temperature (x1) the fuzzy membership functions will be

Fig.6 Aggregation of rule outputs

Fig.7 Membership for five fuzzy variables

For superheat degree (x2), the fuzzy membership functions will be

For aluminum level (x3), the fuzzy membership functions will be

![]()

![]()

For aluminum tapping volume (y1), the fuzzy membership functions will be

For AlF3 addition (y2), the fuzzy membership functions will be

For each electrolytic cell, it has own universes of input and output variables. So we translate input variable xi(k) into xi, and output variable y(k) into y through Eqs.(2) and (3), where i=1, 2, …, n; k=1, 2, …, t; n is the number of variables; t is the number of cells. Thus we can only use a set of fuzzy rules to infer for each cell.

4.2 Fuzzy inference

The relationship between fuzzy input and fuzzy output variables in the system is developed using Mamdani fuzzy if–then rules. The fuzzy rules are developed based on interviews with experienced production personnel in aluminum electrolytic plants. The fuzzy rules are also developed based on industrial data and literatures.

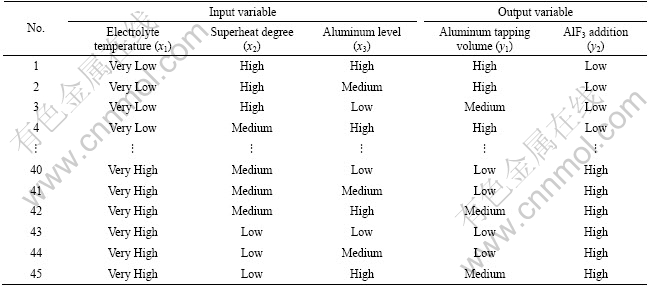

According to fuzzification, electrolyte temperature (x1) is divided into five fuzzy sets, superheat degree (x2) and aluminum level (x3) are respectively divided into three fuzzy sets. We can obtain 45 rules for decision of aluminum tapping volume (y1) and AlF3 addition (y2) based on Eq.(1). The fuzzy rules can be seen in Table 3.

The Mamdani fuzzy inference is based on an implication function minimum (Min) and aggregation function maximum (Max). Therefore, it is also known as Min-Max rule. We can make use of the 45 rules, as shown in Fig.4 and Fig.5.

4.3 Defuzzification

The centroid of gravity (COG) method is the most widely adopted deffuzification method. The centroid defuzzification method finds a point representing the centre of gravity of the aggregated fuzzy sets according to Eq.(6) and Fig.6.

5 Experimental results

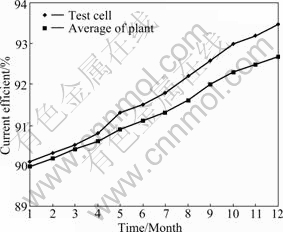

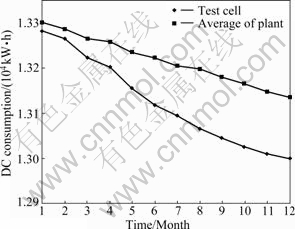

The variable universe fuzzy expert system has been applied to 300 kA aluminum electrolysis cells in a aluminum electrolysis plant for one year. The system makes use of electrolyte temperature, superheat degree, and aluminum level to control aluminum tapping volume and AlF3 addition of electrolysis cell according to 45 fuzzy rules. Fig.8 shows the the average current efficiency of 4 test cells is increased to 93.5% in 12 months. Compared with the whole plant, the current efficiency is enhanced by 0.8%. Fig.9 shows that the average DC consumption per ton aluminum for 4 test cells is reduced to 13 000 kW·h in 12 months, which is reduced by 135 kW·h.

The results show that the current efficiency is improved and DC power consumption is reduced after the system runs normally. This system maintains the electrolyte temperature between 945 and 955 °C, so the current efficiency is greater than 93.5%, and DC power consumption per ton aluminum is less than 13 100 kW·h.

The fuzzy expert system makes use of 45 fuzzy rules which are adaptive to give decisions for different cells. However, the system cannot update the standard

Table 3 Fuzzy rules of aluminum electrolysis

Fig.8 Comparison of current efficiency of electrolysis cells with fuzzy expert system in 12 months

Fig.9 Comparison of DC consumption of electrolysis cells with fuzzy expert system in 12 months

values of parameters of cells automatically according to historical data of electrolytic cells. This will be the next target.

6 Conclusions

1) Variable universe fuzzy expert system provides a greater flexibility to model aluminum electrolysis production by acquiring human expert knowledge. Using aluminum electrolysis expert knowledge from plants, a Mamdani fuzzy expert model is developed and 45 fuzzy rules are generated.

2) The rules in the fuzzy expert system describe the relationship between electrolyte temperature, superheat degree, and aluminum level in the electrolysis cell, and adjust aluminum tapping volume and AlF3 addition in order to improve the current efficiency and the stability of the electrolytic cell. A novel variable universe approach resolves the problem that different cells have different universes of parameters. In practice, the system obtains obvious effects.

3) The system has been applied to 300 kA aluminum electrolysis cell in aluminum plant for 12 months. The current efficiency is enhanced by 0.8%, and the DC power consumption per ton aluminum is reduced by 135 kW?h.

References

[1] AMELIA L, WAHAB D A, HASSAN A. Modelling of palm oil production using fuzzy expert system [J]. Expert Systems with Applications, 2009, 36: 8735-8749.

[2] ZENG Ke, XU Wen-li, ZHANG Nai-yao. Universal approximation of special mamdani fuzzy systems [J]. Control and Decision, 2000, 15(4): 435-438. (in Chinese)

[3] DAMOUSIS I G, TZOVARAS D, STRINTZIS M G. A fuzzy expert system for the early warning of accidents due to driver hypo-vigilance [J]. Pers Ubiquit Comput, 2009, 13: 43-49.

[4] ALLAHVERDI N, TORUN S, SARITAS I. Design of a fuzzy expert system for determination of coronary heart disease risk [C]// International Conference on Computer Systems and Technologies (CompSysTech’07). New York: ACM, 2007: IIIA.14-1-IIIA.14-8.

[5] SARITAS I, ETIK N, ALLAHVERDI N, UNAL SERT I. Fuzzy expert system design for operating room aircondition control systems [C]// International Conference on Computer Systems and Technologies (CompSysTech’07). New York: ACM, 2007: IIIA.1-1-IIIA.1-8.

[6] LIU Xiao-yun, LI Liang-feng, CHEN Wu-fan. A variable universe fuzzy control algoeith based on fuzzy inference [C]// Proceedings of the 2007 International Conference on Wavelet Analysis and Pattern Recognition. Beijing, China: LEEE, 2007: 453-457.

[7] LI H X, MIAO Z H, WANG J I. Variable universe adaptive fuzzy control of a nonlinear system [J]. Science in China, Ser E, 2002, 45(3): 799-815.

[8] CUI B X, YANG J P, FANG B. New type of adaptive fuzzy controllers based on variable universe in application of traffic signal control [J]. Journal of System and Simulation, 2007, 19(2): 380-383. (in Chinese)

[9] WEN Sheng-ping, ZHAO Guo-ping, CAI Kang-xiong. A fuzzy-control adaptive algorithm with variable domain [J]. Control Theory & Applications, 2009, 26(3): 265-268. (in Chinese)

[10] WANG Jiang, QIAO Guo-dong, DENG Bi. Variable universe adaptive fuzzy control and its application for Chua’s chaotic circuit [J]. Control Theory & Applications, 2006, 23(3): 433-438. (in Chinese)

[11] MEGHLAOUI A, ALJABRI N. Aluminum fluoride control strategy improvement [J]. Light Metals, 2003, 132: 425-429.

[12] YURKOV V, MANN V. A simple dynamic realtime model for aluminum reduction cell control system [J]. Light Metals, 2005, 134: 423-428.

[13] LI Jie, ZHANG Wen-gen, DING Feng-qi, LIU Ye-xiang. Fuzzy expert control method based on on-line intelligent identification and its application [J]. Journal of Central South University of Technology: Natural Science, 2004, 35(6): 911-914. (in Chinese)

[14] ZENG Shui-ping, LI Jin-hong, DING Lei. Fault diagnosis system for 350 kA pre-baked aluminum reduction cell based on BP neural network [J]. Light Metals, 2007, 136: 583-587.

[15] ZENG Shui-ping, ZHANG Qiu-ping. Mathematical model of current efficiency with anode current distribution in aluminum production [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 681-685. (in Chinese)

[16] ZENG Shui-ping, LI Jin-hong, REN Bi-jun. Fuzzy determination of AlF3 addition and aluminum tapping volume in aluminum electrolyzing process [J]. Metallurgical Industry Automation, 2008, 32(1): 18-21. (in Chinese)

面向铝电解槽的变论域模糊专家系统

曹丹阳1, 曾水平2, 李晋宏1

1. 北方工业大学 信息工程学院, 北京 100144; 2. 北方工业大学 机电工程学院, 北京 100144

摘 要: 在铝电解过程中有很多参数影响电流效率和电解槽的稳定性。AlF3添加量和出铝量是2个影响铝电解生产经济效益的重要因素。模糊逻辑提供一种合适的机制来描述铝电解过程参数与电流效率之间的关系。在铝电解过程中,采用基于Mamdani模糊推理过程的模糊专家系统调整AlF3添加量和出铝量。系统应用一种新的变论域方法,解决不同电解槽具有不同参数论域的问题,并将系统应用于某电解厂的300 kA铝电解槽中。实验结果表明,电解质温度稳定在945 °C~955 °C,电流效率达到93.5%,吨铝直流电耗为13 000 kW·h。

关键词: 变论域;模糊专家系统;铝电解

(Edited by YUAN Sai-qian)

Foundation item: Project (2009BAE85B00) supported by the National Key Technology R&D Program of China; Project (PHR20100509) supported by Funding Project for Academic Human Resources Development in Institutions of Higher Learning under the Jurisdiction of Beijing Municipality, China

Corresponding author: CAO Dan-yang; Tel: +86-10-88803022-22; E-mail: ufocdy@163.com

DOI: 10.1016/S1003-6326(11)60732-2