DOI:10.19476/j.ysxb.1004.0609.2017.11.14

热压烧结GZO陶瓷致密化与固相反应

叶林龙1, 2,孙宜华1,方 亮1,陈鑫智1,常宝成2,程志敏1

(1. 三峡大学 材料与化工学院 无机非金属晶态与能源转换材料重点实验室,宜昌 443002;

2. 广西新未来信息产业股份有限公司,北海 536000)

摘 要:

以Ga2O3掺杂量(质量分数)为3%的ZnO-Ga2O3混合粉体为原料,采用热压烧结法制备GZO陶瓷。通过XRD、SEM、阿基米德排水法和四探针法对烧结试样的物相组成、显微结构、密度和电阻率等进行分析表征。结果表明:外加压力能有效降低GZO陶瓷烧结致密化温度;当外加压力为18 MPa时,随烧结温度升高,烧结体的密度和电导率增大;当烧结温度达1150 ℃时,烧结体密度和电导率达到最大值;但当烧结温度继续增大时,由于晶粒粗化和Zn元素挥发导致试样中气孔长大,试样致密度与导电性呈下降趋势。此外,ZnO-Ga2O3混合粉体在烧结温度较低时(1050 ℃),Ga2O3与ZnO固相反应生成ZnGa2O4立方尖晶石相;随着烧结温度升高,ZnGa2O4将与ZnO继续反应,生成与ZnO六方纤锌矿结构呈共格关系的复杂化合物ZnxGa2Ox+3,并且化合物化学式中x值随着烧结温度的升高而增加,化合物晶体结构逐渐接近ZnO六方纤锌矿结构。

关键词:

文章编号:1004-0609(2017)-11-2293-06 中图分类号:TQ174 文献标志码:A

透明导电氧化物(TCO)薄膜是一种具有独特光电特性的材料,其本身具有较高的载流子浓度,是良好的导电体,同时又具备一定的透光性。因此,被广泛应用于电子、信息、光学等各个领域。ZnO作为TCO薄膜材料之一,具有带隙宽、介电常数低、温度稳定性好、光透过率高、化学性能稳定等特点,并且Zn储量丰富,价格低廉,自20世纪80年代起就被广泛报到和研究[1]。通过对ZnO的掺杂改性可以有效提高其导电性能和稳定性,目前所采用的掺杂元素有Al、Ga、In、B、Si、Ge、Ti、Zr、Fe等[2-10]。其中,对Al掺杂ZnO(AZO)和Ga掺杂ZnO(GZO)的研究报告最为多见。然而与Al相比,由于Ga不属于活泼金属,且与Zn有相近的原子半径,使得GZO在性能上表现出优异的光学、电学性能和良好的稳定性[1, 11],近年来受到广泛关注。

TCO薄膜的制备方法众多,其中磁控溅射法应用较为广泛。研究表明,磁控溅射用陶瓷靶材的性能对其薄膜的性能有较大的影响。因此,诸多学者对制备高性能的磁控溅射用陶瓷靶材进行了大量研究。孙文燕等[12]采用凝胶注模成型+常压烧结的方法制备ZnO陶瓷靶材,研究了烧结工艺对ZnO陶瓷靶材各项性能的影响。LIU 等[13]采用无压烧结法制备GZO陶瓷靶材,在掺杂浓度(质量分数)0.578%Ga时获得最高相对密度为理论密度(Theoretical density)的99.23 %,并研究了陶瓷靶材与沉积薄膜性能之间的关系。LIU 等[14]研究了不同Ga掺杂浓度(0~3%)对靶材性能的影响。WU 等[15]研究了GZO陶瓷靶材掺杂3%和5%的Ga时无压烧结的相转变与致密化机理,在两种掺杂浓度下分别制得相对密度为99.3%和94.3%的靶材。从现有文献报道来看,GZO陶瓷靶材只有在Ga掺杂量较低时才容易获得较高的烧结密度,然而GZO薄膜光电性能在Ga掺杂量为3%~5%时才更为优异,这与高Ga含量陶瓷靶材无压烧结致密化困难之间存在矛盾。究其原因在于Ga在ZnO中的固溶极限为0.578%[16],当掺杂量超过固溶极限后,高温固相反应较为复杂,影响靶材致密化。此外,目前GZO陶瓷致密化多采用无压固相法烧结,烧结温度一般在1400 ℃左右,不仅耗能,还会造成Zn元素高温挥发或异常晶粒长大等问题,影响靶材质量。

白雪等[17]、王星明等[18-19]采用热压烧结法制备2%Al掺杂的AZO陶瓷靶材,研究了热压致密化机制和烧结过程中Al元素的存在形式和扩散机制,并采用分段热压法在外加压力35 MPa的条件下先后在1050 ℃和1100 ℃保温保压1 h,最终制得相对密度为99%的靶材。可见采用热压烧结法,能够有效降低陶瓷的烧结温度。然而,有关 GZO 靶材的热压烧结研究还未见报导。本文作者以ZnO和Ga2O3粉体为原料,在施加外加压力的情况下研究烧结温度对Ga掺杂量为3%的ZnO(GZO-3Ga)陶瓷致密化的影响,分析了Ga元素的存在形式、分布状态以及热压烧结中的固相反应机理。

1 实验

实验用初始粉体采用纯度为99.7%的ZnO粉(上海京华化工)和纯度为99.99%的Ga2O3粉(长沙亚光),湿法球磨混料,初始粉体质量比为m(ZnO):m(Ga2O3)= 97:3。按固含量60%制备浆料,分散剂为聚丙烯酸(PAA),用量为0.25%,浆料pH值为9,混料36 h后真空抽滤去水、120 ℃干燥、500 ℃煅烧6 h,除去其中的水和PAA,得到混合粉体。

称取30 g混合粉体,装入Al2O3陶瓷模具中(内径30.2 mm),在热压烧结炉(HPS-20-14,上海广益高温)进行烧结。热压烧结温度分别为1050、1100、1150和1200 ℃,升温速率为10 ℃/min,外加压力为18 MPa,保温50 min,随炉冷却。

从烧结试样上线切割5 mm×5 mm×8 mm的小样块,用2500号砂纸打磨光滑,超声清洗后将样块在马弗炉中进行热腐蚀处理,腐蚀温度为1150 ℃,升温速率为10 ℃/min,保温10 min。

采用X射线衍射仪(XRD, Ultima IV, Japan)分析物相组成,采用冷场发射扫描电子显微镜(SEM, JSM-7500F, Japan)分析烧结试样的微观结构和元素分布,用阿基米德排水法测量试样密度,用四探针(RTS-9, China)测量电阻率。采用MENDELSON的线性截距法[20]测试样平均晶粒大小( ),即

),即

式中: 为4条任意穿越显微照片的直线在晶粒边界上的截距的平均值。

为4条任意穿越显微照片的直线在晶粒边界上的截距的平均值。

2 结果与分析

2.1 物相与晶体结构

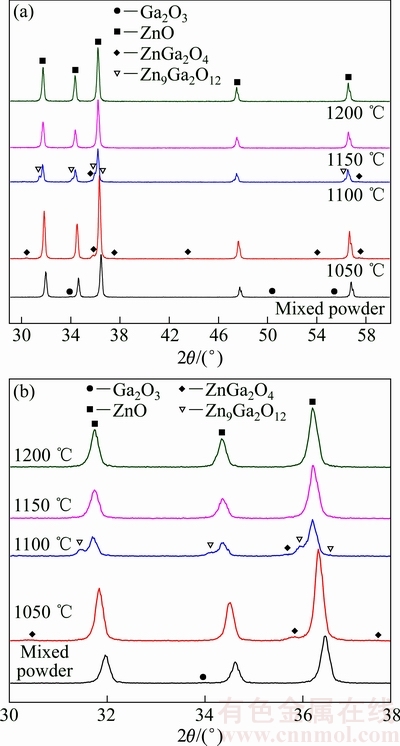

图1所示为混合粉体和不同热压烧结温度烧结体的XRD谱。由图1可见,衍射角(2θ)为31.961°、34.620°、36.459°、47.737°和56.794°的衍射峰与ZnO标准PDF卡片(JCPDS # 36-1451)的衍射峰基本一致。混合粉体XRD谱中,除ZnO的衍射峰外,在衍射角为33.968°、50.455°和55.382°处可见Ga2O3的衍射峰。而在烧结温度为1050~1200 ℃的烧结体XRD谱中,Ga2O3的衍射峰消失,并且ZnO衍射峰的峰位向小角度方向移动。分析表明,热压烧结试样主要是多晶六方纤锌矿结构,部分Ga元素成功掺入ZnO晶格中取代了原来位置的Zn原子,造成晶格收缩,晶面间距变小,但对ZnO六方纤锌矿结构没有明显的影响。

热压烧结温度为1050 ℃时,在烧结体XRD谱中2θ为30.476°、35.854°、37.528°、43.572°、54.008°和57.557°处出现新的衍射峰;当热压烧结温度为1100 ℃时,上述衍射峰部分消失或衍射强度降低,但在31.428°、34.157°、35.936°、36.551°和56.270°处又有新的衍射峰出现。根据文献[13, 15]及XRD结果,1050 ℃时,烧结体中有ZnGa2O4尖晶石相生成;当烧结温度升高到1100 ℃时,烧结体中的ZnGa2O4尖晶石相的含量减少,同时生成复杂化合物Zn9Ga2O12。当热压烧结温度上升到1150 ℃后,Zn9Ga2O12相的衍射峰消失,此时的XRD谱中只有31.740°、34.361°、36.220°、47.499°和56.560°处的衍射峰,峰形与ZnO基本一致,峰位向小角度方向移动。热压烧结温度为1200 ℃的烧结体衍射谱与1150 ℃的烧结体XRD谱相比,峰形不变,峰位左移,且峰高变高。

图1 GZO混合粉末和不同温度烧结体的XRD谱

Fig. 1 XRD patterns of mixed GZO powders and sintered bodies at different temperatures

对比WU等[15]的研究,Ga含量为3%的GZO陶瓷无压烧结时,在800 ℃开始出现ZnGa2O4尖晶石相;温度超过1000 ℃后,开始有Zn9Ga2O12反应生成;温度超过1200 ℃时,Zn9Ga2O12大量出现,ZnGa2O4尖晶石相完全消失。可见,外加压力使GZO-3Ga陶瓷烧结过程中生成Zn9Ga2O12相的固相反应温度降低。这一现象在AZO陶瓷靶材的热压烧结研究中也有出现[18-19],究其原因可能是因为外加压力促进了颗粒间烧结颈的形成,为元素在低温下扩散提供通道,导致固相反应可在更低的温度下发生。NAKAMURA等[21]研究表明,经1350 ℃无压烧结GZO陶瓷反应体系中存在ZnO-ZnGa2O4的平衡相位关系,宏观产物可看作是ZnxGa2Ox+3(x为较大的整数)的化合物。因此,结合XRD分析可知,GZO-3Ga试样经1050 ℃热压烧结首先生成ZnGa2O4尖晶石相;烧结温度继续升高,ZnGa2O4尖晶石相将继续与ZnO反应,形成与ZnO共格的复杂化合物ZnxGa2Ox+3。由于ZnxGa2Ox+3的晶体结构与ZnO接近一致,其衍射峰与ZnO的重合。

2.2 相对密度和导电性

图2所示为不同烧结温度下GZO-3Ga热压试样的晶粒尺寸、相对密度和电阻率(ZnO理论密度取5.61 g/cm3)。如图2所示,经1050 ℃和1100 ℃烧结的试样致密化虽未完成,但相对密度随温度上升由81.73%升高到90.21%,其电阻率呈下降趋势;随着烧结温度的上升,试样的晶粒尺寸增大,气孔减少,同时Ga掺入ZnO晶格的量增多,形成的自由载流子增多;当烧结温度为1150 ℃时,试样致密化达到最高值,相对密度为95.04%TD,电阻率达到最低值9.0×10-3 Ω·cm;当烧结温度增加到1200 ℃时,试样晶粒尺寸进一步增大,但由于出现了过烧现象,试样中的气孔异常长大,使得电子传输通道截面变小,试样的相对密度下降,电阻率变大。

图2 不同烧结温度下GZO-3Ga热压试样的晶粒尺寸、相对密度和电阻率

Fig. 2 Grain sizes, relative density and resistivity of GZO-3Ga hot-pressing samples at different sintering temperatures

2.3 断口形貌分析

图3所示为不同热压烧结温度下烧结体断口形貌ESEM像。由图3(a)中可见,试样经过1050 ℃烧结,其粉体颗粒与颗粒之间已经形成了烧结颈,有少量孔洞开始闭合,这说明此时的试样处于烧结初期阶段结束的时期,此时的颗粒已发生变形和重排,但致密化程度不高。试样断口处的断裂类型为沿晶断裂。由图3(b)可见,1100 ℃的试样显微组织结构发生了明显地变化,晶粒形成连续的网络结构,其中的孔洞已经完全闭合,形成一个个孤立的气孔,此时断口的断裂类型为沿晶断裂和穿晶断裂共存,可能是试样中的ZnGa2O4开始溶入ZnO形成新的化合物,使晶界强度增强。当烧结温度提升至1150 ℃时(见图3(c)),烧结致密化已经基本完成,各晶粒紧密排列,有极少量的小气孔分布其中。当烧结温度提升到1200 ℃时(见图3(d)),试样出现了过烧现象。在过高的温度及外加压力的作用下,试样的平均晶粒尺寸变大;另外,由于ZnO在高温下Zn有很高的蒸汽压,同时可能由于外加压力使烧结气氛中氧分压升高,从而促进了ZnO中Zn元素的挥发,最终导致气孔长大、晶粒粗化,使烧结体致密度下降,影响其力学、电学性能。

图3 不同烧结温度烧制的GZO试样断口ESEM像

Fig. 3 ESEM images showing fracture morphologies of GZO ceramic at different temperatures

2.4 元素分布

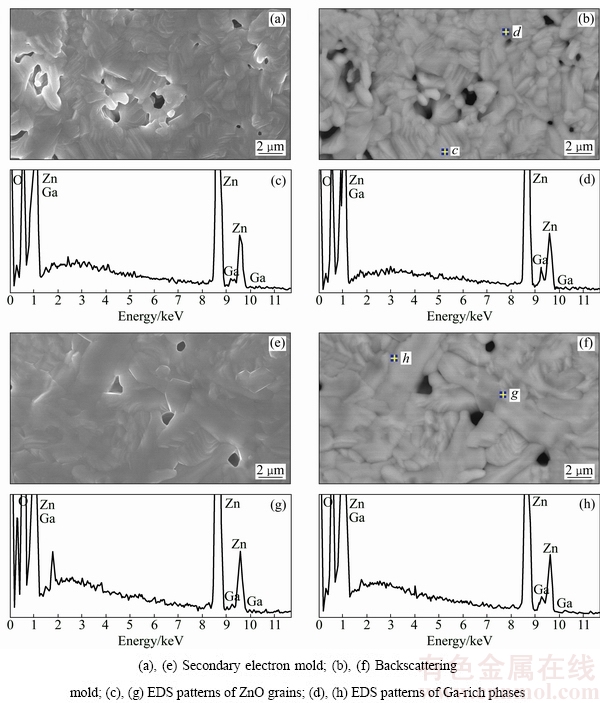

图4所示为GZO-3Ga热腐蚀试样的二次电子图像、背散射图像和EDS谱。其中图4(a)和(b)所示为1100 ℃烧结体热腐蚀试样的二次电子和背散射图像,c点为ZnO晶内的EDS谱,d点为三叉晶界处的EDS谱;图4(e)和(f)所示为1150 ℃烧结体热腐蚀试样的二次电子和背散射图像,g点为ZnO晶内的EDS谱,h点为晶界处的EDS谱。

图4 GZO-3Ga热腐蚀试样的SEM像和ZnO晶内及Ga富集区EDS谱

Fig. 4 SEM images of thermally etched surface of GZO-3Ga ceramics

由图4(b)和(f)可以看出,试样的平均晶粒尺寸在2~7 μm之间,且试样中没有明显可见的区别于主晶相的区域。从图4(c)和(g)中可看出,试样中ZnO晶粒内有Ga元素分布;从图4(d)和(h)可以看出,在ZnO的晶界和三叉晶界处存在Ga元素富集区。区别于众多已有报道的AZO陶瓷[22],GZO陶瓷在较高的烧结温度时,原先晶界和三叉晶界处Ga2O3与ZnO反应生成的新相颗粒(尖晶石相)逐渐消失,最终在ZnO显微组织中靠近晶界的区域内形成了Ga元素的富集区。综合XRD分析与EDS能谱分析,可以认为这与形成和ZnO共格的化合物ZnxGa2Ox+3(x随烧结温度的升高而增大)有关。究其原因,应该是Ga与Zn的原子半径相近,导致Ga更容易取代Zn在晶格中的位置形成置换替代,最终形成了与ZnO有共格关系的复杂化合物。

此外,在1100 ℃和1150 ℃试样中的Ga富集区,Zn与Ga的摩尔比分别为24.3:1 和27.9:1。可见,随着烧结温度的上升,Ga富集区中的Ga元素所占比例有所下降。结合XRD分析认为,在1100 ℃烧结时,ZnGa2O4尖晶石相与ZnO反应生成了Zn9Ga2O12,但该反应还未结束,在Ga富集区中还存在有ZnGa2O4;而在1150 ℃烧结时,试样中ZnGa2O4尖晶石相已经完全与ZnO发生固相反应生成了Zn9Ga2O12。随着烧结温度的提高,Ga元素继续向ZnO晶粒中扩散,进一步生成的复杂化合物ZnxGa2Ox+3,即x的值随温度的升高而增大。这与XRD分析结果相一致。

3 结论

1) GZO陶瓷在1050℃烧结时生成ZnGa2O4尖晶石相,随着烧结温度升高,ZnGa2O4尖晶石相继续与ZnO反应,生成与ZnO共格的化合物ZnxGa2Ox+3(x随烧结温度的升高而增大),其晶体结构随烧结温度升高逐渐接近于ZnO六方纤锌矿结构。

2) 与无压烧结相比,外加压力有效降低GZO陶瓷的烧结温度,GZO-3Ga陶瓷在热压烧结温度为1150 ℃时达到致密化温度。

3) 在外加压力18 MPa,烧结温度1150 ℃时,GZO-3Ga陶瓷的相对密度为95.04%,电阻率为9.0×10-3 Ω·cm。

REFERENCES

[1] DAS D, MONDAL P. Low temperature grown ZnO:Ga films with predominant c-axis orientation in wurtzite structure demonstrating high conductance, transmittance and photoluminescence[J]. Rsc Advances, 2016, 6(8): 6144-6153.

[2] WANG Fang-hsing, CHANG Chiao-lu. Effect of substrate temperature on transparent conducting Al and F co-doped ZnO thin films pre-pared by RF magnetron sputtering[J]. Applied Surface Science, 2016, 370: 83-91.

[3] WANG Hai-lin, SUN Yi-hua, CHEN Jian, FANG Liang, WANG Lei, YE Lin-long, LI Wei. High performance AZO thin films deposited by RF magnetron sputtering at low temperature[J]. Recent Patents on Materials Science. 2015, 8(3): 265-269.

[4] BIAN Hai-qin, MA Shu-yi, YANG Gui-jin, ZHU Hai-bin, XU Xiao-li, YAN Shao-hui, GAO Ji-ming, ZHANG Zheng-mei. The optical and electrical properties of ZnO:Zr films[J]. Journal of Alloys and Com-pounds, 2016, 672: 20-26.

[5] MAO Cai-ying, FANG Liang, ZHANG Hong, LI Wan-jun, WU Fang, QIN Guo-ping, RUAN Hai-bo, KONG Chun-yang. Effect of B doping on optical, electrical properties and defects of ZnO films[J]. Journal of Alloys and Compounds, 2016, 676: 135-141.

[6] CHEN Jian, SUN Yi-hua, Lü Xin, LI De-rong, FANG Liang, WANG Hai-lin, SUN Xiao-hua, HUANG Cai-hua, YU Hai-zhou, FENG Ping. Preparation and characterization of high-transmittance AZO films using RF magnetron sputtering at room temperature[J]. Applied Surface Science, 2014, 317: 1000-1003.

[7] KUMAR A, DHIMAN P, SINGH M. Effect of Fe-doping on the structural, optical and magnetic properties of ZnO thin films prepared by RF magnetron sputtering[J]. Ceramics International, 2016, 42(7): 7918-7923.

[8] SUN Yi-hua, XIONG Wei-hao, LI Chen-hui. Fabrication of ultrahigh density ZnO-Al2O3 ceramic composites by slip casting[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 624-631.

[9] 王志勇, 彭超群, 王日初, 王小锋, 刘 兵. 氧化锌铝陶瓷(AZO)靶材的制备及其电阻性能的测定[J]. 中国有色金属学报, 2013, 23(12): 3341-3347.

WANG Zhi-yong, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing. Precipitation of Al-doped-ZnO(AZO) ceramic targets and determination of its resistance properties [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3341-3447.

[10] 王 敏, 吴 波, 刘海龙, 黄超然, 付金彪, 赵春凤, 吴育锋, 熊远鹏, 周泽友. 常压烧结法制备ZAO靶材及其性质研究[J]. 硅酸盐通报, 2013, 35(4): 708-713.

WANG Min, WU Bo, LIU Hai-long, WANGChao-ran, FU Jin-biao, ZHAO Chun-feng, WU Yu-feng, XIONG Yuan-peng, ZHOU Ze-you. Precipitation of Al-doped-ZnO(AZO) ceramic targets and determination of its resistance properties [J]. Bulletin of the Chinese Ceramic Society. 2013, 35(4): 708-713.

[11] NG Z N, CHAN K Y, LOW C Y, KAMARUDDIN S A, SAHDAN M Z. Al and Ga doped ZnO films prepared by a sol-gel spin coating technique[J]. Ceramics International, 2015, 41: S254-S258.

[12] 孙文燕, 王日初, 王小锋, 彭超群. 常压烧结法制备ZnO陶瓷靶材[J]. 中国有色金属学报, 2015, 25(6): 1625-1633.

SUN Wen-yan, WANG Ri-chu, WANG Xiao-feng, PENG Chao-qun. Fabrication of ZnO ceramic target by conventional sintering[J]. Chinese Journal of Rare Metals, 2015, 25(6): 1625-1633.

[13] LIU Jia, ZHANG Wei-jia, SONG Deng-yuan, MA Qiang, ZHANG Lei, ZHANG Hui, MA Xiao-bo, SONG Hai-yang. Gallium-doped zinc oxide targets fabricated by sintering: Impact of target quality on sputtered thin film properties[J]. Materials Science in Semiconductor Processing, 2014, 27: 1-11.

[14] LIU Cun-qi, CAI Xue-xian, ZHANG Zhong-jian, GAO Ling, XIAO Chao, SHANG Fu-liang, YANG Hai-tao. Effect of gallium doping on the properties of GZO target[J]. Advanced Materials Research, 2013, 779/780: 363-367.

[15] WU Ming-Wei, LAI Pang-Hsin, HONG Chia-Hong, CHOU Fang-Cheng. The sintering behavior, microstructure, and electrical properties of gallium-doped zinc oxide ceramic targets[J]. Journal of the European Ceramic Society, 2014, 34(15): 3715-3722.

[16] JANG M S, RYU M K, YOON M H, LEE S H, KIM H K, ONODERA A, KOJIMA S. A study on the Raman spectra of Al-doped and Ga-doped ZnO ceramics[J]. Current Applied Physics, 2009, 9(3): 651-657.

[17] 白 雪, 王星明, 储茂友, 张碧田, 段华英, 石志霞, 孙 静, 韩 沧. AZO靶材热压致密化及Al元素扩散研究[J]. 粉末冶金技术, 2012, 30(6): 420-427.

BAI Xue, WANG Xing-ming, CHU Mao-you, ZHANG Bi-tian, DUAN Hua-ying, SHI Zhi-xia, SUN Jing, HAN Cang. Study of the hot-pressing densification process of AZO target and the diffusion behavior of Al element[J]. Powder Metallurgy Technology, 2012, 30(6): 420-427.

[18] 王星明, 白 雪, 段华英, 孙 静, 卢世刚, 黄松涛. AZO热压靶材的制备及性能表征研究[J]. 稀有金属, 2011, 35(3): 398-403.

WANG Xing-ming, BAI Xue, DUAN Hua-ying, SUN Jing, LU Shi-gang, HUANG Song-tao. Preparation and characterization of hot pressing AZO sputter target[J]. Chinese Journal of Rare Metals, 2011, 35(3): 398-403.

[19] WANG Xing-ming, BAI Xue, DUAN Hua-ying, SHI Zhi-xia, SUN Jing, LU Shi-gang, HUANG Song-tao. Preparation of Al-doped ZnO sputter target by hot pressing[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1550-1556.

[20] MENDELSON M I. Average grain size in polycrystalline ceramics[J]. Journal of the American Ceramic Society, 1969, 52(8): 443-446.

[21] NAKAMURA M, KIMIZUKA N, MOHRI T. The phase relations in the In2O3-Ga2ZnO4-ZnO system at 1350 ℃[J]. Journal of Solid State Chemistry. 1991, 93(2): 298-315.

[22] SUN Yi-hua, XIONG Wei-hao, LI Chen-hui, YUAN Lu. Effect of dispersant concentration on preparation of an ultrahigh Density ZnO-Al2O3 target by slip casting[J]. Journal of the American Ceramic Society, 2009, 92(9): 2168-2171.

Densification and solid phase reaction of gallium-doped zinc oxide ceramic prepared by hot-pressing

YE Lin-long1, 2, SUN Yi-hua1, FANG Liang1, CHEN Xin-zhi1, CHANG Bao-cheng2, CHENG Zhi-min1

(1. Key Laboratory of Inorganic Nonmetallic Crystalline and Energy Conversion Materials, College of Materials and Chemical Engineering, China Three Gorges University, Yichang 443002, China;

2. New Future Information Industry Co., Ltd., Beihai 536000, China)

Abstract: Gallium-doped zinc oxide ceramic (GZO) was prepared by hot-pressing using 97% ZnO and 3% Ga2O3 mixture powder as raw materials. The phase structure was measured by X-ray diffraction. The microstructure of ceramic was observed by SEM. The density of ceramic was measured by Archimedes method. The electrical property of ceramic was investigated by four-point probe method. The results show that sintering temperature is reduced effectively by external pressure during sintering. With increasing sintering temperature, the relative density increases and electrical resistivity decreases at 18 MPa. The maximum relative density and the lowest resistivity of ceramic are achieved at 1150 ℃. The density and electrical conductivity deceases as temperature rising above 1150 ℃, due to grain coarsening and Zn volatilization caused by porosity growth. In addition, ZnGa2O4 cubic spinel phase is synthesized by solid-phase reaction of Ga2O3 and ZnO at 1050 ℃. As the temperature further increases, ZnGa2O4 reacts with ZnO to form ZnxGa2Ox+3 which has coherent relation with hexagonal wurtzite structure of ZnO, while x rises with temperature increasing, the structure of the complex compounds become more similar to that of ZnO.

Keywords: GZO ceramic; hot-pressing; sintering temperature; densification; solid-phase reaction

Foundation item: Project(61604087) supported by the National Natural Science Foundation of China

Received date: 2017-05-08; Accepted date: 2017-07-26

Corresponding author: SUN Yi-hua; Tel: +86-13872496451; E-mail: sunyihua316181@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(61604087)

收稿日期:2017-05-08;修订日期:2017-07-26

通信作者:孙宜华,教授,博士;电话:13872496451;E-mail:sunyihua316181@163.com

摘 要:以Ga2O3掺杂量(质量分数)为3%的ZnO-Ga2O3混合粉体为原料,采用热压烧结法制备GZO陶瓷。通过XRD、SEM、阿基米德排水法和四探针法对烧结试样的物相组成、显微结构、密度和电阻率等进行分析表征。结果表明:外加压力能有效降低GZO陶瓷烧结致密化温度;当外加压力为18 MPa时,随烧结温度升高,烧结体的密度和电导率增大;当烧结温度达1150 ℃时,烧结体密度和电导率达到最大值;但当烧结温度继续增大时,由于晶粒粗化和Zn元素挥发导致试样中气孔长大,试样致密度与导电性呈下降趋势。此外,ZnO-Ga2O3混合粉体在烧结温度较低时(1050 ℃),Ga2O3与ZnO固相反应生成ZnGa2O4立方尖晶石相;随着烧结温度升高,ZnGa2O4将与ZnO继续反应,生成与ZnO六方纤锌矿结构呈共格关系的复杂化合物ZnxGa2Ox+3,并且化合物化学式中x值随着烧结温度的升高而增加,化合物晶体结构逐渐接近ZnO六方纤锌矿结构。

[9] 王志勇, 彭超群, 王日初, 王小锋, 刘 兵. 氧化锌铝陶瓷(AZO)靶材的制备及其电阻性能的测定[J]. 中国有色金属学报, 2013, 23(12): 3341-3347.

[12] 孙文燕, 王日初, 王小锋, 彭超群. 常压烧结法制备ZnO陶瓷靶材[J]. 中国有色金属学报, 2015, 25(6): 1625-1633.

[17] 白 雪, 王星明, 储茂友, 张碧田, 段华英, 石志霞, 孙 静, 韩 沧. AZO靶材热压致密化及Al元素扩散研究[J]. 粉末冶金技术, 2012, 30(6): 420-427.

[18] 王星明, 白 雪, 段华英, 孙 静, 卢世刚, 黄松涛. AZO热压靶材的制备及性能表征研究[J]. 稀有金属, 2011, 35(3): 398-403.