岩石断裂韧度与抗压强度的相关规律

李江腾,古德生,曹 平,吴 超

(中南大学 资源与安全工程学院,湖南 长沙,410083)

摘 要:

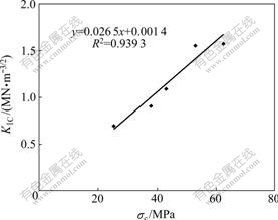

摘 要:利用Instron1342型电液伺服材料试验机,采用单轴压缩试验和双扭常位移松弛试验对大理岩、上盘二辉橄榄岩、下盘二辉橄榄岩、矿石、混合岩5组岩石的试件进行力学参数测试,获得相应的抗压强度、Ⅰ型断裂韧度等试验数据。以试验数据为依据,分析这5组岩石的Ⅰ型断裂韧度与抗压强度的关系。研究结果表明:随着抗压强度σc的增加,Ⅰ型断裂韧度![]() 相应增大,且呈很好的线性关系,其关系式为:

相应增大,且呈很好的线性关系,其关系式为:![]() =0.026 5σc+0.001 4,其相关系数R2为0.94。基于该关系式,可由易于测试的抗压强度估算Ⅰ型断裂韧度。

=0.026 5σc+0.001 4,其相关系数R2为0.94。基于该关系式,可由易于测试的抗压强度估算Ⅰ型断裂韧度。

关键词:

中图分类号:O342.1 文献标志码:A 文章编号:1672-7207(2009)06-1695-05

Interrelated law between mode-Ⅰ fracture toughness and compression strength of rock

LI Jiang-teng, GU De-sheng, CAO Ping, WU Chao

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: The mechanics parameters of marble, upper lherzolite, down lherzolite, granite and ore were tested by uniaxial compression testing and relaxation method of double torsion constant displacement load using Instron1342 type electro hydraulic servo test machine. Compression strength and the mode-Ⅰ fracture toughness ![]() were obtained. Their relationships were studied based on the testing data. The results show that mode-Ⅰ fracture toughness

were obtained. Their relationships were studied based on the testing data. The results show that mode-Ⅰ fracture toughness ![]() increases with the increase of compression strength σc, and the curve of mode-Ⅰ fracture toughness

increases with the increase of compression strength σc, and the curve of mode-Ⅰ fracture toughness ![]() and compression strength σc is in accordance with linear rule, the expression is:

and compression strength σc is in accordance with linear rule, the expression is: ![]() =0.026 5σc+0.001 4, and the coefficient of determination R2 is 0.94. The expression may provide a helpful method for estimating the fracture toughness through the compression strength which can be measured easily.

=0.026 5σc+0.001 4, and the coefficient of determination R2 is 0.94. The expression may provide a helpful method for estimating the fracture toughness through the compression strength which can be measured easily.

Key words: rock; compression strength; fracture toughness

由于岩石的抗压强度远远高于抗拉强度,两者相差高达数十倍,工程中的岩石结构大多设计成处于受压状态。即使是自然状态中的岩体,由于构造应力和自重应力的作用,通常也处于这种受载状态,从而使岩石的压剪破坏成为最常见的破坏模式。处于压剪应力状态的裂纹,其裂纹尖端仍处于拉剪应力状态,使裂纹发生转折、断裂面发生分离都是由于张应力超过了原子间的结合力,并导致Ⅰ型破坏,因而,压剪断裂与Ⅰ型断裂密切相关[1],即:裂纹的扩展必然包括Ⅰ型断裂的机理。Lajtai[2]研究了压缩下裂纹的张性扩展现象。Bazant等[3-4]的实验结果表明:当混凝土等脆性材料内的裂纹受压扩展时,裂纹前端的I型模式占支配地位。事实上,早在人们研究Ⅱ型和Ⅲ型断裂问题时就注意到了岩石张性起裂现象。Ebrahimi等[5]指出:在相应加载下,滑移型(Ⅱ型)和撕开型(Ⅲ型)裂纹扩展并不会发生,断裂模式总是张开的,其实质是裂纹Ⅰ型起裂后在扩展过程中产生的次生现象。Nemat- Nasser等[6-8]的研究也表明:在压剪应力状态,裂纹总是以转折(Kink)的方式发生Ⅰ型断裂。因此,探讨岩石的抗压强度与Ⅰ型断裂韧度之间的关系具有十分重要的理论意义和工程意义。目前,人们研究了岩石断裂韧度与材料参数[9-10],对岩石断裂韧度与抗压强度之间的关系研究较少。为此,本文作者利用Instron1342型电液伺服材料试验机,采用单轴压缩试验和双扭常位移松弛试验对大理岩、上盘二辉橄榄岩、下盘二辉橄榄岩、矿石、混合岩5组岩石的试件进行力学参数测试,以试验数据为依据,分析5组岩石的Ⅰ型断裂韧度与抗压强度的关系。

1 岩石抗压强度试验

抗压强度试验在中南大学测试中心INSTRON 1342伺服机上进行,采用位移控制,所有试验数据通过计算机采集。

抗压强度σc的计算式为:

1.1 试样加工

试样为经过高精度加工制成的圆柱体,直径D为50 mm,高度L为100 mm,两端不平度为0.5 mm,尺寸误差为±0.3 mm,两端面垂直于轴线误差为±0.25?。

1.2 测试结果

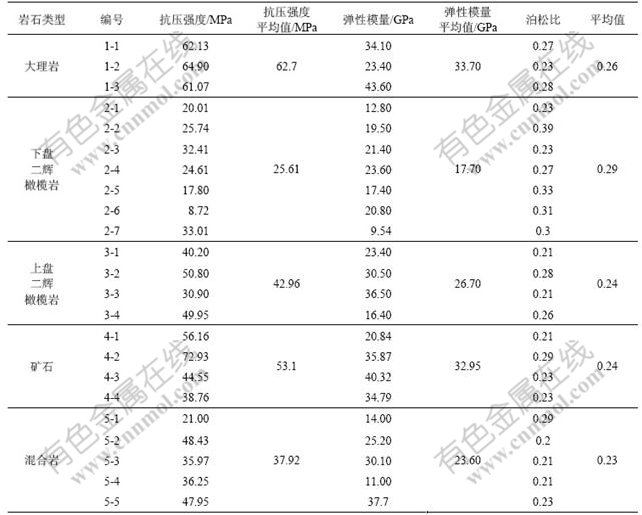

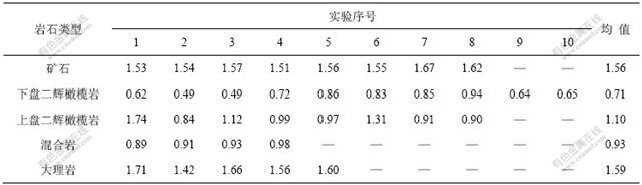

表1所示为5组岩石各试样抗压强度、弹性模量等力学参数测试结果。

表1 抗压强度和弹性模量测试结果

Table 1 Testing values of compression strength and Young modulus

2 Ⅰ型断裂韧度![]() 试验

试验

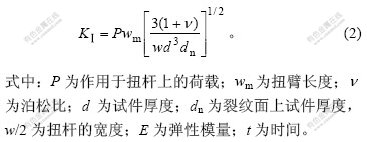

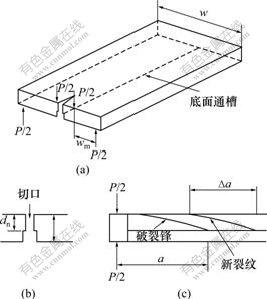

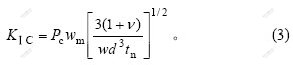

采用双扭试验测试岩石的断裂韧度,其试样示意图见图1,试验装置示意图见图2。试件为1块矩形薄板,在板的下表面沿长度方向的对称线开一中槽,以使裂纹沿中槽扩展。双扭试件可以看作由2个弹性扭转杆组成。对于小变形, 当扭转杆的宽度远大于试件的厚度时,参照文献[11-16],可以推得裂纹尖端的应力强度因子![]() 为:

为:

(a) 试件形状;(b) 横向截面;(c) 纵向截面

图1 双扭试件示意图

Fig.1 Schematic diagram of double torsion specimen

(a) 试验装置;(b) 加载方式

图2 试验装置和加载方式示意图

Fig.2 Schematic diagram of testing device and loading mode

当载荷P达到临界值Pc时,裂纹快速扩展,此时,![]() 也达到临界值,即为断裂韧度

也达到临界值,即为断裂韧度![]() 。

。

2.1 试样制备

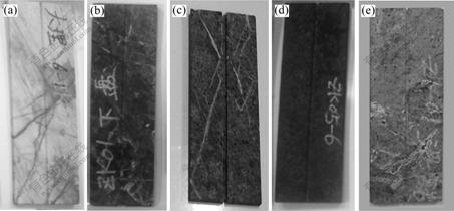

从金川矿区工地取回5种岩石的岩芯,用岩石切割机将岩石锯成矩形薄片双扭试件,沿中央轴线锯制1条通槽,槽宽为1 mm,槽深约为t/3。在试样一端沿中央轴线开1个长为10 mm的“V”型切口。在加载过程中,裂纹从切口开始,并沿导向槽延伸。加工时,试样上、下表面平整,不平行度误差低于 25 μm[11-14, 17]。图3所示为5种岩石的双扭试样。

(a) 第1组;(b) 第2组;(c) 第3组;(d) 第4组;(e) 第5组

图3 双扭试件

Fig.3 Double torsion specimens

2.2 测试方法

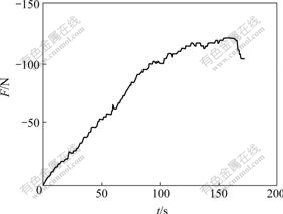

双扭试验在中南大学测试中心Instron1342型电液伺服材料试验机上进行。为获得合理的![]() ,需对试件以恒定位移速率进行预裂[11-13, 17],预裂速度为0.05 mm/min。图4所示为典型试件预裂时的载荷—时间曲线。

,需对试件以恒定位移速率进行预裂[11-13, 17],预裂速度为0.05 mm/min。图4所示为典型试件预裂时的载荷—时间曲线。

图4 典型试件预裂载荷—时间曲线

Fig.4 Load—time curve of typical specimen in pre-crack

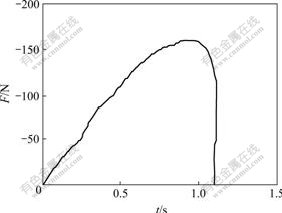

在测试断裂韧度![]() 时,以20 mm/min的恒定位移速率[9, 14] 对预裂过的试件加载,测得其破坏载荷Pc,利用式(3)可求得断裂韧度

时,以20 mm/min的恒定位移速率[9, 14] 对预裂过的试件加载,测得其破坏载荷Pc,利用式(3)可求得断裂韧度![]() 。图5所示为典型试件测试断裂韧度

。图5所示为典型试件测试断裂韧度![]() 时所采集的载荷—时间曲线。

时所采集的载荷—时间曲线。

图5 典型试件![]() 实测载荷—时间曲线

实测载荷—时间曲线

Fig.5 Load—time curve of typical specimen in testing ![]()

2.3 测试结果

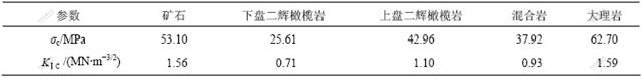

表2所示为5组岩石Ⅰ型断裂韧度![]() 测试值。

测试值。

表2 断裂韧度![]() 测试值

测试值

Table 2 Fracture toughness ![]() testing value

testing value ![]() /(MN·m-3/2)

/(MN·m-3/2)

3 断裂韧度与抗压强度相关规律

理论上,抗压强度越高,其抵抗裂纹扩展的能力增强,即断裂韧度越大。表3所示为5组岩石的抗压强度和断裂韧度,图6所示为岩石抗压强度与Ⅰ型断裂韧度的变化关系。从图6可以看出,Ⅰ型断裂韧度随抗压强度的增加而增加,理论结果与实际结果一致。

表3 岩石断裂韧度![]() 和抗压强度σc

和抗压强度σc

Table 3 Fracture toughness and compression strength of rock

图6 Ⅰ型断裂韧度随抗压强度变化关系

Fig.6 Relationship between Mode -Ⅰ fracture toughness and compression strength

4 结 论

a. 利用Instron1342型电液伺服材料试验机,采用单轴压缩试验和双扭常位移松弛试验对矿石、上盘二辉橄榄岩、下盘二辉橄榄岩、大理岩、花岗岩5组岩石的力学参数进行了试验研究,获得了相应的Ⅰ型断裂韧度、抗压强度等试验数据,分析了岩石断裂韧度与抗压强度之间的关系。

b. 随着抗压强度的增加,岩石的Ⅰ型断裂韧度也增大,与实际结果一致,且呈很好的线性关系,其关系为:![]() =0.026 5σc+0.001 4 (相关系数R2=0.94)。

=0.026 5σc+0.001 4 (相关系数R2=0.94)。

c. 由于抗压强度测试方法简单,而断裂韧度测试方法较复杂,基于该关系式,可由易于测试的抗压强度估算Ⅰ型断裂韧度。

参考文献:

[1] 陈 枫. 岩石压剪断裂的理论与实验研究[D]. 长沙: 中南大学资源与安全工程学院, 2002.

CHEN Feng. Study on theory and experiment of compressive- shear fracture[D]. Changsha: School of Resources and Safety Engineering, Central South University, 2002.

[2] Lajtai E Z. A theoretical and experimental evaluation of Griffith theory of brittle fracture[J]. Tectonophysics, 1971, 11(2): 129-156.

[3] Bazant Z P. Crack band theory for fracture of concrete[J]. Materials and Structures, 1983, 16(2): 155-177.

[4] Santiago S D, Hilsdorf H K. Fracture mechanism of concrete under compressive loads[J]. Cement and Concrete Research, 1973, 3(4): 363-388.

[5] Ebrahimi M E, Chevalier J, Fantozzi G. Slow crack growth behavior of alumina ceramics[J]. Journal of Materials Research, 2000, 15(1): 142-147.

[6] Nemat-Nasser S, Horii H. Compression-induced non-planar crack extension with application to splitting, exfoliation and rockbursts[J]. Journal of Geophysics Research, 1982, 87(B8): 6805-6821.

[7] Melin S. When does a crack grow under mode Ⅱ conditions[J]. International Journal of Fracture, 1986, 30(1): 103-104.

[8] LI Jiang-teng, CAO Ping, YUAN Hai-ping. Testing study of subcritical crack growth velocity and fracture toughness of marble[J]. Journal of Coal Science & Engineering (China), 2005, 11(1): 23-25.

[9] Zhang Z X. An empirical relation between mode I fracture toughness and the tensile strength of rock [J]. International Journal of Rock Mechanics & Mining Sciences, 2002, 39(3): 401-406

[10] Brown G J, Reddish D J. Experimental relationship between rock fracture toughness and density [J]. International Journal of Rock Mechanics & Mining Sciences, 1997, 34(1): 153-155.

[11] 李江腾. 硬岩矿柱失稳及时间相依性研究[D]. 长沙: 中南大学资源与安全工程学院, 2005.

LI Jiang-teng. Study on instability and time dependence of pillar in hard rock mass[D]. Changsha: School of Resources and Safety Engineering, Central South University, 2005.

[12] 袁海平, 曹 平, 周正义. 金川矿岩亚临界裂纹扩展试验研究[J]. 中南大学学报: 自然科学版, 2006, 37(2): 381-384.

YUAN Hai-ping, CAO Ping, ZHOU Zheng-yi. Testing study of subcritical crack growth of ore in Jinchuan mine[J]. Journal of Central South University: Science and Technology, 2006, 37(2): 381-384.

[13] CAO Ping, LI Jiang-teng, YUAN Hai-ping. Testing study of subcritical crack growth and fracture toughness in different rocks[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 709-713.

[14] Andreas K, Eckhard P, Jorg W, et al. Subcritical crack growth in Al2O3 with submicron grain size[J]. Journal of the European Ceramic Society, 2003, 23(1): 81-89.

[15] Ciccotti M, Gonzato G, Mulargia F. The double torsion loading configuration for fracture propagation: an improved methodology for the load-relaxation at constant displacement[J]. International Journal of Rock Mechanics & Mining Sciences, 2000, 37(7): 1103-1113.

[16] Ciccotti M, Negri N, Gonzato G, et al. Practical application of an improved methodology for the double torsion load relaxation method[J]. International Journal of Rock Mechanics & Mining Sciences, 2001, 38(4): 569-576.

[17] 于骁中. 岩石和混凝土断裂力学[M]. 长沙: 中南工业大学出版社, 1991.

YU Xiao-zhong. Fracture mechanics of rock and concrete[M]. Changsha: Press of Central South University of Technology, 1991.

收稿日期:2008-10-25;修回日期:2009-01-08

基金项目:国家自然科学基金资助项目(50774093);中国博士后科学基金资助项目(20060400264);中南大学博士后科学基金资助项目(20060400264)

通信作者:李江腾(1964-),女,湖南株洲人,博士,教授,从事岩土工程的研究;电话:13973113109;E-mail: ljtcsu@163.com