文章编号:1004-0609(2015)-07-1731-13

耐烧蚀超高温陶瓷改性C/C复合材料的研究进展

李 军,杨 鑫,刘红卫,黄启忠,苏哲安

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:

炭/炭(C/C)复合材料在高温含氧环境中易氧化烧蚀的问题影响了其在航空航天领域的应用,引入超高温陶瓷能有效地提高其超高温耐烧蚀性能。介绍和分析了化学气相渗透、先驱体浸渍裂解、反应熔渗等基体改性工艺及其优缺点;综述了近年来C/C复合材料基体改性提高其超高温抗烧蚀性能的最新研究进展;并评述了国内在提高C/C复合材料超高温抗烧蚀性能方面取得的一些成果;最后,提出了提高C/C复合材料超高温长时抗烧蚀性能的潜在发展方向。

关键词:

中图分类号:TB332 文献标志码:A

Research process of ultra high temperature ceramics modified carbon/carbon composites for ablation resistance

LI Jun, YANG Xin, LIU Hong-wei, HUANG Qi-zhong, SU Zhe-an

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The shortcoming of easy oxidation for carbon/carbon(C/C) composites in oxidizing environments has limited the applications of C/C composites in aerospace field. Adding ultra-high temperature ceramics (UHTCs) to C/C composites can improve their ablation resistance. The technologies for matrix modification, including chemical vapor infiltration, precursor infiltration pyrolysis, reactive melt infiltration, and the advantages and disadvantages of these technologies were introduced and analyzed. Recent progress on anti-ablation properties for C/C composites at ultra-high temperature was reviewed. Some results about the anti-ablation property of C/C composites were also summarized. Finally, the potential development direction of improving long-time ablation resistance for C/C composites was proposed.

Key words: C/C composites; ultra-high temperature ceramic; matrix modification; anti-ablation property

随着科技的发展,炭/炭(C/C)复合材料作为当今新材料领域中重点研究和开发的超高温材料,它不仅继承了炭素材料的良好导电、导热、轻质的性能,还具有金属材料的耐摩擦、耐热和耐蚀性[1-2],特别是在高温下其力学性能优于常温下的力学性能,从而使其在航天航空领域中的地位越来越高[3]。

虽然C/C复合材料有着众多优点,但其在450 ℃以上的氧气气氛下易被氧化烧蚀[4-5],从而降低了材料的物理化学性能。而C/C复合材料在航空航天中的应用环境是非常严酷的,通常要承受高温高压以及高速含氧气流的氧化和冲蚀。应用于航天飞机机翼前缘和鼻锥结构的C/C复合材料进入大气层时需承受1538 ℃的高温氧化;未来航天飞机机翼和尾翼前缘需要耐1930 ℃的高温氧化,而鼻锥被希望耐高温达2760 ℃,并要满足可重复使用的有限寿命要求[6]。故普通的 C/C复合材料已经无法满足在航空航天中的使用要求。因此,必须对C/C复合材料进行改性处理。

超高温陶瓷(UHTC)因具有超高熔点、高强度以及耐烧蚀等优点而被用于超高速飞行器的热防护系统,但其抗热震性能较差,在高低温瞬时热震中易产生裂纹,而通过结合炭纤维和超高温陶瓷,则能发挥出纤维的韧性和陶瓷的耐烧蚀性能。目前,在国内外对C/C复合材料的研究中,主要是通过在C/C复合材料表面制备抗氧化涂层[7-12]或通过基体改性技术向C/C基体中引入ZrC[13-14]、TaC[15-16]、ZrB2[17-18]、SiC[19-20]等难熔碳化物和硼化物陶瓷相来提高复合材料的超高温耐烧蚀性能。虽然从理论上说通过表面涂层能极大的隔绝氧气与基体接触,从而对基体起到一定的氧化保护作用,但是由于涂层和基体间的热膨胀系数不同,在应用于超高温、强冲刷、高频振动、高低温瞬时热震等极端苛刻环境时,涂层易发生开裂、剥落、烧蚀等失效[21]。而通过基体改性技术则能极大地提高C/C复合材料的超高温耐烧蚀性能。

本文作者根据近年来国内外的相关研究报道,对采用基体改性技术改善C/C复合材料的超高温耐烧蚀性能的研究进展进行了综述,并对各制备工艺的优缺点进行了评述。

1 C/C复合材料基体改性工艺

基体改性技术主要有内部涂层法和添加剂法。其中,内部涂层是通过在炭纤维表面或在基体的孔隙内涂覆具有阻挡氧扩散的阻氧层,这对提高C/C复合材料自身抗氧化能力有一定的促进作用,但内部涂层只能对纤维表面起到保护作用,并不能确保材料整体不被氧化,且当纤维的横截面暴露于空气中时,纤维会从内部烧蚀而留下涂层,因此其氧化防护效果十分有限[6]。而添加剂法则是通过向C/C基体中引入抑制剂或封闭剂填封活性点,从而降低材料的氧化速率,达到提高抗氧化耐烧蚀的目的。目前,主要是向基体中添加难熔碳化物或硼化物来提高材料的超高温抗氧化耐烧蚀性能,其添加方法主要包括化学气相渗透法(CVI)[22]、先驱体浸渍裂解法(PIP)[23]、反应熔体熔渗法(RMI)[14, 24]、热压法(HP)[25]和浆料浸渍法(SI)[26]等。

1.1 化学气相渗透法

化学气相渗透法是在化学气相沉积(CVD)的基础上发展起来的方法。它是碳源气体热解生成的炭随着载气气流流过反应炉中的多孔材料体时,借助对流或扩散等传质过程向多孔材料内部转移,最后生成固体产物并放出气体副产物的方法。化学气相渗透法具有制备温度较低,材料的组织均匀,对纤维的损伤小,能对复杂异形件进行近净成形,并可对微观尺寸进行成分设计等优点。但是,该方法不可避免地会存在一些缺点,如对设备要求高、致密化速度低、周期长、生产成本高,且由于产生大量副产物气体,并易在材料表面形成“结壳”现象[21],故致密化程度不太高,会留下10%~15%的孔隙[3]。

LAMOUROUX等[27]先在炭纤维上沉积一层热解炭保护炭纤维,再以CH3SiCl3和H2为原料,通过CVI法制得C/C-SiC复合材料,最后再在材料表面沉积一层SiC膜,得到的复合材料抗氧化性明显优于C/C复合材料,并提出了一个氧化机制的模型。CHEN等[28]通过两步CVI法制备了C/SiC复合材料,并研究了其在2900和3550 ℃下烧蚀的形貌及机制,得到在2900 ℃下以SiC的氧化和热分解为主要烧蚀行为,而在3550 ℃下则以炭纤维和SiC的升华为主。LI等[29]以二茂铁为催化剂的流动催化膜CVI法制备了丝状纳米纤维(NFC)增强C/C复合材料。此外,时启龙[30]采用CH3SiCl3(MTS)作为SiC的液态前驱体,高纯氢气作为载气,高纯氩气作为稀释气体,并采用鼓泡方式将气态MTS带入反应器的CVI法制备了C/C-SiC复合材料。TANG等[31]先将ZrB2粉末与纤维一起通过针刺的方法制成纤维-粉末预制体,然后通过CVI法将SiC引入预制体制得具有良好抗氧化耐烧蚀性能的Cf/ZrB2-SiC复合材料。

1.2 先驱体浸渍裂解法

先驱体浸渍裂解法(PIP),又称先驱体转化法,是利用有机先驱体对C/C预制体进行浸渍,然后在100~200℃下固化,最后再进行高温裂解得到所需的陶瓷基复合材料的方法。PIP法通过对高分子聚合物组成与结构的设计,从而可以实现对最终陶瓷的结构、成分和性能的设计。同时,PIP法还可以制备形状复杂的异形件,并得到分布均匀且纯度高的陶瓷相。但是,由于先驱体的转化率一般较低,因而要进行多次浸渍-裂解的循环操作,制备周期较长,成本高,且在裂解过程中陶瓷产量低,基体会产生很大的收缩,易导致裂纹和气孔,最终的材料孔隙率相对较高。

LI等[32]通过PIP法制备出了具有良好力学性能和优异烧蚀性能的Cf/ZrB2-ZrC-SiC复合材料。CHEN等[15, 33]研究了TaC含量对2D C/SiC-TaC复合材料性能的影响,结果表明随着TaC含量的增加,密度会增加,但弯曲性能和弹性模量都降低,在1200 ℃的空气中氧化20 min以后弯曲强度为174 MPa;并研究了热处理温度对C/SiC-ZrB2复合材料的影响,在认为1400 ℃时得到的复合材料综合性能较好。YAN等[34]通过不同的浸渍PCS次数制备了Cf/ZrC-SiC复合材料,结果表明浸渍次数多的复合材料具有更好的力学性能,且在高温氧化测试中,发现在材料表面形成了一层熔融ZrO2层,这有利于提高材料的抗氧化耐烧蚀性能。武海棠等[35]研究了不同ZrC含量的C/C-ZrC-SiC复合材料的超高温烧蚀性能,得到当ZrC含量为17.45%时材料具有更优的耐烧蚀性能,在表面温度为2200 ℃等离子焰烧蚀300 s后, 其质量烧蚀率仅为0.00177 g/s, 线烧蚀率为0.00055 mm/s。另外,中南大学的曹柳絮等[36]和LIU等[37]对先驱体转化过程中聚碳硅烷和ZrC先驱体的陶瓷化机理进行了相关研究。

1.3 反应熔体熔渗法

反应熔体熔渗法(RMI)是指在一定的气氛下熔融金属(Si、Zr等)通过毛细管作用浸入多孔C/C预制体中并与气氛或基体炭反应生成陶瓷基复合材料的方法。RMI法具有设备简单、制备周期短、成本低、残余孔隙率低(2%~5%)以及可以近净成形的优点,极具市场竞争力[38]。但是,通过RMI法制备的C/C复合材料会对纤维造成一定的损伤,降低了纤维的增韧效果,故材料的力学性能会受到一定的影响。

WANG等[39]以Zr2Cu为熔渗剂,在1200~1400 ℃的相对低温下制备了Cf/ZrC复合材料,并研究了渗透时间和温度对材料显微组织和性能的影响,结果表明在1200 ℃下熔渗4 h的样品具有优异的抗烧蚀性能和断裂功,烧蚀270 s后其质量烧蚀率和线烧蚀率分别为0.00057 g·cm-2·s-1和0.00024 mm/s。ZHU等[40]也通过RMI法熔渗Zr2Cu制备了Cf/ZrC复合材料,认为在1800 ℃下热处理时会由于ZrC颗粒间的烧结而提高材料的断裂韧性。但奇善等[38]研究了不同孔隙度的C/C 多孔体在熔渗过程中的增密行为和渗Zr后的相组成及显微组织以及C/C-ZrC 复合材料的烧蚀性能,认为密度为1.40 g/cm3的多孔体熔渗效果最佳,且其在3000 ℃下烧蚀60 s后质量烧蚀和线烧蚀速率分别为0.0090 g/s和0.0080 mm/s。WANG等[41, 42]制备了具有优异的抗氧化耐烧蚀性能的C/C-ZrC和C/C-SiC-ZrC复合材料,并建立了动力学模型来研究其渗透过程。PI等[43]也通过熔渗ZrSi2合金制备了弯曲性能和抗烧蚀性能都十分优异的C/SiC-ZrB2-ZrC复合材料。

1.4 热压法

热压法(HP)是将炭纤维与改性用的的金属、非金属粉料混合制成预制体,然后通过高温高压下的烧结而得到陶瓷基复合材料的方法。HP法简单易行,得到的材料密度高,但是由于经过高温高压处理,所以在这过程中,会对炭纤维造成比较严重的损伤,降低了炭纤维的增韧作用,从而使材料的力学性能有所下降,且只能制备形状简单的部件。

TONG等[44]通过热压法制备了沥青ZrC/C复合材料,并研究了Zr含量和颗粒尺寸对抗烧蚀性能的影响,结果表明Zr含量大于7.5%时,烧蚀后在材料表面形成一层均匀致密的ZrO2保护膜,且细颗粒陶瓷的抗烧蚀性能优于大颗粒陶瓷的烧蚀性能。GAO等[17]研究了添加ZrB2以及ZrB2-SiC后的氧化机制,认为添加ZrB2-SiC后的抗氧化能力优于只添加ZrB2的性能。ZHAO等[45]研究了ZrC-30%SiC(体积分数)复合材料从低温到超高温的抗氧化性能。黄向东等[46]研究了不同炭纤维含量对Cf/TiC/Cu复合材料性能的影响,认为在Ti含量不变的情况下,炭纤维质量分数增加会使材料性能下降,当纤维含量为5%时,材料的性能最好。DING等[47]通过热压法制备了不同炭纤维含量的Cf/SiC复合材料,认为炭纤维含量越高,材料的致密化越困难。

1.5 浆料浸渍法

浆料浸渍法(SI)是制造连续纤维增强陶瓷基复合材料的传统方法,主要是将改性用的陶瓷颗粒溶于有机溶剂并混合均匀,制成均匀的浆料,然后将浆料浸渍C/C预制体而得到相应的陶瓷基复合材料。浆料浸渍法简单,设备要求不高,但是浆料浸渍时,颗粒一般无法填充炭纤维束内部的孔隙,易聚集在材料表层引起封孔结壳现象,致密化程度不高,陶瓷相分布不均匀,生产周期相对也较长。

CHEN等[48]通过浆料浸渍法用ZrB2改性了炭-酚醛树脂复合材料,由于在烧蚀过程中生成了ZrO2和B2O3而极大地提高了材料的耐烧蚀性能。樊乾国等[49]研究了不同ZrB2含量的C/C-SiC-ZrB2复合材料的烧蚀性能,结果表明随着ZrB2含量的增加,材料的抗烧蚀性能随之提高。WANG等[50]将ZrC引入炭纤维预制体中提高材料的高温性能。FENG等[51]制备了Cf/SiC-ZrC复合材料并对其进行了等离子风洞测试,结果表明,材料有较好的耐烧蚀性能。另外,SHEN等[26]研究了不同ZrC含量的C/C-ZrC复合材料的烧蚀性能,当ZrC质量分数为4.14%时,材料的线烧蚀率和质量烧蚀率分别比C/C复合材料降低了83.0%和77.0%。

1.6 其他工艺

单一的制备方法都存在着各自的优缺点,所以,研究者们就希望能够通过结合不同的工艺,充分利用各工艺的优势,制备出性能更好、成本低、制备周期短的改性C/C复合材料。CHEN等[52]利用“CVD+PIP”法制备了具有优异耐烧蚀性能的C/ZrC-SiC复合材料。LI等[53-54]先用等温CVI法向纤维预制体中引入 炭基体,然后通过RMI法将Zr、Si、C和ZrO2粉末引入而制得C/C-SiC-ZrC复合材料,并研究了不同密度炭基体复合材料改性后的抗烧蚀性能,得到C/C骨架密度为1.51 g/cm3时,其线烧蚀和质量烧蚀率分别为1.44 μm/s和0.21 mg/s。ZHANG等[55]通过“PIP+RMI”法分3步制备了较致密且烧蚀性能优异的3D Cf/ZrC-SiC复合材料,其烧蚀性能优于相同条件下只通过RMI法制备成的3D Cf/ZrC-SiC复合材料。XIE等[56-57]结合热梯度CVI法和PIP法制备了C/C-ZrC-SiC复合材料,该材料抗循环短时烧蚀性能非常好,其线烧蚀和质量烧蚀率分别为-0.3 μm/s和-2.29 mg/s。

2 C/C复合材料基体改性耐烧蚀性能研究进展

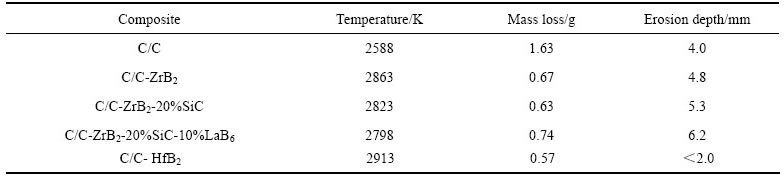

在国外,亚利桑那大学的LUKE等[58]用SiC先驱体和ZrB2粉末混合后制成浆料,然后通过浆料渗透制得C/C-ZrB2-SiC复合材料,在氧化烧蚀过程中,由于在材料表面形成了能自愈合的玻璃态ZrO2-SiO2而使材料的抗氧化耐烧蚀性得到明显提高。ERICA等[59]通过ZrB2和B4C改性C/C复合材料来提高其抗烧蚀性能,结果表明:在1200 ℃以下B4C的添加能对C/C复合材料的抗烧蚀性能起到一定的改善作用,但在1500 ℃下烧蚀300 s后,C/C-B4C的质量烧蚀率(0.1727%)高于C/C复合材料的质量烧蚀率(0.1552%),而ZrB2的添加则明显增强了抗烧蚀性能,在相同条件下C/C-ZrB2-B4C复合材料的质量烧蚀率仅为0.0428%,这主要归因于B4C和ZrB2在高温下氧化形成的B2O3和ZrO2能封填材料表面的裂纹、凹坑等缺陷。但是由于B2O3在1000 ℃以上易挥发,且在该材料中ZrB2含量相对较低,故其烧蚀性能虽有所改善但还有待提高。LEVINE等[60]分别将HfB2、SiC粉末与丙烯基聚碳硅烷混合成浆料,然后用所得浆料浸渍C/C预制体得到Cf/HfB2-SiC复合材料,经1805 ℃下烧蚀240 s后材料质量损失率仅有1.9%。PAUL等[61]分别将HfB2、HfC、ZrB2、ZrB2-20%SiC和ZrB2-20%SiC-10%LaB6粉末与酚醛树脂以及丙酮均匀混合制成浆料,然后分别用这些浆料对C/C预制体进行加压渗透而制得Cf-UHTC复合材料并对所得材料进行氧乙炔焰测试,经过60 s的烧蚀后,其参数如表1所列,显然陶瓷相的加入增强了C/C复合材料的超高温耐烧蚀性能。DANIEL等[62]通过反应渗透处理(RIP)技术将八水氯氧化锆、硼酸和酚醛树脂分别溶于酒精后再依次混合,然后向该凝胶溶液中加入ZrB2粉末并均匀混合,最后再通过浸渍而制得C/C-ZrB2复合材料,并对其在2500 ℃下进行60 s的烧蚀实验,烧蚀后在材料表面形成一层ZrO2膜,从而使材料的耐烧蚀性能得以提高。SURESH等[63]研究了四维C/C-SiC复合材料的烧蚀性能,在热流量为10 MW/m2下烧蚀60 s后,材料质量和线烧蚀率分别为103.282 g·m-2·s-1和57 μm/s。JULIEN等[64]通过对预制体渗透无机聚合物制备了炭纤维和碳化硅纤维增强玻璃陶瓷基体K2O-SiO2复合材料,对其进行氧乙炔焰测试,在2500 K下烧蚀20 s后炭纤维增强相的质量烧蚀率和线烧蚀率分别为15 mg/s和75 μm/s,而碳化硅纤维增强相则因为SiC氧化生成SiO2的过程是一个质量增加过程,且生成的SiO2能帮助封填材料表面缺陷而使得材料的质量和线烧蚀率只有3 mg/s和50 μm/s。虽然K2O-SiO2玻璃陶瓷能对材料起到一定的保护作用,但是K2O和SiO2的熔点只有770和1700 ℃,在超高温高速气流作用下易自挥发和表面剥蚀而大大降低氧化膜的保护效率,从而使材料烧蚀率快速增加。另外,PICHON等[65]通过CVI法制备了C/SiC复合材并将其应用于“Pre-X载具”运载火箭上。

表1 不同复合材料烧蚀60 s后的实验参数[61]

Table 1 Experiment parameter of different composites after 60 s oxyacetylene torch testing [61]

根据相关文献报道来看,国内对C/C复合材料基体改性抗烧蚀性能方面的研究主要集中在西北工业大学[66]、国防科技大学[67]、中南大学[68]、中国科学院金属研究所[69]、中国科学院上海硅酸盐研究所[70]、北京航天材料与工艺研究所[71]以及西安航天复合材料研究所[72]等高校和科研院所。

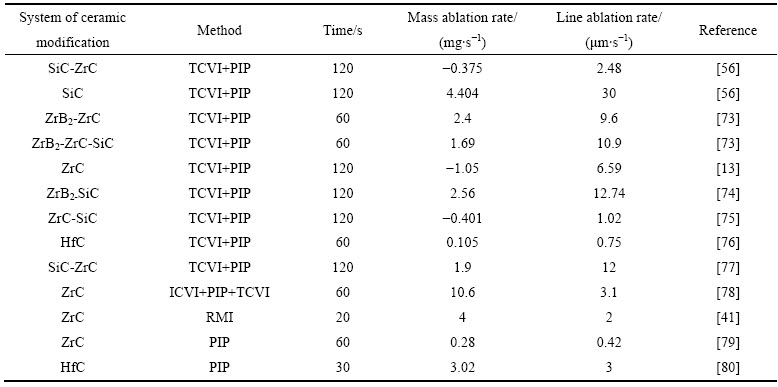

在C/C复合材料基体改性技术方面,西北工业大学的研究人员重点发展了先驱体浸渍裂解、热梯度化学气相沉积和反应熔体熔渗等技术[66]。表2所列为西北工业大学按照GJB323A-96氧乙炔焰烧蚀条件进行的各类陶瓷体系改性C/C复合材料烧蚀性能的测试结果[13, 41, 56, 73-80]。由表2可以看出,通过ZrC、ZrB2、SiC、HfC等超高温难熔陶瓷基改性的C/C复合材料普遍具有优异的超高温短时抗烧蚀性能。其中,LI等[75]采用“TCVI+PIP”工艺制备的C/C-ZrC-SiC复合材料在氧乙炔焰下烧蚀120 s后试样的质量有所增加,线烧蚀率也仅为1.02 μm/s。这主要是因为有机先驱体具有较好的流动性,在浸渍过程中可流入纤维束间的间隙,裂解后能较均匀的分布在基体中,且基体中Zr、Si含量也较高,在超高温下烧蚀后在材料表面形成了连续的保护膜,降低了氧化性气氛的渗透速率,同时,岛状ZrO2还能起到一定的钉扎作用,降低高速气流对氧化膜的冲刷。XIE等[56]制备的C/C-SiC-ZrC烧蚀120 s后的线烧蚀率比在相同工艺条件下制备C/C-SiC的降低了一个数量级,且烧蚀后质量不降反增,由此可知,向C/C复合材料中引入ZrC后,C/C复合材料的抗烧蚀性能得到显著提高。由于SiO2的理想使用温度低于1700 ℃,在3000 ℃的氧乙炔焰下,SiO2的防护作用快速降低,而ZrO2比SiO2具有更高的熔点,在超高温下其耐冲刷性更好。由LIU等[73]的研究可知,相同工艺条件下C/C复合材料中引入ZrB2-ZrC-SiC陶瓷相和ZrB2-ZrC陶瓷相的质量烧蚀率和线烧蚀率变化不大,说明在该工艺条件下引入SiC后对C/C复合材料超高温抗烧蚀性能影响不大,这与PAUL等[61]的研究结果相似。此外,采用“TCVI+PIP”工艺制备的C/C-ZrC[13]、C/C-ZrB2-SiC[74]、C/C-HfC[76]以及C/C-SiC- ZrC[77]均具有很好短时抗烧蚀性能。通过PIP法制备的C/C-ZrC[79]比RMI法制备的C/C- ZrC[41]具有更优异的抗烧蚀性能,在材料的制备过程中,RMI法采用的Zr金属溶液黏度比PIP法采用的ZrOCl2水溶液的大,使得熔渗时Zr主要分布在材料的表层,且分布没有使用PIP法时的均匀,故其烧蚀性能比使用PIP法的略差,虽然两种方法所制得的材料均具有较好的耐烧蚀性能,但在材料制备过程中都可能会与炭纤维反应而对其造成损伤,因此还有待改善。LI等[80]通过HfC改性的C/C-HfC复合材料在30 s烧蚀后的质量和线烧蚀率也仅为0.00302 g/s和0.003 mm/s,其同样具有非常优异的短时耐烧蚀性能。

表2 西北工业大学研究的各类陶瓷基体改性C/C复合材料的氧乙炔焰烧蚀性能[13, 41, 56, 73-80]

Table 2 Oxyacetylene ablation properties of different ceramic systems modified C/C composites developed by Northwestern Polytechnical University[13, 41, 56, 73-80]

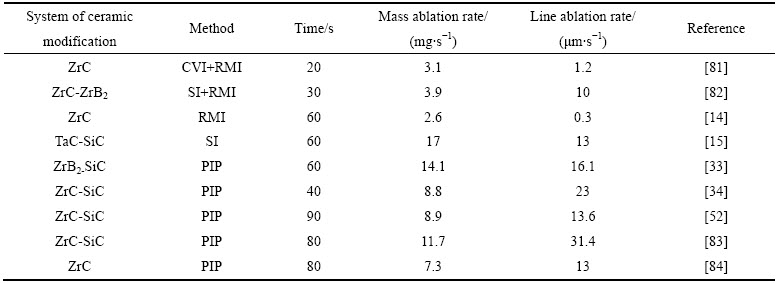

国防科技大学的研究人员在C/C复合材料基体改性方面也进行了多年的研究,其中,重点研究了先驱体浸渍裂解、反应熔体熔渗、化学气相渗透和浆料渗透工艺。表3所列为国防科技大学根据GJB323A-96氧乙炔焰烧蚀标准测试的各类陶瓷基体改性C/C复合材料的烧蚀性能[14-15, 33-34, 52, 81-84]。由表3可知,国防科技大学采用RMI法制备的炭纤维增强陶瓷基复合材料的烧蚀性能优于采用PIP法制备的材料的烧蚀性能。ZHU等[14]采用Zr-Cu合金为原料,通过RMI法在1200 ℃的相对低温下制备的Cf/ZrC复合材料烧蚀60 s后,质量烧蚀率和线烧蚀率分别为0.0026 g/s和0.0003 mm/s,同时研究发现,随着锆铜合金中铜含量的增加,C/C复合材料中形成的ZrC含量逐渐降低,这将不利于材料烧蚀性能的提高。该法通过引入Cu使制备C/C-ZrC的温度大幅度降低,进而减小了对纤维的损伤,但是,当Cu过量时,会形成Cu-Zr-C的共晶体而使ZrC的含量降低,从而使材料的耐烧蚀性能下降。CHEN等[82]先将B4C粉末与酚醛树脂和乙醇混合成均匀浆料,然后通过浆料浸渍制成C/C-B4C复合材料,最后再经过RMI法熔渗Zr而制得的C/C-ZrC-ZrB2 复合材料也具有非常优异的超高温短时耐烧蚀性能,这主要归因于基体中ZrC-ZrB2的含量非常高,在氧乙炔焰下烧蚀时,ZrC-ZrB2氧化为连续的ZrO2防护膜,且B2O3的快速挥发能带走大量的热,从而降低材料表面温度,进而增强材料的耐烧蚀性能。但基体中的残余Zr以及部分Zr与纤维反应都会降低材料的力学性能。C/SiC-TaC复合材料烧蚀过程中在材料表面形成一层二元SiO2- Ta2O5氧化薄膜[15],虽然TaC的熔点(3880 ℃)高于ZrC的(3540 ℃),但是Ta2O5的熔点(1870 ℃)明显的低于ZrO2的(2715 ℃),在超高温下SiO2-Ta2O5氧化薄膜易被高速气流冲走,所以C/SiC-TaC复合材料的耐烧蚀性能低于C/C-ZrC复合材料的[81, 84]。此外,由于采用的原材料以及基体内ZrC、SiC的含量不同,通过PIP法制备的C/C-ZrC-SiC复合材料[34, 83]与CHEN等[52]制备的C/C-ZrC- SiC相比质量烧蚀率略微增加,但线烧蚀率却明显增大,CHEN等制备的C/C-ZrC–SiC复合材料含有更高的ZrC和相对较少的SiC,由于ZrO2熔点更高,在高速气流作用下,二元相ZrO2-SiO2被吹走的量也相对减少,故其线烧蚀率更低,同时,在这3种材料中均存在孔隙率过大的问题,为氧化性气氛的渗透提供了大量通道,这可能也是材料的抗烧蚀性能不是非常优异的原因所在。

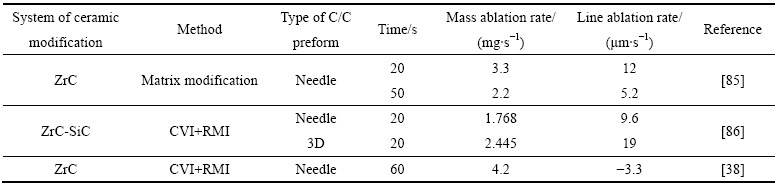

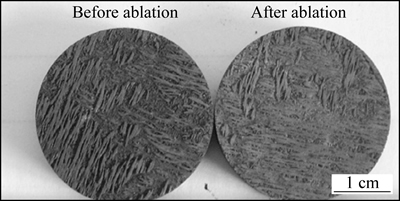

中南大学的研究人员在C/C复合材料耐烧蚀性能方面也做了大量的工作,取得了一些较好的成果。表4所列是中南大学研究人员根据GJB323A-96氧乙炔焰烧蚀标准测试的各类陶瓷基体改性C/C复合材料的烧蚀性能[38, 85-86]。杨鑫等[85]通过基体改性技术制备了ZrC质量分数为26.46%的C/C-ZrC复合材料,烧蚀20 s后其质量烧蚀率和线烧蚀率分别为3.3 mg/s和12 μm/s,比C/C复合材料的分别降低了50%和7.6%,而经过50 s烧蚀后,C/C-ZrC复合材料的质量烧蚀率和线烧蚀率分别下降到2.2 mg/s和5.2 μm/s。当烧蚀时间较短时,C/C-ZrC材料表面形成的ZrO2薄膜不连续,氧化性气氛易渗透到基体内部与炭反应,而随着烧蚀时间的逐渐延长,所生成的ZrO2防护膜逐渐趋于连续致密,大大的降低了氧气的渗透速度,且融化的氧化物薄膜还能填充材料表面的裂纹和凹坑等缺陷,因而使其烧蚀率快速降低。房啸等[86]采用CVI和RMI工艺相结合,分别用针刺编制预制体和三维编织预制体制备了C/C-SiC-ZrC复合材料,氧乙炔焰下烧蚀20 s后针刺预制体的C/C-SiC-ZrC复合材料烧蚀性能优于三维预制体的C/C-SiC-ZrC复合材料的,这主要是由于三维预制体内部纤维密度较高,可用于生成ZrC-SiC陶瓷相的空间较少,且纤维含量高会导致热解炭含量减少,故C/C-SiC-ZrC复合材料中的陶瓷相含量不高,从而影响了材料的烧蚀性能。同样采用CVI和RMI工艺相结合制备的C/C-ZrC[38]复合材料经过60 s烧蚀后质量烧蚀率为4.2 mg/s,而厚度则有所增加,展现了优异的短时超高温耐烧蚀性能,该材料在熔渗后孔隙率仅有6.6%,含有较高的陶瓷含量,在烧蚀过程中陶瓷能很快氧化成连续保护薄膜,减少为氧气的渗透提供的通道,从而减少内部炭的氧化。同时,中南大学研究人员制备的改性C/C复合材料还通过了2500和2800 K的高温电弧风洞考核,发现试样表面完整,无明显烧蚀迹象[10]。此外,刘春轩等[68, 87]还将基体改性技术与涂层技术相结合,采用“CVI+PIP+RMI”工艺,先用基体改性制备了C/C-ZrC- SiC复合材料,然后又在材料表面分别制备了SiC和ZrC-SiC涂层,并在等离子火焰下进行烧蚀测试,实验过程中材料表面最高温度超过2300 ℃,经过120 s的烧蚀后,ZrC-SiC涂层的C/C-ZrC-SiC复合材料质量烧蚀率和线烧蚀率分别为0.0045 g/s和0.0048 mm/s,SiC涂层的C/C-ZrC-SiC复合材料质量烧蚀率和线烧蚀率分别为0.0026 g/s 和0.0037 mm/s,且材料表面仍然完整(见图1),没有明显的烧蚀凹坑或孔洞,展现了非常优异的短时超烧蚀性能。先基体改性、再涂层的方法为材料的超高温耐烧蚀性提供了双层保险,烧蚀过程中,材料表面的SiC和ZrC-SiC涂层优先氧化,在其消耗完以后,基体中的SiC-ZrC又可氧化成ZrO2-SiO2二元防护膜,从而大幅度提高材料的超高温耐烧蚀性能。最近,XUE等[88]通过PIP法制备的C/C-HfC复合材料在2573 K的温度下烧蚀240 s后质量烧蚀率和线烧蚀率分别仅为0.55 mg/cm2s和5.31 μm/s,PIP法能使HfC均匀的分布在基体中,且烧蚀时能在材料表面形成树枝状的HfO2相和低氧扩散速率的HfCxOy相,这都能极大地提高材料的耐烧蚀性能。

表3 国防科技大学研究的各类陶瓷基体改性C/C复合材料的氧乙炔焰烧蚀性能[14-15, 33-34, 52, 81-84]

Table 3 Oxyacetylene ablation properties of different ceramic systems modified C/C composites developed by National University of Defense Technology[14-15, 33-34, 52, 81-84]

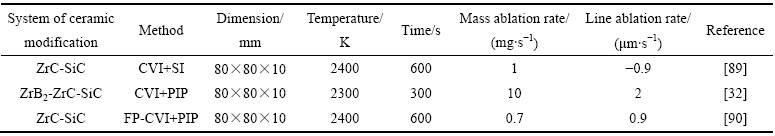

此外,国内外对陶瓷改性C/C复合材料还进行了等离子烧蚀测试。表5所列是中国科学院上海硅酸盐研究所的LI等[32, 89-90]研究的各类陶瓷基体改性C/C复合材料的等离子风洞烧蚀性能。其中,采用“CVI+PIP”工艺制备出的Cf/ZrB2-ZrC- SiC在材料表面温度为2300 K的温度下烧蚀300 s后质量烧蚀率和线烧蚀率分别为10 mg/s和2 μm/s[32],而用“FP-CVI+PIP”工艺制备的Cf/ZrC-SiC复合材料经2400 K下烧蚀600 s后材料的质量和厚度变化更加微小,展现出了更加优异的耐烧蚀性能[90]。这可能是得益于“FP-CVI+PIP”工艺制备的材料开孔率更低,且基体中ZrC-SiC陶瓷含量更高,烧蚀时具有更低的氧气透过率和更易在表面形成连续氧化膜阻挡基体的烧蚀。同时,LI等[89]通过将锆粉、硅粉和酚醛树脂按一定比例混合溶于乙醇制成均匀浆料,然后经过浆料浸渍C/C预制体而制得的Cf/ZrC-SiC复合材料经2400 K下烧蚀600 s后质量烧蚀率仅为1 mg/s,材料的厚度在烧蚀后还有所增加,这主要归因于材料内部原位反应带来的体积收缩更小,使基体更致密,且基体中ZrC含量高于SiC含量,氧化后形成大量的ZrO2,这能极大地提高氧化膜的抗冲刷能力,最终在材料表面形成大量的氧化膜而使材料厚度有所增加。但是,该法中用粉末制成的浆料不易渗入纤维束的孔隙中使得陶瓷相的分布不够均匀,进而影响材料性能。

表4 中南大学研究的各类陶瓷基体改性C/C复合材料的氧乙炔焰烧蚀性能[38, 85-86]

Table 4 Oxyacetylene ablation properties of different ceramic systems modified C/C composites developed by Central South University[38, 85-86]

表5 上海硅酸盐研究所研究的各类陶瓷基体改性C/C复合材料的等离子风洞烧蚀性能[32, 89-90]

Table 5 Plasma wind tunnel ablation properties of different ceramic systems modified C/C composites developed by Shanghai Institute of Ceramics[32, 89-90]

图1 C/C-ZrC-SiC复合材料烧蚀表面形貌[68]

Fig. 1 Surface morphologies of C/C-ZrC-SiC composite after ablation[68]

3 结论

1) 现在世界各国的高端国防科技的热防护领域中,C/C复合材料的地位越来越高,对C/C复合材料的超高温抗氧化耐烧蚀性能要求也越来越苛刻,同时,这也是世界各国争相研究的重点和难点。就国内来看,经过多年的努力,C/C复合材料在1600 ℃以下的中低温段长时静态抗氧化防护问题已较为成熟,在1600~1800 ℃也有一定的成果,但是对更高温度,特别是2000 ℃以上的超高温抗氧化耐烧蚀性还急需更多的研究。

2) 由于添加超高温陶瓷后,在高温有氧环境下能在C/C复合材料表面形成氧化物薄膜,进而起到吸收热量、降低氧气渗透率和降低高速气体冲蚀的作用,故陶瓷相的含量及分布对C/C复合材料的耐烧蚀性能具有很大影响,只有当足量的陶瓷相均匀分布于C/C材料基体和纤维中时,才能在材料表面形成连续致密的氧化薄膜保护层。目前能实现陶瓷颗粒相对均匀分布的基体改性工艺成本太高,而低成本的工艺又存在对纤维损伤大、残留原材料等缺陷,故必须发展相应的低成本高性能改性技术。此外,由于现阶段发展的锆基、铪基、硅基等改性陶瓷只有在一定温度段时才具有最佳抗氧化耐烧蚀防护作用,而在实际应用中,用于高性能发动机热端部件、高超音速飞行器热防护系统的C/C材料必须承受全温域的性能检测。因此,必须发展新的复合陶瓷改性体系。

3) 目前通过基体改性技术还只能提高C/C复合材料的短时超高温耐烧蚀性能,而想要取得长时超高温抗氧化耐烧蚀方面的进步,单靠涂层技术或基体改性技术都是很难实现的,必须结合涂层和基体改性技术,通过对涂层结构和体系的设计(如多层复合涂层),以及探寻更好的陶瓷组分配比和优化基体改性工艺,发挥涂层的长时防护和基体改性的耐烧蚀性能。同时,还必须跟进与真实应用环境相似的检测技术,从而实现对新一代飞行器热防护系统的全温域长时氧化烧蚀防护。

REFERENCES

[1] LI Cui-yan, LI Ke-zhi, LI He-jun, OUYANG Hai-bo, ZHANG Yu-lei, GUO Ling-jun. Mechanical and thermophysical properties of carbon/carbon composites with hafnium carbide[J]. Ceramics International, 2013, 39(6): 6769-6776.

[2] 冉丽萍, 李文军, 杨 琳, 易茂中. C/C-Cu复合材料的烧蚀性能及烧蚀机理[J]. 中国有色金属学报, 2010, 20(3): 510-515.

RAN Li-ping, LI Wen-jun, YANG Lin, YI Mao-zhong. Ablation properties and ablation mechanism of C/C-Cu composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 510-515.

[3] 杨国威. C/C-ZrB2(ZrC、TaC)超高温陶瓷基复合材料制备工艺及性能研究[D]. 长沙: 国防科技大学, 2008: 5-7.

YANG Guo-wei. Preparation and properties of C/C-ZrB2(ZrC、TaC) ultra-high temperature ceramic matrix composites[D]. Changsha: National University of Defense Technology, 2008: 5-7.

[4] CHEN Zhao-ke, XIONG Xiang, HUANG Bai-yun, LI Guo-dong, XIAO Peng, WANG Ya-lei, WANG Qiong. Oxidation mechanisms of C-SiC-TaC-C composites prepared by chemical vapor infiltration[J]. Transactions of Nonferrous Metal Society of China, 2007, 17(1): 145-149.

[5] MANOCHA L M, MANOCHA S, PATEL K B, GLOGAR P. Oxidation behaviour of Carbon/Carbon Composites impregnated with silica and silicon oxycarbide[J]. Carbon, 2000, 38(10): 1481-1491.

[6] 黄启忠. 高性能炭/炭复合材料的制备、结构与应用[M]. 长沙: 中南大学出版, 2010: 423-427.

HUANG Qi-zhong. Fabrication, structure and application of high performance carbon/carbon composites[M]. Changsha: Central South University Press, 2010: 423-427.

[7] YANG Xin, HUANG Qi-zhong, SU Zhe-an, CHAI Li-yuan, WANG Xiu-fei, ZHOU Le-ping. A double layer nanostructure SiC coating for anti-oxidation protection of carbon/carbon composites prepared by chemical vapor reaction and chemical vapor deposition[J]. Ceramics International, 2013, 39(5): 5053-5062.

[8] YANG Xin, SU Zhe-an, HUANG Qi-zhong, CHAI Li-yuan. Preparation and oxidation resistance of mullite/SiC coating for carbon materials at 1150 ℃[J]. Transactions of Nonferrous Metal Society of China, 2012, 22(12): 2997-3002.

[9] ZHANG Yu-lei, REN Jin-cui, TIAN Song, LI He-jun, HU Zhi-xiong. SiC coating toughened by HfC nanowires to protect C/C composites against oxidation[J]. Appl Surf Sci, 2014, 311: 208-213.

[10] 杨 鑫, 黄启忠, 苏哲安, 常 新. C/C复合材料的高温抗氧化防护研究进展[J]. 宇航材料工艺, 2014(1): 1-15.

YANG Xin, HUANG Qi-zhong, SU Zhe-an, CHANG Xin. Review of recent progress on oxidation protection for C/C composites at high temperature[J]. Aerospace Materials and Technology, 2014(1): 1-15.

[11] 苏哲安, 杨 鑫, 黄启忠, 黄伯云, 李建立, 张明瑜, 谢志勇. SiC涂层对C/C复合材料高温氧乙炔焰烧蚀性能影响[J]. 中国有色金属学报, 2011, 21(11): 2838-2845.

SU Zhe-an, YANG Xin, HUANG Qi-zhong, HUANG Bai-yun, LI Jian-li, ZHANG Ming-yu, XIE Zhi-yong. Effect of SiC coating on ablation resistance of C/C composites under oxyacetylene torch flame[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2838-2845.

[12] GE Yi-cheng, YANG Ling-yun, WU Shuai, LI Chan, LUO Jian, YI Mao-zhong. Influence of heat-treatment on oxidation- resistance of phosphate-coating for C/C composite[J]. Transactions of Nonferrous Metal Society of China, 2014, 24(2): 455-461.

[13] LI Ke-zhi, XIE Jing, LI He-jun, FU Qian-gang. Ablative and mechanical properties of C/C-ZrC composites prepared by precursor infiltration and pyrolysis process[J]. Journal of Materials Science and Technology, 2015, 31(1): 77-82.

[14] ZHU Yu-lin, WANG Song, CHEN Hong-mei, LI Wei, JIANG Jin-ming, CHEN Zhao-hui. Fabrication of Cf/ZrC composites by infiltrating Cf/C performs with Zr-Cu alloys[J]. Materials Letters, 2013, 108: 204-207.

[15] CHEN Si-an, HU Hai-feng, ZHANG Yu-di, ZHANG Chang-rui, WANG Qi-kun. Effects of TaC amount on the properties of 2D C/SiC-TaC composites prepared via precursor infiltration and pyrolysis[J]. Materials and Design, 2013, 51: 19-24.

[16] 王雅雷, 熊 翔, 李国栋, 肖 鹏, 陈招科. 新型C/C-TaC复合材料的微观结构及其力学性能[J]. 中国有色金属学报, 2008, 18(4): 608-613.

WANG Ya-lei, XIONG Xiang, LI Guo-dong, XIAO Peng, CHEN Zhao-ke. Microstructures and mechanical properties of novel C/C-TaC composite[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 608-613.

[17] GAO Zeng-hua, XU Jing-jun, ZHANG Zhong-wei, QIAN Yu-hai, LI Mei-shuan. Effects of ZrB2 and SiC dual addition on the oxidation resistance of graphite at 1600-2000 ℃[J]. Corrosion Science, 2013, 76: 182-191.

[18] WANG Di-ni, ZENG Yi, XIONG Xiang, LI Guo-dong, CHEN Zhao-ke, SUN Wei, WANG Ya-lei. Preparation and ablation properties of ZrB2-SiC protective laminae for carbon/carbon composites[J]. Ceramics International, 2014, 40(9): 14215-14222.

[19] KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems[J]. Materials Science and Engineering A, 2005, 412(1/2): 177-181.

[20] JIANG Si-zhou, XIONG Xiang, CHEN Zhao-ke, XIAO Peng, HUANG Bai-yun. Influence factors of C/C-SiC dual matrix composites prepared by reactive melt infiltration[J]. Materials and Design, 2009, 30(9): 3738-3742.

[21] 付前刚, 李贺军, 沈学涛, 李克智. 国内C/C复合材料基体改性研究进展[J]. 中国材料进展, 2011, 30(11): 6-12.

FU Qian-gang, LI He-jun, SHEN Xue-tao, LI Ke-zhi. Domestic research process of matrix modification for carbon/carbon composites[J]. Materials China, 2011, 30(11): 6-12.

[22] 陈招科, 熊 翔, 李国栋. 预制体类型及孔隙结构对化学气相渗透TaC的影响[J]. 中国有色金属学报, 2010, 20(9): 1759-1765.

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong. Influence of preforms and pore structures on chemical vapor infiltration of TaC[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1759-1765.

[23] LIU Lei, LI He-jun, SHI Xiao-hong, FU Qian-gang, FENG Wei, YAO Xi-yuan, NI Chang. Influence of SiC additive on the ablation behavior of C/C composites modified by ZrB2-ZrC particles under oxyacetylene torch[J]. Ceramics International, 2014, 40(1): 541-549.

[24] YANG Xin, SU Zhe-an, HUANG Qi-zhong, FANG Xiao, CHAI Li-yuan. Microstructure and mechanical properties of C/C-ZrC-SiC composites fabricated by reactive melt infiltration with Zr, Si mixed powders[J]. J Mater Sci Technol, 2013, 29(8): 702-710.

[25] LEE S H, WEINMANN M, ALDINGER F. Fabrication of fiber-reinforced ceramic composites by the modified slurry infiltration technique[J]. J Am Ceram Soc, 2007, 90(8): 2657-2660.

[26] SHEN Xue-tao, LI Ke-zhi, LI He-jun, DU Hong-ying, CAO Wei-feng, LAN Feng-tao. Microstructure and ablation properties of zirconium carbide doped carbon/carbon composites[J]. Carbon, 2010, 48(2): 344-351.

[27] LAMOUROUX F, BOURRAT X, NASLAIN R, THEBAULT J. Silicon carbide infiltration of porous C-C composites for improving oxidation resistance[J]. Carbon, 1995, 33(4): 525-535.

[28] CHEN Zhao-feng, FANG Dan, MIAO Yun-liang, YAN Bo. Comparison of morphology and microstructure of ablation centre of C/SiC composites by oxy-acetylene torch at 2900 and 3550 ℃[J]. Corrosion Science, 2008, 50(12): 3378-3381.

[29] LI Ke-zhi, DENG Hai-liang, CUI Hong, LI He-jun, XIE Jing, ZHENG Jin-huang, WANG Chuang. Floating catalyst chemical vapor infiltration of nanofilamentous carbon reinforced carbon/carbon composites —Densification behavior and matrix microstructure[J]. Carbon, 2014, 75: 353-365.

[30] 时启龙. 化学气相渗透制备C/C-SiC摩擦材料的微观结构及摩擦行为研究[D]. 长沙: 中南大学, 2012: 27-30.

SHI Qi-long. Microstructure and tribological behavior of C/C-SiC braking composites fabricated by chemical vapor infiltration process[D]. Changsha: Central South University, 2012: 27-30.

[31] TANG Su-fang, DENG Jing-yi, WANG Shi-jun, LIU Wen-chuan. Fabrication and characterization of an ultra-high temperature carbon fiber-reinforced ZrB2-SiC matrix composite[J]. J Am Ceram Soc, 2007, 90(10): 3320-3322.

[32] LI Qing-gang, DONG Shao-ming, WANG Zhi, SHI Guo-pu. Fabrication and properties of 3-D Cf/ZrB2-ZrC-SiC composites via polymer infiltration and pyrolysis[J]. Ceramics International, 2013, 39(5): 5937-5941.

[33] CHEN Si-an, HU Hai-feng, ZHANG Yu-di, ZHANG Chang-rui, WANG Qi-kun. Effects of high-temperature annealing on the microstructure and properties of C/SiC-ZrB2 composites[J]. Materials and Design, 2014, 53: 791-796.

[34] YAN Chun-lei, LIU Rong-jun, CAO Ying-bin, ZHANG Chang-rui. Fabrication and properties of PIP 3D Cf/ZrC-SiC composites. Materials Science and Engineering A, 2014, 591: 105-110.

[35] 武海棠, 魏 玺, 于守泉, 张伟刚. 整体抗氧化C/C-ZrC-SiC复合材料的超高温烧蚀性能研究[J]. 无机材料学报, 2011, 26(8): 852-856.

WU Hai-tang, WEI Xi, YU Shou-quan, ZHANG Wei-gang. Ablation performances of multi-phased C/C-ZrC-SiC ultra-high temperature composites[J]. Journal of Inorganic Materials, 2011, 26(8): 852-856.

[36] 曹柳絮, 陈建勋, 刘春轩, 薛 亮, 黄启忠. 聚碳硅烷的高温陶瓷化机理[J]. 中南大学学报, 2014, 45(1): 52-57.

CAO Liu-xu, CHEN Jian-xun, LIU Chun-xuan, XUE Liang, HUANG Qi-zhong. Ceramization mechanism of polycarbosilane treated with high temperature[J]. Journal of Central South University, 2014, 45(1): 52-57.

[37] LIU Chun-xuan, CHEN Jian-xun, SU Zhe-an, YANG Xin, CAO Liu-xu, HUANG Qing-zhong. Pyrolysis mechanism of ZrC precursor and fabrication of C/C-ZrC composites by precursor infiltration and pyrolysis[J]. Transactions of Nonferrous Metal Society of China, 2014, 24(6): 1779-1784.

[38] 但奇善, 孙 威, 熊 翔, 王子璇, 吴雯倩. 反应熔渗法制备C/C-ZrC复合材料的微观结构及烧蚀性能[J]. 粉末冶金材料科学与工程, 2013, 18(3): 403-408.

DAN Qi-shan, SUN Wei, XIONG Xiang, WANG Zi-xuan, WU Wen-qian. Microstructure and ablation property of C/C-ZrC composites manufactured by reactive melt infiltration[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(3): 403-408.

[39] WANG Dong, WANG Yu-jin, RAO Jian-cun, OUYANG Jia-hu, ZHOU Yu, SONG Gui-ming. Influence of reactive melt infiltration parameters on microstructure and properties of low temperature derived Cf/ZrC composites[J]. Materials Science and Engineering A, 2013, 568: 25-32.

[40] ZHU Yu-lin, WANG Song, CHEN Hong-mei, LI Wei, JIANG Jin-ming, CHEN Zhao-hui. Microstructure and mechanical properties of Cf/ZrC composites fabricated by reactive melt infiltration at relatively low temperature[J]. Ceramics International, 2013, 39(8): 9085-9089.

[41] WANG Yi-guang, ZHU Xiao-juan, ZHANG Li-tong, CHENG Lai-fei. Reaction kinetics and ablation properties of C/C-ZrC composites fabricated by reactive melt infiltration[J]. Ceramics International, 2011, 37(4): 1277-1283.

[42] WANG Yi-guang, ZHU Xiao-juan, ZHANG Li-tong, CHENG Lai-fei. C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13alloy[J]. Ceramics International, 2012, 38(5): 4337-4343.

[43] PI Hui-long, FAN Shang-wu, WANG Yi-guang. C/SiC-ZrB2-ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy[J]. Ceramics International, 2012, 38(8): 6541-6548.

[44] TONG Qing-feng, SHI Jing-li, SONG Yong-zhong, GUO Quan-gui, LIU Lang. Resistance to ablation of pitch-derived ZrC/C composites[J]. Carbon, 2004, 42(12/13): 2495-2500.

[45] ZHAO Li-you, JIA De-chang, DUAN Xiao-ming, YANG Zhi-hua, ZHOU Yu. Oxidation of ZrC-30 vol% SiC composite in air from low to ultrahigh temperature[J]. Journal of the European Ceramic Society, 2012, 32(4): 947-954.

[46] 黄向东, 刘桂香, 叶学青, 李 强. 热压烧结法制备Cf/TiC/Cu复合材料的组织及性能[J]. 中国有色金属学报, 2010, 20(8): 1605-1611.

HUANG Xiang-dong, LIU Gui-xiang, YE Xue-qing, LI Qiang. Microstructures and properties of Cf/TiC/Cu composites prepared by hot-pressed sintering[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1605-1611.

[47] DING Yu-sheng, DONG Shao-ming, ZHOU Qing, HUANG Zhen-ren, JIANG Dong-liang. Preparation of C/SiC composites by hot pressing, using different C fiber content as reinforcement[J]. J Am Ceram Soc, 2006, 89(4): 1447-1449.

[48] CHEN Ya-xi, CHEN Ping, HONG Chang-qing, ZHANG Bao-xi, DAVID H. Improved ablation resistance of carbon-phenolic composites by introducing zirconium diboride particles[J]. Composites: Part B, 2013, 47: 320-325.

[49] 樊乾国, 崔 红, 闫联生, 张 强, 孟祥利, 杨 星. 浆料浸渍法制备C/C-SiC-ZrB2超高温复合材料及其烧蚀性能研究[J]. 无机材料学报, 2013, 28(9): 1014-1018.

FAN Qian-guo, CUI Hong, YAN Lian-sheng, ZHANG Qiang, MENG Xiang-li, YANG Xing. Ablation resistance properties of ultra-high temperature composites C/C-SiC-ZrB2 by slurry impregnation method[J]. Journal of Inorganic Materials, 2013, 28(9): 1014-1018.

[50] WANG Zhen, DONG Shao-ming, ZHANG Xiang-yu, ZHOU Hai-jun, WU Ding-xing, ZHOU Qing, JIANG Dong-liang. Fabrication and properties of Cf/SiC-ZrC composites[J]. J Am Ceram Soc, 2008, 91(10): 3434-3436.

[51] FENG Q, WANG Z, ZHOU H J, HE P, GAO L, KAN Y M, ZHANG X Y, DING Y S, DONG S M. Microstructure analysis of Cf/SiC-ZrC composites in both fabrication and plasma wind tunnel testing processes[J]. Ceramics International, 2014, 40(1): 1199-1204.

[52] CHEN Si-an, ZHANG Chang-rui, ZANG Yu-di, ZHAO Dan, HU Hai-feng, ZHANG Zhi-bin. Mechanism of ablation of 3D C/ZrC-SiC composite under an oxyacetylene flame[J]. Corrosion Science, 2013, 68: 168-175.

[53] LI Zhao-qian, LI He-jun, ZHANG Shou-yang, LI Ke-zhi. Microstructure and ablation behaviors of integer felt reinforced C/C-SiC-ZrC composites prepared by a two-step method[J]. Ceramics International, 2012, 38(4): 3419-3425.

[54] LI Zhao-qian, LI He-jun, ZHANG Shou-yang, LI Wei, WANG Jie. Microstructures and ablation properties of C/C-SiC-ZrC composites prepared using C/C skeletons with various densities[J]. Ceramics International, 2013, 39(7): 8173-8181.

[55] ZHANG Liang-run, DONG Shao-ming, ZHOU Hai-jun, KAN Yan-me, ZHOU Fan, WANG Zhen. 3D Cf/ZrC-SiC composites fabricated with ZrC nanoparticles and ZrSi2 alloy[J]. Ceramics International 2014, 40(8): 11795-11801.

[56] XIE Jing, LI Ke-zhi, LI He-jun, FU Qian-gang, GUO Ling-jun. Ablation behavior and mechanism of C/C-ZrC-SiC composites under an oxyacetylene torch at 3000 ℃[J]. Ceramics International, 2013, 39(4): 4171-4178.

[57] XIE Jing, LI Ke-zhi, LI He-jun, FU Qian-gang, LIU Lei, Cyclic ablation behavior of C/C-ZrC-SiC composites under oxyacetylene torch[J]. Ceramics International, 2014, 40(4): 5165-5171.

[58] LUKE S W, ERICA L C. Self-generating high-temperature oxidation-resistant glass-ceramic coatings for C-C composites using UHTCs[J]. J Am Ceram Soc, 2014, 97(9): 3004-3011.

[59] ERICA L C, LUKE S W. Improved ablation resistance of C-C composites using zirconium diboride and boron carbide[J]. Journal of the European Ceramic Society, 2010, 30(11): 2357-2364.

[60] LEVINE S R, OPILA E J, ROBINSON R C, LORINCZ J A. Characterization of an ultra-high temperature ceramic composite[R]. Cleveland: NASA Glenn Research Center, 2004.

[61] PAUL A, VENUGOPAL S, BINNER J G P, VAIDHVANATHAN B, HEATON A C J, BROWN P M. UHTC-carbon fibre composites: Preparation, oxyacetylene torch testing and characterisation[J]. Journal of the European Ceramic Society, 2013, 33(2): 423-432.

[62] DANIEL D J, RAFAEL G S, PETER B, WILLIAM E L. Reactive infiltration processing (RIP) of ultra high temperature ceramics(UHTC) into porous C/C composite tubes[J]. Journal of the European Ceramic Society, 2011, 31(3): 361-368.

[63] SURESH K, JUHI K, SAMAR M, ANIL K, JAIN R K, ROHINI D G. Fabrication and ablation testing of 4D C/C composite at 10 MW/m2 heat flux under a plasma arc heater[J]. Materials Science and Engineering A, 2013, 566: 102-111.

[64] JULIEN B, JONATHAN C, ANDRE D, MAGALI R, GUILLAUME B. Ablation properties of C fibers and sic fibers reinforced glass ceramic matrix composites upon oxyacetylene torch exposure[J]. Materials Sciences and Applications, 2011, 2(10): 1399-1406.

[65] PICHON T, BARRETEAU R, SOYRIS P, FOUCAULT A, PARENTEAU J M, PREL Y, GUEDRON S. CMC thermal protection system for future reusable launch vehicles: Generic shingle technological maturation and tests[J]. Acta Astronautica, 2009, 65(1/2): 165-176.

[66] LI Lu-lu, WANG Yi-guang, CHENG Lai-fei, ZHANG Li-tong. Preparation and properties of 2D C/SiC-ZrB2-TaC composites[J]. Ceramics International, 2011, 37(3): 891-896.

[67] TONG Yong-gang, BAI Shu-xin, CHEN Ke. C/C-ZrC composite prepared by chemical vapor infiltration combined with alloyed reactive melt infiltration[J]. Ceramics International, 2012, 38(7): 5723-5730.

[68] LIU Chun-xuan, CAO Liu-xu, CHEN Jian-xun, XUE Liang, TANG Xian, HUANG Qi-zhong. Microstructure and ablation behavior of SiC coated C/C-SiC-ZrC composites prepared by a hybrid infiltration process[J]. Carbon, 2013, 65: 196-205.

[69] HU Cheng-long, PANG Sheng-yang, TANG Su-fang, WANG Shi-jun, HUANG Hong-tao, CHENG Hui-ming. Ablation and mechanical behavior of a sandwich-structured composite with an inner layer of Cf/SiC between two outer layers of Cf/SiC-ZrB2-ZrC[J]. Corrosion Science, 2014, 80: 154-163.

[70] WANG Zhen, DONG Shao-ming, HE Ping, GAO Le, ZHOU Hai-jun, YANG Jin-shan, JIANG Dong-liang. Fabrication of carbon fiber reinforced ceramic matrix composites with improved oxidation resistance using boron as active filler[J]. Journal of the European Ceramic Society, 2010, 30(3): 787-792.

[71] 宋永忠, 徐 林, 许正辉, 王俊山, 冯志海. 超高温本体抗氧化碳/碳复合材料研究[J]. 中国材料进展, 2012, 31(8): 15-19.

SONG Yong-zhong, XU Lin, XU Zheng-hui, WANG Jun-shan, FENG Zhi-hai. Research progress of ultra-high temperature matrix anti-oxidation carbon/carbon composites[J]. Materials China, 2012, 31(8): 15-19.

[72] 秦淑颖, 闰联生, 崔 红, 刘建超. Cf/SiC陶瓷基复合材料在航天领域的研究与应用[J]. 材料导报, 2007, 21(z2): 239-240, 252.

QIN Shu-ying, YAN Lian-sheng, CUI Hong, LIU Jian-chao. Application and development of Cf/SiC ceramic matrix composites in aerospace[J]. Materials Review, 2007, 21(z2): 239-240, 252.

[73] LIU Lei, LI He-jun, FENG Wei, SHI Xiao-hong, LI Ke-zhi, GUO Ling-jun. Ablation in different heat fluxes of C/C composites modified by ZrB2-ZrC and ZrB2-ZrC-SiC particles[J]. Corros Sci, 2013, 74: 159-167.

[74] LI He-jun, YAO Xi-yuan, ZHANG Yu-lei, LI Ke-zhi, GUO Ling-jun, LIU Lei. Effect of heat flux on ablation behavior and mechanism of C/C-ZrB2-SiC composite under oxyacetylene torch flame[J]. Corros Sci, 2013, 74: 265-270.

[75] LI Ke-zhi, XIE Jing, FU Qian-gang, LI He-jun, GUO Ling-jun. Effects of porous C/C density on the densification behavior and ablation property of C/C-ZrC-SiC composites[J]. Carbon, 2013, 57: 161-168.

[76] LI Cui-yan, LI Ke-zhi, LI He-jun, OUYANG Hai-bo, ZHANG Yu-lei, GUO Ling-jun. Ablation resistance and thermal conductivity of carbon/carbon composites containing hafnium carbide[J]. Corrosion Science, 2013, 75: 169-175.

[77] FENG Bo, LI He-jun, ZHANG Yu-lei, LIU Lei, YAN Min. Effect of SiC/ZrC ratio on the mechanical and ablation properties of C/C-SiC-ZrC composites[J]. Corrosion Science, 2014, 82: 27-35.

[78] LI Cui-yan, LI Ke-zhi, LI He-jun, ZHANG Yu-lei, OUYANG Hai-bo, YAO Dong-jia, LIU Lei. Microstructure and ablation resistance of carbon/carbon composites with a zirconium carbide rich surface layer[J]. Corrosion Science, 2014, 85: 160-166.

[79] SHEN Xue-tao, LI Ke-zhi, LI He-jun, FU Qian-gang, LI Shu-ping, DENG Fei. The effect of zirconium carbide on ablation of carbon/carbon composites under an oxyacetylene flame[J]. Corrosion Science, 2011, 53: 105-112.

[80] LI Shu-ping, LI Ke-zhi, LI He-jun, LI Yu-long, YUAN Qin-lu. Effect of HfC on the ablative and mechanical properties of C/C composites[J]. Materials Science and Engineering A, 2009, 517(1/2): 61-67.

[81] CHEN Si-an, ZHANG Chang-rui, ZHANG Yu-di, HU Hai-feng. Influence of pyrocarbon amount in C/C preform on the microstructure and properties of C/ZrC composites prepared via reactive melt infiltration[J]. Materials and Design, 2014, 58: 570-576.

[82] CHEN Si-an, ZHANG Chang-rui, ZHANG Yu-di, HU Hai-feng. Preparation and properties of carbon fiber reinforced ZrC-ZrB2 based composites via reactive melt infiltration[J]. Composites: Part B, 2014, 60: 222-226.

[83] YAN Chun-lei, LIU Rong-jun, CAO Ying-bin, ZHANG Chang-rui, ZHANG De-ke. Preparation and properties of 3D needle-punched C/ZrC-SiC composites by polymer infiltration and pyrolysis process[J]. Ceramics International, 2014, 40(7): 10961-10970.

[84] YAN Chun-lei, LIU Rong-jun, CAO Ying-bin, ZHANG Chang-rui, ZHANG De-ke. Ablation behavior and mechanism of C/ZrC, C/ZrC-SiC and C/SiC composites fabricated by polymer infiltration and pyrolysis process[J]. Corrosion Science, 2014, 86: 131-141.

[85] 杨 鑫, 苏哲安, 黄启忠, 陈建勋. C/C-ZrC复合材料高温氧乙炔焰烧蚀性能及机理研究[J]. 中国材料进展, 2011, 30(11): 32-38.

YANG Xin, SU Zhe-an, HUANG Qi-zhong, CHENG Jian-xun. Ablation behavior and mechanism of C/C-ZrC composites under oxyacetylene torch flame[J]. Materials China, 2011, 30(11): 32-38.

[86] 房 啸. 高温熔渗反应制备C/C-SiC-ZrC复合材料及性能研究[D]. 长沙: 中南大学, 2013: 46-48.

FANG Xiao. Preparation of C/C-SiC-ZrC composites by reaction melt infiltration and study on performance of the materials[D]. Changsha: Central South University, 2013: 46-48.

[87] LIU Chun-xuan, SU Zhe-an, HUANG Qi-zhong, CHEN Jian-xun, YANG Xin, CAO Liu-xu, YIN Teng, ZHONG Ping. Ablation behavior of ZrC-SiC coated C/C-ZrC-SiC composites prepared by precursor infiltration pyrolysis combined with reactive melt infiltration[J]. Journal of Alloys and Compounds, 2014, 597: 236-242.

[88] XUE Liang, SU Zhe-an, YANG Xin, HUANG Dong, YIN Teng, LIU Chun-xuan, HUANG Qi-zhong. Microstructure and ablation behavior of C/C-HfC composites prepared by precursor infiltration and pyrolysis[J]. Corrosion Science, 2015, 94: 165-170.

[89] LI Qing-gang, DONG Shao-ming, WANG Zhi, SHI Guo-pu, MA Yan, ZHOU Hai-jun, WANG Zhen. Fabrication and properties of 3-DCf/ZrC-SiC composites via in-situ reaction[J]. Ceramics International, 2014, 40(1): 2483-2488.

[90] LI Qing-gang, DONG Shao-ming, WANG Zhi, SHI Guo-pu, MA Yan, ZHOU Hai-jun, WANG Zhen. Microstructures and mechanical properties of 3D 4-directional, Cf/ZrC-SiC composites using ZrC precursor and polycarbosilane[J]. Materials Science and Engineering B, 2013, 178(18): 1186-1190.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51304249);国家重点基础研究发展计划(2011CB605801);湖南省自然科学基金资助项目(14JJ3023);湖南省战略性新兴产业重大科技攻关项目(2014GK1017)

收稿日期:2014-12-01;修订日期:2015-04-07

通信作者:黄启忠,教授,博士;电话:0731-88877671;E-mail:qzhuang@csu.edu.cn

摘 要:炭/炭(C/C)复合材料在高温含氧环境中易氧化烧蚀的问题影响了其在航空航天领域的应用,引入超高温陶瓷能有效地提高其超高温耐烧蚀性能。介绍和分析了化学气相渗透、先驱体浸渍裂解、反应熔渗等基体改性工艺及其优缺点;综述了近年来C/C复合材料基体改性提高其超高温抗烧蚀性能的最新研究进展;并评述了国内在提高C/C复合材料超高温抗烧蚀性能方面取得的一些成果;最后,提出了提高C/C复合材料超高温长时抗烧蚀性能的潜在发展方向。

[2] 冉丽萍, 李文军, 杨 琳, 易茂中. C/C-Cu复合材料的烧蚀性能及烧蚀机理[J]. 中国有色金属学报, 2010, 20(3): 510-515.

[3] 杨国威. C/C-ZrB2(ZrC、TaC)超高温陶瓷基复合材料制备工艺及性能研究[D]. 长沙: 国防科技大学, 2008: 5-7.

[6] 黄启忠. 高性能炭/炭复合材料的制备、结构与应用[M]. 长沙: 中南大学出版, 2010: 423-427.

[10] 杨 鑫, 黄启忠, 苏哲安, 常 新. C/C复合材料的高温抗氧化防护研究进展[J]. 宇航材料工艺, 2014(1): 1-15.

[16] 王雅雷, 熊 翔, 李国栋, 肖 鹏, 陈招科. 新型C/C-TaC复合材料的微观结构及其力学性能[J]. 中国有色金属学报, 2008, 18(4): 608-613.

[21] 付前刚, 李贺军, 沈学涛, 李克智. 国内C/C复合材料基体改性研究进展[J]. 中国材料进展, 2011, 30(11): 6-12.

[22] 陈招科, 熊 翔, 李国栋. 预制体类型及孔隙结构对化学气相渗透TaC的影响[J]. 中国有色金属学报, 2010, 20(9): 1759-1765.

[30] 时启龙. 化学气相渗透制备C/C-SiC摩擦材料的微观结构及摩擦行为研究[D]. 长沙: 中南大学, 2012: 27-30.

[35] 武海棠, 魏 玺, 于守泉, 张伟刚. 整体抗氧化C/C-ZrC-SiC复合材料的超高温烧蚀性能研究[J]. 无机材料学报, 2011, 26(8): 852-856.

[36] 曹柳絮, 陈建勋, 刘春轩, 薛 亮, 黄启忠. 聚碳硅烷的高温陶瓷化机理[J]. 中南大学学报, 2014, 45(1): 52-57.

[38] 但奇善, 孙 威, 熊 翔, 王子璇, 吴雯倩. 反应熔渗法制备C/C-ZrC复合材料的微观结构及烧蚀性能[J]. 粉末冶金材料科学与工程, 2013, 18(3): 403-408.

[46] 黄向东, 刘桂香, 叶学青, 李 强. 热压烧结法制备Cf/TiC/Cu复合材料的组织及性能[J]. 中国有色金属学报, 2010, 20(8): 1605-1611.

[71] 宋永忠, 徐 林, 许正辉, 王俊山, 冯志海. 超高温本体抗氧化碳/碳复合材料研究[J]. 中国材料进展, 2012, 31(8): 15-19.

[72] 秦淑颖, 闰联生, 崔 红, 刘建超. Cf/SiC陶瓷基复合材料在航天领域的研究与应用[J]. 材料导报, 2007, 21(z2): 239-240, 252.

[85] 杨 鑫, 苏哲安, 黄启忠, 陈建勋. C/C-ZrC复合材料高温氧乙炔焰烧蚀性能及机理研究[J]. 中国材料进展, 2011, 30(11): 32-38.

[86] 房 啸. 高温熔渗反应制备C/C-SiC-ZrC复合材料及性能研究[D]. 长沙: 中南大学, 2013: 46-48.