- Abstract:

- 1 Introduction▲

- 2 Experimental proce...▲

- 3 Results and discus...▲

- 4 Conclusions▲

- References

- Figure

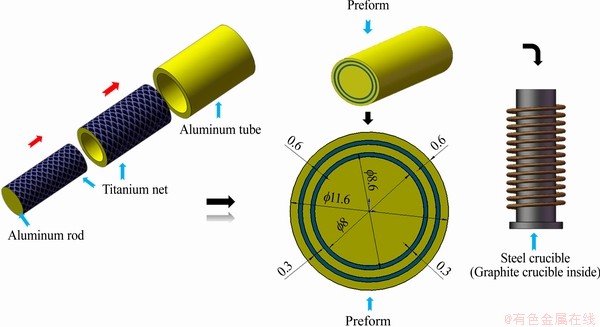

- Figure 1 Schematic diagram of composite preform preparation process (Unit: mm)

- Figure 2 XRD patterns of Al3Ti/Al composite

- Figure 3 SEM morphology and EDS spectrum of Al3Ti/Al composites under different induction heating powers: (a), (b) 1.6 kW; (c), (d) 1.8 kW; (e), (f) 2.0 kW; (g), (h) 2.2 kW; (i), (j) EDS analyzing results corresponding to (d), (f)

- Figure 4 Size distributions of Al3Ti particles under different induction heating power and Gaussian fitting curves (Particles to analyze size distribution were collected from Figures 3(b), 3(d), 3(f), 3(h))

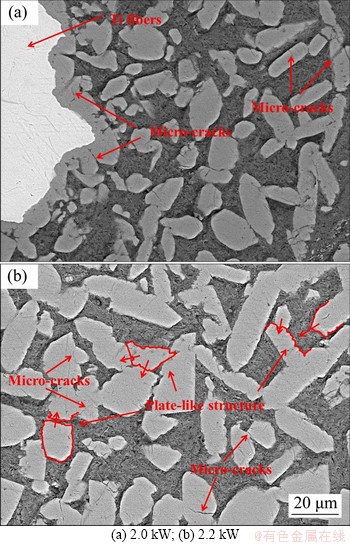

- Figure 5 SEM images of Al3Ti particles located in reaction zone and diffusion zone:

- Figure 6 Schematic diagram of reaction processes between titanium fiber and liquid aluminum

- Figure 7 Comparison of wear rates at different states

- Figure 8 SEM images of surfaces of Al3Ti/Al composites after wear tests:

J. Cent. South Univ. (2020) 27: 3594-3602

DOI: https://doi.org/10.1007/s11771-020-4500-1

Formation and wear behaviors of in-situ Al3Ti/Al composites using aluminum and titanium fibers under electromagnetic induction heating

MA Jun(马俊)1, NIU Li-bin(牛立斌)1, 2, WU Hong(武宏)2, GAO Chong(高冲)1, AN Yu-jiao(安玉姣)1

1. College of Materials Science and Engineering, Xi’an University of Science and Technology,Xi’an 710054, China;

2. Shaanxi Key Laboratory of Nano-materials and Technology, Xi’an University of Architecture and Technology, Xi’an 710055, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract:

Under various electromagnetic induction heating powers, different Al3Ti/Al composites were fabricated by in-situ synthesis method from aluminum and titanium fibers. Microstructures and particles distribution of the composites were examined by XRD, SEM and EDS. The results show that no other intermetallic compounds beside Al3Ti can be in-situ synthesized. Around the titanium fibers, the reaction zones and diffusion zones can be obviously found. Due to the stirring of the electromagnetic function, the formation of the micro-cracks inside the reaction zone was conducive to the peeling off of the Al3Ti particles, and ensures the continuous reaction between liquid aluminum and titanium fibers, as well as the diffusion of Al3Ti particles. At the same time, there were secondary splits of Al3Ti particles located in diffusion zones. Two-body abrasion test shows that with the increase of induction heating power, the wear rates of the composites reduced and the number of grooves decreased.

Key words:

in-situ synthesis; induction heating; Al3Ti intermetallic; particle distribution; wear behaviors;

Cite this article as:

MA Jun, NIU Li-bin, WU Hong, GAO Chong, AN Yu-jiao. Formation and wear behaviors of in-situ Al3Ti/Al composites using aluminum and titanium fibers under electromagnetic induction heating [J]. Journal of Central South University, 2020, 27(12): 3594-3602.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-020-4500-11 Introduction

With low density, high hardness, good abrasion resistance and close coefficient of thermal expansion with the based metal [1, 2], the characteristics of transition-metal aluminide intermetallic has attracted great attention from researchers in the field of particle reinforced aluminum metal matrix composites (AMMCs) [3, 4]. Al3Ti intermetallic compound is considered to be good reinforcement in enhanced AMMCs attributed to the low density of 3.3 g/cm3, high melting point (1348℃) and high elastic modulus (218 GPa) [5]. In the preparation of AMMCs, ex-situ particles with the serious surface contamination and the poor wettability with the matrix, even if the reinforcing particles are subjected carefully before addition, can not achieve satisfactory results [6]. Reinforcing phases prepared by in-situ synthesis have good wettability and thermodynamic stability with the alloy matrix, and the phenomenon of the poor bonding of the external particles was eliminated effectively [7].

In-situ reaction can form ceramic phases through chemical reaction between elements or compound [8], and several attempts have been reported to fabricate Al3Ti/Al composites. QIN et al [9] prepared in-situ Al3Ti particles by globular Ti powers and Al alloy melt under ultrasonic vibration, and established the reaction model of liquid aluminum and Ti powder. ARJMAND et al [10] prepared via in-situ surface coating of Ti using tungsten inert gas welding, and studied the wear resistance of the composites. These Al3Ti/Al composites are mainly prepared by salt-melt reaction in stir casting, which all have problems such as too long reaction time, uneven particle morphology, and poor particle diffusion ability [11]. Induction heating may solve these problems effectively.

By the in-situ synthesis from titanium fibers and aluminum under induction heating, the problems of non-uniform particles distribution and high production cost in the traditional preparation method may be avoided. At the same time, the traditional in-situ reaction relies on the salt-molten as the reaction system [3], and there are few attempts to use the composite preforms as the reaction system. In this study, Al3Ti particles were generated by in-situ reaction to reinforce Al matrix. Induction heating can generate a large temperature gradient; and the electromagnetic force modifies the distribution of products. Thus, it is desirable and favorable to prepare better performance Al3Ti/Al composites. The investigation of the formation and wear behaviors supports the foundation of this kind of composite application.

2 Experimental processes

The net of titanium fibers (99.9 wt%, Φ 0.2 mm) and the variable commercial Al tubes and rod (99.9 wt%) were used to prepare the composites. Before fabrication, the net of titanium fibers was cleaned by 4 wt% HF to obtain the fresh surface. The preparation process is shown in Figure 1. The preforms were prepared and placed in a graphite crucible for induction heating, and the heating process was performed by induction heater with voltage of 220 V and frequency of 50 Hz. To improve the efficiency of induction heating, the graphite crucible was fixed inside a heater made of stainless steel, which was connected to a vacuum device to ensure that aluminum alloys were not oxidized during the heating process. Based on the results of pre-researches, the reaction time was fixed at 30 min and the power parameters were range from 1.6 kW to 2.2 kW.

The metallographic specimens were mounted, ground, and polished with a diamond paste and etched with a 2% nitric alcohol solution for characterization. The X-ray diffraction (XRD) data were recorded on a PW 1730 X-ray diffract meter. Microstructure and elemental analyses were conducted by using a TESCAN VEGA 3 scanning electron microscope (SEM) and energy dispersive X-ray spectroscope (EDS), respectively.

Two-body abrasive wear test was characterized by a TE 67 pin-on-disc tester with a cylindrical specimen of diameter 6 mm and length 30 mm. The cylindrical specimens were loaded against a rotating disc, which carried a bonded abrasive SiC paper with a mesh of 240, and the worn SiC abrasive paper was replaced with a new one for every sliding distance of 10 m. The sliding speed was 1 m/s, and the applied normal loads were 9.8 N. The wear resistance test was repeated thrice, and the weight losses were measured in an electronic balance with an accuracy of 0.01 mg.

Figure 1 Schematic diagram of composite preform preparation process (Unit: mm)

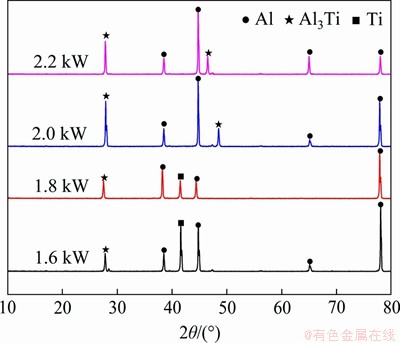

Figure 2 XRD patterns of Al3Ti/Al composite

3 Results and discussion

3.1 XRD phase analysis

XRD patterns of the composites under different induction powers are shown in Figure 2. In addition to the peaks corresponding to aluminum and titanium, only the peaks of Al3Ti intermetallic were found, which means that there were no other intermetallic compounds such as AlTi, AlTi3 formed. The formation of Al3Ti phase was attributed to the reaction between the molten Al and titanium fibers, and XRD results also revealed that with the increase of the induction power, the peaks intensity of Al3Ti increased and the titanium gradually weakened.

3.2 Microstructure of in-situ Al3Ti/Al composites

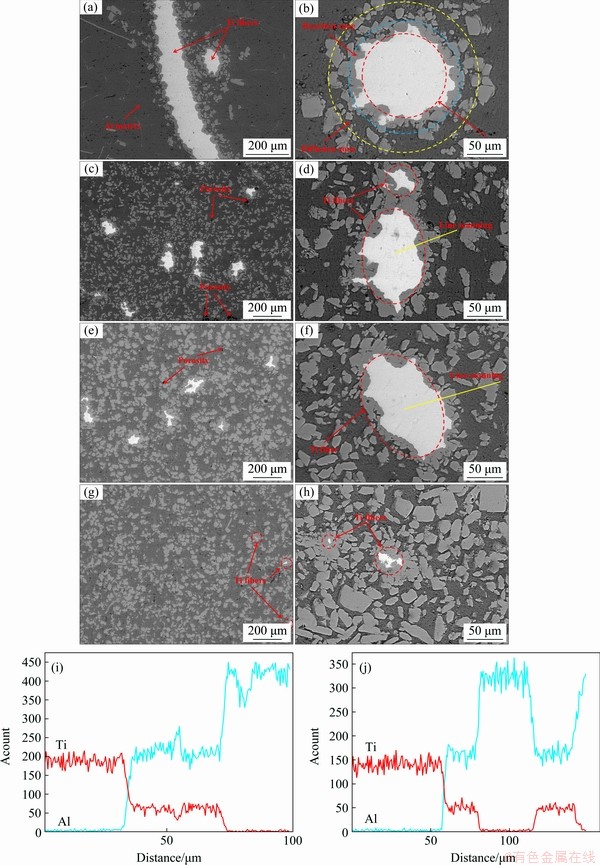

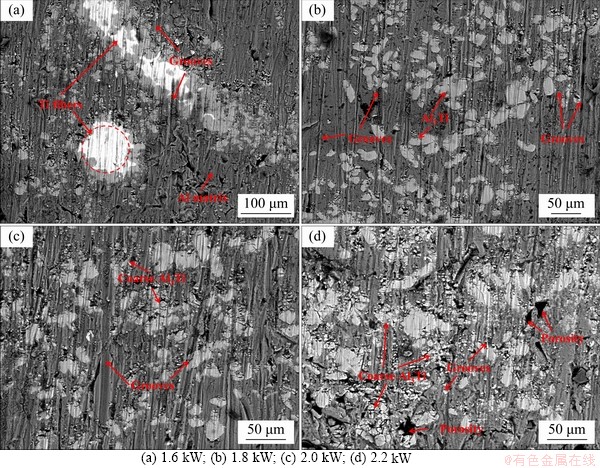

The microstructures of the Al3Ti/Al composite under different induction heating powers are shown in Figure 3. When the heating power was 1.6 kW, the area of the unreacted titanium fibers was larger (Figure 3(a)), and the amount of gray particles distributed around the titanium fibers was small and the diffusion distance was short. With the increase of heating power, the number of gray particles gradually increased and the diffusion distance extended (Figures 3(c), 3(e)). Until the heating power increased to 2.2 kW, the area of unreacted titanium fibers almost disappeared, and the distribution of gray particles was more uniform (Figure 3(g)). At the same time, some pores can be observed in the composite matrix.

From the high magnification, there were two obvious zones around the titanium fibers, the reaction zone where the gray particles contacted the titanium fibers (outside the red dashed circle on Figure 3(b)) and the diffusion zone where the gray particles peeled off (outside the blue dashed circle). The same appearance (including reaction zone and diffusion zone) around the titanium fibers also presented on others specimens, but the areas of these two zones were different due to the reaction degree (Figures 3(d), 3(f), 3(h)). At the same time, the shape of the unreacted titanium fibers was not completely round, which may be due to the defects on the surface of titanium fibers, at which the liquid aluminum contacted the fibers and reacted at the defects firstly.

According to the line EDS result (Figure 3(i)), the Al/Ti atomic ratio of the gray particles in the reaction zone in Figure 3(d) was close to 3: 1, which means that the gray particles were Al3Ti. There was no change in Al/Ti atom ratio of the particles in the reaction zone and the diffusion zone, as seen in Figure 3(j). From the results of EDS, Al3Ti was the only product in the preparation process, which was consistent with the result of the previous XRD analysis. During the reaction process, titanium atoms are difficult to diffuse into Al3Ti crystal structure, but aluminum atoms can easily diffuse into the microstructure of Al3Ti [12]. Based on the Al-Ti phase diagram, Al3Ti can be generated when the aluminum content is over 75 at%, and the content of aluminum is higher in the micro-region, so Al3Ti is the only product during the reaction from the liquid aluminum and titanium fibers [13]. Combining with thermodynamic analysis, these products of Al3Ti, AlTi, and AlTi3 may be formed in the in-situ Al-Ti reaction system, and the thermodynamic stability of these intermetallic compounds is in the order of Al3Ti>AlTi>AlTi3 [14], so the main reaction product in the Al-Ti micro- region is Al3Ti.

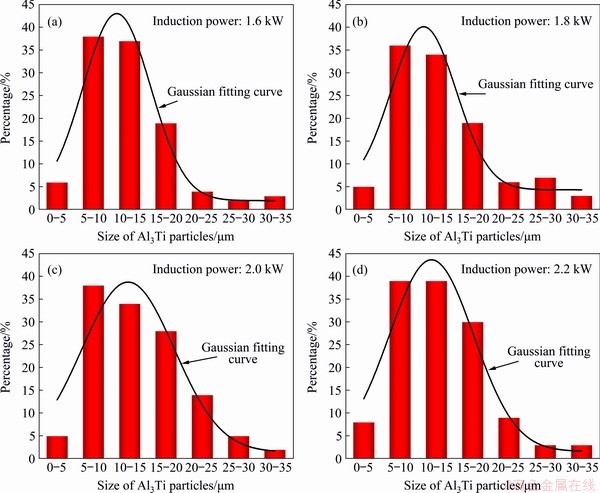

3.3 Distribution of Al3Ti particles

ImageJ software was used to analyze the size distribution of Al3Ti particles in the composites (Figure 4). Because the Al3Ti is not nearly spherical, to exactly describe the size of particles, in this study, the average size (calculated from the sum of the longest side and the shortest side of each particle) was considered to the size of the particle. We calculated the average value of more than 100 particles from Figures 3(b), 3(d), 3(f), 3(h), respectively. The size distribution regulations of particles are shown in Figure 4. Based on the statistics results, the size of about 90% Al3Ti particles was in the range of 5-20 μm, and the average size was about 12 μm, following the Gaussian distribution well. It can also be found that with the increase of the induction heating power, the proportion of particles in the scope of 5-15 μm increased.

Figure 3 SEM morphology and EDS spectrum of Al3Ti/Al composites under different induction heating powers: (a), (b) 1.6 kW; (c), (d) 1.8 kW; (e), (f) 2.0 kW; (g), (h) 2.2 kW; (i), (j) EDS analyzing results corresponding to (d), (f)

Figure 4 Size distributions of Al3Ti particles under different induction heating power and Gaussian fitting curves (Particles to analyze size distribution were collected from Figures 3(b), 3(d), 3(f), 3(h))

Figure 5 gives the higher magnification microstructures of the Al3Ti/Al composite. It could be found that there are obvious micro-cracks on the reaction zone (Figure 5(a)). Due to the effect of capillary phenomenon from micro-cracks, the diffusion of Al atoms into the unreacted titanium fibers will be promoted, which is also conducive to the flaking and further shifting of the particles. There were plate-like structures and smaller micro-cracks among some Al3Ti particles in the diffusion zone (Figure 5(b)), which revealed that the Al3Ti particles undergo the second time flaking during the diffusion process. On the other hand, it can also be found that the morphology of Al3Ti particles gradually tended to be elongated, which may be due to the influence of the vortex of the electromagnetic field, the growth orientation of Al3Ti particles will be parallel to the direction of heat flow and particles with large aspect ratios tend to form [15].

3.4 Al3Ti particle formation and distribution mechanism

Some observations have been done on the formation mechanism of Al3Ti particles in the in-situ reaction of fabricating of Al3Ti/Al composites. In Ref. [9], the authors proposed that during the reaction between molten Al and solid titanium, liquid Ti/Al, Al3Ti, and Al/Ti micro-regions existed in the system, and the main reaction was to form Al3Ti due to the difference between Al and Ti atoms diffusion rate. In this study, titanium remained in solid state, which reveals that the formation of Al3Ti was mainly relied on the diffusion of Al atoms. During the reaction, Al atoms diffused around titanium fibers and continued to react with Ti fibers, but the diffusion ability of aluminum atoms was limited by the temperature of the system. By increasing the induction heating power, the diffusion ability of Al atoms can be improved. However, as the reaction progressed, the amount of Al3Ti particles gradually increased, and these particles would hinder the further diffusion of Al atoms. Therefore, the diffusion distance of Al atoms was in a certain scope, the reaction between Al and Ti became harder. It is concluded that the flaking and diffusion of the Al3Ti were very important for aluminum and titanium fibers reaction.

Figure 5 SEM images of Al3Ti particles located in reaction zone and diffusion zone:

Combined with the previous analysis, the reaction of formula (1) occurred in this study. The enthalpy of formation of the reaction is -39.2 kJ/mol (1073 K) [16], and it can be judged that the reaction is exothermic. With the progress of the reaction, there will be a substantial amount of reaction heat released, which will increase the thermal stress of the reaction system. On the other hand, the crystal structure of Ti is HCP (<1095.5 K) and BCC microstructure (>1095.5 K), and Al3Ti is face-centered square cubic microstructure [17]. The differences in structure will increase the mechanical stress between the products and the titanium fibers [18, 19]. Above reasons are beneficial to the formation of micro-cracks on the surface of Al3Ti. As the molten Al diffused into these micro-cracks, it was easy to form stress concentration at the crack tip, which will accelerate the flaking of Al3Ti.

(1)

(1)

In addition to the reaction heat and structural difference of the system, electromagnetic stirring force generated during the induction heating process also had an important influence on the morphology and distribution of Al3Ti. Induction heating uses vortex to heat the sample and the vortex is generated in the skin layer on the surface of the sample. The penetration depth of the skin effect is related to the frequency of the current [20], which means that the penetration depth of the skin effect was constant in this study. The electromagnetic stirring force of induction heating can be calculated by formula (2), where F is electromagnetic stirring force, f is the frequency of the power (Hz), r is the resistance of the sample (Ω·cm), P is the power consumed by the sample and S is the surface area of the sample. It can be inferred from formula (2) that the electromagnetic stirring force (F) is proportional to the input power (P).

(2)

(2)

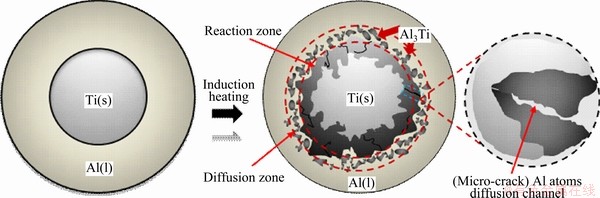

During the induction heating process, the current direction in the induction coil is opposite to the induction current in the molten metal, and there is repulsive force between the liquid metal and the coil, and compressive force also existed inside the liquid metal. The combined action of these two forces produces stirring effect on the molten metal [21]. Under the effect of stirring force, Al3Ti particles will show a distribution orientation along the vortex direction, which can also explain the reason why the number of elongated Al3Ti particles gradually increased with the increase of heating power in Figure 3. As the heating power rose, the driving force for Al atoms diffusion was larger, and the relative diffusion speed of Al3Ti particles increased. Under the action of the shear stress of the vortex current [22], Al3Ti particles had plate-like secondary splitting during movement, which is caused by the large energy fluctuations and structural fluctuations inside the molten metal [23]. The schematic diagram of reaction process of in-situ synthesis composites is shown in Figure 6. Micro-cracks located in Al3Ti particles at the reaction zone can act as diffusion channels for Al atoms during the in-situ reaction, which will cooperate with the tip effect to promote the reaction between liquid aluminum and titanium fibers, and also accelerate the flaking of Al3Ti particles.

Figure 6 Schematic diagram of reaction processes between titanium fiber and liquid aluminum

3.5 Wear behaviors

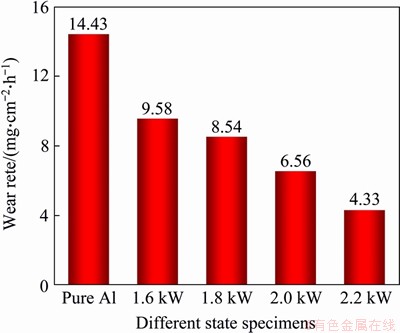

The results of the two-body abrasive wear are shown in Figure 7. It can be seen that the wear resistance of Al3Ti/Al composites produced by electromagnetic induction are higher than that of the Al matrix. The wear rate of the composites varies to 9.58, 8.54, 6.56, 4.33 mg/(cm2·h-1) with electromagnetic induction increase, compared with the wear rates of the pure Al matrix (14.43 mg/ (cm2·h-1). In this study, the wear rate was defined as the rate of material removal per unit sliding distance.

Figure 7 Comparison of wear rates at different states

Figure 8 shows the SEM images of the worn surfaces of the composites under different heating power. It can be observed that there were many grooves on the aluminum matrix in the composite with a small amount of titanium fiber (Figure 8(a)). The depth of the grooves around the titanium fibers and Al3Ti particles was shallow, and the amount of deformation of the aluminum matrix was small. With the increase of the induction heating power, the number and depth of the grooves on the aluminum substrate gradually decreased, and the morphology of the Al3Ti particles also changed from polygons to coarse (Figures 8(b)-(c)), which confirmed that Al3Ti particles as the wear-resistant phases enhanced the wear resistance of the composites. At the same time, part of the pores can be observed on the matrix of the composite from Figure 8(d), which may be due to the lower bonding between the generated Al3Ti particles and the aluminum matrix.

Figure 8 SEM images of surfaces of Al3Ti/Al composites after wear tests:

The wear resistance of the composite mainly depends on the volume fraction and distribution of the reinforcement phases, which can effectively strengthen the matrix and protect the matrix from severe abrasion [24]. For Al3Ti/Al composite, with the increase of induction heating power, the amount of Al3Ti particles was increased and the distribution was more uniform, which improved the wear resistance of the composite. Therefore, the number of grooves on the matrix of the composite gradually decreased, and Al3Ti intermetallic compounds acted as wear-resistant phases to protect the matrix.

4 Conclusions

1) Al3Ti/Al composites can be prepared by in-situ reaction of liquid aluminum with titanium fibers by induction heating.

2) The results of XRD patterns show that Al3Ti intermetallic compound was the only product. The size distribution results revealed that the size of about 90% Al3Ti particles was in the range of 5-20 μm and the average size was about 12 μm.

3) There were obvious reaction zones and diffusion zones around the titanium fibers. Induction heating can generate a large temperature gradient inside the sample, which cooperates with the stirring force to promote the diffusion of Al3Ti particles. At the same time, there were secondary splits during the diffusion of Al3Ti particles.

4) Two-body abrasion test shows that with the increase of the induction heating power, the wear rate of the composite was reduced, and the number of grooves on the substrate of composite was also reduced.

Contributors

The overarching research goals were developed by NIU Li-bin, WU Hong and MA Jun. MA Jun and NIU Li-bin provided the first draft of manuscript. GAO Chong provided the measured data. AN Yu-jiao conducted the literature review. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

MA Jun, NIU Li-bin, WU Hong, GAO Chong and AN Yu-jiao declare that they have no conflict of interest.

References

[1] GUPTA P K, SRIVASTAVA R K. Fabrication of ceramic reinforcement aluminium and its alloys metal matrix composite materials: A review [J]. Materials Today: Proceedings, 2018, 5(9): 18761-18775. DOI: 10.1016/ j.matpr.2018.06.223.

[2] ZHU He-guo, JIANG Ya-ling, SONG Jin-zhu, LI Jian-liang, MUNROE P, XIE Zong-han. In situ synthesis and characterization of a hierarchically structured Al2O3/Al3Ti composite [J]. Journal of Materials Science, 2013, 48(2): 929-935. DOI: 10.1007/s10853-012-6817-0.

[3] LIU Zhi-wei, CHENG Na, ZHENG Qiao-ling, WU Jian-hua, HAN Qing-you, HUANG Zhi-fu, XING Jian-dong, LI Ye-fei, GAO Yi-ming. Processing and tensile properties of A356 composites containing in situ small-sized Al3Ti particulates [J]. Materials Science and Engineering A, 2018, 710: 392-399. DOI:10.1016/j.msea.2017.11.005.

[4] ZHANG Dong-qiang, YANG Ping, WU Jian-yang, ZHAO Jing, CHEN Yan-an. Preparation of defect free ceramic/Ti composite membranes by surface modification and in situ oxidation [J]. Journal of Central South University, 2019, 26(12): 3295-3304. DOI: https://doi.org/10.1007/s11771- 019-4253- x.

[5] GUPTA R, DANIEL B S S. Impression creep behaviour of in-situ Al3Ti reinforced Al alloy composite fabricated by salt-melt reaction technique [J]. Materials Today: Proceedings, 2018, 5(9): 16936-16945. DOI:10.1016/j.matpr. 2018.04.097.

[6] CHIANEH V A, HOSSEINI H M, NOFAR M. Micro structural features and mechanical properties of Al-Al3Ti composite fabricated by in-situ powder metallurgy route [J]. Journal of Alloys and Compounds, 2009, 473(1, 2): 127-132. DOI:10.1016/j.jallcom.2008.05.068.

[7] GUPTA R, DANIEL B S S. Impression creep behaviour of ultrasonically processed in-situ Al3Ti reinforced aluminium composite [J]. Materials Science and Engineering A, 2018, 733: 257-266. DOI:10.1016/j.msea.2018.07.017.

[8] XU Qian-gang, ZHANG Hai-feng, DING Bing-zhe, HU Zhuang-qi. Nature and growth of interaction layers formed during the reaction between solid Ni and liquid Al [J]. Journal of Materials Sciences and Technology, 2009, 18(6): 512-515. DOI: EN/Y2002/V18/I06/512.

[9] QIN Jin, CHEN Gang, WANG Bo, HU Nan, HAN Fei, DU Zhi-ming. Formation of in-situ Al3Ti particles from globular Ti powders and Al alloy melt under ultrasonic vibration [J]. Journal of Alloys and Compounds, 2015, 653: 32-38. DOI: 10.1016/j.jallcom.2015.09.005.

[10] ARJMAND S, KHAYATI G R, AKBAIR, G H. Al/Ti5Si3- Al3Ti composite prepared via in-situ surface coating of Ti using tungsten inert gas welding [J]. Journal of Alloys and Compounds, 2019, 808: 151739. DOI: 10.1016/j.jallcom. 2019.151739.

[11] KESANGAM N, PINITSOONTORN S, SRIMANOSAOWAPAK S. Effect of initial microstructure on induction heating of A319 aluminium alloy [J]. Materials Today: Proceedings, 2018, 5(3): 9615-9623. DOI: 10.1016/ j.matpr.2017.10.148.

[12] TOCHAEE E B, HOSSEINI H M, REIHANI S S. Fabrication of high strength in-situ Al-Al3Ti nanocomposite by mechanical alloying and hot extrusion: Investigation of fracture toughness [J]. Materials Science and Engineering A, 2016, 658: 246-254. DOI:10.1016/j.msea.2016.02.010.

[13] LIU Zhi-wei, HAN Qing-you, LI Jian-guo. Fabrication of in situ Al3Ti/Al composites by using ultrasound assisted direct reaction between solid Ti powders and liquid Al [J]. Powder Technology, 2013, 247: 55-59. DOI: 10.1016/j.powtec.2013. 07.005.

[14] TOMOSHIGE R, MATSUSHITA T. Production of titanium-aluminum-carbon ternary composites with dispersed fine TiC particles by combustion synthesis and their microstructure observations[J].Ceram Soc Jpn, 1996, 104: 94-100. DOI: 10.2109/jcersj.104.94.

[15] LI Gui-rong, WANG Hong-ming, ZHAO Yu-tao, CHEN Deng-bin, CHEN Gang, CHENG Xiao-nong. Microstructure of in situ Al3Ti/6351Al composites fabricated with electromagnetic stirring and fluxes [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 577-583. DOI: 10.1016/S1003-6326(09)60181-3.

[16] MIRJALILI M, SOLTANIEH M, MATSUURA K, OHNO M. On the kinetics of TiAl3 intermetallic layer formation in the titanium and aluminum diffusion couple [J]. Intermetallics, 2013, 32: 297-302. DOI: 10.1016/j.intermet.2012.08.017.

[17] SATO H, WATANABE Y. Three-dimensional microstructural analysis of fragmentation behavior of platelet Al3Ti particles in Al-Al3Ti composite deformed by equal-channel angular pressing [J]. Materials Characterization, 2018, 144: 305-315. DOI: 10.1016/j.matchar.2018.07.005.

[18] JIANG Shu-ying, LI Shi-chun, ZHANG Lei. Microstructure evolution of Al–Ti liquid–solid interface [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3545-3552. DOI: 10.1016/S1003-6326(13)62899-X.

[19] MA Si-ming, WANG Yong-shneg, WANG Xiao-ming. The in-situ formation of Al3Ti reinforcing particulates in an Al-7wt% Si alloy and their effects on mechanical properties [J]. Journal of Alloys and Compounds, 2019, 792: 365-374. DOI: 10.1016/j.jallcom.2019.04.064.

[20] WANG Hong-ming, LI Gui-rong, ZHAO Yu-tao, ZHANG Zhao. Microstructure, billet surface quality and tensile property of (Al2O3+Al3Zr)p/Al composites in situ synthesized with electromagnetic field [J]. Journal of Alloys and Compounds, 2011, 509(18): 5696-5700. DOI: 10.1016/j.jallcom.2011.02.139.

[21] LIU Zheng, LIU Xiao-mei, HU Chun-hui, MAO Wei-min. Research on fractal characteristics of primary phase morphology in semi-solid A356 alloy [J]. Acta Metallurgica Sinica (English Letters), 2009, 22(6): 421-428. DOI: 10.1016/S1006-7191(08)60118-0.

[22] ZOU Qing-chuan, HAN Ning, SHEN Zhang-feng, JIE Jin-chuan, LI Ting-ju. Effects of AlB2/AlP phase and electromagnetic stirring on impurity B/P removal in the solidification process of Al-30Si alloy [J]. Separation and Purification Technology, 2018, 207: 151-157. DOI: 10.1016/ j.seppur.2018.06.052.

[23] LI Y, ZHANG Yu, BI Jing, LUO Zhen. Impact of electromagnetic stirring upon weld quality of Al/Ti dissimilar materials resistance spot welding [J]. Materials & Design, 2015: 577-586. DOI: 10.1016/j.matdes.2015.06.042.

[24] AGRAWAL S, GHOSE A K, CHAKRABARTY I. Effect of rotary electromagnetic stirring during solidification of in-situ Al-TiB2 composites [J]. Materials & Design, 2017, 113: 195-206. DOI: 10.1016/j.matdes.2016.10.007.

(Edited by YANG Hua)

中文导读

感应加热作用下铝和钛纤维原位合成Al3Ti/Al复合材料及其磨损行为研究

摘要:通过施加不同的感应加热功率,由铝和钛纤维进行原位反应,制备出Al3Ti/Al复合材料。通过XRD,SEM和EDS表征了复合材料的微观结构和颗粒分布情况。结果表明,反应产物仅为Al3Ti金属间化合物,钛纤维周围有明显的反应区和扩散区。反应区的微裂纹有利于Al3Ti颗粒的剥离,促进了液态铝与钛纤维之间的反应。由于电磁感应加热的搅拌功能,促进了Al3Ti颗粒的反应和扩散。同时,Al3Ti颗粒在扩散过程中存在二次分离与剥落。两体磨损试验表明,随着感应加热功率的加大,磨损率和沟槽数量减少,复合材料的耐磨性能提高。

关键词:原位制备;电磁感应加热;Al3Ti金属间化合物;颗粒分布;磨损性能

Foundation item: Project(2015DFR50990-01) supported by International Cooperation Project of Ministry of Science and Technology of China; Projects(18JS060, 18JS075) supported by the Shaanxi Key Laboratory of Nano-materials and Technology, China

Received date: 2020-05-02; Accepted date: 2020-08-27

Corresponding author: NIU Li-bin, PhD, Assistance Professor; Tel: +86-29-85587373; E-mail: dy059@126.com; ORCID: https://orcid. org/0000-0003-3164-0310; WU Hong, PhD, Professor; Tel: +86-29-8202531; E-mail: wuhong-xa@163.com; ORCID: https://orcid.org/0000-0002-4237-3556

Abstract: Under various electromagnetic induction heating powers, different Al3Ti/Al composites were fabricated by in-situ synthesis method from aluminum and titanium fibers. Microstructures and particles distribution of the composites were examined by XRD, SEM and EDS. The results show that no other intermetallic compounds beside Al3Ti can be in-situ synthesized. Around the titanium fibers, the reaction zones and diffusion zones can be obviously found. Due to the stirring of the electromagnetic function, the formation of the micro-cracks inside the reaction zone was conducive to the peeling off of the Al3Ti particles, and ensures the continuous reaction between liquid aluminum and titanium fibers, as well as the diffusion of Al3Ti particles. At the same time, there were secondary splits of Al3Ti particles located in diffusion zones. Two-body abrasion test shows that with the increase of induction heating power, the wear rates of the composites reduced and the number of grooves decreased.

- Formation and wear behaviors of in-situ Al3Ti/Al composites using aluminum and titanium fibers under electromagnetic induction heating