文章编号:1004-0609(2011)11-2869-06

定向凝固Ni47Mn32Ga21多晶合金的结构、相变及磁特性

蔡培阳, 冯尚申, 薛双喜, 陈卫平, 周 英, 吴建波, 王古平

(台州学院 物理与电子工程学院,台州 318000)

摘 要:

采用定向凝固方法制备了Ni47Mn32Ga21多晶合金,通过XRD谱和金相照片研究合金的结构,通过对合金磁化强度与温度关系、电阻与温度关系、磁化曲线和磁感生应变曲线的测量分析,研究了合金的相变、磁化特性及磁感生应变特性。结果表明:Ni47Mn32Ga21合金在室温(298K)时为四方结构马氏体相,晶格参数a=b=0.593 8 nm,c=0.553 1 nm。合金的马氏体相变起始温度Ms和终止温度Mf分别为309 K和295 K,逆马氏体相变起始温度As与终止温度Af 分别为306 K和319 K,居里温度TC为365 K。室温无压力下,Ni47Mn32Ga21合金有较好的双向可恢复磁感生应变,其饱和磁感生应变值达到-700×10-6。

关键词:

Ni-Mn-Ga合金;定向凝固;马氏体相变;形状记忆合金;磁感生应变;

中图分类号:TG 139.6 文献标志码:A

Structure, phase transformation and magnetic properties in polycrystalline Ni47Mn32Ga21 directionally solidified alloy

CAI Pei-yang, FENG Shang-shen, XUE Shuang-xi, CHEN Wei-ping, ZHOU Ying, WU Jian-bo, WANG Gu-ping

(School of Physics and Electronic Engineering, Taizhou University, Taizhou 318000, China)

Abstract: Ni47Mn32Ga21 polycrystalline alloy was prepared by the directional solidification technique. The structure of the alloy were investigated using XRD and metallography methods. The phase-transformation, magnetization properties and magnetic-field-induced strains were also studied through analyzing the magnetization as a function of temperature, the resistance as a function of temperature, magnetization and magnetic field-induced strain curves. The results show that Ni47Mn32Ga21 alloy exhibits martensitic phase of a tetragonal structure with lattice parameters a=b=0.593 8 nm and c=0.553 1 nm at room temperature (298 K). The martensitic start temperature Ms and the martensitic finish temperature Mf are 310 K and 295 K, respectively. The austenitic start temperature As and austenitic finish temperature Af are 306 K and 319 K, respectively. The Curie temperature of alloy TC is 365 K. Ni47Mn32Ga21 alloy exhibits excellent free recoverability of the magnetic-field-induced strains at room temperature without external stress. The saturated value of magnetic-field-induced strain reaches -700×10-6.

Key words: Ni-Mn-Ga alloy; directional solidification; martensitic transformation; shape memory alloy; magnetic-field- induced strain

铁磁性形状记忆合金Ni2MnGa是兼有热弹性马氏体相变和铁磁性转变的新型功能材料。它不仅可以在温度、压力场作用下诱发形状记忆效应,而且还可以在磁场作用下产生形状记忆效应。由于其在磁场控制下的形状记忆具有输出应变大、响应频率高及可精确控制等特点,使其可能在大功率水下声纳、微位移器、震动和噪声控制、微波器件、机器人等领域有重要应用,有望成为压电陶瓷和磁致伸缩材料之后的新一代驱动与传感材料[1-5]。对该材料的早期研究主要集中在单晶样品以及磁感生应变性能研究上,但化学计量成分的 Ni2MnGa合金的马氏体相变温度为202 K,远低于室温,不利于材料的应用,为使材料的马氏体相变温度达到室温以上, 往往采用偏离化学计量成分的合金样品。通过调整非化学计量Ni2MnGa,WU等[6]在Ni52Mn22.2Ga25.8单晶中得到室温0.3%的磁感生应变,WANG等[7]在Ni52Mn24Ga24单晶中得到室温1.2%的磁感生应变,CHEN[8]在277 K的 Ni50.5Mn26.2Ga23.4单晶中得到1.7%的磁感生应变, LIKHACHEV等[9]在Ni48Mn30Ga22单晶中得到室温5%的磁感生应变,MURRAY等[10-11]在Ni47.4Mn32.1Ga20.5单晶中得到室温6%的磁感生应变和5.7%磁剪切应变,JIANG等[12-13]在Ni50Mn27.5Ga22.5单晶中得到室温6.3%的磁感生应变,SOZINOY等[14]在Ni48.8Mn29.7Ga21.5单晶中得到室温9.5%的磁感生应变,可见富Mn单晶NiMnGa样品具有较大的磁感生应变。由于单晶制备工艺复杂、制备成本高、材料脆性大、生产效率低,很难大规模推广应用。近年来,关于非化学计量Ni2MnGa合金多晶材料的研究逐渐发展起来,主要集中在如何改善Ni2MnGa合金的温度、应变、机械等综合性能上。研究者们在实践中发现退火、定向凝固、甩带快淬、薄膜沉积、掺杂、加压等方法能有效地改善合金的相变温度、磁感生应变和机械性 能[15-22]。

本文作者报道利用真空电弧炉熔炼和定向凝固方法制备的非化学计量多晶Ni47Mn32Ga21合金的结构、相变、电磁性能及磁感生应变等特性,并对产生这些特性的原因进行了分析与探讨。

1 实验

取纯度为99.9 %的单质金属Ni、Mn、Ga,按Ni47Mn32Ga21的化学计量进行配料。将配料置于真空电弧炉的水冷铜坩埚中,在高纯氩气保护下进行熔炼,熔炼过程中为保证成分均匀,反复翻转重熔4次,浇注成d 8 mm×80 mm的圆柱形母合金铸锭棒。 然后取铸锭棒进行定向凝固生长,制备具有一定晶体取向的多晶试样。定向凝固生长是在真空充氩气保护条件下进行,生长温度为1 573 K,生长速度为2 mm/min。最后把定向凝固试样在真空充氩气保护下进行退火处理,以便消除杂散内应力,使原子更高度有序排列。退火温度为1 023 K,保温24 h,然后在冰水混合物中淬火。

用Bruker D8 Advance X射线衍射仪(XRD)对合金进行相结构分析,射线源为Cu Kα。用OLYMPUS DX51型光学显微镜对合金进行微结构分析,用于金相观察的合金表面经抛光与腐蚀处理,腐蚀剂用3%(体积分数)的硝酸酒精溶液,腐蚀时间为15 min。合金相变温度与磁特性用HH-15振动样品磁场计(VSM)和标准四引线法在变温装置中进行测量。直流磁化强度M与外磁场H及直流磁化强度M与温度T关系测量时,振杆的振动频率为77 Hz,M—T测量时偏置磁场为7.96 kA/m,升降温速率都为1.5 K/min。电阻R与温度T关系测量时,降温速率为1.5 K/min,升降温速率在室温下为1.5 K/min、在室温以上为5 K/min。采用电阻应变片法沿晶体生长方向在JDAW-2011型交直流磁致伸缩参数测量仪上测量样品在室温(298 K)下的磁感生应变。

2 结果与讨论

2.1 Ni47Mn32Ga21合金样品的结构

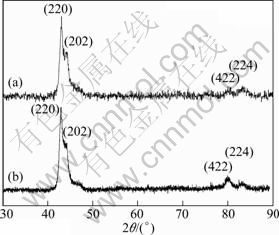

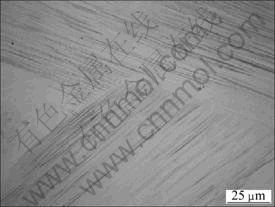

图1所示为Ni47Mn32Ga21合金样品粉末在室温(298 K)下的XRD谱。从图1中可以看出,铸态样品和定向凝固样品的衍射峰位置一致,但定向凝固样品的衍射峰强度较大,特别是(422)衍射峰强度远大于铸态,这说明铸态合金与定向凝固合金的相组织是相同的,定向凝固过程中合金在一定的晶体方向发生了择优取向。此外,主要衍射峰(220)已分裂为(220)、(202)两个衍射峰,(422)、(224)衍射峰也都发生了较明显的分裂。这显示室温下样品为四方马氏体结构,经计算其晶格参数a=b=0.593 8 nm,c=0.553 1 nm,四方度c/a=0.931。样品在室温下呈现四方结构,说明样品的马氏体相变温度高于室温,这是由于部分Mn替代Ga、Ni的结果,与文献[9-15]的报导相一致,也和本研究中的M—T和R—T等测量结果相吻合。图2所示为室温下光学金相显微镜观察到的,定向凝固合金表面经过机械抛光与3%的硝酸酒精溶液腐蚀过的金相照片,从照片上可以清晰地看到合金表面马氏体孪晶排列整齐。这些都预示着样品在室温下可能有较大的磁感生应变。

图1 Ni47Mn32Ga21合金粉末在室温下的XRD谱

Fig.1 XRD patterns of Ni47Mn32Ga21 alloy powder at room temperature: (a) As-cast; (b) Directional solidification

图2 Ni47Mn32Ga21合金室温下的金相照片

Fig.2 Metallograph of Ni47Mn32Ga21 alloy at room temperature

2.2 Ni47Mn32Ga21合金样品的相变特性

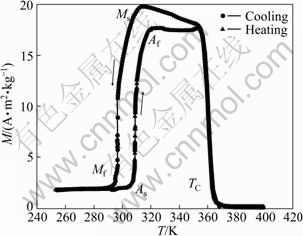

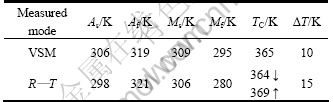

通过测量样品的磁化强度M与温度T及电阻R与温度T的关系来分析样品的相变特性。图3所示为样品直流磁化强度M随温度T的变化关系,测量时外磁场保持在7.96 kA/m不变,上下两条曲线分别为降温和升温曲线。从图3中可以看出,样品的马氏体相变起始温度Ms和终止温度Mf分别为309 K和295 K,逆马氏体相变起始温度As与终止温度Af分别为306 K和319 K,相变热滞温度ΔT(ΔT=Af-Ms)为10 K,居里温度TC为365 K。样品的Ms比化学计量Ni2MnGa合金的202 K要高得多,这是由于晶胞体积减少和电子浓度增大造成的[23],样品的电子浓度(e/a)为7.57,大于Ni2MnGa的7.5。样品的居里温度TC比Ni2MnGa的376 K要略低,这又是由于NiMnGa合金的磁性主要来源于Mn原子,当Mn原子过量时,过量的Mn原子影响了未被替代Mn原子的电子结构,进而使未被替代Mn原子的磁矩减少引起的,但成份变化对TC影响总体不大[23]。

图4所示为样品的R—T曲线。从曲线中也能清晰地看出材料的马氏体相变起始温度Ms和终止温度Mf分别为306 K和280 K,逆马氏体相变起始温度As与终了温度Af分别为398 K和321 K,热滞温度ΔT为15 K,降温时居里温度TC1为364 K,升温时居里温度TC2为369 K。表1清晰地列出样品在不同测方法下的各个相变温度,从表中可明显地看出这一测量结果与上面M—T测量结果略有不同,这种不同主要有两个原因。一个原因是M—T曲线与R—T曲线所表征的物理性质不同,其所测得的相变温度本身就略有差异[24]。另一个原因是仪器本身在室温以上的升温速率大于降温速率造成的,这从高温段升温R—T曲线与降温R—T曲线偏离较大,升温居里温度TC2偏大可以看出。这也是造成R—T测量时ΔT偏大的主要原因,因为不同表征相变温度的方法对ΔT都没有什么影响[24]。

图3 Ni47Mn32Ga21样品合金的直流磁化强度M隨温度T的变化曲线

Fig.3 DC magnetization M as a function of temperature T for Ni47Mn32Ga21 alloy

图4 Ni47Mn32Ga21样品合金的电阻R与温度T的变化曲线

Fig.4 Resistance (R) as function of temperature (T) for Ni47Mn32Ga21 alloy

表1 不同测量方式下各相变过程中的特征温度

Table 1 Characteristic temperatures of phase transformation by different measurements

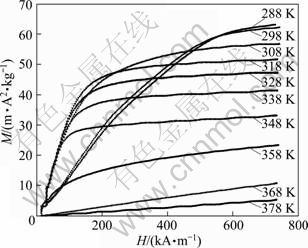

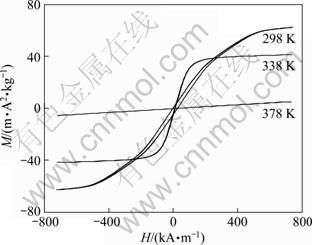

2.3 Ni47Mn32Ga21合金样品的磁化特性

图5所示为Ni47Mn32Ga21样品合金在不同温度下的初始磁化曲线(M—H曲线),图6所示为样品在298 、338和378 K 3个典型温度下的磁滞回线(M—H回线)。由图线可明显看出吗,样品在室温(298 K)及以下时难磁化,表现出62 A·m2/kg的高饱和磁化强度及650 kA/m的大饱和磁场;当温度高于318 K时样品易磁化,其饱和磁场迅速减少至250 kA/m;当温度进一步升高样品的饱和磁化强度及饱和磁场也将进一步减少;当温度升到368 K及以上时,样品表现为顺磁性。由图6还可进一步看出,随着样品温度的升高,样品的矫顽力在不断减少。NiMnGa合金在马氏体相时不容易磁化,表现出强磁晶各向异性;在奥氏体相时容易磁化,表现出弱磁晶各向异性。这也间接表明样品在室温下已为马氏体相,可见这一测量结果和以上的XRD和相变温度的测量结果相一致。样品在室温下有高饱和磁化强度和强磁晶各向异性,也预示着样品在室温下可能有较大的磁感生应变。

图5 Ni47Mn32Ga21样品合金温度从288 K至378 K的初始磁化曲线(M—H曲线)

Fig.5 Initial magnetization isotherms of Ni47Mn32Ga21 alloy in temperature rang from 288 K to 378 K (M—H curves)

图6 Ni47Mn32Ga21样品合金在298、338和378 K不同典型温度下的磁滞回线(M—H回线)

Fig.6 Magnetization hysteresis loops of Ni47Mn32Ga21 alloy at different temperatures (M—H loops)

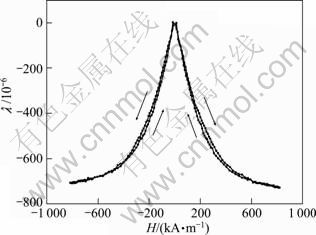

2.4 Ni47Mn32Ga21合金样品的磁感生应变

图7所示为Ni47Mn32Ga21合金样品退火后在室温(298 K)、无压力的状态下应变λ随磁场H的变化关系。由图7中可以看出,样品在外加磁场增加和减少,及磁场反向增加和反向减少时,其磁感生应变曲线都能良好重合,这说明样品在自由状态下具有良好的双向可逆磁感生应变特性。这一特性在工程技术上具有较大应用价值。此外,从图7中还可以看出,退火后的Ni47Mn32Ga21合金在室温下的饱和磁感生应变值(λ)达到了-700×10-6,自由状态下这样大的双向可恢复磁感生应变在NiMnGa多晶定向凝固样品中也是不多见的,具有潜在的工程应用价值。造成样品在室温下有较好的磁感生应变,可能有以下主要原因:1) Ni47Mn32Ga21合金样品在室温时已为马氏体相,合金中马氏体受到磁场驱动使不同马氏体变体间的孪晶界发生滑移,从而在宏观上表现出大的磁感生应变[6-14];2) 在定向凝固过程中,合金在一定的晶体方向发生择优取向,导致合金在磁场作用下产生较大的宏观应 变[16];3) 退火处理降低了样品的杂散内应力对马氏体择优取向的阻碍,从而增大了合金的磁感生应变[2, 6-8, 16]。

图7 Ni47Mn32Ga21样品合金在298K时磁感生应变随磁场强度变化的曲线

Fig.7 Magnetic field-induced strains measured at 298K as function of magnetic field for Ni47Mn32Ga21 alloy

3 结论

1) 定向凝固多晶Ni47Mn32Ga21合金样品具有室温以上的马氏体相变温度,在室温(298 K)时合金为四方结构马氏体相,其晶格参数为a=b=0.593 8 nm,c=0.553 1 nm,四方度c/a=0.931。

2) 定向凝固多晶Ni47Mn32Ga21合金样品的马氏体相变起始温度Ms和终止温度Mf分别为309 K和295 K, 逆马氏体相变起始温度As与终止温度Af分别为306 K和319 K,居里温度TC为365 K。

3) 定向凝固多晶Ni47Mn32Ga21合金样品在室温时表现出62A m2/kg的高饱和磁化强度及650 kA/m的大饱和磁场,室温下合金样品具有强磁晶各向异性。

4) 定向凝固多晶Ni47Mn32Ga21合金样品经1 023 K退火后,在室温无压力下有较好的双向可恢复磁感生应变,其饱和磁感生应变值达到-700×10-6。

REFERENCES

[1] ULLAKKO K, HUANG J K, KANTNER C, O’HANDLEY R C, KOKORIN V V. Large magnetic-field-induced strains in Ni2MnGa single crystals[J]. Appl Phys Lett, 1996, 69(13): 1966-1968.

[2] 崔玉亭, 王万录, 廖克俊. Ni50.5Mn26.5Ga23单晶磁感生应变的温度依赖性[J]. 材料研究学报, 2004, 18(2): 123-129.

CUI Yu-ting, WANG Wan-lu, LIAO Ke-jun. Temperature dependence of the magnetic-field-induced induced strain in Ni50.5Mn26.5Ga23 single crystal[J]. Chinese Journal of Materials Research, 2004, 18(2): 123-129.

[3] 郭世海, 张羊换, 王国清, 祁 焱, 全白云, 王新林. 淬速对Ni-Mi-Ga快淬合金相变的影响[J]. 中国有色金属学报, 2005, 15(11): 1755-1760.

GUO Shi-hai, ZHANG Yang-huan, WANG Guo-qing, QI Yan, QUAN Bai-yun, WANG Xin-lin. Effect of quenching rate on phase transformation of Ni-Mr-Ga melt-spinning alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1755-1760.

[4] S?DERBERG O, GE Y, SOZINOV A, HANNULA S P, LINDROOS V K. Recent breakthrough development of the magnetic shape memory effect in Ni-Mn-Ga alloys[J]. Smart Mater Struct, 2005, 14: S223-S235.

[5] XU Hui-bin, WANG Jing-min, JIANG Cheng-bao, LI Yan. Ni-Mn-Ga shape memory alloys development in China[J]. Current Opinion in Solid State and Materials Science, 2005, 9: 319-325.

[6] WU G H, YU C H, MENG L Q, CHEN J L, YANG F M, QI S R, ZHAN W S, WANG Z, ZHENG Y F, ZHAO L C. Giant magnetic-field-induced strains in Heusler alloy NiMnGa with modified composition[J]. Appl Phys Lett, 1999, 75(19): 2990-2992.

[7] WANG W H, WU G H, CHEN J L, YU C H, GAO S X, ZHAN W S, WANG Z, GAO Z Y, ZHENG Y F, ZHAO L C. Stress-free two-way thermoelastic shape memory and field-enhanced strain in Ni52Mn24Ga24 single crystals[J]. Appl Phys Lett, 2000, 77(20): 3245-3247.

[8] CHEN F, GAO Z Y, CAI W, ZHAO L C, WU GH, CHEN J L, ZHAN W S. Strains induced by magnetic field and phase transformation in Ni50.5Mn26.2Ga23.4 ferromagnetic shape memory alloy[J]. J Mater Sci Lett, 2003, 22(18): 1241-1242.

[9] LIKHACHEV A A, ULLAKKO K. Magnetic-field-controlled twin boundaries motion and giant magneto-mechanical effects in Ni-Mn-Ga shape memory alloy[J]. Phys Lett A, 2000, 275(1/2): 142-151.

[10] MURRAY S J, MARIONI M, ALLEN S M, HANDLEY R C, LOGRASSO T A. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni-Mn-Ga[J]. Appl Phys Lett, 2000, 77(6): 886-888.

[11] MURRAY S J, MARIONI M A, KUKLA A M, ROBINSON J, O’HANDLEY R C, ALLEN S M. Large field induced strain in single crystalline Ni-Mn-Ga ferromagnetic shape memory alloy[J]. J Appl Phys. 2000, 87(9): 5774-5777.

[12] JIANG C B, WANG J M, XU H B. Temperature dependence of the giant magnetostrain in a NiMnGa magnetic shape memory alloy[J]. Appl Phys Lett, 2005, 86(25): 252508-3.

[13] WANG J M, JIANG C B, XU H B. Stress induced and magnetic field enhanced twin variants reorientation strain in NiMnGa single crystal[J]. Mater Sci Forum, 2005, 475/479: 2013-2016.

[14] SOZINOW A, LIKHACHEV A A, LANSKA N, ULLAKKO K. Giant magnetic-field-induced strain in NiMnGa seven-layer martensitic phase[J]. Appl Phys Lett, 2002, 80(10): 1746-1748.

[15] ULLAKKO K, EZER Y, SOZINOV A, KIMMEL G, YAKOVENKO P, LINDROOS V K. Magnetic-field-induced strains in polycrystalline Ni-Mn-Ga at room temperature[J]. Scripta Mater, 2001, 44(3): 475-480.

[16] 郭世海, 张羊换, 赵增祺, 李健靓, 王新林. 定向凝固生长对Ni-Mn-Ga-RE(RE=Tb, Sm)合金磁感生应变的影响[J]. 物理学报, 2004, 53(5): 1599-1603.

GUO Shi-hai, ZHANG Yang-huan, ZHAO Zeng-qi, LI Jian-liang, WANG Xin-lin. Effect of directional solidification on magnetic-field-induced strain in Ni-Mn-Ga-RE(RE=Tb, Sm) alloys[J]. Aact Physica Sinica, 2004, 53(5): 1599-1603.

[17] CHERECHUKIN A A, KHOVAILO V V, KOPOSOV R V, KRASNOPEROV E P, TAKAGI T, TANI J. Training of the Ni-Mn-Fe-Ga ferromagnetic shape-memory alloys due cycling in high magnetic field[J]. J Magn Magn Mater, 2003, 258/259: 523-525.

[18] MALLA A, DAPINO M J, LOGRASSO T A, SCHLAGEL D L. Large magnetically induced strains in Ni50Mn28.7Ga21.3 driven with collinear field and stress[J]. J Appl Phys, 2006, 99(6): 063903-9.

[19] RAFAL W, MARCIN L, ZHAO Zeng-qi, JIANG Li-ping. Structure and properties of Ni-Mn-Ga magnetic shape memory alloys containing minor addition of terbium[J]. Journal of Magnetism and Magnetic Materials, 2007, 316: e595-e598.

[20] PANDA A K, GHOSH M, KUMAR ARVIND, MITRA A. Magnetic transitions and structure of a NiMnGa ferromagnetic shape memory alloy prepared by melt spinning technique[J]. Journal of Magnetism and Magnetic Materials, 2008, 320: L116-L120.

[21] 王省哲, 何宝明. 铁磁形状记忆合金Ni2MnGa多晶的磁-力学特性[J]. 功能材料, 2008, 39(8): 1272-1275.

WANG Xing-zhe, HE Bao-ming. Magnetomechanical characteristics of ferromagnetic shape memory alloy Ni2MnGa polycrystals[J]. Functional Materials, 2008, 39(8): 1272-1275.

[22] ZHANG Yue-peng, HUGHES R A, BRITTEN J F, GONG Wen-he, PRESTON J S, BOTTON G A, NIEWCZAS M. Epitaxial Ni-Mn-Ga films derived through high temperature in situ depositions[J]. Smart Mater Struct, 2009, 18 (2): 025019-6.

[23] JIANG Cheng-bao, Muhammad Y, DENG Li-feng, WU Wei, XU Hui-bin. Composition dependence on the martensitic structures of the Mn-rich NiMnGa alloys[J]. Acta Materialia, 2004, 52(9): 2779-2785.

[24] 高淑侠, 王文洪, 柳祝红, 陈京兰, 吴光恒, 梁 婷, 徐惠彬, 蔡 伟, 郑玉峰, 赵连城. 铁磁形状记忆合金Ni52.2Mn23.8Ga24的马氏体相变及其物理表征[J].物理学报, 2002, 51(2): 0332-0336.

GAO Shu-xia, WANG Wen-hong, LIU Zhu-hong, CHEN Jing-lan, WU Guang-heng, LIANG Ting, XU Hui-bin, CAI Wei, ZHENG Yu-feng, ZHAO Lian-cheng. Martensitic transformation and physics characterization of ferromagnetic shape memory alloy Ni52.2Mn23.8Ga24[J]. Aact Physica Sinica, 2002, 51(2): 0332-0336.

(编辑 李艳红)

基金项目:浙江省科技厅重点项目(2006C21085 );台州市科技计划项目(08KY11)

收稿日期:2010-10-08;修订日期:2011-03-07

通信作者:冯尚申,教授,博士;电话:0576-85173158;E-mail: fss@tzc.edu.cn

摘 要:采用定向凝固方法制备了Ni47Mn32Ga21多晶合金,通过XRD谱和金相照片研究合金的结构,通过对合金磁化强度与温度关系、电阻与温度关系、磁化曲线和磁感生应变曲线的测量分析,研究了合金的相变、磁化特性及磁感生应变特性。结果表明:Ni47Mn32Ga21合金在室温(298K)时为四方结构马氏体相,晶格参数a=b=0.593 8 nm,c=0.553 1 nm。合金的马氏体相变起始温度Ms和终止温度Mf分别为309 K和295 K,逆马氏体相变起始温度As与终止温度Af 分别为306 K和319 K,居里温度TC为365 K。室温无压力下,Ni47Mn32Ga21合金有较好的双向可恢复磁感生应变,其饱和磁感生应变值达到-700×10-6。