- Abstract:

- 1 Introduction▲

- 2 Experimental▲

- 3 Experimental results▲

- 3.2 General observations of experimental tests

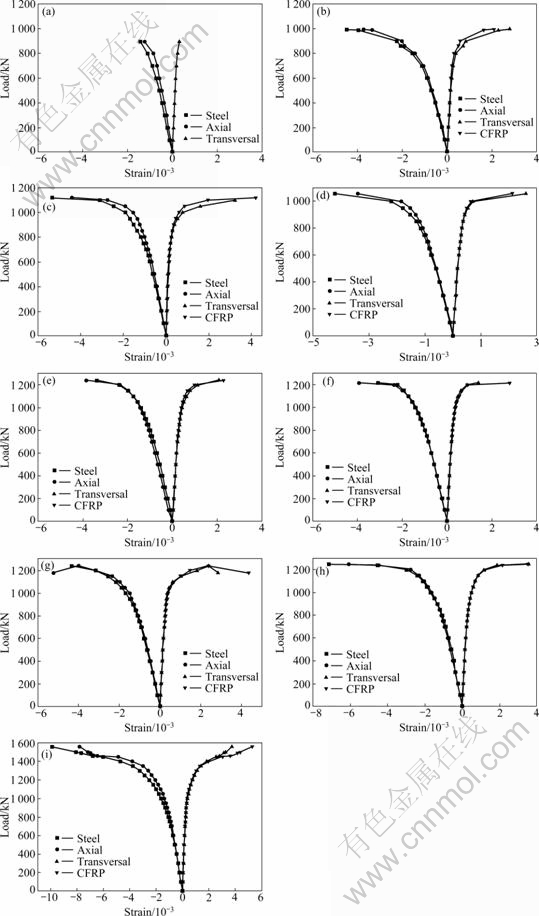

- 3.3 Load—strain curves

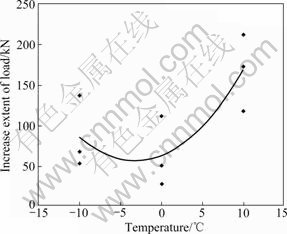

- 3.4 Influence of temperature on strengthening effect

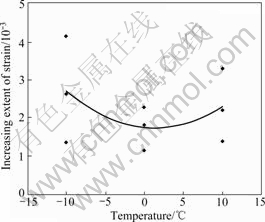

- 3.5 Influence of temperature on axial strain

- 3.6 Mechanism of low temperature on strengthening effect

- 4 Conclusions▲

- References

- Figure

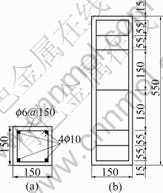

- Fig.1 Sketch of reinforcement (Unit: mm): (a) Top view; (b) Vertical view

- Fig.2 Failure patterns of specimens: (a) 1-3; (b) 2-3; (c) 8-1

- Fig.3 Load—train curves of various concrete columns: (a) 1-3; (b) 2-3; (c) 3-2; (d) 4-3; (e) 5-1; (f) 6-1; (g) 7-2; (h) 8-1; (i) 9-1

- Fig.4 Influence of temperature on strengthening effect

- Fig.5 Influence of temperature on axial strain

J. Cent. South Univ. Technol. (2009) 16: 0835-0840

DOI: 10.1007/s11771-009-0138-8

![]()

Square concrete columns strengthened with

carbon fiber reinforced plastics sheets at low temperatures

MA Qin-yong(马芹永)1, LU Xiao-yu(卢小雨)2

(1. School of Civil Engineering and Architecture,

Anhui University of Science and Technology, Huainan 232001, China;

2. Science School, Anhui University of Science and Technology, Huainan 232001, China)

Abstract:

Twenty-one square concrete columns were constructed and tested. The testing results indicate that bonded carbon fiber reinforced plastics (CFRP) sheets can be used to increase the strength and improve the serviceability of damaged concrete columns at low temperatures. The failure of the specimens, in most cases, takes place within the middle half of the columns. And the failure of strengthened columns is sudden and explosive. The CFRP sheets increase both the axial load capacity and the ultimate concrete compressive strain of the columns. The ultimate loads of strengthened columns at -10, 0 and 10 ℃ increase averagely by 9.09%, 6.63% and 17.83%, respectively, as compared with those of the control specimens. The axial compressive strength of strengthened columns is related to the curing temperatures. The improvement of axial compressive strength decreases with reducing temperature, and when the temperature drops to a certain value, the improvement increases with falling temperature.

Key words:

carbon fiber reinforced plastics (CFRP) sheet; square concrete column; stress—strain model;

1 Introduction

Applications of carbon fiber reinforced plastics (CFRP) sheets in civil engineering are growing [1-3], but one of the areas where knowledge is limited is the behaviour of concrete columns strengthened with CFRP sheets at low temperatures. To overcome this deficiency, tests were conducted to evaluate the effectiveness and feasibility of bonded CFRP sheets on the behaviour of strengthened square concrete columns subjected to room and low temperatures. The research provides the foundation of science for the application of carbon fiber strengthening in winter weather.

So far there have been only a few reviews related to the effect of low temperature on the performance of strengthened concrete beams. CHAJES et al [4-5] found that the environmental exposure can lead to change in failure mode compared to non-exposed specimens. While NAAMAN [6] and GREEN et al [7-8] found that the failure mode of strengthened beams tested at low temperature was the same as that of beams loaded at room temperature. GREEN et al [7-8], HOA et al [9], FINCH et al [10], NOLLET et al [11], MOHAMAD et al [12] and TU[13] found that FRP sheets can be effectively bonded to concrete under winter weather and the ultimate load at freezing temperature can be increased as compared to the control beams. AROCKIASAMY et al [14] and BAUMERT et al [15] found that flexure behaviour of strengthened specimens was not affected by the reduced temperature exposure.

2 Experimental

2.1 Columns description and design

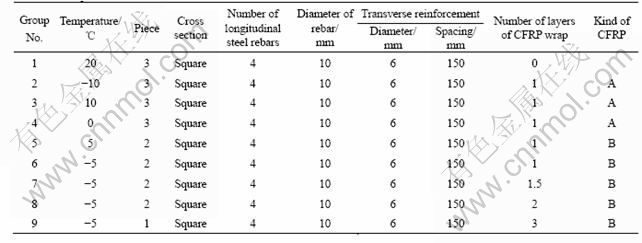

Twenty-one square columns with 150 mm in width and 550 mm in length were constructed and tested. All specimens were loaded in axial compression until failure. Details of the test specimen are shown in Fig.1. The test specimens were divided into nine groups. Table 1 gives the details of the test specimens.

2.2 Material properties

The mechanical properties of the concrete and reinforcement at room temperature were obtained from ancillary tests. The concrete mixture proportion in mass was 1.00(cement)?1.35(fine aggregate)?2.21(coarse aggregate). The water-cement ratio was 0.39 and the cement content was 484.85 kg/m3. Ordinary Portland cement and well-rounded graded gravel with the maximum aggregate size of 15 mm were used.

The mechanical properties of the resin and CFRP were obtained from the descriptions provided by the

manufacturers. The low temperature strength properties of the reinforcement were not determined, due to the lack of appropriate low temperature test facilities and

Fig.1 Sketch of reinforcement (Unit: mm): (a) Top view; (b) Vertical view

apparatus. The properties of concrete, reinforcement, resin epoxy and CFRP sheets are presented in Tables 2- 5, respectively.

2.3 Column fabrication

The steel cages were assembled and carefully placed in the forms. A care was taken not to damage the strain gauges mounted on the reinforcement bars. The concrete mixture was slowly pumped into the forms to prevent segregation, and vibrators were used to vibrate the concrete carefully to prevent voids from forming. Slump tests were taken on site to ensure the quality of concrete. The concrete columns were covered with burlap sheets and moist cured for a period of 2 d. Then the columns were removed from the iron formwork. At the time of casting the columns, six standard cubes (150 mm×150 mm×150 mm), were cast from the same mixture for ancillary tests to determine the compressive strength of the concrete.

The concrete columns, after curing, were striped, sharp edges were ground, and then the specimens were carefully sand blasted. A thin layer of penetrating primer was applied to the concrete specimen and allowed to cure for 2 h. Voids and deformities on the surface of the specimens were filled using aligning epoxy and allowed to cure for 2 h. The macerating epoxy, consisting of resin and hardener, was applied to the concrete specimen. The CFRP sheets were then applied directly to the surface of the specimens, providing unidirectional lateral confinement in the hoop direction. Finally, four wood plates tied the specimens wrapped with CFRP sheets.

Table 1 Main parameters of each column

Table 2 Mechanical properties of concrete at 28 d

Table 3 Mechanical properties of longitudinal steel rebars

Table 4 Mechanical properties of resin

Table 5 Mechanical properties of CFRP

The wood plates were removed after the specimens were cured at different low temperatures for 7 d.

2.4 Test setup and instrument

A hydraulic testing machine with a capacity of 2 MN applied the axial load. Prior to the actual test, the columns were loaded initially to a small pre-load and then unload. The purpose of this step was to stabilize the column. The records of the strain gauges were then brought back to zero. The load was applied gradually through a load-control mode. The columns were subjected to a static monotonic load and tested until the ultimate load was attained. Four 2 mm-long strain gauges were mounted at middle locations on each longitudinal steel rebar to measure the longitudinal strain of longitudinal steel rebar. Six 20 mm-long strain gauges were mounted at middle locations on CFRP sheets to measure the lateral strain of CFRP sheet. Eight 50 mm- long strain gages were mounted at middle locations on the concrete to measure the longitudinal and lateral strain of the concrete. All the strain gages were located on central section of the specimens.

3 Experimental results

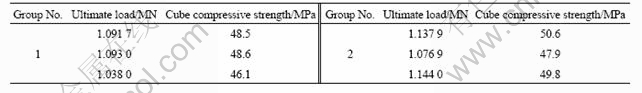

3.1Ultimate load and strain results

The results of ultimate load and strain at failure are given in Table 6. The ultimate loads of strengthened columns at -10, 0 and 10 ℃ increase averagely by 9.09%, 6.63% and 17.83%, respectively, as compared with those of the control specimens.

The ultimate loads of strengthened columns at -5 and 5 ℃ increase averagely by 25.42% and 28.96%, respectively, as compared with those of the control specimens. The experimental results show that using CFRP sheets can effectively increase the ultimate loads and ultimate strain of strengthened columns, regardless of their curing temperatures.

3.2 General observations of experimental tests

As can be seen in Fig.2, large longitudinal cracks are developed under loading that leads to the complete disintegration of the control specimen. And pieces of broken concrete are found.

Cracking noises start to be heard at moments prior to failure, indicating the occurrence of stress transfer from the dilated concrete to the jacket. The failure is sudden and explosive, and the CFRP sheets, in most cases, rupture in the middle portion of the specimens. The CFRP sheets rupture starts at one of the corners within the mid height of the specimens and progresses up and down along the specimen. Pieces of broken concrete are found. The broken specimens show a good contact between the CFRP sheets and the concrete, indicating that no de-bonding takes place. A complete dilation of the core concrete is obvious, as shown in Fig.2.

3.3 Load—strain curves

The typical load-strain curves of various concrete columns are shown in Fig.3.

Fig.2 Failure patterns of specimens: (a) 1-3; (b) 2-3; (c) 8-1

Fig.3 Load—train curves of various concrete columns: (a) 1-3; (b) 2-3; (c) 3-2; (d) 4-3; (e) 5-1; (f) 6-1; (g) 7-2; (h) 8-1; (i) 9-1

Table 6 Ultimate load and strain results

3.4 Influence of temperature on strengthening effect

Fig.4 shows that the axial compressive strength of strengthened columns is related to the curing temperatures. The improvement of axial compressive strength decreases with reducing temperature, and when the temperature drops to a certain value, the improvement increases with falling temperature. The regressive equation and coefficient of correlation are y=0.626 7t2+4.133 3t+62.667, R2=0.600 1.

Fig.4 Influence of temperature on strengthening effect

3.5 Influence of temperature on axial strain

Fig.5 shows that the axial strain of strengthened columns is related to the curing temperatures. The improvement of axial strain decreases with reducing temperature. When the temperature drops to a certain value the improvement increases with falling tempera- ture. The regressive equation and coefficient of correla- tion are y=7.516 7t2-20.867t+1 756.3, R2=0.179 9.

Fig.5 Influence of temperature on axial strain

3.6 Mechanism of low temperature on strengthening effect

The main reason for the improvement of axial compressive strength decreasing with reducing temperature is that the resin becomes brittle at low temperature, which leads to uneven loading of the CFRP sheet, especially for the CFRP sheets at the corners. Therefore, the failure of CFRP sheets at the corners is always tensile failure at first. But when temperature is lower than the freezing point of water and then drops form -12 to -10 ℃, concrete shows a small increase in strength with increasing time. When temperature is lower than -12 ℃, concrete does not appear to gain strength with time. BROWNE and BAMFORTH [16] found that the strength of concrete increased at temperature lower than -11 ℃. So the improvement increases with falling temperature.

4 Conclusions

(1) The failure of the specimens, in most cases, takes place within the middle half of the columns. And the failure of strengthened columns is sudden and explosive.

(2) The CFRP sheets increase both the axial load capacity and the ultimate concrete compressive strain of the columns at low temperatures.

(3) The ultimate loads of strengthened columns at -10, 0 and 10 ℃ increase averagely by 9.09%, 6.63% and 17.83%, respectively, as compared with those of the control specimens. The ultimate loads of strengthened columns at -5 ℃ and 5 ℃ increase averagely by 25.42% and 28.96%, respectively, as compared with that of the control specimens.

(4) Comparison of room and low temperature test results indicates that the axial compressive strength of strengthened columns is related to the curing temperatures.

(5) The improvement of axial compressive strength decreases with reducing temperature, and when the temperature drops to a certain value, the improvement increases with falling temperature.

References

[1] ZHAO Tong, XIE Jian. New technology of CFRP strengthened concrete structure [M]. Tianjin: Tianjin University Press, 2001. (in Chinese)

[2] TENG J G, CHEN J F, SMITH S T, LIN L. FRP strengthened RC structures [M]. LI Rong, TENG Jing-guang, GU Lei, transl. Beijing: China Building Industry Press, 2001. (in Chinese)

[3] HE Xue-jun, ZHOU Chao-yang, LI Yi-hui, XU Ling. Lagged strain of laminates in RC beams strengthened with fiber-reinforced polymer [J]. Journal of Central South University of Technology, 2007, 14(3): 432-435.

[4] CHAJES M J, MERTZ D R, THOMSON T A, FARSCHMAN C A. Durability of composite material reinforcement [C]// KIM D B. Proceedings of the 3rd Material Engineering Conference on Infrastructure: New Materials and Methods of Repair. San Diego, California: ASCE, 1994: 598-605.

[5] CHAJES M J, THOMSON T A, FARSCHMAN C A. Durability of concrete beams externally reinforced with composite fabrics [J]. Construction and Building Materials, 1995, 9(3): 141-148.

[6] NAAMAN A. Repair and strengthening of reinforced concrete Beams using CFRP laminates [D]. Michigan: University of Michigan, 1999.

[7] GREEN M, SOUDKI K A, JOHNSON M M. Freeze-thaw behaviour of reinforced concrete beams strengthened by fibre reinforced plastic sheets [C]// Proceedings of the 1997 Annual Conference of the Canadian Society for Civil Engineering. Sherbrooke, Quebec, 1997: 31-39.

[8] GREEN M, SOUDKI K A. FRP strengthened concrete structures in cold region [C]// MEIER U, BETTI R. Proceedings of the US-Europe Workshop on Recent Advances in bridge Engineering: Advanced Rehabilitation, Durable Materials, Non-destructive Evaluation, and Management. Dubendorf and Zurich, Switzerland, 1997: 219-226.

[9] HOA, S V, XIE M, XIAO X R. Repair of steel reinforced concrete with carbon/epoxy composites [C]// EL-BADRY M M. Proceedings of the 2nd International Conference on Advanced Composite Materials in Bridges and Structures. Montreal, 1996: 573-580.

[10] FINCH W W, CHAJES M J, MERTZ D R, KALIAKING V N, FAQIRI A. Bridge rehabilitation using composite materials [C]// KIM D B. Proceedings of the 3rd Material Engineering Conference on Infrastructure: New Materials and Methods of Repair. San Diego, California: ASCE, 1994: 1140-1147.

[11] NOLLET M J, PERJATON D, CHAALLAL O. Flexural behaviour of CFRP strengthened RC beams under room and freezing temperatures [C]// Proceedings of the 8th International Conference on Extending the Life of Bridges, Civil and Building Structures. London, 1999.

[12] MOHAMAD R, EL-HACHA A. Prestress CFRP sheets for strengthening concrete beams at room and low temperatures [D]. Kingston, Ontario: Queen’s University, 2000.

[13] TU Zhi-yi. Experimental study on reinforced concrete beams strengthened with carbon fiber reinforced plastics under low temperature [D]. Huainan: Anhui University of Science and Technology, 2005. (in Chinese)

[14] AROCKIASAMY M, THAYER C C, DUTTA P K. Damage process of CFRP composite-concrete interface under fatigue loading at low temperatures [C]// Proceedings of the 8th International Offshore and Polar Engineering Conference. Montreal, 1998: 211-218.

[15] BAUMERT M E, GREEN M F, ERKI M A. low temperature behaviour of concrete beams strengthened with FRP sheets [C]// Proceedings of the 1996 Annual Conference of the Canadian Society for Civil Engineering. Edmonton Alberta, 1996: 179-190.

[16] BROWNE R D, BAMFORTH P B. The use of concrete for cryogenic storage: A summary of research, past, and present [C]// Proceedings of the 1st International Conference on Cryogenic Concrete. London: The Concrete Society, 1981: 135-166.

(Edited by YANG You-ping)

Foundation item: Project(04043076) supported by the Outstanding Youth Foundation for Scientific and Technological Research of Anhui Province, China; Project(2007jq1035) supported by the Scientific Research Projects for Young College Teachers of Anhui Province, China

Received date: 2008-09-23; Accepted date: 2009-06-17

Corresponding author: LU Xiao-yu, Doctoral candidate; Tel: +86-554-6668286; E-mail: luxy@aust.edu.cn

- Square concrete columns strengthened withcarbon fiber reinforced plastics sheets at low temperatures