Nonlinear temperature characteristic of thermal expansion of Grf/Mg composites

SONG Mei-hui (宋美慧), XIU Zi-yang(修子扬), WU Gao-hui(武高辉), CHEN Guo-qin(陈国钦)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 10 June 2009; accepted 15 August 2009

Abstract:

Graphite fiber reinforced magnesium matrix(Grf/Mg) composites were fabricated by squeeze casting technology. M40 graphite fibers were reinforced to AZ91D and ZM6, their thermal expansion behaviors of M40/AZ91D and M40/ZM6 composites in the temperature range from 20 to 490 ℃ were investigated. The results show that the interfacial species and thermal stress have significant influence on the thermal expansion behavior of the composites. Simultaneously, the longitudinal coefficient of thermal expansion of Grf/Mg composites are affected by the thermal stress, interfacial species and yield strength of matrix alloy, it also decreases with increasing temperature and descending rate of longitudinal coefficient of thermal expansion(CTEs) of Grf/Mg composites changed in different temperature ranges. In terms of different descending rates, the curve of coefficient of thermal expansion vs temperature can be divided into three stages. The matrix alloys M40/AZ91D and M40/ZM6 yield at 170 and 155℃ in the thermal expansion, respectively.

Key words:

magnesium matrix composites; thermal expansion; interface; thermal stress;

1 Introduction

Graphite fibers reinforced lightmass metals (e.g. Al and Mg) are one of the main metal matrix composites which have the highest specific strength and specific stiffness[1]. They have many advantages such as low density, low coefficient of thermal expansion(CTEs), high thermal and electrical conductivity and excellent dimensional stability[2-3]. Compared with conventional polymer-based composites, Grf/Mg can offer significant gains in terms of transverse strength, stiffness, thermal and electrical conductivity besides resistance to radiation, moisture and fire. Moreover, a zero or near-zero CTEs over a wide temperature range can be achieved by the correct selection of fibers volume fraction[4-5]. Therefore, they have been identified as potential candidate materials for primary structural element applications in high-precision spacebased systems[6]. Currently, they are mainly used in the manufacture of large-scale optical system components, as well as spatial structures of high precision, such as mirror of space optical systems, satellite, radar antenna, waveguide and board with installed instruments in the space station[7-11].

The thermal expansion behavior of continuous fibers reinforced metal matrix composites is influenced by many factors, including the properties of the matrix and fibers, content and arrangement of fibers, interfacial properties, and thermal stress due to the mismatch of the CTEs between the fibers and matrix and so on[12-14]. Interface plays important roles in the load transfer and stress relaxation[15-16]. Attributed to the fall of the interfacial bonding strength and the increase of thermal stress along the fibers direction, the interfacial properties would change with temperature, therefore sliding or debonding occur between the interfaces. All of these will affect the restriction of fibers on the matrix, thus lead to the change of CTEs with temperature[19-20].

In this work a research was carried out on the thermal expansion behavior of Grf/Mg composites. The strain changing with temperature and the role of thermal stress on the matrix were investigated. The influence of interfaces species on thermal expansion behavior was also discussed.

2 Experimental

2.1 Materials

Unidirectional M40 fibers (60%, volume fraction) reinforced magnesium matrix composites were prepared by squeeze casting method. AZ91D and ZM6 were used as matrix alloys. The chemical compositions of these alloys were as follows. AZ91D: 9% (mass fraction) Al, 1% Zn, 0.2% Mn. ZM6: 2.8% RE, 0.2% Zn, 0.5% Zr. The basic properties of M40 fiber and matrix alloys are listed in Table 1.

Table 1 Properties of M40 fiber and matrix alloys

2.2 Test

The longitudinal thermal expansion behavior in the temperature range at 20-490 ℃ was measured on a DIL 402C dilameter, with a heating rate of 5 ℃/min and a helium atmosphere flowing rate of 50 mL/min. The specimens with size of 4.3 mm×4.3 mm×25 mm were used in this work. The average CTEs at various temperatures were obtained by the thermal expansion curves.

The microstructures and interfaces between the matrix and fibers were observed by a ZEISS-40MAX optical micrograph(OM) and a PhilipsCM-12 transmission electron micrograph(TEM).

3 Results and discussion

3.1 Microstructure

The microstructures of the interface Grf/Mg composites are shown in Fig.1. It should be noted that the discontinuous needle-shaped precipitate and blocky precipitate are evident at the interface, which are indicated to be Al4C3 and Mg17Al12 by electron diffraction, respectively. Mg12Nd phase forms along the adjacent fibers in M40/ZM6 composites. In the graphite fiber reinforced magnesium composites, the fiber and matrix alloy are non-wetting and thus they are bonded by mechanical bonding, which is a weak type of bonding. To a certain extent, the interfacial reaction enhances the interfacial bonding strength and friction of interfacial slipping. Therefore, with increasing temperature, the expansion of matrix alloy will be restricted by fibers and lead to longitudinal strain of Grf/Mg composites.

3.2 Nonlinear temperature characteristic of thermal expansion behaviors

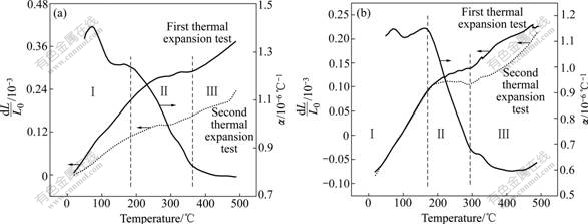

The thermal expansion curves and CTEs of matrix alloys and Grf/Mg composites are shown in Figs.2 and 3, respectively. As shown in Figs.2 and 3 that the strain of composites and matrix alloys appear to have different variation laws with temperature. By comparing the strain response shown in Fig.3(a), it is apparent that the knee occurs at 250 ℃ in Fig.3(a) and at a lower temperature (200 ℃) in Fig.3(b).

The coordination of fiber and matrix strain during the thermal expansion are realized by interface sliding [11,15], which results in fibers protruding significantly from the matrix, as shown in Fig.4. In order to further verify the function of interface to thermal expansion behaviors of the composites, the same tests were took a second time, using the same samples in the first test. All the results in Fig.4 show why the thermal expansion curves change remarkably compared with these in the first test. The strains of both kinds of composite increases with the elevation of temperature and the knees of thermal strain curves of two kinds composites are short. It is believed that high temperature reduces the restriction of graphite fibers on the matrix after the first thermal expansion test. This is why the thermal expansion increases as temperature rises during the second test.

3.3 CTEs of Grf/Mg composites

According to Figs.2 and 3, the mean values of CTEs in different temperature ranges are calculated. The CTEs

Fig.1 Microstructures of interface of Grf/Mg composites: (a) M40/AZ91D; (b) M40/ZM6

Fig.2 Thermal expansion curves and CTEs of matrix alloys: (a) AZ91D; (b) ZM6

Fig.3 Thermal expansion curves and CTEs of Grf/Mg: (a) M40/AZ91D; (b) M40/ZM6

Fig.4 SEM micrographs of composites after thermal expansion test: (a) M40/AZ91D; (b) M40/ZM6

of Grf/Mg composites are much lower than these of the magnesium matrix alloy. Compared to that of the magnesium matrix alloy, the change tendencies of the two kinds of composites with temperature are different. The longitudinal CTEs of Grf/Mg composites decrease with increasing temperature and it even falls to negative value when the temperature is above 400 ℃ (the average CTEs in the range of 0-400 ℃ are -0.03×10-6 ?C-1). Furthermore, the descending rate of CTEs of Grf/Mg composites changes in the range of different temperature. According to the different descending rate of CTEs, the CTE—temperature curve is divided into three stages: slow decline, rapid decline and slow decline again, i.e. Ⅰ, Ⅱ and Ⅲ stages in shown Fig.3.

As we know that the CTEs of Grf/Mg composites are affected by the thermal stress and interfaces between the matrix and fibers. When the temperature varies, the thermal stress would be distributed on the graphite fibers that produced by the mismatch of CTEs between the graphite fibers and matrix. So, the thermal stress paralleling to the fibers can be expressed as [17]

![]() (1)

(1)

where σf is stress of the fiber; αf and Ef are coefficients of thermal expansion and elastic modulus of the fiber, respectively.

When the temperature increases from T0 (293 K) to T, the axial tensile stress of fibers can be obtained through integral transformation of Eq.(1):

![]() (2)

(2)

Then, the thermal stress acting on the fibers is given by

![]() (3)

(3)

As the residual thermal stress caused in fabricate process has been relieved in annealing, σf(T0) in Eq.(3) can be negligible. Subsequently, the axial tensile stress of the fibers is then expressed as

![]() (4)

(4)

If no plastic deformation in the matrix is found, the inner stress is balanceable, that is[11]:

![]() (5)

(5)

where V is the volume fraction. The properties of the fiber and matrix are denoted by f and m subscripts, respectively.

Thus the thermal stress acting on matrix alloy can be expressed as

![]() (6)

(6)

where αT is the CTE of composites when temperature is T; αf is the CTE of fibers; V is the volume fraction.

Since the sm(T0) approximates to zero, the compressive stress acted on the matrix alloy during the expansion process of composites can be calculated according to Eq.(6). The results show that the compressive stress acted on matrix alloy gradually increases with increasing temperature. The thermal stress reaches the yield strength[18-20] of matrix alloy (AZ91D, 160 MPa; ZM6, 120 MPa, respectively) when the temperatures are 170 ℃ (M40/AZ91D) and 155 ℃ (M40/ZM6). This is similar to the division temperatures in stages Ⅰand Ⅱ in Fig.3.

When the temperature increases, the yield strength of matrix alloy and interfacial bonding strength between the fibers and matrix alloys reduce[11, 16]. Therefore, the variation of CTEs with temperature in Fig.3 can be explained as shown in Fig.5. In the first stage, when the thermal stress is smaller than the yield strength of the matrix alloy, the CTEs of composites reduced slowly confined by the positive expansion of matrix alloy. In the second stage, when the thermal stress is more than the yield strength of matrix alloy, the plastic deformation of matrix alloy occurs and leads to the stress relaxation. Then, the CTEs of composites are mainly controlled by fibers. Due to negative expansion, the descending rate of CTEs increases. Finally, in the third stage, the restriction of interface on the matrix alloy declines with increasing temperature. The CTEs of composites controlled by matrix alloy lead to the slow descending rate again.

Fig.5 Thermal stress model of Grf/Mg composites

4 Conclusions

1) Thermal expansion behavior compared to magnesium alloy is different in the Grf/Mg composites fabricated by squeeze casting technology. The thermal expansion is apparent and the knee occurs at a lower temperature for Grf/Mg composites.

2) The longitudinal CTEs of Grf/Mg composites are much lower than these of matrix alloy, as these are affected by thermal stress and species of interfaces in the composites, and decrease nonlinearly with increasing temperature. In terms of different descending rate, the CTE-temperature curve can be divided into three stages.

3) The calculation result of thermal stress acted on matrix alloy shows that the thermal stress increases with temperature during the thermal expansion process of Grf/Mg composites. The matrix alloys M40/AZ91D and M40/ZM6 yield at 170 and 155 ℃, respectively.

References

[1] LI Kun, PEI Yong-liang, GONG Jun, SHI Nan-lin, SUN Chao. Fabricating of SiO2 coating on carbon fibre and its application in Mg-based composite [J]. Acta Metallurgica Sinica, 2007, 43(12): 1282-1286.

[2] SVOBODA M, PAHUTOV? M, KUCHA?OV? K. Microstructure and creep behaviour of magnesium hybrid composites [J]. Mater Sci Eng A, 2007, 462: 220–224.

[3] ARMIN F, ECKHARD P, J?RG W. Interface engineering of carbon-fiber reinforced Mg-Al alloys [J]. Advanced Engineering Materials, 2000, 2(8): 471-481.

[4] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration [J]. Mater Sci Eng A, 2005, 391: 114-120.

[5] HAKTAN KARADENIZ Z, KUMLUTAS D. A numerical study on the coefficients of thermal expansion of fiber reinforced composite materials [J]. Composite Structures, 2007, 78: 1-10.

[6] ZHAO Hui-feng, XIA Cun-juan, MA Nai-heng, WANG Hao-wei, LI Xian-feng. Coating carbon fiber reinforced magnesium composite [J]. Material & Heat Treatment, 2007, 36(12): 37-39.

[7] K?RNER C, SCH?FF W, OTTM?LLER M, SINGER R F. Carbon long fiber reinforced magnesium alloys [J]. Advanced Engineering Materials, 2000, 2(6): 327-331.

[8] RAWAL S. Metal matrix composites for space applications [J]. JOM, 2001, 4: 14-17.

[9] HUFENBACH W, ANDRICH M, LANGKAMP A, CZULAK A. Fabrication technology and material characterization of carbon fibre reinforced magnesium [J]. Journal of Materials Processing Technology, 2006, 175: 218-224.

[10] RUSSELL-STEVENS M, TODD R, PAPAKYRIACOU M. Microstructural analysis of a carbon fibre reinforced AZ91D magnesium alloy composite [J]. Surface and Interface Analysis, 2005, 37: 336–342.

[11] RUSSELL-STEVENS M, TODD R, PAPAKYRIACOU M. The effect of thermal cycling on the properties of a carbon fibre reinforced magnesium composite [J]. Mater Sci Eng A, 2005, 397: 249–256.

[12] WENDT R, MISRA M. Fabrication of near-net shape graphite/magnesium composites for large mirrors [J]. Advances in Optical Structure Systems, 1990, 1303: 554-561.

[13] FEI Liang-jun, ZHU Xiu-rong, TONG Wei-jun. Fiber reinforced aluminum matrix composite and application [J]. Special Casting & Nonferrous Alloys, 2001, 1: 59-62.

[14] MA Zhi-jun, YANG Yan-qing, ZHU Yan. Progress in thermal residual stresses of continuous fiber reinforced titanium matrix composites [J]. Rare Metal Materials and Engineering, 2004, 33(12): 1248-1251.

[15] DUTTA I. Role of interfacial and matrix creep during thermal cycling of continuous fiber reinforced metal-matrix composites [J]. Acta Materialia, 2000, 48: 1055-1074.

[16] RUSSELL-STEVENS M, TODD R, PAPAKYRIACOU M. Thermal expansion behaviour of ultra-high modulus carbon fibre reinforced magnesium composite during thermal cycling [J]. Journal of Materials Science, 2006, 41: 6228–6236.

[17] QIN Yao-chun, HE Shi-yu, YANG De-zhuang. Effect of thermal mechanical cycling on thermal expansion behavior of boron fiber reinforced aluminum matrix composite [J]. Materials Chemistry and Physics, 2004, 86: 204-209.

[18] ZHANG Hong-jie, MENG Jian, TANG Ding-xiang. Investigation, exploitation and application of magnesium rare earth alloy as a structure material [J]. Journal of the Chinese Rare Earth Society, 2004, 22(1): 40-47.

[19] WANG Hong-hua, LI Xie-gan, ZHANG Guo-ding. Effects of the varieties of matrix and fiber on the thermal expansion behaviors of composites [J]. Materials for Mechanical Engineering, 1990, 1: 14-18.

[20] WANG Hong-hua, LI Xie-gan. Thermal expansion of Grf/Mg composites [J]. Aerospace Materials & Technology, 1995, 1: 41-44.

(Edited by LONG Huai-zhong)

Corresponding author: SONG Mei-hui; Tel: +86-451-86402373-4053; E-mail: smh1980@126.com