DOI:10.19476/j.ysxb.1004.0609.2019.05.04

Cu含量对大应变轧制Al-Cu-Mg合金微观组织及力学行为的影响

王松辉,孙有平,何江美,蒋莉萍,李旺珍

(广西科技大学 机械工程学院,柳州 545006)

摘 要:

采用光学金相显微镜、X射线衍射、拉伸试验、扫描电镜、透射电镜等技术,研究Cu含量对Al-Cu-Mg合金微观组织及力学性能的影响。结果表明:铸态Al-Cu-Mg合金中存在明显的树枝晶,沿晶界分布着大量块状S(Al2CuMg)和θ(Al2Cu)析出相。均匀化退火处理后,非平衡低熔点相基本熔入基体,晶间组织分布趋于均匀。大应变轧制变形后,3种Al-Cu-Mg合金中均得到典型的纤维状组织,合金中的第二相主要为S(Al2CuMg)相、θ(Al2Cu)相和T(Al20Cu2Mn3)相,沿晶界呈连续而均匀分布。经时效处理后,3种Al-Cu-Mg合金均表现出优异的综合力学性能,Cu含量为2%(质量分数)时,Al-Cu-Mg合金的抗拉强度、屈服强度和伸长率分别为507 MPa、430 MPa和10.3%;合金的力学性能随着Cu含量的增加呈递增趋势,当Cu含量为4.5%时,Al-Cu-Mg合金的抗拉强度、屈服强度和伸长率分别为644 MPa、547 MPa和10.5%。

关键词:

Al-Cu-Mg合金;Cu含量;大应变轧制;显微组织;力学性能;

文章编号:1004-0609(2019)-05-0914-09 中图分类号:TG146.2 文献标志码:A

Al-Cu-Mg合金是一种广泛用于航空航天的商业合金,比强度高,具有优异的耐热性,良好的抗疲劳性和断裂韧性[1-3]。已经成功应用于波音777、空客A380、F-35战机的蒙皮、隔框等部件上[4-6],是飞机蒙皮的首选材料[7-9]。Cu是Al-Cu-Mg合金的主要合金化元素,研究表明,Cu含量每增加1%(质量分数),合金密度增加2.3%,这对于实现结构减轻质量是不利的。因此,有学者提出应在满足强度等力学性能要求的情况下,尽量降低Cu含量,以节约成本[10]。

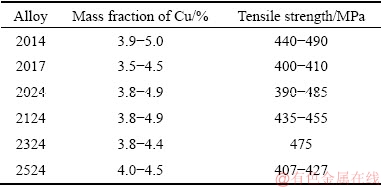

Cu是2xxx系铝合金中最重要的合金化元素,我国现行的Al-Cu-Mg系硬铝合金的Cu元素含量为2.2%~5.0%(质量分数),当Cu元素的含量超过2%时,会生成α(Al)+θ(Al2Cu)共晶相。针对Cu元素的作用机制,孙萍等[11]研究了Cu含量对Al-Cu合金板材组织及性能的影响,结果表明Cu含量增加时,合金中弥散析出的第二相质点逐渐增多;当Cu含量为5.654%~9.806%时,合金的综合力学性能较为理想。肖代红等[12]研究了Cu含量对Al-Cu-0.4Mg-0.6Ag合金组织与性能的影响,结果表明,增加Cu含量能提高合金的时效硬化与抗拉强度。综上所述,随着Cu元素含量的增加,合金中强化相的数量增多,密度变大,合金的强度也随之升高。但研究同样表明,当Cu含量超过5.6%时,合金强度基本保持不变,其断裂韧性却会随着Cu含量的增加而降低[10]。在Al-Cu-Mg合金中添加微量的Ag、Er、Sc等贵金属元素也可以细化合金晶粒,显著提高合金的力学性能和抗疲劳性能[13-14],但是成本也会大幅度提高。

大应变轧制技术近年来得到了广泛的应用,该技术可以显著提高合金的力学性能,而且具有生产效率高、操作流程短等特点。朱素琴等[15-10]和严红革等[17]开发了一种新型的高应变率轧制技术,并针对Mg-Al-Zn-Mn [15]和Mg-Zn-Mn [17]合金开展了大量研究工作,所制备的Mg-3Al-1Zn-0.3Mn合金晶粒尺寸约1.5 μm,其抗拉强度、屈服强度和伸长率分别为340 MPa、266 MPa和23%,证实高应变率轧制可以有效细化镁合金晶粒、提高其力学性能。周学浩等[18]也研究了温度对大应变轧制Al-Mg-Si-Cu合金组织与力学性能的影响,所制备的Al-Mg-Si-Cu合金强度达到490 MPa以上。

本文制备了Cu含量分别为2%、3%和4.5%的Al-Cu-Mg合金铸造锭坯,采用大应变轧制技术对其进行塑性变形,探索Cu含量对Al-Cu-Mg合金板材的微观组织和力学性能的影响。

1 实验

试验所用Al-Cu-Mg合金铸锭名义成分见表1。采用坩埚电阻炉进行熔炼,浇铸温度为740 ℃,将熔体浇铸成200 mm×150 mm×20 mm的铸锭。在SX-16-14Q型电阻炉中对其进行均匀化处理,试验温度为485 ℃,保温10 h。采用VMC650数控铣床铣成厚度为14 mm的板材,在1×10 s-1应变速率下从14 mm热轧到4 mm,然后从4 mm冷轧到2 mm,总变形量85.7%。采用混合酸水溶液(1 mL氢氟酸(体积分数40%)+1.5 mL盐酸(体积分数36%~38%)+2.5 mL硝酸(体积分数65%~68%)+95 mL蒸馏水)侵蚀。采用DMI3000M型金相显微镜观察合金显微组织。采用HVS-1000Z型显微硬度计测试合金硬度变化规律,加载载荷为9.8 N,加载时间为10 s,每个试样测试8次,取其平均值。在ETM105D型电子万能试验机上检测合金的室温力学性能。采用DX-2700型X射线衍射仪进行物相分析。在FEI Technai G2 F20透射电子显微镜上进行TEM观察。采用SIGMA场发射扫描电镜观察其断口形貌。

表1 Al-Cu-Mg合金名义化学成分

Table 1 Chemical compositions of Al-Cu-Mg alloy

2 结果与讨论

2.1 铸态与均匀化组织

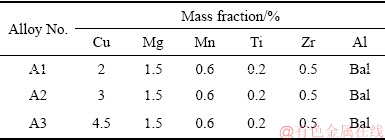

图1所示为不同Cu含量的Al-Cu-Mg合金铸态SEM像。从图1中可以看出,3种Al-Cu-Mg合金的铸态组织均表现出明显的非平衡凝固特征,晶界上和枝晶间组织粗大,沿晶界分布着大量连续的第二相。由EDS能谱分析可知,黑色相主要为S(Al2CuMg)相(见图1(a)和(b)),灰色相主要为θ(Al2Cu)相(见图1(c))。在晶粒内部,第二相多以不规则的块状及片状分布,而且分布不均匀。

图1 铸态Al-Cu-Mg合金SEM像

Fig. 1 SEM images of as-cast Al-Cu-Mg alloy

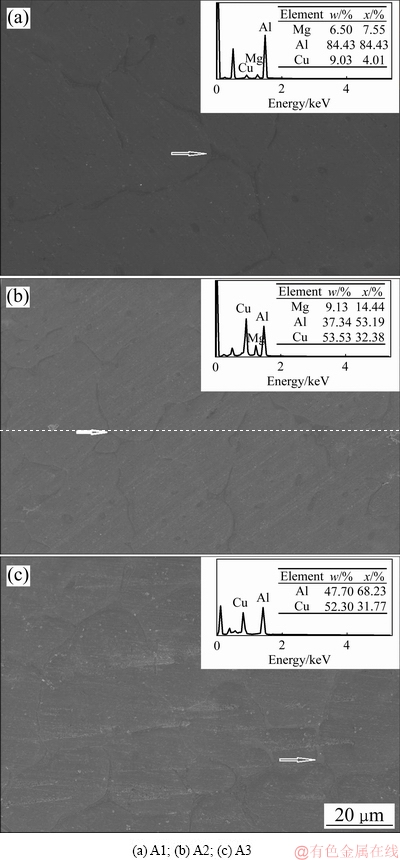

图2所示为不同Cu含量的Al-Cu-Mg合金经过(485 ℃, 10 h)均匀化处理后的组织。从图2(a)中可以看出, A1合金中依然存在较明显的枝晶偏析,且晶界上有大量连续分布的未熔共晶组织;A2合金均匀化处理后枝晶偏析基本消失(见图2(b)),粗大相基本熔入基体;A3合金中的枝晶偏析则基本完全消失,晶界间未发现粗大相,晶粒无明显粗化现象(见图2(c))。

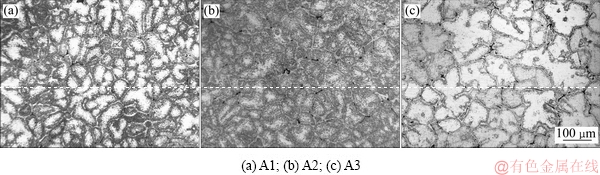

2.2 轧制组织

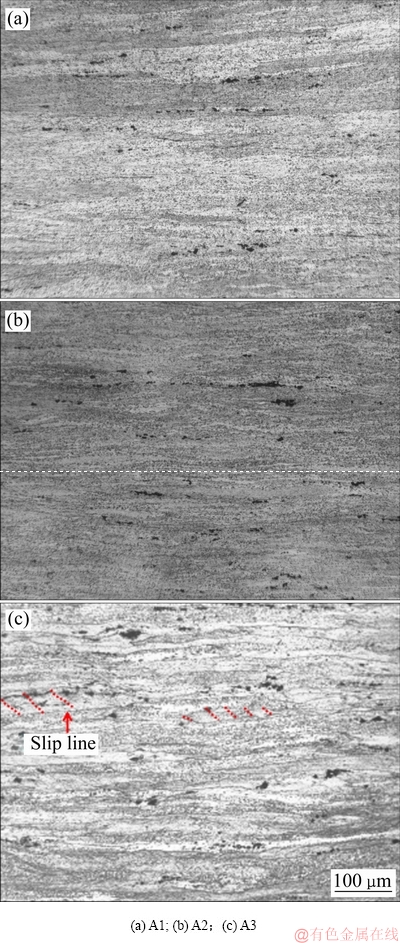

图3和4所示分别为Al-Cu-Mg合金经冷轧变形和冷轧变形以及(150 ℃, 4 h)终时效处理的微观组织。从图3和4可以看出,合金在冷轧后出现了明显的纤维状组织(见图3(a)),在基体中可以看到明显的滑移线(见图3(b)和(c)),且这些特征在时效处理后不会消失(见图4(c)),并对合金的力学性能有显著影响[19]。沿纤维方向分布着连续的(见图3(b))、分散的(见图3(c))第二相,由EDS分析可知(见图3(d)、(e)、(f)),这些第二相主要为S(Al2CuMg)相、θ(Al2Cu)相和T(Al20Cu2Mn3)相。

图2 均匀化处理之后Al-Cu-Mg合金显微组织

Fig. 2 Microstructures of Al-Cu-Mg alloys after homogenization

图3 冷轧态Al-Cu-Mg合金的显微组织和EDS谱

Fig. 3 Microstructures and EDS spectra of Al-Cu-Mg alloy after cold rolling

由研究表明[20],S(Al2CuMg)相和θ(Al2Cu)相通常会促进再结晶的形成。

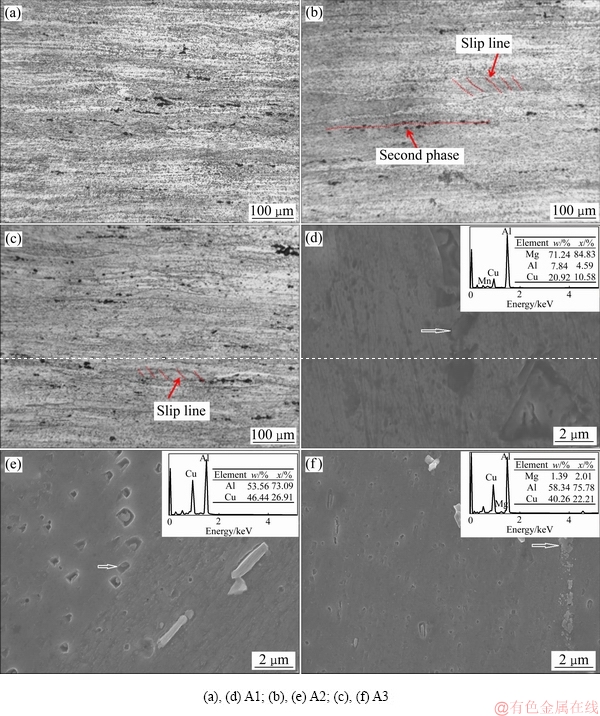

图4 冷轧+(150 ℃, 4 h)时效处理态Al-Cu-Mg合金的显微组织

Fig. 4 Microstructures of Al-Cu-Mg alloy after cold rolling+ (150 ℃, 4 h) aging treatment

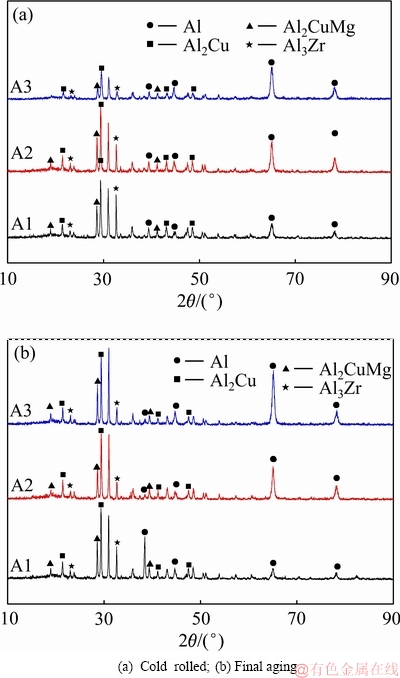

图5(a)所示为Al-Cu-Mg合金经过大应变轧制之后的XRD谱,从图中可以看出,合金中除了S(Al2CuMg)相和θ(Al2Cu)相外,还存在Al3Zr相,这说明Zr元素除了固溶入α(Al)中,还形成了弥散的Al3Zr质点。由此可以确定,Al-Cu-Mg合金中的主要强化相为S(Al2CuMg)相、θ(Al2Cu)和Al3Zr相。合金经过(150 ℃, 4 h)时效处理后,其衍射峰与冷轧态相比有所增强(见图5(b))。从衍射峰的强度上也证实了合金经过(150 ℃, 4 h)时效处理后强度增强(见图5(c))。

2.3 TEM像

图5 Al-Cu-Mg合金的XRD谱

Fig. 5 XRD patterns of Al-Cu-Mg alloy

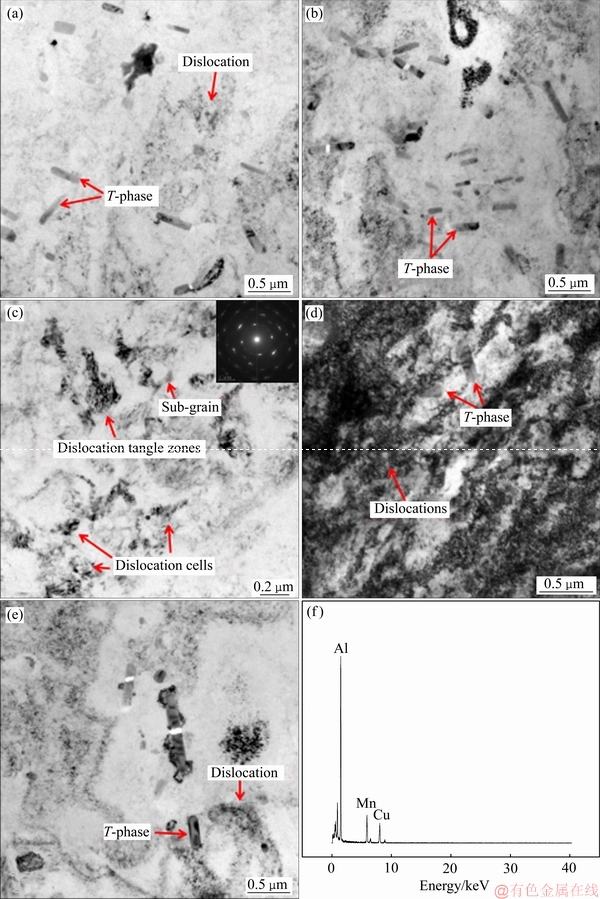

图6(a)和(b)所示分别是A1和A2合金冷轧态TME像,可见在合金中还存在大量细小的短棒状相;经EDX分析可知,短棒状相为T(Al20Cu2Mn3)相(见图6(f)),其长度约为0.5 μm,宽度约为0.2 μm。同时在α(Al)基体中和T相周围存在大量位错,细小短棒状T(Al20Cu2Mn3)相可以有效钉扎位错,阻碍位错运动[21]。图6(c)所示为A3合金冷轧态TEM像,在经过50%的冷轧变形之后,A3合金的微观组织发生了改变,相比A1和A2合金,衍射光斑显示出小角度晶界形成的扩散环,这与文献[22]的研究结果类似。合金中含有许多细小的位错胞、亚晶粒以及位错缠结区(见图6(c)),在T相周围还可以观察到明显的高密度位错区域(见图6(d)),晶粒细化和位错密度增殖是导致A3合金力学性能提高的主要因素。研究表明,增加轧制道次应变量,或者通过细小第二相粒子钉扎位错运动均可以达到增加位错密度的效果[23]。图6(e)所示为A3合金冷轧+(150 ℃, 4 h)时效处理后的TEM像。从图6(e)中可以看出,此时A3合金中的位错密度降低,这通常会使合金强度降低,塑性提高;但时效过程中析出的细小第二相有助于提高合金强度[24]。本次研究表明,细小第二相析出强化比位错密度降低对Al-Cu-Mg合金力学性能的影响更大,因而时效处理后Al-Cu-Mg合金的强度和延展性同时增加。

图6 Al-Cu-Mg合金的TEM像及T相的EDX分析

Fig. 6 TEM images of Al-Cu-Mg alloy with cold rolling state of A1(a), A2(b), A3((c), (d)), final aging of A3(e) and EDX analysis of T phase(f)

2.4 力学性能

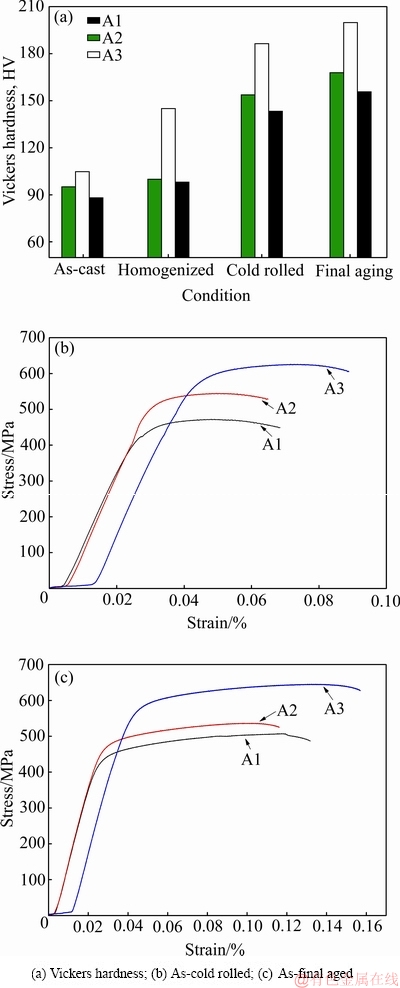

图7所示为不同状态Al-Cu-Mg合金的力学性能。从图7(a)可以看出,3种Al-Cu-Mg合金铸态、均匀化处理态、冷轧态和终时效处理后的硬度均随着Cu含量的增加呈递增趋势,A1合金终时效处理态的硬度为155.5 HV,A3合金终时效处理态的硬度为199.6 HV,硬度提高约28.4%。这是由于Cu含量的增加使强化 相S(Al2CuMg)和θ(Al2Cu)的数量增多(见图4(b))。由图7(b)可见,Al-Cu-Mg合金的抗拉强度和屈服强度都随着Cu含量的增加呈递增趋势。由图7(c)可看出,当Cu含量为2%时,A1合金的抗拉强度、屈服强度和伸长率分别为507 MPa、430 MPa和10.3%,表现出良好的力学性能。与国内外常用航空用铝合金相比[10],A1合金的Cu含量降低了约50%,但力学性能更优,这说明大应变轧制技术可以显著提高Al-Cu-Mg合金的力学性能,在降低Al-Cu-Mg成本方面具有较大潜力。当Cu含量增加至4.5%时,Al-Cu-Mg合金的抗拉强度、屈服强度和伸长率分别为644 MPa、547 MPa和10.5%,其综合力学性能优异。

图7 不同状态Al-Cu-Mg合金的力学性能

Fig. 7 Mechanical properties of Al-Cu-Mg alloy under different conditions

对于可热处理强化Al-Cu-Mg合金来说,强化机制主要有固溶强化、晶界强化、沉淀强化及位错强化等[18]。有学者又将晶界强化机制分为普通晶界强化和亚晶界强化[25]。在合金塑性变形时存在可变形粒子强化和不可变形粒子强化,可变形粒子强化主要体现在位错切过第二相粒子时而引起的强化作用,而不可变形粒子强化主要体现在位错绕过第二相粒子时所引起的强化作用。依据位错理论,当强化相被位错切割时有如下关系式[18]:

(1)

(1)

当位错绕过第二相粒子时有如下关系式:

(2)

(2)

式中:τG为位错切割时的临界切应力;τA为位错绕过第二相粒子时的临界切应力;r为粒子半径;b为柏氏矢量;G为基体剪切模量;A为位错中心尺寸;τ0为初始切应力;γ为反相畴界能;f 为质点体积分数;K1、K2为常数。

随着Cu含量的增加,析出第二相更多,质点体积分数不断增大,根据公式(1)和(2),合金强度也将不断增大。因此,在本研究中当Cu含量由2%增大至4.5%时,Al-Cu-Mg合金的综合力学性能不断提高。

表2 2xxx铝合金Cu含量和抗拉强度的关系[10]

Table 2 Relationship of Cu content and tensile strength of 2xxx aluminum alloys[10]

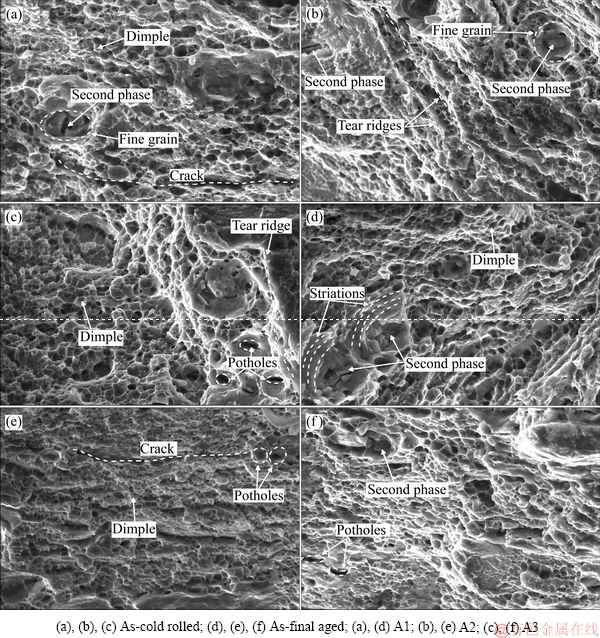

图8所示为不同状态Al-Cu-Mg合金拉伸断口的SEM像。由图8(a)和(b)可知,冷轧态A1和A2合金断口中韧窝底部存在破碎的第二相粒子;在拉伸应力作用下,裂纹优先在第二相粒子与基体的界面处形核,随后积聚、连接成为裂纹,并最终导致合金发生断裂[26-27];而A3合金断口中则存在大量孔洞,同时,存在着由于孔洞扩展而形成的撕裂脊。终时效处理后,A1合金断口存在大量细小而均匀的韧窝,韧窝底部有较多破碎的第二相粒子,韧窝边界存在明显的滑移条纹,这与文献[21,27]的研究结果一致。

图8 Al-Cu-Mg合金拉伸断口的SEM像

Fig. 8 SEM images for tensile fracture of Al-Cu-Mg alloy

3 结论

1) 铸态Al-Cu-Mg合金中组织粗大,沿晶界分布着大量粗大析出相,主要为S(Al2CuMg)相和θ(Al2Cu)相。

2) Al-Cu-Mg合金经过大应变轧制之后,合金中存在明显纤维状组织,第二相沿晶界连续而均匀分布;经时效处理后,析出均匀、细小的强化相,主要为S(Al2CuMg)、θ(Al2Cu)、T(Al20Cu2Mn3)相和Al3Zr相。

3) 当Cu含量为2%时,Al-Cu-Mg合金力学性能良好,其抗拉强度、屈服强度和伸长率分别为507 MPa、430 MPa和10.3%;随着Cu含量的增加合金的力学性能呈现递增趋势,当Cu含量为4.5%时,具有优异的综合力学性能,其抗拉强度、屈服强度和伸长率分别为644 MPa、547 MPa和10.5%。

REFERENCES

[1] LIN Y C, XIA Y C, JIANG Y Q, ZHOU H M, LI L T. Precipitation hardening of 2024-T3 aluminum alloy during creep aging[J]. Materials Science and Engineering A, 2013, 565: 420-429.

[2] LIN Y C, XIA Y C, JIANG Y Q, LI L T. Precipitation in Al-Cu-Mg alloy during creep exposure[J]. Materials Science and Engineering A, 2012, 556: 796-800.

[3] 宋艳芳, 潘清林, 丰 雷, 王 迎, 李 晨. Mg含量对Al-Cu-Mg-Ag合金组织与力学性能的影响[J]. 中国有色金属学报, 2013, 23(7): 1812-1818.

SONG Yan-fang, PAN Qing-lin, FENG Lei, WANG Ying, LI Chen. Effects of Mg content on microstructure and mechanical properties of Al-Cu-Mg-Ag alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1812- 1818.

[4] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[5] 孙有平, 张扬扬, 敖 哲, 韩 俊, 何江美. 2524铝合金轧制板材热稳定性研究[J]. 材料导报, 2015, 29(S2): 508-510, 541.

SUN You-ping, ZHANG Yang-yang, AO Zhe, HAN Jun, HE Jiang-mei. Investigation on thermal-stability of 2524Al alloy fabricated by hot rolling[J]. Materials Review, 2015, 29(S2): 508-510, 541.

[6] 曹素芳, 潘清林, 刘晓艳, 陆智伦, 何运斌, 李文斌. 外加应力对Al-Cu-Mg-Ag合金时效析出行为的影响[J]. 中国有色金属学报, 2010, 20(8): 1513-1519.

CAO Su-fang, PAN Qing-lin, LIU Xiao-yan, LU Zhi-lun, HE Yun-bin, LI Wen-bin. Effects of external stress on aging precipitation behavior of Al-Cu-Mg-Ag alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1513-1519.

[7] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloy[J]. Materials and Design, 2014, 56: 862-871.

[8] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W. S. Recent development in aluminum alloy aerospace applications[J]. Materials Science and Engineering A, 2000, 280: 102-107.

[9] 雷彬彬, 周志明, 黄伟九, 唐丽文. Al-Cu-Mg高强铝合金的研究进展[J]. 热加工工艺, 2012, 41(2): 41-45.

LEI Bin-bin, ZHOU Zhi-ming, HUANG Jiu-wei, TANG Li-wen. Development of high-strength Al-Cu-Mg alloy[J]. Hot Working Technology, 2012, 41(2): 41-45.

[10] 戴圣龙, 张 坤, 杨守杰, 黄 敏. 先进航空铝合金材料与应用[M]. 北京: 国防工业出版社, 2012.

DAI Sheng-long, ZHANG Kun, YANG Shou-jie, HUANG Min. Advanced area nautical aluminum alloy materials technology and application[M]. Beijing: National Defense Industry Press, 2012.

[11] 孙 萍, 陈忠家, 刘 程, 王克廷. Cu含量对Al-Cu合金板材组织及性能的影响[J]. 有色金属加工, 2012, 41(2): 31-34.

SUN Ping, CHEN Zhong-jia, LIU Cheng, WANG Ke-ting. Influence of copper content on the microstructure and properties of Al-Cu alloy plate[J]. Nonferrous Metals Processing, 2012, 41(2): 31-34.

[12] 肖代红, 王健农, 陈康华. Cu含量对Al-Cu-0.4Mg-0.6Ag合金组织与力学性能的影响[J]. 有色金属, 2009, 61(1): 6-10.

XIAO Dai-hong, WANG Jian-nong, CHEN Kang-hua. Effect of Cu content on microstructure and mechanical properties of Al-Cu-0.4Mg-0.6Ag alloy[J]. Nonferrous Metals, 2009, 61(1): 6-10.

[13] KANG W, LI H Y, ZHAO S X, HAN Y, YANG C L, MA G. Effects of homogenization treatments on the microstructure evolution, microhardness and electrical conductivity of dilute Al-Sc-Zr-Er alloys[J]. Journal of Alloys and Compounds, 2017, 704: 683-692.

[14] SUN F F, NASH G L, LI Q Y, LIU E Z, HE C N, SHI C S, ZHUO N Q. Effect of Sc and Zr additions on microstructures and corrosion behavior of Al-Cu-Mg-Sc-Zr alloys[J]. Journal of Materials Science & Technology, 2017, 33: 1015-1022.

[15] ZHU S Q, YAN H G, CHEN J H, WU Z Y, DU Y G, LIAO X Z. Fabrication of Mg-Al-Zn-Mn alloy sheets with homogeneous fine-grained structures using high strain-rate rolling in a wide temperature range[J]. Materials Science and Engineering A, 2013, 559: 765-772.

[16] ZHU S Q, YAN H G, CHEN J H, WU Y Z, SU B, DU Y G, LIAO X Z. Feasibility of high strain-rate rolling of a magnesium alloy across a wide temperature range[J]. Scripta Materialia, 2012, 67: 404-407.

[17] CHEN Chao, CHEN Ji-hua, YAN Hong-ge, SU Bin, SONG Min, ZHU Su-qin. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling[J]. Materials and Design, 2016, 100: 58-66.

[18] 周学浩, 孙有平, 王文熙, 何江美, 李旺珍. 轧制温度对大应变轧制Al-Mg-Si-Cu合金组织与力学性能的影响[J]. 金属热处理, 2017, 42(9): 21-25.

ZHOU Xue-hao, SUN You-ping, WANG Wen-xi, HE Jiang-mei, LI Wang-zhen. Effect of temperature on microstructures and mechanical properties of Al-Mg-Si-Cu alloy fabricated by severe strain rolling[J]. Heat Treatment of Metals, 2017, 42(9): 21-25.

[19] SHEN Fang-hua, YI Dan-qing, WANG Bin, LIU Hui-qun, JIANG Yong, TANG Cong. Semi-quantitative evaluation of texture components and anisotropy of the yield strength in 2524 T3 alloy sheets[J]. Materials Science & Engineering A, 2016, 675: 386-395.

[20] SHEN Fang-hua, WANG Bin, YI Dan-qing, LIU Hui-qun, TANG Cong, SHOU Wen-bin. Effects of heating rate during solid-solution treatment on microstructure and fatigue properties of AA2524 T3 Al-Cu-Mg sheet[J]. Materials and Design, 2016, 104: 116-125.

[21] SHEN Fang-hua, WANG Bin, LIU Hui-qun, JIANG Yong, TANG Cong, SHOU Wen-bin, PAN Su-ping, CHEN Yu-qiang, YI Dan-ying. Effects of secondary particle- induced recrystallization on fatigue crack growth in AA2524/ Al-Cu-Mg T3 alloy sheets[J]. Journal of Alloys and Compounds, 2016, 685: 571-580.

[22] SINGH D, NAGESWARA RAO R, JAYAGANTHAN R. Effect of deformation temperature on mechanical properties of ultrafine grained Al-Mg alloys processed by rolling[J]. Materials and Design, 2013, 50: 646-655.

[23] CHENG S, ZHAO Y H, ZHU Y T, MA E S. Optimizing the strength and ductility of fine structured 2024Al alloy by nano-precipitation[J]. Acta Materialia, 2007, 55(17): 5822- 5832.

[24] NIRANJANI V L, HARI KUMAR K C, SUBRAMANYA S V. Development of high strength Al-Mg-Si AA6061 alloy through cold rolling and ageing[J]. Materials Science and Engineering A, 2009, 515: 169-174.

[25] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51(17): 5131-5150.

[26] 祝国川, 熊柏青, 佟有志, 张永安, 黄树晖, 李志辉, 李锡武, 李明原. 固溶处理对7B52铝合金板材力学性能和断裂行为的影响[J]. 中国有色金属学报, 2017, 27(5): 877-884.

ZHU Guo-chuan, XIONG Bai-qing, TONG You-zhi, ZHANG Yong-an, HUANG Shu-hui, LI Zhi-hui, LI Xi-wu, LI Ming-yuan. Effect of solution treatment on mechanical properties and fracture behavior of 7B52 aluminum alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(5): 877-884.

[27] 黄 敏, 陈 轶, 李 超, 陈军洲, 汝继刚. 7A12-T7352铝合金高温力学性能及断裂行为研究[J]. 航空材料学报, 2014, 34(1): 82-85.

HUANG Min, CHEN Yi, LI Chao, CHEN Jun-zhou, RU Ji-gang. High temperature mechanical properties and fracture characteristics of 7A12-T7352[J]. Journal of Aeronautical Materials, 2014, 34(1): 82-85.

Effect of Cu content on microstructures and mechanical properties of Al-Cu-Mg alloy fabricated by large strain rolling

WANG Song-hui, SUN You-ping, HE Jiang-mei, JIANG Li-ping, LI Wang-zhen

(College of Mechanical Engineering, Guangxi University of Science and Technology, Liuzhou 545006)

Abstract: The effects of Cu content on microstructures and mechanical properties of Al-Cu-Mg alloy were investigated by optical microscopy, X-ray diffraction, tensile tester, scanning electron microscope and transmission electron microscope. The results show that there is obvious dendrite segregation in as-cast Al-Cu-Mg alloys, and a large number of massive S(Al2CuMg) and θ(Al2Cu) precipitates are distributed along the grain boundaries. After homogenization annealing treatment, the non-equilibrium low-melting phases are substantially dissolved into the matrix, and the intergranular structure distribution tends to be more uniform. After large strain rolling deformation, typical fibrous structures are obtained in the three kinds of Al-Cu-Mg alloys and the main secondary phases in the alloys are S(Al2CuMg), θ(Al2Cu) and T(Al20Cu2Mn3), which are continuous along the grain boundaries and evenly distributed. After aging treatment, all three kinds of Al-Cu-Mg alloys exhibit excellent comprehensive mechanical properties. When the Cu content is 2%(mass fraction), the tensile strength, yield strength and elongation are 507 MPa, 430 MPa and 10.3%, respectively. With the increase of Cu content, the mechanical properties of Al-Cu-Mg alloys show increasing trends, and the increase of Cu content has a significant effect on the mechanical properties of the alloy. When the Cu content is 4.5%, the tensile strength, yield strength, and the elongation of Al-Cu-Mg alloy are 644 MPa, 547 MPa, and 10.5%, respectively.

Key words: Al-Cu-Mg alloy; Cu content; large strain rolling; microstructure; mechanical property

Foundation item: Project(51864006) supported by the National Natural Science Foundation of China

Received date: 2018-04-17; Accepted date: 2018-09-22

Corresponding author: SUN You-ping; Tel: +86-13627723445; E-mail: syptaiji@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51864006)

收稿日期:2018-04-17;修订日期:2018-09-22

通信作者:孙有平,教授,博士;电话:13627723445;E-mail:syptaiji@126.com

摘 要:采用光学金相显微镜、X射线衍射、拉伸试验、扫描电镜、透射电镜等技术,研究Cu含量对Al-Cu-Mg合金微观组织及力学性能的影响。结果表明:铸态Al-Cu-Mg合金中存在明显的树枝晶,沿晶界分布着大量块状S(Al2CuMg)和θ(Al2Cu)析出相。均匀化退火处理后,非平衡低熔点相基本熔入基体,晶间组织分布趋于均匀。大应变轧制变形后,3种Al-Cu-Mg合金中均得到典型的纤维状组织,合金中的第二相主要为S(Al2CuMg)相、θ(Al2Cu)相和T(Al20Cu2Mn3)相,沿晶界呈连续而均匀分布。经时效处理后,3种Al-Cu-Mg合金均表现出优异的综合力学性能,Cu含量为2%(质量分数)时,Al-Cu-Mg合金的抗拉强度、屈服强度和伸长率分别为507 MPa、430 MPa和10.3%;合金的力学性能随着Cu含量的增加呈递增趋势,当Cu含量为4.5%时,Al-Cu-Mg合金的抗拉强度、屈服强度和伸长率分别为644 MPa、547 MPa和10.5%。

[3] 宋艳芳, 潘清林, 丰 雷, 王 迎, 李 晨. Mg含量对Al-Cu-Mg-Ag合金组织与力学性能的影响[J]. 中国有色金属学报, 2013, 23(7): 1812-1818.

[4] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

[5] 孙有平, 张扬扬, 敖 哲, 韩 俊, 何江美. 2524铝合金轧制板材热稳定性研究[J]. 材料导报, 2015, 29(S2): 508-510, 541.

[6] 曹素芳, 潘清林, 刘晓艳, 陆智伦, 何运斌, 李文斌. 外加应力对Al-Cu-Mg-Ag合金时效析出行为的影响[J]. 中国有色金属学报, 2010, 20(8): 1513-1519.

[9] 雷彬彬, 周志明, 黄伟九, 唐丽文. Al-Cu-Mg高强铝合金的研究进展[J]. 热加工工艺, 2012, 41(2): 41-45.

[10] 戴圣龙, 张 坤, 杨守杰, 黄 敏. 先进航空铝合金材料与应用[M]. 北京: 国防工业出版社, 2012.

[11] 孙 萍, 陈忠家, 刘 程, 王克廷. Cu含量对Al-Cu合金板材组织及性能的影响[J]. 有色金属加工, 2012, 41(2): 31-34.

[12] 肖代红, 王健农, 陈康华. Cu含量对Al-Cu-0.4Mg-0.6Ag合金组织与力学性能的影响[J]. 有色金属, 2009, 61(1): 6-10.

[18] 周学浩, 孙有平, 王文熙, 何江美, 李旺珍. 轧制温度对大应变轧制Al-Mg-Si-Cu合金组织与力学性能的影响[J]. 金属热处理, 2017, 42(9): 21-25.

[27] 黄 敏, 陈 轶, 李 超, 陈军洲, 汝继刚. 7A12-T7352铝合金高温力学性能及断裂行为研究[J]. 航空材料学报, 2014, 34(1): 82-85.