网络首发时间: 2019-06-24 17:11

等通道挤压变形技术制备超细晶镁合金的研究进展

代晓军 杨西荣 荆磊 王岚 程军 于振涛

西安建筑科技大学冶金工程学院

西北有色金属研究院陕西省医用金属材料重点实验室

东北大学材料科学与工程学院

摘 要:

近年来,镁合金在汽车、航空航天和医疗器械等领域获得广泛应用,被誉为21世纪的绿色工程材料。值得关注的是,镁合金与人体骨在密度、弹性模量等方面的物理性能相近,因此成为最有潜力的医用可降解金属材料,但其强度低、塑性差及耐蚀性差的缺点制约了其发展应用。剧烈塑性变形(SPD)加工被认为是目前最有效的镁合金细晶化方法,其中等径角挤压(ECAP)作为最有潜力的块体超细晶材料制备技术而备受关注,可制备出具有良好综合性能的超细晶或纳米晶镁合金材料。综述了利用ECAP技术制备超细晶镁合金的相关研究进展,探讨了加工温度、模具角度、挤压路径、道次加工量等变形参数对镁合金晶粒细化行为的影响,重点讨论了ECAP变形对超细晶镁合金力学性能及耐腐蚀性能的影响,分析了织构引起的超细晶镁合金“强度异常”现象的原因,提出了ECAP加工后退火强化及后续冷加工以提高镁合金强度的思路,并展望了超细晶镁合金研究中的可能方向。

关键词:

超细晶 ;镁合金 ;等通道挤压(ECAP) ;

中图分类号: TG146.22

作者简介: 代晓军(1989-),男,陕西咸阳人,博士,研究方向:医用金属材料设计与加工,E-mail:296648131@qq.com; *于振涛,教授,电话:029-86264213,E-mail:yzt@c-nin.com;

收稿日期: 2019-05-05

基金: 陕西省重点科技创新团队项目(2016KTC-30); 陕西省国际合作基地项目(2017GHJD-014); 陕西省重点研发计划项目(2019GY-151)资助;

Research Progress in Ultrafine Grain Magnesium Alloy by Equal Channel Angular Pressing

Dai Xiaojun Yang Xirong Jing Lei Wang Lan Cheng Jun Yu Zhentao

School of Metallurgical Engineering,Xi'an University of Architecture and Technology

Northwest Institute for Non-ferrous Metal Research,Shaanxi Key Laboratory of Biomedical Metal Materials

School of Materials Science and Engineering,Northeastern University

Abstract:

In recent years,magnesium alloys have been widely used in the fields of automobiles,aerospace and medical devices,and are known as green engineering materials in the 21st century.It is worth noting that the physical properties in terms of density and elastic modulus of magnesium alloy and human bone are similar,which is the most promising medical degradable metallic material.However,low strength,poor plasticity and poor corrosion resistance of magnesium alloys limit their development and application.Severe plastic deformation(SPD)processing was considered to be the most effective method of grain refinement for magnesium alloy at present.The equal channel angular pressing(ECAP)has attracted much attention as the most promising bulk ultra-fine grain material processing technology in SPD,which could produce ultrafine or nanocrystalline magnesium alloy materials with good comprehensive properties.In this paper,the research progress of ultrafine grain magnesium alloy by ECAP technology was reviewed.The effects of deformation parameters such as processing temperature,mold angle,extrusion path and pass processing on the grain refinement behavior of magnesium alloy were discussed.The effects of ECAP deformation on the mechanical properties and corrosion resistance of ultrafine grain magnesium alloys were emphatically analyzed.And the reason of the "abnormal strength" phenomenon of ultrafine grain magnesium alloy caused by texture was analyzed.The grain annealing and subsequent cold working after ECAP were proposed to improve the strength of magnesium alloy and prospect the possible directions in the future study of ultrafine grain magnesium alloys.

Keyword:

ultrafine grain; magnesium alloy; equal channel angular pressing(ECAP);

Received: 2019-05-05

镁合金被誉为21世纪的绿色工程材料,较高的比强度、比刚度及良好的铸造、减震、切削加工和尺寸稳定性等性能大大扩展了其使用领域

[1 ]

。在生物医用金属领域,镁合金良好的生物相容性和生物降解性使其被用于制备医用植入物,服役完成后可在人体降解,并且降解产物对人体无副作用

[2 ]

。但是,镁合金强度低,塑性差,腐蚀速率快等缺点制约了其应用,提升材料的综合性能已成为镁合金最主要的研究课题

[3 ]

。

近年来,研究人员发现超细晶镁合金表现出了较好的综合性能,而等通道挤压(ECAP)加工是其中最有效的块体镁合金细晶化技术。20世纪70年代,前苏联科学家Segal

[4 ]

基于纯剪切变形理论提出了ECAP加工技术,变形试样在外力的作用下通过等径通道,在模具通道的夹角处发生了近似纯剪切变形,变形试样的形状和尺寸在挤压过程中几乎不发生变化,从而可进行重复挤压来积累较大的塑性应变,已成功用于加工小尺寸(直径10~50 mm)的超细晶块体材料,显著增强了材料的综合性能。

1 ECAP加工参数对镁合金性能的影响因素

ECAP加工过程中,变形参数如加工温度、模具角度、挤压路径、变形道次等对块体金属材料显微组织超细化行为影响较大,ECAP示意图如图1所示。

1.1 挤压温度对晶粒细化行为的影响

镁及镁合金在不同挤压温度下,可得到材料性能不同的最终组织,挤压温度越高,晶粒细化效果越差,高温挤压下材料更容易产生动态回复及再结晶,不利于积累较大的应变

[5 ]

。但是,因具有密排六方晶体结构的镁合金可开动滑移系较少而塑性较差,故塑性挤压温度太低会引起镁合金表面开裂,甚至无法实现挤压变形,目前为防止挤压开裂采取的主要措施是施加背应力及改善镁合金表面润滑条件

[6 ]

。

图1 ECAP示意图和剪切变形示意图

Fig.1 ECAP schematic(a)and schematic diagram of shear deformation(b)

Gan等

[7 ]

对纯镁进行350℃下的四道次挤压,由于挤压温度高,其晶粒细化程度较低,最终组织晶粒尺寸为35?m,高的挤压温度导致晶粒长大。Biswas等

[8 ]

对纯镁进行逐道次温度递减的挤压,前4道次挤压温度为250℃,挤压后晶粒细化至6.3?m。后续逐道次降低挤压温度至室温,8道次后晶粒可细化至250 nm。

Xia等

[9 ]

对AZ31镁合金进行了200℃下的ECAP加工,发现试样200℃时挤压4道次后晶粒可细化至3?m;150℃加工4道次时晶粒可细化至1.4?m,后续100℃再加工4道次,晶粒细化至0.2~0.3?m。Svoboda和Vago

[10 ]

在350℃下对AZ31镁合金进行4道次挤压,晶粒可细化至3.1?m,增加挤压道次后再结晶晶粒的比例可增大至96%。

1.2 模具角度对晶粒细化行为的影响

ECAP模具角度的不同导致材料在挤压过程中得到不同的应变,晶粒细化程度差异较大。内交角(Φ)是ECAP模具影响应变量的最主要因素,决定了挤压变形的应变量,影响材料晶粒细化的效果

[11 ]

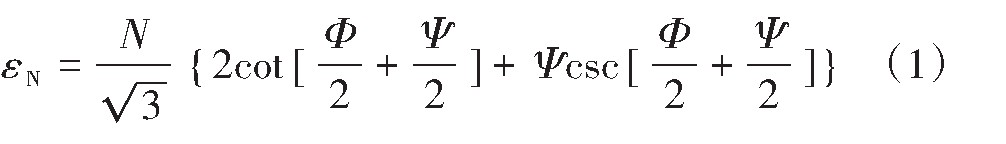

,ECAP过程中的累积应变计算如式(1)所示。

式中,N为挤压道次数,Φ为内交角,Ψ为外交角。

Nakashima等

[12 ]

研究了内交角对晶粒细化行为的影响,由式(1)可知内交角越小,其变形程度越激烈,试样经过Φ=90°通道挤压时变形后更容易获得细化均匀的等轴晶;当Φ<90°时,变形更加剧烈,道次变形量更大,但试样在挤压过程中由于变形硬化而容易断裂;当Φ>90°时,单道次变形应变小,但是可对试样进行多道次的反复挤压以达到细化效果。由于镁合金晶体结构为hcp结构,滑移系较少,因此文献中镁合金ECAP挤压几乎全部使用Φ>90°模具,4道次后可获得均匀分布的等轴晶粒。

1.3 挤压方式对晶粒细化行为的影响

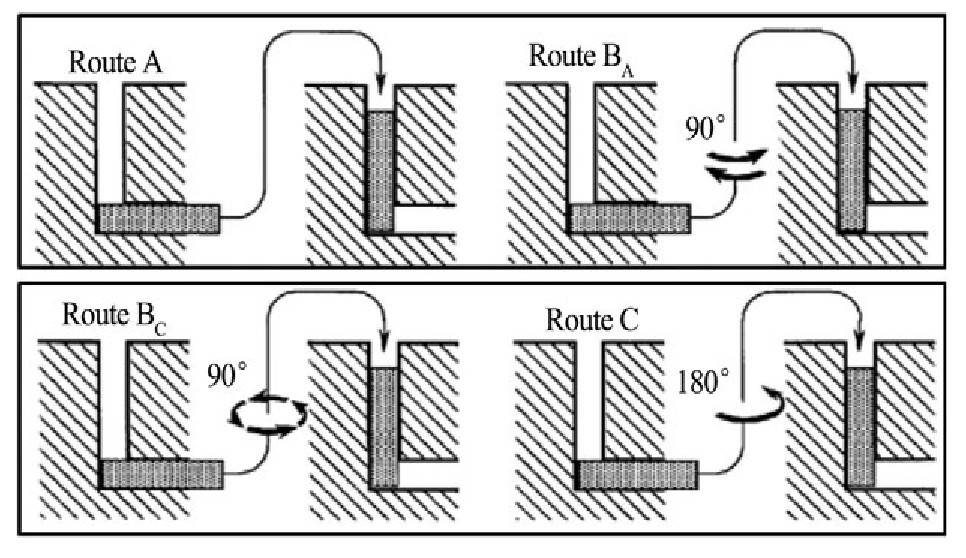

ECAP挤压主要有4种不同的挤压方式,不同的挤压方式影响材料的细化程度及材料最终力学性能。其中,路径A试样经过挤压变形后不绕轴线旋转,直接进行下一道次挤压;路径B试样进行挤压后须绕轴线进行90°旋转后进入下一道次挤压,根据翻转角度,交替旋转为路径BA ,按同一方向旋转为路径BC ;路径C试样进行挤压后须绕轴线进行180°旋转后进入下一道次挤压。路径BC 可激活更多的滑移系,进而更好的改善镁合金的塑性。4种常用ECAP挤压路径示意图如图2所示

[12 ]

。

Gan等

[7 ]

将铸态纯镁分别经过A,BC ,C 3种ECAP挤压路径进行挤压,路径C挤压后细化程度明显高于其他两路径,晶粒尺寸约为通过其他两种路径挤压后晶粒的一半。路径BC 挤压后最终组织中晶粒尺寸比路径A稍大,并在晶粒内发现大量的孪晶(3种挤压路径中最多)。Suh等

[13 ]

将热轧态AZ31镁合金分别经过A,B,C挤压方式进行挤压,发现路径A,C挤压会弱化基面织构,路径B使得基面织构沿轧制方向与横向方向组成的面进行90°旋转。材料经路径C挤压后具有最好的延伸率,而路径B挤压后的材料各向同性硬化行为最好。路径B挤压过程中可明显降低轧制材料中的双孪晶{101- 2}-{101- 1}分数比例(轧制态的AZ31镁合金在双轴拉伸下过早的失效与产生此类孪晶有关)。

1.4 挤压道次对晶粒细化行为的影响

文献显示,镁合金ECAP加工中前两道次的细化作用最明显,大部分晶粒可得到细化,但显微组织并不均匀,沿挤压方向多呈现板条状组织,小晶粒围绕着大晶粒分布,形成混晶结构。随着挤压道次的增加,大晶粒破碎为细小的等轴晶并且分布均匀。随着挤压道次的增加,累积的塑性变形量就会越大,晶粒细化的程度理论上应该更高,但试验显示当晶粒细化至一定程度后,随着挤压道次的增加,晶粒不再减小并且有增大的趋势

[14 ]

。

图2 4种常用ECAP挤压路径示意图

Fig.2 Schematic diagram of four common paths of ECAP ex-trusion

[12]

镁合金经ECAP单道次挤压后,晶粒中位错密度较小,材料内部畸变能较小,这时位错的增殖速度大于湮灭速度,位错增殖占主导地位,可形成位错胞结构,在晶粒内部出现了大量的小角度晶界。随着应变量的增加,小角度晶界转变为大角度晶界,在原始粗大晶粒内部相继产生亚晶,晶粒细化效果显著

[15 ]

。

Ma等

[16 ]

对Mg-4.9Zn-1.4Re-0.7Zr镁合金进行ECAP加工时发现,分别挤压32道次和8道次后晶粒的尺寸没有显著差别,且材料抗拉强度和屈服强度也无明显变化。在ECAP热挤压过程中,晶粒易发生动态再结晶且有长大趋势,动态再结晶程度与晶粒细化程度呈正比例关系。Cheng等

[14 ]

在300℃下对Mg-8Sn-6Zn-2Al镁合金进行8道次ECAP挤压,显微组织表现出明显的动态再结晶行为。挤压6道次后晶粒的动态再结晶分数达到(91.1±0.5)%,晶粒细化至2.49?m,挤压8道次后动态再结晶分数下降至(82.8±0.6)%,晶粒粗化至3.07?m。

2 镁合金ECAP细晶化对材料性能的影响

2.1 细晶化对镁合金力学性能的影响

Hil?er等

[17 ]

利用90°模角ECAP模具对AZ61镁合金进行加工,挤压3道次后晶粒细化至1.4?m。显微组织显示,ECAP过程中的塑性变形机制主要以滑移为主,在晶粒内部形成了高密度的位错网格,晶粒细化可归因于位错重排形成的大角度晶界多边形化过程。

细晶强化是金属材料的强化机制之一,ECAP细晶化行为主要为机械剪切和动态再结晶的共同作用,主要通过细化晶粒的方法提高材料的强度并保持一定塑性,根据经典的Hall-Petch关系式(2):

式中,σs 为材料的屈服强度,σ0 是单个位错滑移时产生的晶格摩擦阻力,K为与晶体类型有关的常数,d是显微组织中晶粒平均直径。从关系式可以看出,随晶粒尺寸的减小(即晶界总面积的增加),金属材料的强度可以显著增加。

Fintová等

[18 ]

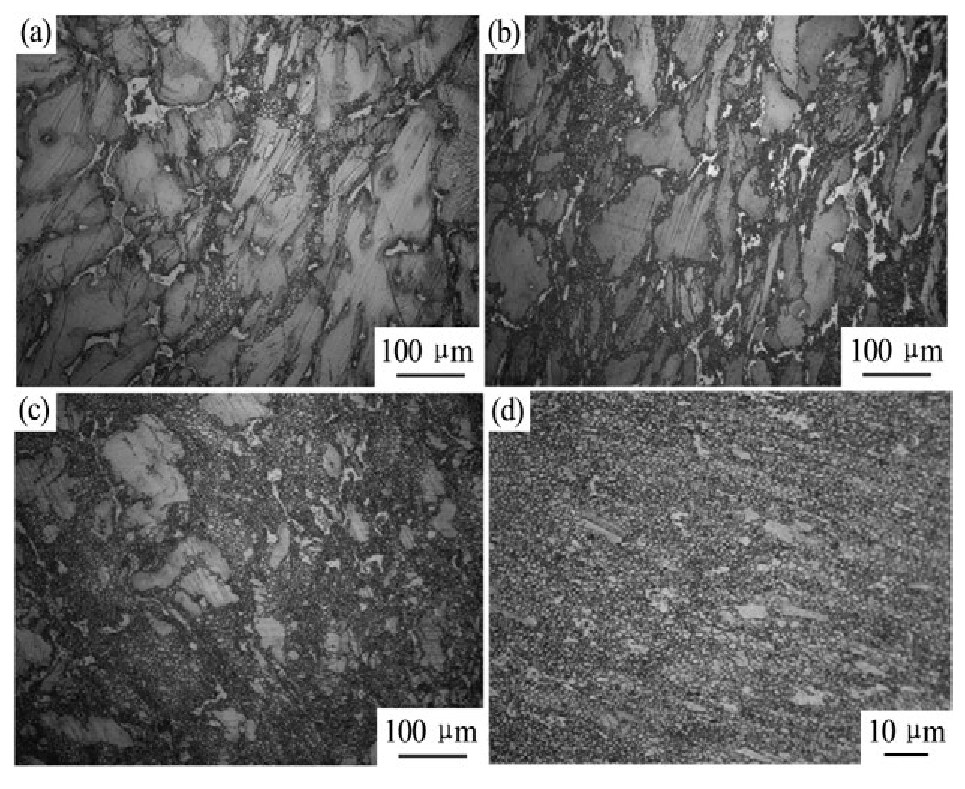

在300℃下对铸态AZ91镁合金进行6道次ECAP加工,晶粒可细化至3.5?m,初始粗晶材料室温抗拉强度、屈服强度、延伸率分别为167 MPa,87 MPa,3.1%最优增加到342 MPa,164MPa,10.1%。Lin等

[19 ]

在180℃下对ZA85镁合金进行6道次ECAP加工,抗拉强度提高230%,延伸率提高270%,可归因为变形过程中的晶粒细化及细小的析出相Mg32 (Al,Zn)49 均匀分布,如图3所示。Wang等

[20 ]

在250℃下对AZ80镁合金连续进行1,2,4道次ECAP加工,将原始粗晶由11.2?m细化至1~2?m,随着ECAP挤压道次的增加,细晶强化机制显著提高了AZ80合金的力学性能。Furui等

[21 ]

对Mg-8Li镁合金先经普通热挤后再进行200℃温度下的ECAP加工,超细晶最终组织的超塑性延伸率达到1780%,较铸态相比提高8.5倍,较普通热挤态提高3倍。Balogh等

[22 ]

将ZK60镁合金进行8道次ECAP挤压后发现,随着变形道次的增加,合金硬度先升高后降低(5道次后开始降低),文献认为随着应变的增加,位错大量塞积使得亚晶界数量的增多并形成孪晶以协调材料变形。

此外,镁及镁合金超细晶组织显现出的反常“退火强化”现象已引起研究者的广泛关注

[23 ,24 ,25 ]

。Lei等

[23 ]

将ECAP挤压后纯镁分别进行15、30、60 min的退火处理,发现其屈服强度降低,但抗拉强度的及塑性得到大幅提升。林楷等

[24 ]

将Mg-Li镁合金进行ECAP挤压后进行退火处理,其强度也得到了显著提高。Song等

[25 ]

将Mg-2Zn-Mn-Ca-Ce镁合金经过ECAP处理后在160℃退火3 h,发现其强度及塑性均明显提高,且材料抗腐蚀能力大幅提升。目前对镁合金中的“退火强化”机制研究尚无统一定论,有研究者认为“退火强化”现象可归因于细晶化及ECAP加工过程中大量产生的位错。需要注意的是,其他金属如Ti、Cu、Al等材料的超细晶组织中也发现了“退火强化”现象,归纳并阐明该现象的深层机制仍是当前研究热点

[26 ,27 ,28 ]

。

图3 ZA85镁合金180℃不同挤压道次(N)的ECAP变形的光学显微(OM)照片

Fig.3 OM images of different passes ECAP deformation of ZA85 magnesium alloy at 180℃

[19]

(a)N=1,(b)N=2,(c)N=4,(d)N=6

2.2 细晶化对镁合金抗腐蚀能力的影响

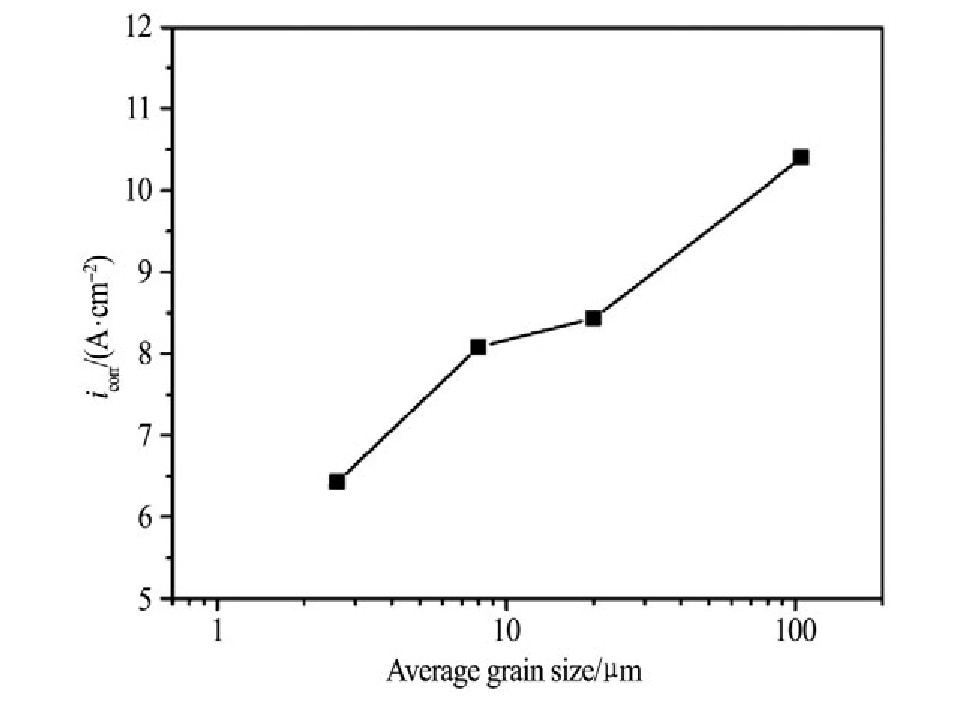

镁的标准电极电位为-2.372 V,故镁合金腐蚀速率较快,材料的抗腐蚀能力是重要的研究热点,其抗腐蚀能力的优劣是检验镁合金品质的重要指标。文献显示,在镁合金ECAP挤压过程中,细晶化程度与材料抗腐蚀能力正相关,镁合金晶粒尺寸越小,其腐蚀电流越小,抗腐蚀能力越强,镁合金经ECAP加工后腐蚀机制由局部腐蚀向均匀腐蚀转变

[29 ]

。Birbilis等

[30 ]

对纯镁进行ECAP挤压后发现,显微组织中小角度晶界减少,大角度晶界增多,腐蚀电流与晶粒尺寸成反比例线性关系,如图4所示。潘瑜等

[31 ]

发现Mg-3Sn-0.5Mn镁合金在ECAP后,腐蚀电位逐渐升高,与初始态腐蚀电位(-1.71±0.02)V相比,挤压4道次腐蚀电位升高至(-1.65±0.02)V,腐蚀电流密度从初始态的(46.4±0.3)m A·cm-2 降低至(36.5±0.5)m A·cm-2 。

ECAP变形可细化镁合金中第二相并促使其均匀分布。Gopi等

[32 ]

研究了AM90镁合金挤压4道次后的电化学腐蚀行为,动态电位极化测试显示,挤压后材料的腐蚀电流密度降低,抗腐蚀能力提高,除细晶化作用外,均匀分布的第二相颗粒在化学腐蚀过程中可在材料表面形成保护性钝化膜。Gu等

[33 ]

通过Hanks模拟体液浸泡实验对比研究了ECAP挤压前后的AZ31镁合金试样,发现未挤压试样表面产生了5~10?m的点蚀微孔洞,而挤压4道次后的试样表面仅产生了1~2?m的点蚀微孔洞,故ECAP变形可提高材料的抗腐蚀能力。

3 ECAP加工过程中的织构变化对性能的影响

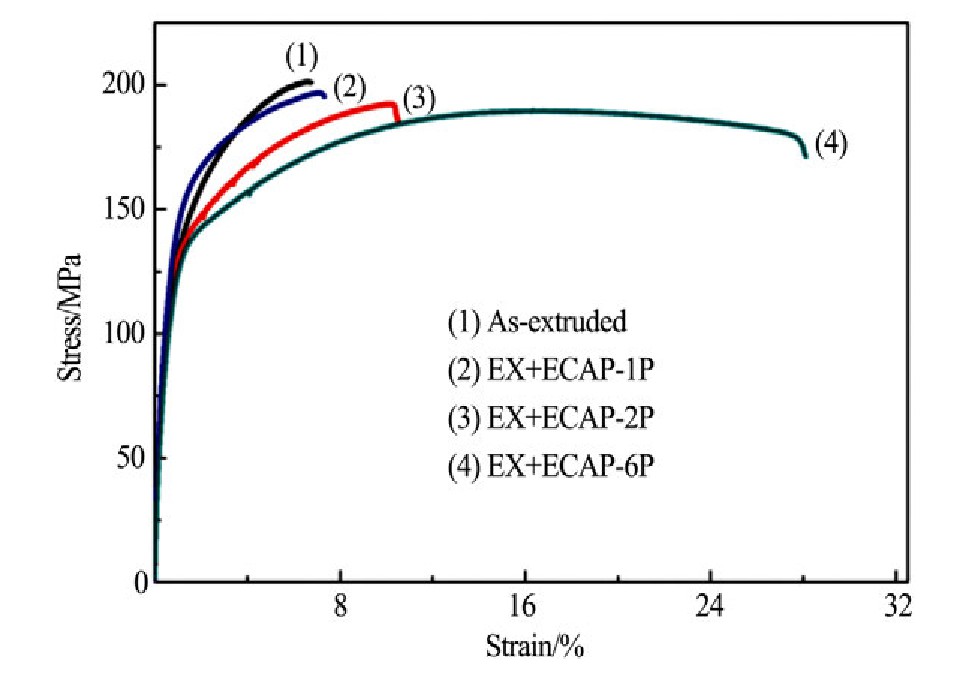

常规热挤压态镁合金经ECAP加工后,出现了不符合Hall-Petch关系的现象,即随着加工道次的提高,虽然材料晶粒不断细化,但材料强度略有下降,塑性显著升高

[31 ,34 ,35 ,36 ,37 ]

,典型室温拉伸曲线如图5所示。潘瑜等

[31 ]

研究发现,此类现象可归因为ECAP变形过程中的织构变化影响了后续材料塑性变形中的滑移系类型及分剪切力。Fan等

[34 ]

研究发现,随着挤压道次的增加,纯镁基面的施密特因子升高,基面滑移系更易开动,基面织构软化引起了以上所述现象。Mostaed等

[35 ]

认为,ECAP变形过程中(0002)织构的强度与基面滑移的施密特因子的增加,促进了基面的位错滑移,提高了材料的塑性,其基面织构如图6所示。Akbaripanah等

[37 ]

研究发现,织构变化是材料强度降低,塑性升高的主要原因,织构软化抵消了细化晶粒对材料强度的增强作用。

镁合金塑性变形时产生的织构主要包括:平行于挤压方向的织构和沿剪切面与挤压方向成一定夹角的织构

[37 ]

。Mostaed等

[35 ]

在研究ZK60镁合金织构取向及强度时发现,常规热挤压后的晶粒纤维织构平行于挤压方向,而经ECAP挤压后平行于切应力方向。Minárik等

[39 ]

对AE21,AE42,LAE442镁合金进行ECAP挤压12道次后发现,AE21和AE42镁合金基面织构发生显著变化,与挤压方向呈55°的典型织构取代了平行于挤压方向的纤维织构。

图4 纯镁ECAP加工后晶粒尺寸与腐蚀电流的关系

Fig.4 Relationship between grain size and corrosion current of pure magnesium after ECAP processing

[30]

图5 纯镁经不同道次ECAP变形的室温拉伸曲线

Fig.5 Room temperature tensile curves of pure magnesium with different ECAP deformation

[34]

图6 ZK60镁合金ECAP变形前后(0002)极图

Fig.6 ZK60 magnesium alloy(0002)pole figure before and after ECAP deformation

[35]

(a)BM;(b)E2;(c)E3;(d)E5

综上所述,镁合金经ECAP加工后,获得的超细晶组织性能不仅与晶粒细化程度有关,还与织构变化行为直接相关。潘复生院士团队研究认为

[40 ,41 ]

,镁合金不均匀变形理论可合理解释镁合金剧烈塑性变形后的塑性升高,非对称变形会产生局部剪切区,材料在挤压过程中发生剪切变形,可以激活其非基面滑移系,宏观表现为材料的塑性升高。

4 结论及展望

镁合金晶粒经ECAP加工后得到了明显细化,可显著提高镁合金性能。本文分析了镁合金ECAP变形参数对材料性能的影响及原因,为后续制定镁合金ECAP工艺提供了理论依据。解读了细晶化行为与性能之间的关系,分析了镁合金在加工过程中的强度降低,塑性提高的现象,综述了镁合金ECAP加工过程中的织构行为。

镁合金通过ECAP变形可获得超细晶组织以优化其综合性能,但目前只限于实验室研究阶段,限制其应用发展的主要存在下面两个方面:(1)纯镁及镁合金经ECAP挤压完成后,很难进行冷加工或低温变形至产品要求尺寸,退火或热加工容易导致晶粒长大。(2)试样经ECAP挤压后,试样弯曲较大,需要进行矫直工序,生产的连续性较差。

通过大量研究人员的努力,超细晶镁合金及其ECAP加工技术必将获得广泛应用。目前,在镁合金超细晶组织研究中主要有以下热点:(1)不均匀变形产生的混晶组织,其中细晶增加了材料强度,粗晶保证其塑性

[42 ]

。虽暂未检索到镁合金相关文献,但镁合金ECAP前两道次变形后,均出现了混晶组织。(2)镁合金基面织构在ECAP变形后会产生弱化,可提高材料塑性。若继续进行冷变形加工,可提高镁合金强度及抗腐蚀性能

[43 ]

。(3)对超细晶镁合金进行合理的退火工艺,会出现塑性,强度同时增加的现象

[44 ]

。(4)镁合金ECAP加工过程中,变形不一致会引起材料局部流动性的不同,导致材料挤压出来弯曲度较大,无法进行连续性生产,有文献研究通过表面研磨等技术改变材料上下表面粗糙度以控制材料的不均匀变形

[45 ]

。

参考文献

[1] Zeng R C,Ke W,Xu Y B,Han E H,Zhu Z Y. The latest development and application prospect of Mg alloy[J]. Acta Metallosinica,2001,37(7):673.(曾荣昌,柯伟,徐永波,韩恩厚,朱自勇. Mg合金的最新发展及应用前景[J].金属学报,2001,37(7):673.)

[2] Yuan G,Zhang J,Ding W. Research progress of Mgbased alloys as degradable biomedical materials[J]. Materials China,2011,30(2):44.

[3] Wan P,Tan L,Yang K. Surface modification on biodegradable magnesium alloys as orthopedic implant materials to improve the bio-adaptability:a review[J]. Journal of Materials Science&Technology, 2016, 32(9):827.

[4] Segal V M. Materials processing by simple shear[J].Materials Science&Engineering A,1995,197(2):157.

[5] Li J,Xu W,Wu X,Ding H,Xia K. Effects of grain size on compressive behaviour in ultrafine grained pure Mg processed by equal channel angular pressing at room temperature[J]. Materials Science&Engineering A,2011,528(18):5993.

[6] Lei W,Wei L,Wang H,Guo H. Evolution of texture and mechanical properties of pure Mg processed by ECAP at room temperature[J]. JOM,2017,69(11):2297.

[7] Gan W M,Zheng M Y,Chang H,Wang X J,Qiao X G,Wu K,Schwebke B,Brokmeier H G. Microstructure and tensile property of the ECAPed pure magnesium[J]. Journal of Alloys&Compounds,2009,470(1-2):256.

[8] Biswas S,Dhinwal S S,Suwas S. Room-temperature equal channel angular extrusion of pure magnesium[J].Acta Materialia,2010,58(9):3247.

[9] Xia K,Wang J T,Wu X,Chen G,Gurvan M. Equal channel angular pressing of magnesium alloy AZ31[J].MaterialsScience&EngineeringA,2005,410(12):324.

[10] Svoboda H G,Vago F. Superplastic behavior of AZ31processed by ECAP[J]. Procedia Materials Science,2015,9:590.

[11] Yang X R,Jing F F,Liu X Y,Luo L. Microstructure and properties of CP-Zr by ECAP at room temperature with different die angles[J]. Chinese Journal of Rare Metals,2018,42(4):367.(杨西荣,井菲菲,刘晓燕,罗雷.模具角度对CPZr室温ECAP变形组织与性能的影响[J].稀有金属,2018,42(4):367.)

[12] Nakashima K,Horita Z,Nemoto M,Langdon T G. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing[J]. Acta Materialia,1998,46(5):1589.

[13] Suh J,Victoria-Hernández J,Letzig D,Golle R,Volk W. Effect of processing route on texture and cold formability of AZ31 Mg alloy sheets processed by ECAP[J].Materials Science&Engineering A,2016,669:159.

[14] Cheng W,Tian L,Ma S,Bai Y,Wang H. Influence of equal channel angular pressing passes on the microstructures and tensile properties of Mg-8Sn-6Zn-2Al alloy[J]. Materials,2017,10(7):708.

[15] Chang J Y,Yoon J S,Kim G H. Development of submicron sized grain during cyclic equal channel angular pressing[J]. Scripta Materialia,2001,45(3):347.

[16] Ma A,Jiang J,Saito N,Shigematsu I,Yuan Y,Yang D,Nishida Y. Improving both strength and ductility of a Mg alloy through a large number of ECAP passes[J].MaterialsScience&EngineeringA,2009,513(11):122.

[17] Hil?er O,Rusz S,Maziarz W,Chulist R,Dutkiewicz J,?í?ek L,Kraus M,Tomasz T. Grain refinement of AZ61 alloy after ECAP processing[J]. Materials Science Forum,2017,891:372.

[18] FintováS,Pantělejev L,Kunz L. Microstructure and mechanical properties of ultrafine-grained magnesium AZ91 alloy[J]. Materials Science Forum, 2014,782:384.

[19] Lin C Y,Tsai H J,Chao C G,Liu T F. Effects of equal channel angular extrusion on the microstructure and high-temperature mechanical properties of ZA85 magnesium alloy[J]. Journal of Alloys&Compounds,2012,530(9):48.

[20] Wang L,Mostaed E,Cao X,Huang G,Fabrizi A,Bonollo F,Chi C,Vedani M. Effects of texture and grain size on mechanical properties of AZ80 magnesium alloys at lower temperatures[J]. Materials&Design,2016,89:1.

[21] Furui M,Kitamura H,Anada H,Langdon T G. Influence of preliminary extrusion conditions on the superplastic properties of a magnesium alloy processed by ECAP[J]. Acta Materialia,2007,55(3):1083.

[22] Balogh L,Figueiredo R B,Ungár T,Langdon T G. The contributions of grain size,dislocation density and twinning to the strength of a magnesium alloy processed by ECAP[J]. Materials Science&Engineering A,2010,528(1):533.

[23] Lei W,Wei L,Wang H,Sun Y. Effect of annealing on the texture and mechanical properties of pure Mg by ECAP at room temperature[J]. Vacuum, 2017,144:281.

[24] Lin K,Kang Z X,Fang Q,Zhang J Y. Microstructure and mechanical properties of Mg-Li alloys subjected to severe plastic deformation and annealing[J]. Chinese Journal of Nonferrous Metals,2013,23(12):3267.(林楷,康志新,方强,张俊逸.剧塑性变形及退火后Mg-Li合金的组织与力学性能[J].中国有色金属学报,2013,23(12):3267.)

[25] Song D,Li C,Liang N,Yang F,Jiang J,Sun J,Wu G,Ma A,Ma X. Simultaneously improving corrosion resistance and mechanical properties of a magnesium alloy via equal-channel angular pressing and post water annealing[J]. Materials&Design,2019,166:107621.

[26] Wang Y M,Cheng S,Wei Q M,Ma E,Nieh T G,Hamza A. Effects of annealing and impurities on tensile properties of electrodeposited nanocrystalline Ni[J].Scripta Materialia,2004,51(11):1023.

[27] Valiev R Z,Sergueeva A V,Mukherjee A K. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium[J]. Scripta Materialia,2003,49(7):669.

[28] Huang X,Kamikawa N,Hansen N. Strengthening mechanisms in nanostructured aluminum[J]. Materials Science&Engineering A,2008,483(14):102.

[29] Orlov D,Ralston K D,Birbilis N,Estrin Y. Enhanced corrosion resistance of Mg alloy ZK60 after processing by integrated extrusion and equal channel angular pressing[J]. Acta Materialia,2011,59(15):6176.

[30] Birbilis N,Ralston K D,Virtanen S,Fraser H L,Davies C H J. Grain character influences on corrosion of ECAPed pure magnesium[J]. British Corrosion Journal,2010,45(3):224.

[31] Pan Y,Zhang D T,Tan Y N,Li Z,Zheng Y F,Li L.Preparation of medical ultrafine Mg-3Sn-0.5Mn alloy and its mechanical properties by channel extrusion[J].Acta Metallis Sinica,2017,53(10):1357.(潘瑜,张殿涛,谭雨宁,李珍,郑玉峰,李莉.等通道挤压制备医用超细晶Mg-3Sn-0.5Mn合金及其力学性能[J].金属学报,2017,53(10):1357.)

[32] Gopi K R,Nayaka H S,Sahu S. Corrosion behavior of ECAP-processed AM90 magnesium alloy[J]. Arabian Journal for Science&Engineering,2018,43:4871.

[33] Gu X N,Li N,Zheng Y F,Kang F,Wang J T,Ruan L.In vitro study on equal channel angular pressing AZ31magnesium alloy with and without back pressure[J].Materials Science&Engineering B,2011,176(20):1802.

[34] Fan G D,Zheng M Y,Hu X S,Xu C,Wu K,Golovin I S. Improved mechanical property and internal friction of pure Mg processed by ECAP[J]. Materials Science&Engineering A,2012,556(9):588.

[35] Mostaed E,Hashempour M,Fabrizi A,Dellasega D,Bestetti M,Bonollo F,Vedani M. Microstructure,texture evolution,mechanical properties and corrosion behavior of ECAP processed ZK60 magnesium alloy for biodegradable applications[J]. J. Mech. Behav.Biomed. Mater.,2014,37:307.

[36] Mostaed E,Fabrizi A,Dellasega D,Bonollo F,Vedani M. Microstructure,mechanical behavior and low temperature superplasticity of ECAP processed ZM21 Mg alloy[J]. Journal of Alloys&Compounds,2015,638:267.

[37] Akbaripanah F,Fereshteh-Saniee F,Mahmudi R,Kim H K. The influences of extrusion and equal channel angular pressing(ECAP)processes on the fatigue behavior of AM60 magnesium alloy[J]. Materials Science&Engineering A,2013,565(5):308.

[38] Liu Q. The research progress on plastic deformation mechanism of magnesium alloys[J]. Acta Metallis Sinica,2010,46(11):1458.(刘庆.镁合金塑性变形机理研究进展[J].金属学报,2010,46(11):1458.)

[39] Minárik P,Král R,?í?ek J,Chmelík F. Effect of different c/a ratio on the microstructure and mechanical properties in magnesium alloys processed by ECAP[J]. Acta Materialia,2016,107:83.

[40] Xu J,Yang T,Jiang B,Song J,He J,Wang Q,Chai Y,Huang G,Pan F S. Improved mechanical properties of Mg-3Al-1Zn alloy sheets by optimizing the extrusion die angles:microstructural and texture evolution[J].Journal of Alloys&Compounds,2018,762:719.

[41] Yang Q,Jiang B,Zhou G,Dai J,Pan F S. Influence of an asymmetric shear deformation on microstructure evolution and mechanical behavior of AZ31 magnesium alloy sheet[J]. Materials Science&Engineering A,2014,590(1):440.

[42] Wu X,Yang M,Yuan F,Wu G,Wei Y,Huang X,Zhu Y. Heterogeneous lamella structure unites ultrafinegrain strength with coarse-grain ductility[J]. Proceedings of the National Academy of Sciences of the United States of America,2015,112(47):14501.

[43] Yuan Y,Ma A,Gou X,Jiang J,Lu F,Dan S,Zhu Y.Superior mechanical properties of ZK60 Mg alloy processed by equal channel angular pressing and rolling[J]. Materials Science&Engineering A,2015,630(6):45.

[44] Biswas S,Singh D S,Beausir B,Toth L S,Suwas S.Thermal response on the microstructure and texture of ECAP and cold-rolled pure magnesium[J]. Metallurgical&Materials Transactions A,2015,46(6):1.

[45] Chen H,Yang J,Zhou H,Moering J,Yin Z,Gong Y,Zhao K Y. Mechanical properties of gradient structure Mg alloy[J]. Metallurgical&Materials Transactions A,2017,48(9):3961.