文章编号:1004-0609(2014)12-3082-06

NiTi合金形状记忆表面的临界应变

覃恩伟1, 2,吴树辉1

(1. 苏州热工研究院有限公司 表面工程研究所,苏州 215004;

2. INM-Leibniz Institute for New Materials, Saarbrucken 66123, Germany)

摘 要:

利用维氏四棱锥压痕方法,通过温度控制在NiTi合金中获得凸起-平整的双程形状记忆效应表面。通过研磨剥层法,发现随着消除深度的增加所获得的凸起高度和直径减小,在消除160 μm深度后,表面凸起现象消失,并从理论上定量分析该深度所对应的临界应变大小。实验表明:双程形状记忆效应是通过对形状记忆合金进行温度-应变循环变形而获得。因此,可能存在一定的临界应变,在低于该应变时,材料不能表现双程形状记忆效应。

关键词:

中图分类号:TG139.6 文献标志码:A

Critical strain on shape surface of NiTi shape memory alloy

QIN En-wei1, 2, WU Shu-hui1

(1. Division for Surface Engineering, Suzhou Nuclear Power Research Institute Co., Ltd., Suzhou 215004, China;

2. INM-Leibniz Institute for New Materials, Saarbrucken 66123, Germany)

Abstract: Two-way shape memory effect (TWSME) surface in NiTi was obtained using Vickers four-sided pyramidal indentation method, namely, the switchable surface between protrusions and flat state controlled by temperature. By gradual grinding off the deformed layer after indenting, the diameter and height of the protrusions decrease as increasing the removal layer. It is found that no protrusions are observed after 160 μm thick layer was removed. The critical microstrain at this depth is further theoretically calculated. It shows that TWSME can be obtained by means of thermomechanical training in shape memory alloys. Thus, there probably exists a critical microstrain, below which no TWSME will occur.

Key words: NiTi alloy; two-way shape memory effect; critical strain; strain distribution; indentation

形状记忆合金具备独特的双程形状记忆效应,即合金在温度的控制下能在两种形态间循环变化,这在微/纳电机系统部件(如微传感器、微夹持器、微阀门、微驱动器等)有广泛的应用前景[1-3]。然而,该效应不是形状记忆合金固有的本征性能。传统方法是采用热机械循环法制备材料,即在一定温度下对其进行反复加载-卸载变形,或在一定应力水平下进行反复的升温-降温引起奥氏体-马氏体相变[4-5]。大量的实验研究表明[4-7]:在热机械过程中,采用的应力水平和循环次数决定了产生的位错结构和内应力,从而决定了马氏体变体的择优取向,反应出所获得的双程形状记忆效应的应变大小。此外,材料本身的晶体各向异性[8-10]、晶粒尺寸[11-12]和塑性变形临界应力[13-15]也显著影响所获得双程形状记忆效应的大小。

近年来,对由形状记忆效应产生的双程形状记忆表面进行了广泛的研究[16-19]。采用球形或锥形压头的压痕方法,在形状记忆合金表面进行塑性变形。由于双向形状记忆效应而产生的形状记忆表面,在低温马氏体组织压痕位置呈现平面平整,在高温奥氏体态原压痕位置处呈现一定高度的圆锥状凸起,该凸起源于奥氏体-马氏体相变或压痕产生的应力诱发的马氏体。研究表明,形状记忆表面效应的大小与压痕所采用的压头形态和载荷等因素相关。NI等[16]和SHAW等[17]通过球形压头和锥形压头,分析了压头尖端形态对形状记忆效应的影响。在球形压头作用下,卸载低于5 N的载荷后,样品表面由于发生超弹性完全回复,因而没有形状记忆效应。而锥形压头由于尖端锐利,虽然压头生产工艺因素会导致尖端产生一定程度的钝化,但是利用锥形压头总能获得单程形状记忆效应。至今,还没有实验研究表明能否在任意应变下均获得双程形状记忆效应。

本文作者通过锥形压头在NiTi合金中获得双程形状记忆表面。通过研磨剥层法,分析压痕变形层对形状记忆效应的影响。探讨是否存在一定的临界应变,在低于该应变下不能获得双程形状记忆效应。双程形状记忆效应临界应变的分析对其在微纳尺度器械中的潜在应用具有重要的理论意义。

1 实验

实验材料选用NiTi合金,其中Ni的摩尔分数为50.9%。NiTi合金初始为冷轧态,经过550 ℃退火1.5 h,淬入水中。

采用Leco V-100系统在液氮中进行压痕实验。选用维氏四面锥型压头,其面角度为138°,载荷为200 N,载荷持续时间为10 s。压痕实验开始前,将样品浸泡在液氮中约5 min,使之充分冷却至液氮温度,NiTi合金处于完全马氏体态;然后,迅速将样品放置于压头下开始实验。压痕实验后,将样品加热至85 ℃保温5 min,然后淬入液氮中充分冷却。该加热-冷却循环可以消除单向形状记忆效应的影响。依次采用600号、1200号、2400号砂纸将样品研磨至压痕底部,并通过电解抛光以去除压痕,抛光后表面粗糙度Ra约为0.1 μm。此后,以压痕底部为深度零点基准,采用此研磨方法研磨去除样品不同的厚度,并通过加热-冷却过程分别观察样品表面形态。

采用奥林巴斯PMG3型光学显微镜观察压痕形貌,采用Zygo Newview 5000白光干涉仪观测样品在升温或降温后的表面形貌,测量凸起形貌的底部直径和高度。实验误差通过测量3个值取标准偏差。采用Brucker AXS D8 X射线仪分析样品室温下的相组织,扫描步幅为0.02 (°)/s;利用Mettler Toledo DSC1 Star型差示扫描量热仪(DSC)分析马氏体相变温度,升温和降温速度为20 ℃/s。DSC实验所用样品质量为15~20 mg,实验前采用电解抛光消除研磨所产生的应变影响。

2 实验结果

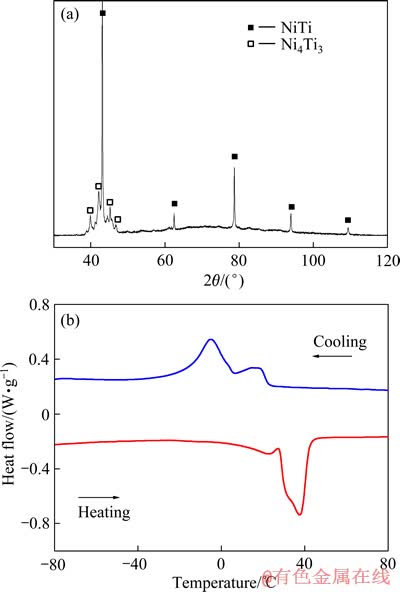

图1(a)所示为热处理后NiTi样品的XRD谱。由图1可知,主要是奥氏体相体心立方结构衍射峰,但在38°~48°间出现数条析出相Ni4Ti3的微弱衍射峰。正是由于这些析出相的存在,使得在奥氏体-马氏体相变过程中出现中间相R,如图1(b)所示。在升温过程中,约0 ℃即发生马氏体向中间相R的转变,随后转变为奥氏体,至42 ℃结束;在降温过程中发生逆反应,24 ℃开始由奥氏体转变为R相,但温度需降低至-18 ℃才能完全转变为马氏体。

图1 热处理后NiTi合金的XRD谱和DSC曲线

Fig. 1 XRD patterns(a) and DSC curves(b) of NiTi alloy

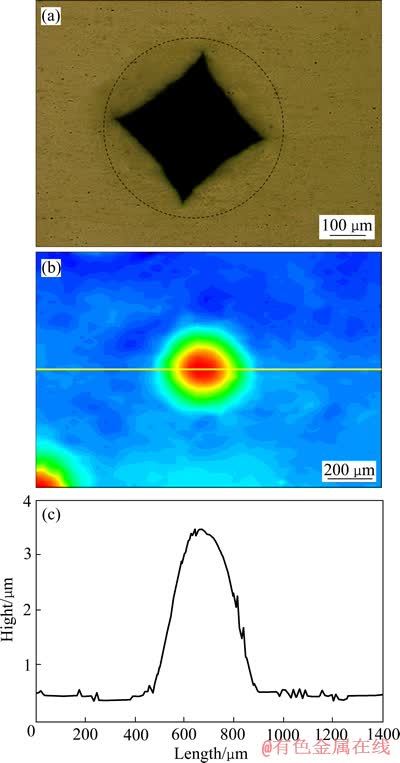

图2(a)所示为压痕典型的表面形貌,在液氮温度下,200 N载荷所产生的压痕对角线长度D为(421±5) μm。在压痕四周可观察到一个塑性变形区,其衬度较为明显,该区域直径略大于压痕对角线长度,如图2(a)中虚线所示。经过首次升温和降温处理消除单向形状记忆效应,再研磨表面至压痕底部,加热样品至奥氏体温度并自然冷却至室温后,在原压痕位置出现一个圆锥状凸起,如图2(b)所示。分析其截面轮廓曲线(见图2(c)可得凸起高度为(2.92±0.17) μm,凸起的底部直径为(510±46) μm。如果利用液氮冷却使该样品发生马氏体相变,在室温下观察发现,该凸起几乎消失,残余高度为(0.83±0.10) μm。

图2 NiTi合金压痕的表面形貌以及研磨去除压痕后原压痕位置的平面投影形貌和截面轮廓曲线

Fig. 2 Optical image of NiTi alloy with an indentation(a) and projection plane view of white-light interferometry image(b) and corresponding cross-sectional profile(c) after heating

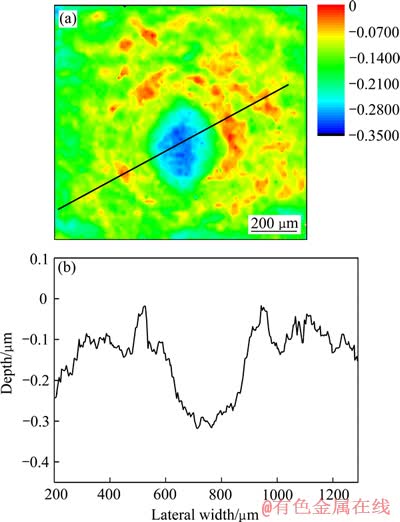

将该冷却样品继续研磨分别磨去厚度3 μm、11 μm后,将样品加热后自然冷却至室温,测量得到的凸起高度分别减小至(2.56±0.17) μm和(1.86±0.15) μm,底部直径分别为(510±46) μm和(495±38) μm。通过液氮冷却后,残余凸起完全消失,在原凸起位置观察不到任何起伏迹象。此后,继续研磨-加热-液氮冷却循环,凸起高度和底部直径均随着研磨厚度的增加而减小,如图3(a)和(b)所示。同时,液氮冷却后在原压痕位置出现凹坑,由图3(a)可知,其深度表现为负值,大小约为数百纳米,直径约为450 μm。图4(a)所示为研磨深度为24 μm时凹坑的白光干涉形貌的平面投影图,其轮廓为四方形,近似维氏压头横截面的形态。从图4(b)所示截面曲线可知,其深度约250 μm,直径约400 μm。当研磨至约160 μm深度后,在加热或液氮冷却后均观察不到明显的凸起形貌。

图3 在加热和冷却后凸起的高度以及加热后凸起圆锥底部直径随着研磨消除深度的变化趋势

Fig. 3 Protrusion height after heating and cooling(a) and relationship between protrusion diameter after heating and layer thickness(b)

图4 研磨去除深度为24 μm时样品冷却后凹坑的白光干涉图像以及切线所对应位置的截面轮廓曲线

Fig. 4 Depression surface morphology of sample after cooling by removing 24 μm thick layer(a) and corresponding cross-sectional profile along black line (b)

3 分析与讨论

形状记忆效应源自马氏体变体在应力环境作用下的择优生长。本实验中选用的NiTi合金虽然在室温下主要为奥氏体态,但是压痕实验在液氮温度下进行。在压痕过程中,四棱锥压头底部产生的应力首先导致马氏体变体发生择优取向变形,随着应力的增大进一步产生一定的位错结构;在应力撤销后,部分马氏体被位错缠结而在室温下稳定存在。因此,在此后的加热-冷却过程中发生马氏体相变,从而在表面产生凸起-平面的双重形貌,具体的机制在文献[19]中有详细论述。

在球形压头实验中[16-17],存在一定的临界载荷,当低于该载荷时,NiTi合金发生完全超弹性变形。当载荷释放后,压痕形状会完全回复,从而不会产生形状记忆效应。而锥形压头顶端尖锐,理论上在无穷小载荷作用下都将发生塑性变形,从而产生形状记忆效应。虽然压头工艺可能导致尖端钝化,但是在实验中发现在较低低载荷也易获得形状记忆效应[17]。

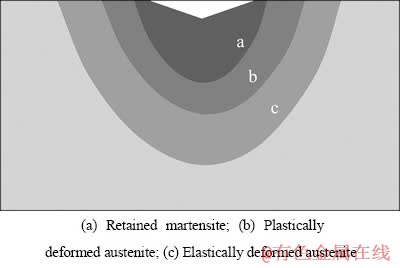

本文作者发现,随着消除压痕影响层深度的增加,残余应变降低,双程形状记忆效应减小,在约160 μm时消失。大量的理论和实验分析表明:产生对角线长度D的压痕,其变形影响区域呈椭圆状,沿深度方向长度可达D值的2~3倍[20-22]。即可致使双程形状记忆效应的变形深度远低于压痕影响层深度,这意味着还有大量受变形影响的NiTi合金并未产生双程形状记忆表面。图5所示为NiTi合金的压痕底部结构的截面示意图,接近压痕底部为由于位错缠结而稳定的马氏体,随着深度的增加,依次为塑性变形奥氏体、弹性变形奥氏体以及未受压痕影响的奥氏体基体。

图5 NiTi合金压痕底部微观结构示意图

Fig. 5 Schematic diagram of deformed structure underneath an indent in NiTi

在压痕过程中,忽略可能产生的材料突起堆积,维氏四棱锥压头产生对角线长度为D,则其压痕体积(V)如下式计算:

V = 0.0238D3

在简单模型下,可以认为该体积材料沿径向呈半球形均匀流变,在距离为r处其位移如下式计算[23]:

该点所对应的应变为

其中负号表示为压应变。

因此,当r为160 μm时,根据D为421 μm,其应变大小为0.13。而实际上,随着深度的增加,应变呈指数递减,在此深度下,应变应小于该模型所计算得到的0.13。因此,当微观应变低于0.13时,材料将不会呈现双程形状记忆效应。此外,CHAUDHRI等[24]和SRIKANT等[21]分析了压痕底部应变分布,对比发现当r/D约0.4时,其相应的应变大小为0.10~0.15,与本模型计算所得0.13符合较好。

4 结论

1) 通过维氏四棱锥压头在NiTi合金中制备了双程形状记忆合金表面。

2) 当样品受热相变后,在原压痕位置呈现直径为510 μm、高度为2.93 μm的圆锥状凸起;在样品冷却后,该凸起消失,表面几乎为平整态。

3) 通过研磨消除一定变形影响层深度,加热后凸起的直径和高度均随着消除深度的增加而减小,直至约160 μm深度处,加热表面不再呈现凸起,该深度处应变约为0.13。因此在马氏体中,应变低于0.13时不会呈现双程形状记忆效应。

REFERENCES

[1] BELLOUARD Y. Shape memory alloys for microsystems: A review from a material research perspective[J]. Mater Sci Engi A, 2008, 481: 582-589.

[2] MANJAIAH M, NARENDRANATH S, BASAVARAJAPPA S. Review on non-conventional machining of shape memory alloys[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 12-21.

[3] NESPOLI A, DALLOLIO V, STORTIERO F, BESSEGHINI S, PASSARETTI F, VILLA E. Design and thermo-mechanical analysis of a new NiTi shape memory alloy fixing clip[J]. Mater Sci Engi C, 2014, 37: 171-176.

[4] WADA K, LIU Y. Thermomechanical training and the shape recovery characteristics of NiTi alloys[J]. Mater Sci Engi A, 2008, 481: 166-169.

[5] 贺志荣, 刘曼倩, 王 芳, 张永宏, 王永善. 时效工艺对Ti-Ni-V形状记忆合金显微组织和超弹性的影响[J]. 中国有色金属学报, 2013, 23(5): 1301-1306.

HE Zhi-rong, LIU Man-qian, WANG Fang, ZHANG Yong-hong, WANG Yong-shan. Effect of aging process on microstructure and superelasticity of Ti-Ni-V shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1301-1306.

[6] WADA K, LIU Y. On the two-way shape memory behavior in NiTi alloy: An experimental analysis[J]. Acta Mater, 2008, 56(13): 3266-3277.

[7] 冯昭伟, 米绪军, 王江波, 袁志山, 缪卫东, 周 瑾. 冷轧变形量及退火温度对Ni47Ti44Nb9板材织构和性能的影响[J]. 中国有色金属学报, 2013, 23(3): 756-764.

FENG Zhao-wei, MI Xu-jun, WANG Jiang-bo, YUAN Zhi-shan, LAO Wei-dong, ZHOU Jin. Influence of cold rolling reduction and annealing temperature on texture and properties of Ni47Ti44Nb9 plate[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 756-764.

[8] LIU Y, XIE Z L, van HUMBEECK J, DELAEY L. Effect of texture orientation on the martensite deformation of NiTi shape memory alloy sheet[J]. Acta Mater, 1999, 47(2): 645-660.

[9] 张宇鹏, 赵四勇, 马 骁, 张新平. 高线性超弹性多孔NiTi合金的压缩力学行为[J]. 中国有色金属学报, 2009, 19(12): 2167-2172.

ZHANG Yu-peng, ZHAO Si-yong, MA Xiao, ZHANG Xin-ping. Compression mechanical behavior of porous NiTi alloys exhibiting high linear superelasticity[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(12): 2167-2172.

[10] WEIGHARDT S C, MAIER H J, CHUMLYAKOV Y I. Dependence of functional degradation on crystallographic orientation in NiTi shape memory alloys aged under stress[J]. J Alloys Compounds, 2013, 577: S219-S221.

[11] KOCKAR B, KARAMAN I, KIM J I, CHUMLYAKOV Y I, SHARP J, YU C J. Thermomechanical cyclic response of an ultrafine-grained NiTi shape memory alloy[J]. Acta Mater, 2008, 56(14): 3630-3646.

[12] JIANG S Y, ZHAO Y N, ZHANG Y Q, HU L, LIANG Y I. Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3658-3667.

[13] LIU Y, LIU Y, van HUMBEECK J. Two-way shape memory effect developed by martensite deformation in NiTi[J]. Acta Mater, 1998, 47(1): 199-209.

[14] 杜泓飞, 曾 攀, 赵加清, 雷丽萍, 方 刚, 瞿体明. NiTi合金中马氏体相变失稳与局部化的原位多场研究[J]. 金属学报, 2013, 49(1): 17-25.

DU Hong-fei, ZENG Pan, ZHAO Jia-qing, LEI Li-ping, FANG Gang, QU Ti-ming. In-situ multi-fields investigation on instability and transformation localization of martensitic phase transformation[J]. Acta Metallurgica Sinica, 2013, 49(1): 17-25

[15] KE C B, CAO S S, MA X, ZHANG X P. Modeling of Ni4Ti3 precipitation during stress-free and stress-assisted aging of bi-crystalline NiTi shape memory alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2578-2585.

[16] NI W, CHENG Y T, GRUMMON D S. Recovery of microindents in a nickel-titanium shape-memory alloy: A “self-healing” effect[J]. Appl Phys Lett, 2002, 80(18): 3310-3312.

[17] SHAW G, STONE D, JOHNSON A, ELLIS A, CRONE W. Shape memory effect in nanoindentation of nickel-titanium thin films[J]. Appl Phys Lett, 2003, 83(2): 257-259.

[18] FEI X, ZHANG Y, GRUMMON D S, CHENG Y T. Indentation-induced two-way shape memory surfaces[J]. J Mater Res, 2009, 24(3): 823-830.

[19] QIN E, PETER N J, FRENSEMEIER M, FRICK C P, ARZT E, SCHNEIDER A S. Vickers indentation induced one-way and two-way shape memory effect in austenitic NiTi[J]. Adv Engi Mater, 2014, 16(1): 72-79.

[20] BUCAILLE J L, STAUSS S, FELDER E, MICHLER J. Determination of plastic properties of metals by instrumented indentation using different sharp indenters[J]. Acta Mater, 2003, 51(6): 1663-1678.

[21] SRIKANT G, CHOLLACOOP N, RAMAMURTY U. Plastic strain distribution underneath a Vickers Indenter: Role of yield strength and work hardening exponent[J]. Acta Mater, 2006, 54(19): 5171-5178.

[22] 孟宪陆, 陈怀宁, 林泉洪, 陈 静. 压痕应变法中压痕周围的应力-应变分布规律[J]. 焊接学报, 2008, 29(3): 109-112.

MENG Xian-lu, CHEN Huai-ning, LIN Quan-hong, LIN Jing. Stress-strain around an indentation in measuring residual stress by indentation strain method[J]. Trans China Welding Instit, 2008, 29(3): 109-112.

[23] MULHEARN T. The deformation of metals by Vickers-type pyramidal indenters[J]. J Mech Phys Solids, 1959, 7(2): 85-88.

[24] CHAUDHRI M. Subsurface strain distribution around Vickers hardness indentations in annealed polycrystalline copper[J]. Acta Mater, 1998, 46(9): 3047-3056.

(编辑 王 超)

收稿日期:2014-04-29;修订日期:2014-08-28

通信作者:覃恩伟,工程师,博士;电话/传真:0512-68602318;E-mail: qinenwei@cgnpc.com.cn

摘 要:利用维氏四棱锥压痕方法,通过温度控制在NiTi合金中获得凸起-平整的双程形状记忆效应表面。通过研磨剥层法,发现随着消除深度的增加所获得的凸起高度和直径减小,在消除160 μm深度后,表面凸起现象消失,并从理论上定量分析该深度所对应的临界应变大小。实验表明:双程形状记忆效应是通过对形状记忆合金进行温度-应变循环变形而获得。因此,可能存在一定的临界应变,在低于该应变时,材料不能表现双程形状记忆效应。

[5] 贺志荣, 刘曼倩, 王 芳, 张永宏, 王永善. 时效工艺对Ti-Ni-V形状记忆合金显微组织和超弹性的影响[J]. 中国有色金属学报, 2013, 23(5): 1301-1306.

[9] 张宇鹏, 赵四勇, 马 骁, 张新平. 高线性超弹性多孔NiTi合金的压缩力学行为[J]. 中国有色金属学报, 2009, 19(12): 2167-2172.

[14] 杜泓飞, 曾 攀, 赵加清, 雷丽萍, 方 刚, 瞿体明. NiTi合金中马氏体相变失稳与局部化的原位多场研究[J]. 金属学报, 2013, 49(1): 17-25.

[22] 孟宪陆, 陈怀宁, 林泉洪, 陈 静. 压痕应变法中压痕周围的应力-应变分布规律[J]. 焊接学报, 2008, 29(3): 109-112.