- Abstract:

- 1 Introduction▲

- 2 Microscopic phase-field...▲

- 3 Simulation results▲

- 4 Conclusions▲

- References

- Figure

- Fig.1 Evolution of LRO parameters of Al and Cr atoms of Ni-15%Al-7.5%Cr alloy at 873 K: (a) Al atoms; (b) Cr atoms

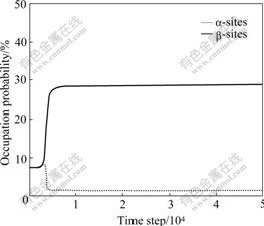

- Fig.2 Evolution of occupation probability of Cr atoms in L12 phase of Ni-15%Al-7.5%C alloy

- Fig.3 Occupation probability of Cr atoms at β-sites vs molar fraction of Cr atoms

- Fig.4 Evolution of atom morphology of formation of DO22 phase in Ni-12%Al-13%Cr alloy: (a) t=40 000; (b) t=80 000

- Fig.5 Evolution of occupation probabilities at phases interface

- Fig.6 Evolution of atom morphology of formation of DO22 phase in Ni-12%Al-13%Cr alloy: (a) t=40 000; (b) t=80 000

- Fig.7 Evolution of occupation probability of Cr and Al atoms at α- and β-sites: (a) α-sites; (b) β-sites

J. Cent. South Univ. Technol. (2008) 15: 588-592

DOI: 10.1007/s11771-008-0110-z

![]()

Microscopic phase-field simulation of Cr atom substitution character during formation of L12 and DO22 phases in Ni-Cr-Al alloy

CHU Zhong(褚 忠)1, CHEN Zheng(陈 铮)2, SHI Yun-xia(石云霞)1,

LU Yan-li(卢艳丽)2, WANG Yong-xin(王永欣)2

(1. School of Mechanical Engineering, Qingdao Technological University, Qingdao 266033, China;

2. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University,

Xi’an 710072, China)

Abstract:

The simulations of Cr atom substitution character during the formation of L12 and DO22 phases in Ni-Cr-Al alloy were performed at 873 K based on microscopic phase-field model. It is found that the substitution of Cr is affected by Cr and Al contents and limits of occupation probabilities of Cr atom in L12 phase are present. The precipitate is single L12 phase when the component is less than the limit, Cr atoms substitute the Al sublattices in L12 phase, and both of atoms Al and Cr occupy the β-sites and complex phases Ni3(Al1-xCrx) are formed; Cr atoms enter Ni sites when Al and Cr contents exceed the limit, and substitute β-sites or both of α- and β-sites. The DO22 phase is formed at the boundary of L12 phase.

Key words:

Ni-Cr-Al alloy; microscope phase-field; precipitation; substitution; simulation;

1 Introduction

A microscopic phase-field kinetics model was developed as a new method of material simulation in 1990s[1-3]. It is a deterministic phase-field method based on the ONSAGER and GINZBURG-LANDAU theory[4]. Microcosmic diffusion equations were first proposed by KHACHATURYAN[5]. In the model, composition is related to a long-range order(LRO) parameter by a nonequilibrium free energy function of atom single-site occupation probabilities, the nonhomogeneous system is described on an atomic scale, and the precipitation caused by atoms transition at crystal lattice sites is simulated with the microscope phase-field model. This model has the advantage of describing the highly nonlinear and nonequilibrium process during alloy precipitation. The authors of Refs.[6-8] simulated phase transformation based on the model.

Atom substitution exits in many materials, which may affect their structure and characteristics[9-11]. Cr atoms may substitute for Al or Ni sites or both of them in Ni-Cr-Al alloy[12-13]. GUARD and WESTBROOK first developed the theory of ternary site preference in the Ni3Al intermetallic compound in 1959. They suggested that the substitution behavior is not controlled by size effect but by the electronic structure of the ternary addition, which could be correlated to the position of the substitution element in the periodic table. OCHIAI et al[14] proposed that the substitution behavior is decided by the direction of the L12 solubility lobe in the ternary diagram. MARTY et al[15] found that Cr atoms occupy both Al and Ni sites in Ni70Al20Cr10 alloy. However, WU et al[16] found that the site preference of the ternary element is generally not related to the direction of the L12 solubility lobe under different compositions and temperatures. Up to now, only qualitative studies have been carried out for the atomic substitution behavior of ternary alloy Ni-Cr-Al.

The aim of this work is to quantitatively describe the substitution character of Cr during the formation of L12 and DO22 phases at 873 K based on microscopic phase-field kinetics model.

2 Microscopic phase-field kinetic model of ternary alloy

The microscopic phase-field kinetic model describes atomic structure morphology by single-site occupation probability. PA(r, t), PB(r, t) and PC(r, t) represent the probabilities of finding atoms A, B or C at a given site r and a given time t. Since PA(r, t)+PB(r, t)+PC(r, t)=1, only two equations are independent at each lattice site, and there will be two independent kinetic equations at each lattice site for atoms A and B:

![]()

![]() (1a)

(1a)

![]()

![]() (1b)

(1b)

where ![]() is the exchange probability between a pair of atoms α and β (α, β=A, B or C); F is the total Helmholtz free energy of the system. In the single-site approximation the free energy F for a ternary system is given by

is the exchange probability between a pair of atoms α and β (α, β=A, B or C); F is the total Helmholtz free energy of the system. In the single-site approximation the free energy F for a ternary system is given by

(2)

(2)

where Vαβ(r-r′) is the pairwise interaction energy between a pair of atoms α and β (=A, B or C) at lattice sites r and r′:

(3)

(3)

Substituting Eqn.(2) into Eqn.(1), then Fourier transforming both sides of the kinetic Eqn.(1) gives

(4a)

(4a)

(4b)

(4b)

where Pαβ(k, t), Lαβ(k), ξαβ(k, t) and Vαβ(k) are Fourier transforms of the corresponding functions in the real space (α, β=A, B or ![]() ).

).

In this work, the fourth nearest-neighbour interatomic model was employed, and the data of interatomic interchange energies were taken from Refs.[6, 17-18]. The three-dimensional face centre cubic(FCC) lattices were projected to a two-dimensional plane to observe the atoms configuration and morphologies easily. 128×128 lattices were selected. The kinetic equations were solved in reciprocal space using the explicit forward Euler technique (Δt=0.000 1), and the occupa- tion probabilities were shown in real space.

3 Simulation results

3.1 L12 phase

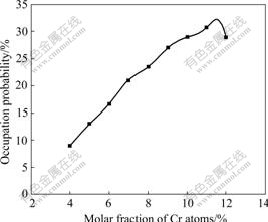

The unit cell of L12 lattice involves two types of sites that are defined as α-site (face center site) and β-site (cube corner site). The ordering phases with L12 structure are formed randomly during the precipitation process of Ni-15%Al-7.5%Cr (molar fraction) alloy. LRO parameter can be used to describe the process of ordering. The evolution of LRO parameters of Cr and Al atoms of the alloy at 873 K is shown in Fig.1. The ordering processes of both atoms are very similar. The two curves present a slight fluctuation simultaneously at time step of 3 200, which indicates the appearance of ordering phases. The ordering processes develop quickly, and the ordering degrees of Al and Cr atoms increase concurrently. They reach the equilibrium value at time step of 4 000, and then keep the value constant during the process of coarsening. The evolution process of the LRO parameter indicates that Al and Cr atoms occupy the β-sites and approach the ordering simultaneously.

Fig.2 shows the evolution of occupation probabilities of Cr atoms at α-sites and β-sites in L12 phase during the precipitation process of Ni-15%Al- 7.5%Cr alloy. The initial stage of annealing is disorder,

Fig.1 Evolution of LRO parameters of Al and Cr atoms of Ni-15%Al-7.5%Cr alloy at 873 K: (a) Al atoms; (b) Cr atoms

Fig.2 Evolution of occupation probability of Cr atoms in L12 phase of Ni-15%Al-7.5%C alloy

so the occupation probabilities of Cr atoms are the same at all sites (about 7.5%). However, the occupation probabilities of Cr atoms at both sites change quickly when the ordering process begins, and reach the equilibrium values (1.8% and 28.0% for α- and β-sites, respectively) at time step of 4 000. It can be concluded that both of Al and Cr atoms share β-sites together, but Cr atoms prefer β-sites to α-sites in L12 phase. The complex phase of Ni3(Al1-xCrx) may be formed.

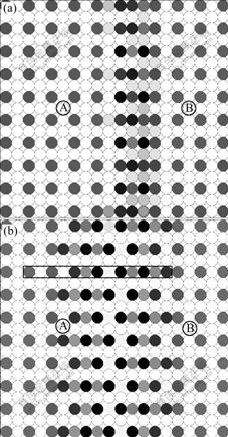

The occupation probability of Cr atoms at β-sites and the structure of precipitate change with the content of Cr atoms in Ni-Cr-Al alloy. Fig.3 shows the occupation probability of Cr atom at β-sites vs molar fraction of Cr atom. It can be seen that the occupation probability of Cr atoms at β-sites increases with increasing Cr content. But it does not increase continuously when molar fraction of Cr atom exceeds 12%. The DO22 phase appears at the boundaries of the L12 phase. The results in Ref.[19] have indicated that the occupation probabilities of Cr atoms at β-sites depend on the component of Cr at XCr+XAl=25% (molar fraction), and reach equilibrium value when XCr is larger than 12%[19].

Fig.3 Occupation probability of Cr atoms at β-sites vs molar fraction of Cr atoms

3.2 Phase boundary of L12 phase

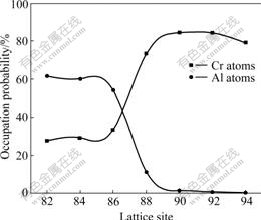

Another ordering phase with DO22 structure appears at boundary of L12 phase with the increase of Cr component. Fig.4 shows a part of the ordering domain boundaries between L12 phases during the precipitation process of Ni-12%Al-13%Cr alloy. There are two ordering domains A and B. At time step of 40 000, the interface of ordering domains is narrow, and it broadens gradually. The color of the lattice at the interface transforms to dark at time step of ![]() which represents the increase of occupation probabilities of Cr atoms at these lattice sites. The arrange of the atoms is consistent with a projection of the DO22 structure, and Ni3Cr phase has the DO22 ordered structure[17]. Ni3Cr phase is formed at the phase boundaries of A and B in the equilibrium state. The evolution of atom occupation probabilities at interface is shown in Fig.5 (the atoms in the rectangle in Fig.4(b), whose vertical coordinate is 60, and horizontal coordinate is from 82 to 94). The occupation probabilities of Cr atoms at these sites increase quickly (from 27% to 85%), and Cr atoms almost occupy the sites fully, but the occupation probabilities of Al atoms at the same sites decrease from

which represents the increase of occupation probabilities of Cr atoms at these lattice sites. The arrange of the atoms is consistent with a projection of the DO22 structure, and Ni3Cr phase has the DO22 ordered structure[17]. Ni3Cr phase is formed at the phase boundaries of A and B in the equilibrium state. The evolution of atom occupation probabilities at interface is shown in Fig.5 (the atoms in the rectangle in Fig.4(b), whose vertical coordinate is 60, and horizontal coordinate is from 82 to 94). The occupation probabilities of Cr atoms at these sites increase quickly (from 27% to 85%), and Cr atoms almost occupy the sites fully, but the occupation probabilities of Al atoms at the same sites decrease from

Fig.4 Evolution of atom morphology of formation of DO22 phase in Ni-12%Al-13%Cr alloy: (a) t=40 000; (b) t=80 000

Fig.5 Evolution of occupation probabilities at phases interface

61.0% to 0.4%. The change of the occupation probabilities at the same lattice sites shows that Cr atoms substitute the sites of Al atoms at L12 phase interface, and the steady Ni3Cr phase is formed. GUARD and WESTBROOK suggested that an addition element substituting for the β-site would form stable geometrically close packed(GCP) phase of Ni3C. If the stability of Ni3C is comparable to that of Ni3Al, element C would occupy the β-site. OCHIAI et al[14] suggested that Cr atoms may substitute Ni and Al sites in Ni3Al and forms quasi-binary Ni3Al-Ni3C. PAREIGE et al[17] and BLAVETTE et al[20] found the same phenomenon with a three dimensional atom probe and Monto-Carlo simulation.

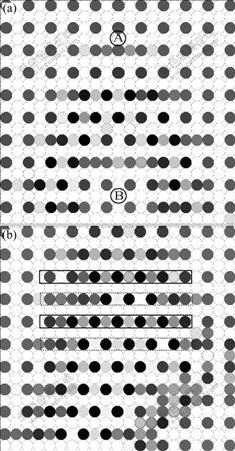

Fig.6 shows another case of the evolution of L12 phase interface during the process of precipitation of Ni-12%Al-13%Cr alloy. There are also two ordering domains A and B. Unlike substitution in Fig.4, Cr atoms enter the α (in dashed frame) and β (in real frame) sites at the boundary of L12 phases simultaneously. The interface broadens gradually, and then all of these atoms form DO22 structure phase at the boundary of L12 phases. Fig.7 shows the evolution of occupation probabilities of Cr and Al atoms at α and β sites during the precipitation of the alloy. The occupation probabilities of the two atoms change symmetrically at α- and β-sites, the equilibrium value of Al atom at α-sites decreases from 60.00% to 0.92%, and that of Cr atom increase from 28% to 85%. The case is similar for β-sites, the equilibrium value of Ni atom at β-sites decreases from 97.5% to 14.0%, and that of Cr atom increases from 2% to 85%. But the summation of the occupation probability of the two atoms is invariable. These indicate that the change of phase interface is resulted from the substitution of Cr atoms at Al sites.

Fig.6 Evolution of atom morphology of formation of DO22 phase in Ni-12%Al-13%Cr alloy: (a) t=40 000; (b) t=80 000

Fig.7 Evolution of occupation probability of Cr and Al atoms at α- and β-sites: (a) α-sites; (b) β-sites

4 Conclusions

1) The ordering of both Al and Cr atoms takes place simultaneously during the precipitation process of Ni-Al- Cr alloy, Cr atoms prefer β-sites to α-sites in L12 phases. Al and Cr atoms occupy β-sites together, the complex phases Ni3(Al1-xCrx) are formed.

2) The limit of occupation probability of Cr atoms at β-sites changes with the Cr and Al contents. Cr atoms substitute the Al sublattice in L12 phase when the content of Cr atoms exceeds the limit, and DO22 phase is formed at the boundary of L12 phases.

3) At the boundary of L12 phase, Cr atoms may substitute Ni sublattice, and the DO22 phase is formed.

References

[1] CHEN L Q, KHACHATURYAN A G. Computer simulation of decomposition reactions accompanied by a congruent ordering of the second kind [J]. Scripta Metall et Mater, 1991, 25(1): 61-66.

[2] CHEN L Q, KHACHATURYAN A G. Computer simulation of structural transformations during precipitation of an ordered intermetallic phase [J]. Acta Metall Mater, 1991, 39(11): 2533-2551.

[3] CHEN Long-qing. A computer simulation technique for spinodal decomposition and ordering in ternary systems [J]. Scripta Metall et Mater, 1993, 29(5): 683-688.

[4] RAABLE D, XIANG J Z. Computational materials science [M]. Beijing: Chemistry Industry Press, 2002: 223-235. (inChinese)

[5] KHACHATURYAN A G. Theory of structural transformations in solids [M]. New York: Wiley, 1983: 23-40.

[6] PODURI R, CHEN L Q. Computer simulation of atomic ordering and compositional clustering in the pseudobinary Ni3Al-Ni3V system [J].Acta Mater, 1998, 46(3): 1719-1729.

[7] ZHANG J X, CHEN L Q. Phase-field microelasticity theory and micromagnetic simulations of domain structures in giant magnetostrictive materials [J].Acta Mater, 2005, 53(5): 2845-2855.

[8] SEOL D J, HU S Y, LI Y L, SHEN J, OH K H, CHEN L Q. Computer simulation of spinodal decomposition in constrained films [J]. Acta Mater, 2003, 51(10): 5173-5185.

[9] LIU Z H, LIU H, ZHANG X X, ZHANG M, DAI X F, HU H F, CHEN T L, WU G H. Martensitic transformation and magnetic properties of Heusler alloy Ni-Fe-Ga ribbon [J]. Physics Letters A, 2004, 329(8): 214-220.

[10] LU Yan-li, CHEN Zheng, LI Yong-sheng. Atomic-scale computer simulation for the coarsening mechanism of the cubic alloy including coherent strain energy [J]. Raremetal Materials and Engineering, 2006, 35(11): 1686-1690. (in Chinese)

[11] ZHAO Yu-hong, ZHANG Yue, CHEN Zheng. Simulation for early precipitation process of Ni75Al4V21 alloy by microscopic phase-field model [J]. Journal of Beijing University of Aeronautics and Astronautics, 2007, 33(8): 978-981. (inChinese)

[12] CERMAK J, GAZDA A, ROTHOVA V. Interdiffusion in ternary Ni3Al/Ni3Al-X diffusion couples with X=Cr, Fe, Nb and Ti [J]. Intermetallics, 2003,11(9): 939-946.

[13] MEKHRABOV A O, AKDENIZ M V, ARER M M. Atomic ordering characteristics of Ni3Al intermetallics with substitutional ternary additions [J]. Acta Mater, 1997, 45(3): 1077-1083.

[14] OCHIAI S, OYA Y, SUZUKI T. Alloys behaviour of Ni3Al, Ni3Ga, Ni3Si and Ni3Ge [J]. Acta Mater, 1984, 32(2): 289-298.

[15] MARTY A, BESSIERE M, BLEY F. Determination of long range order in Ni-base ternary alloys by X-ray anomalous diffraction using synchrotron radiation [J]. Acta Matall Mater, 1990, 38(2): 345-350.

[16] WU Y P, TSO N C, SANCHEN J M. Modeling of ternary site occupation in L12 ordered intermetallics [J]. Acta Mater, 1989, 37(10): 2835-2840.

[17] PAREIGE C, SOISSON F, MARTIN G. Ordering and phase separation in Ni-Cr-Al: Monte Carlo simulations vs three-dimensional atom probe [J]. Acta Mater, 1999, 47(6): 1889-1899.

[18] DUVAL S, CHAMBRLAND S, CARON P, BLVETTE D. Phase composition and chemical order in the single crystal Nickel base siperalloy MC2 [J]. Acta Metall Mater, 1994, 42(1): 185-194.

[19] CHU Zhong, CHEN Zheng, WANG Yong-xin, LU Yan-li. Microscopic phase-field simulation of atom substitution behavior in Ni-Cr-Al alloy [J]. Chinese Physics Letters, 2005, 22(8): 1841-1844.

[20] BLAVETTE D, CADAE L, DECONIHOUT B. The role of the atom probe in the study of nickel-based superalloys [J]. Materials Characterization, 2000, 44(1/2): 133-157.

(Edited by CHEN Wei-ping)

Foundation item: Project(50071046) supported by the National Natural Science Foundation of China

Received date: 2008-01-11; Accepted date: 2008-03-16

Corresponding author: CHU Zhong, Professor, PhD; Tel: +86-13553050352; E-mail: cz@qtech.edu.cn

- Microscopic phase-field simulation of Cr atom substitution character during formation of L12 and DO22 phases in Ni-Cr-Al alloy