Effects of heat treatment on microstructure and mechanical properties of Mg-3Sn-1Mn magnesium alloy

YANG Ming-bo1, 2, 3, QIN Cai-yuan1, PAN Fu-sheng3

1. Materials Science and Engineering College, Chongqing University of Technology, Chongqing 400054, China;

2. Key Laboratory of Automobile Components Manufacturing and Testing Technology of the Education Ministry, Chongqing University of Technology, Chongqing 400054, China;

3. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400030, China

Received 29 October 2010; accepted 14 February 2011

Abstract:

The effects of heat treatment on the microstructure and mechanical properties of Mg-3Sn-1Mn alloy were preliminarily investigated by using optical and electron microscopy, X-ray diffraction (XRD) analysis, and tensile and creep test. The results indicate that the heat treatment has an obvious effect on the microstructure and mechanical properties of the Mg-3Sn-1Mn alloy. After the solid solution treatment at 420 °C, a majority of the Mg2Sn phases in the alloy are dissolved into the matrix. However, after the further aging treatment at 250 °C, lots of fine Mg2Sn phases in the aged alloy are precipitated at the grain boundaries and within the grains. As a result, the tensile and creep properties of the aged alloy are significantly improved. The mechanism for the higher tensile and creep properties of the aged alloy is related to the dispersive distribution of the Mg2Sn phase in the a-Mg matrix.

Key words:

Mg-Sn-Mn alloy; heat treatment; microstructure; mechanical properties;

1 Introduction

Magnesium alloys are the lightest structural alloys commercially available and have great potential for applications in automotive, aerospace and other industries. At present, the most widely used magnesium alloys contain Al as a major alloying element. However, the application of commercially available Mg-Al-based alloys is limited at elevated temperatures by their poor creep behaviour at temperatures exceeding 120 °C [1]. Therefore, attempts have been made to develop new magnesium alloys having improved structural stability at high temperatures. Among many possibilities, Mg-Sn based alloys are of special interest [2-4]. Recently, great efforts have been made on searching suitable alloying elements in Mg-Sn system, and the results indicated that the mechanical properties of Mg-Sn based alloys may be further enhanced by adding RE [5-7], Ca [8-11], Zn and Mn as the ternary alloying elements. It is well known that Mn is conventionally added into Mg-Al and Mg-Zn based alloys to improve the corrosion resistance. In addition, according to the investigations of BURSIK et al [11], the creep resistance of the Mg-xSn-1Mn (x=3%, 5%, mass fraction) ternary alloys is relatively higher than that of the Mg-3Sn-xCa and Mg-5Sn-xCa alloys (x=0.5%-2%, mass fraction) which are thought to can offer superior creep properties even compared with the creep resistant magnesium alloy AE42 (Mg-4Al-2RE) [12-14]. Therefore, Mg-Sn-Mn system alloys are thought as a potential corrosion and creep resistant magnesium alloys.

Though the above works have been carried out to develop Mg-Sn-Mn alloys, these works mainly focused on the as-cast microstructural characterization and/or mechanical property of a limited number of Mg-Sn-Mn alloys [11, 15-17]. It is well known that the solubility of Sn in the a-Mg decreases from 14.85% (mass fraction) at the eutectic transformation temperature of 561 °C to less than 0.45% at 200 °C [18]. This means that the Mg2Sn phase, mainly distributed at the boundaries of the as-cast Mg-Sn alloys, will be redistributed homogeneously in the a-Mg matrix through the solutionizing and aging-treatments, which will enhance mechanical properties at both ambient and elevated temperatures. But up to now, the investigations about the improvement in strength and creep performance of Mg-Sn-Mn alloys via heat treatment are very scarce in the literature. Based on the above mentioned reasons, the present work preliminarily investigates the effect of heat treatment on the microstructure and mechanical properties of Mg-3Sn-1Mn magnesium alloy.

2 Experimental

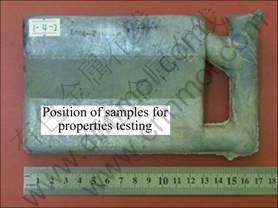

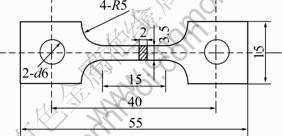

The Mg-3Sn-1Mn (mass fraction, %) alloys were prepared by adding pure Mg and Sn (> 99.9%, mass fraction), and Mg-4.38% Mn (mass fraction) master alloy, which were melted in a resistance furnace and protected by 2% (mass fraction) RJ-2 flux (45% MgCl + 37% KCl +8% NaCl + 4% CaF + 6% BaCl). When the melt temperature approximately reached 740 °C, the melt was homogenized by mechanical stirring. After complete mixing, the melt was held at 740 °C for 20 min and then poured into a preheated permanent mould in order to obtain a casting shown in Fig. 1. The specimens shown in Fig. 2 were fabricated from the casting for tensile and creep tests. The actual composition in mass fraction of the experimental alloy inspected by inductively coupled plasma spectroscopy (ICP) is given as follows: 96.32% Mg, 2.81% Sn and 0.87% Mn.

Fig. 1 Casting with fabricated area of samples for mechanical properties tests

Fig. 2 Configuration of samples used for tensile and creep tests (unit: mm)

In order to investigate the effects of heat treatment on the microstructure and mechanical properties of the experimental alloy, the as-cast samples of the experimental alloy were given a solid solution treatment and followed by aging treatment. Based on the Mg-Sn binary phase diagram [18], the solutionized temperature of 420 °C, which is slightly less than the solutionized temperature of 450-480 °C for the Mg-5%Sn alloy [19-20], was selected for the experimental alloy. In a muffle furnace and under CO2 atmosphere protection, the solution heat treatment of the experimental alloy was carried out at 420 °C for 4-36 h and followed by water quenching. Then, the solutionized samples were aged at 250 °C for 40 h. Every 4 h, a sample was drawn from the oven and followed by atmosphere cooling.

The as-cast and heat-treated samples of the experimental alloy were respectively etched in an 8% nitric acid solution in distilled water and a solution of 1.5 g picric, 25 mL ethanol, 5 mL acetic acid and 10 mL distilled water, and then examined by using an Olympus optical microscope and JEOL/JSM-6460LV type scanning electron microscope (SEM) equipped with Oxford energy dispersive spectrometer (EDS) with an operating voltage of 20 kV. The phases in the experimental alloys were analyzed by D/Max-1200X type X-ray diffraction (XRD) operated at 40 kV and 30 mA. The Vickers hardness of the heat-treated alloys was measured by a HD-1000TM digital microhardness tester with a load of 0.25 N. The tensile tests were performed by CMT5105 type electromechanical universal testing machine of M/s MTS System (China) Co., Ltd. The tensile properties of the as-cast and aged alloys at room temperature and 150 °C were determined from a stress—strain curve. The ultimate tensile strength (UTS), 0.2 % yield strength (YS) and elongation to failure (Elong.) were obtained based on the average of three tests. The constant-load tensile creep tests were performed by GWTA105 type high temperature creep and relaxation testing machine of M/s MTS System (China) Co., Ltd. The total creep strain and the minimum creep rate of the as-cast and aged alloys at 150 °C and 50 MPa for 100 h were respectively measured from each elongation versus time curve and averaged over three tests.

3 Results and discussion

3.1 As-cast microstructure

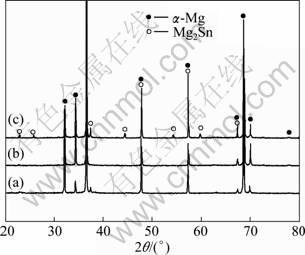

Figure 3 shows the XRD patterns of the as-cast and heat-treated alloys. It is found from Fig. 3 that the as-cast alloy is mainly composed of a-Mg and Mg2Sn phases, no any Mn-containing phases are formed. Furthermore, it is found that the solutionized and aged alloys are still composed of a-Mg and Mg2Sn phases. However, the Mg2Sn phase in the solutionized and aged alloys has lower and higher peak intensities than that in the as-cast alloy, respectively, indicating that the amount of the Mg2Sn phase in the solutionized and aged alloys is smaller and larger than that in the as-cast alloy, respectively.

Fig. 3 XRD patterns of experimental alloys: (a) As-cast alloy; (b) Alloy solutionized at 420 °C for 24 h; (c) Alloy aged at 250 °C for 16 h

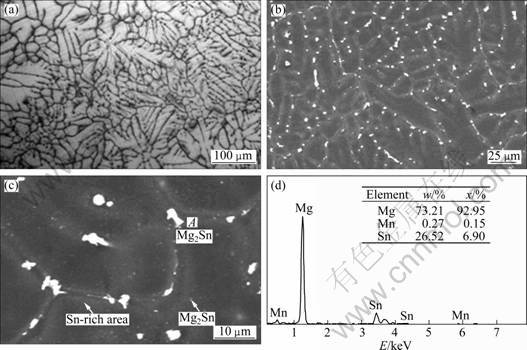

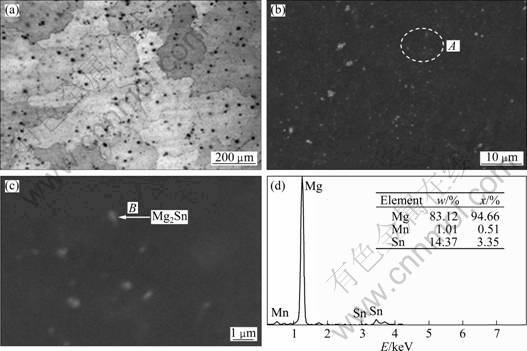

Figure 4 shows the microstructure of the as-cast alloy. It is observed from Fig. 4(a) that the primary a-Mg phase in the as-cast alloy consists of a relatively coarse dendritic microstructure with a secondary dendritic arm spacing of about 25.4 mm. By combining the XRD and EDS results, the intermetallic compounds are identified as Mg2Sn phase mainly distributed at the grain boundaries, and small amounts of Mg2Sn present within grains. In addition, the Sn-rich area is clearly observed in the as-cast alloy.

3.2 Microstructure and hardness of heat-treated alloy

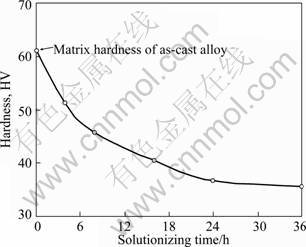

Figure 5 shows the effect of the solutionizing time on the matrix hardness of the experimental alloy. As seen in Fig. 5, for the given solutionized temperature of 420 °C, an increase in the solutionizing time from 4 h to 24 h causes the hardness to gradually decrease. However, along with further increase in the solutionizing time from 24 h to 36 h the change in the hardness is not obvious, which indicates that for the given solutionized temperature of 420 °C the solutionizing time of 24 h is relatively optimal for the experimental alloy. Figure 6 shows the microstructure of the experimental alloy solutionized at 420 °C for 24 h. It is found from Fig. 6 that, after the solid solution treatment at 420 °C for 24 h, the microstructure of the experimental alloy has changed to a nearly equiaxed grain structure with an average grain size of 275 mm. Compared with Figs. 4 and 6, it is further found that a majority of the Mg2Sn phases in the alloy have dissolved into the matrix after the solid solution treatment. Obviously, the above observed-effect of the solutionizing time on the matrix hardness is possibly related to the dissolution of the Mg2Sn phase during the solid solution treatment.

Fig. 4 Optical and SEM images of as-cast alloy: (a) Optical image; (b), (c) SEM image; (d) EDS results of position A in (c)

Fig. 5 Effect of solutionizing time on matrix hardness of experimental alloy

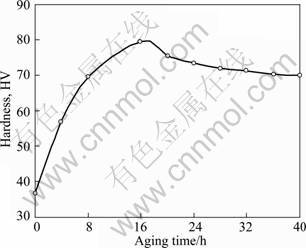

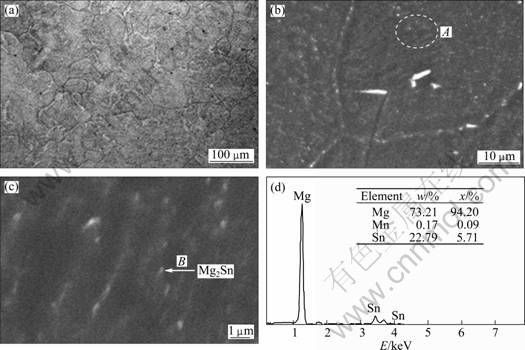

Figure 7 shows the effect of the aging time on the matrix hardness of the experimental alloy solutionized at 420 °C for 24 h and followed by water quenching. As seen in Fig. 7, for the given aged temperature of 250 °C, the hardness first increases along with aging time increase from 4 h to 16 h and attains the maximum at 16 h beyond that it gradually decreases, indicating that the experimental alloy has the obvious aging hardening behavior. Figure 8 shows the microstructure of the peak-aged experimental alloy. It is observed that lots of relatively fine precipitates are distributed mainly at the grain boundaries and within the grains. According to the investigations of LIU et al [20], the fine precipitates at the grain boundaries and within the grains are possibly related to the continuous nonuniform and uniform precipitations of Mg2Sn during the aging treatment, respectively. Furthermore, the EDS results confirm that these precipitates are Mg2Sn phases. Obviously, the higher volume fraction of the Mg2Sn phase in the aging-treated alloy is in consistent with the XRD result.

3.3 Tensile and creep properties

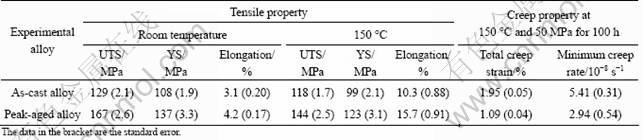

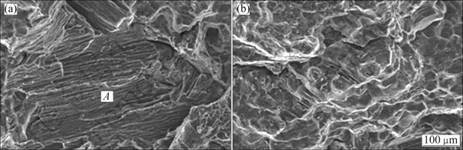

The tensile properties including ultimate tensile strength (UTS), 0.2% yield strength (YS), elongation, and creep properties for the as-cast and the peak-aged alloys are listed in Table 1. It can be observed from Table 1 that the aging treatment significantly improves the tensile properties of the Mg-3Sn-1Mn alloy. It is well known that the presence of fine and uniform phases distributed along the grain boundaries is easier to act as an effective straddle to the dislocation motion, improving the properties of engineering alloys [21]. Apparently, the relatively coarse Mg2Sn phases in the as-cast alloy would give a detrimental effect on the mechanical properties. Oppositely, lots of fine Mg2Sn phases which are uniformly dispersed in the aging microstructure possibly act as an effective straddle to the dislocation motion thus lead to the higher tensile properties. Actually, the difference in the tensile properties of the as-cast and aged alloys may be further confirmed from Fig. 9, which shows the SEM images of the tensile fractographs for the as-cast and peak-aged alloys tested at room temperature.

Fig. 6 Optical and SEM images of alloy solutionized at 420 °C for 24 h: (a) Optical image; (b) SEM image; (c) Local magnification of area A in (b); (d) EDS results of position B in (c)

Fig.7 Effects of aging time on matrix hardness of experimental alloy

As shown in Fig. 9, a number of cleavage planes and steps are present, and some minute lacerated ridges can also be observed in the localized areas of the tensile fracture surfaces, indicating that all the tensile fracture surfaces have mixed characteristics of cleavage and quasi-cleavage fractures. However, the fracture surface of the as-cast alloy exhibits relatively large cleavage-type facets (position A in Fig. 9(a)). On the other hand, the cleavage-type facet on the fracture surface of the aged alloy is relatively small. Therefore, as observed in Table 1, the aged alloy exhibits relatively high tensile properties while the properties of the as-cast alloy are relatively poor.

In addition, it is observed from Table 1 that the creep properties at 150 °C and 50 MPa for 100 h for the aged alloy are higher than those for the as-cast alloy. Since the creep properties of magnesium alloys are mainly related to the structure stability at high temperatures, the improvement of creep properties for the aged alloy is possibly related to the higher volume fraction of the Mg2Sn phase. Furthermore, in contrast to the as-cast alloy, in which the relatively coarse Mg2Sn particles are mainly distributed at the grain boundaries (Fig. 4), the intermetallic particles in the aged alloy are distributed inside the grains as well as at the grain boundaries (Fig. 8). Therefore, these particles can enhance the strength of both the grain interiors and their boundaries, by obstructing the dislocation annihilation and thus restricting the slip inside the grains during dislocation creep regimes, and also by inhibiting the grain boundary migration or grain boundary sliding during diffusion creep [19].

Fig. 8 Optical and SEM images of peak-aged alloy: (a) Optical image; (b) SEM image; (c) Local magnification of area A in (b); (d) EDS results of position B in (c)

Table 1 Tensile and creep properties of as-cast and peak-aged alloys

Fig. 9 SEM images of tensile fractographs tested at room temperature for different experimental alloys: (a) As-cast alloy; (b) Peak-aged alloy

4 Conclusions

1) The as-cast Mg-3Sn-1Mn alloy is mainly composed of a-Mg and Mg2Sn phases mainly distributed at the grain boundaries. After the solid solution treatment at 420 °C, a majority of the Mg2Sn phases in the alloy are dissolved into the matrix. However, after the further aging treatment at 250 °C, lots of fine Mg2Sn phases in the aged alloy are precipitated at the grain boundaries and within the grains.

2) The Mg-3Sn-1Mn alloy exhibits the obvious aging hardening behavior. After being solutionized at 420 °C for 24 h and aged at 250 °C for 4-40 h, the hardness of the alloy first increases along with aging time increasing from 4 h to 16 h and attains the maximum at 16 h beyond that it gradually decreases.

3) The mechanical properties of the Mg-3Sn-1Mn alloy can be improved by the heat treatment. After being solutionized at 420 °C for 24 h and aged at 250 °C for 16 h, the ultimate tensile strength, yield strength and elongation at room temperature and 150 °C are obviously increased. At the same time, the minimum creep rate at 150 °C and 50 MPa for 100 h is obviously decreased. The mechanism for the higher tensile and creep properties of the aged alloy is related to the dispersive distribution of the Mg2Sn phase in the a-Mg matrix.

References

[1] YANG M B, PAN F S, ZHANG J, ZHANG J. An analysis of the development and applications of current and new Mg-Al based elevated temperature alloys [J]. Mater Sci Forum, 2005, 488-489: 923-926.

[2] CHEN Dong, REN Yu-ping, GUO Yun, PEI Wen-li, ZHAO Hong-da, QIN Gao-wu. Microstructures and tensile properties of as-extruded Mg-Sn binary alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1321-1325.

[3] LIU Hong-mei, CHEN Yun-gui, TANG Yong-bai, HUANG De-ming, TU Ming-jing, ZHAO Min, LI Yi-guo. Effect of Zr-adding on microstructure and mechanical properties for Mg-5Sn alloy [J]. Rare Metal Materials and Engineering, 2006, 35(12): 1912-1915. (in Chinese)

[4] NAYYERI G, MAHMUDI R. Effects of Sb additions on the microstructure and impression creep behavior of a cast Mg-5Sn alloy [J]. Mater Sci Eng A, 2010, 527(3): 669-678.

[5] ZHAO Hong-da, QIN Gao-wu, REN Yu-ping, PEI Wen-li, CHEN Dong, GUO Yun. Microstructure and tensile properties of as-extruded Mg-Sn-Y alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S2): s493-s497.

[6] ZHAO Hong-da, REN Yu-ping, PEI Wen-li, GUO Yun, CHEN Dong, QIN Gao-wu. Determination of isothermal section of Mg-riched corner in Mg-Sn-Y ternary system at 500 °C [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 177-181. (in Chinese)

[7] ZHANG Xiao-ping, CHEN Yun-gui, XIAO Su-fen, TANG Yong-bai, NIU Gao, WEI Shang-hai, ZHAO Yuan-hua. Microstructure, tensile properties and compressive creep resistance of Mg-(5-8.5)%Sn-2%La alloys [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(S1): s299-s305.

[8] YANG Ming-bo, CHENG Liang, PAN Fu-sheng. Comparison of as-cast microstructure, tensile and creep properties for Mg-3Sn-1Ca and Mg-3Sn-2Ca magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 584-589.

[9] YANG M B, PAN F S. Effects of Y addition on as-cast microstructure and mechanical properties of Mg-3Sn-2Ca (wt.%) magnesium alloy [J]. Mater Sci Eng A, 2009, 525(1-2): 112-120.

[10] SHI Bin-qing, CHEN Rong-shi, KE Wei. Effect of element Gd on phase constituent and mechanical property of Mg-5Sn-1Ca alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S2): s341-s345.

[11] BURSIK J, BURSIKOVA V, JIRASKOVA Y, ABULEIL T, BLAWERT C, DIETZE W, HORT N, KAINER K U. Microstructure and mechanical properties of as-cast Mg-Sn-Ca and Mg-Sn-Mn alloys [C]//KAINER K U. Magnesium: Proceedings of the 7th International Conference Magnesium Alloys and Their Applications. Weinheim: WILEY-VCH Verlag GambH & Co KGaA, 2006: 37-42.

[12] ABULEIL T, HORT N, DIERINGA H, BLAWERT C, HUANG Y, KAINER K U, RAO K P. Development and characterization of a series of Mg-Sn-Ca alloys[C]//Proceedings of the Magnesium Technology in the Global Age, 45th Annual Conference of Metallurgists of CIM. Montreal, Canada, 2006: 739-749.

[13] HUANG Y, HORT N, ABULEIL T, KAINER K U, LIU Y. Effect of microstructural inhomogeneity on creep response of Mg-Sn alloys [J]. Key Eng Mater, 2007, 345-346: 561-564.

[14] ABULEIL T, HORT N, DIETZEL W, BLAWERT C, HUANG Y, KAINER K U, RAO K P. Microstructure and corrosion behavior of Mg-Sn-Ca alloys after extrusion [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 40-44.

[15] ZHANG Min, ZHANG Wen-zheng, ZHU Guo-zhi, YU Kun. Crystallography of Mg2Sn precipitates in Mg-Sn-Mn-Si alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1428-1432.

[16] ZHANG M, ZHANG W Z, ZHU G Z. The morphology and crystallography of polygonal Mg2Sn precipitates in a Mg-Sn-Mn-Si alloy [J]. Scripta Mater, 2008, 59(8): 866-869.

[17] SHI Zhang-zhi, ZHANG Wen-zheng. Designing Mg-Sn-Mn alloy based on crystallography of phase transformation [J]. Acta Metall Sinica, 2011, 47(1): 41-46. (in Chinese)

[18] MASSALSKI T B, OKAMOTO H. Binary alloy phase diagrams[C]//ASM Handbook. Materials Park, OH: ASM International, 1990: 45.

[19] NAYYERI G, MAHMUDI R. Enhanced creep properties of a cast Mg-5Sn alloy subjected to aging-treatment [J]. Mater Sci Eng A, 2010, 527(18-19): 4613-4618.

[20] LIU Hong-mei, CHEN Yun-gui, TANG Yong-bai, HUANG De-ming, TU Ming-jing, ZHAO Min, LI Yi-guo. Effects of heat treatment on microstructure and microhardness of Mg-5wt%Sn alloy[J]. Transactions of Materials and Heat Treatment, 2007, 28(1): 92-95. (in Chinese)

[21] BALASUBRAMANI N, PILLAI U T S, PAI B C. Optimization of heat treatment parameters in ZA84 magnesium alloy [J]. J Alloys Compd, 2008, 457(1-2): 118-123.

热处理对Mg-3Sn-1Mn镁合金组织和性能的影响

杨明波1, 2, 3, 秦财源1, 潘复生3

1. 重庆理工大学 材料科学与工程学院,重庆 400054;

2. 重庆理工大学 汽车零部件制造及检测技术教育部重点实验室,重庆 400054;

3. 重庆大学 国家镁合金工程研究中心,重庆400030

摘 要:通过光学和电子显微镜、XRD分析以及抗拉和蠕变测试,研究热处理对Mg-3Sn-1Mn镁合金组织和性能的影响。结果表明,热处理对Mg-3Sn-1Mn镁合金的组织和性能有明显影响。当在420 °C固溶处理后,合金中的大多数Mg2Sn相溶入基体。但在250 °C时效处理后,在时效合金的晶界和晶内析出大量细小的Mg2Sn相,从而时效合金的抗拉性能和蠕变性能被明显改善,其强化机理可能与a-Mg基体中Mg2Sn相的弥散析出有关。

关键词: Mg-Sn-Mn合金; 热处理;显微组织;力学性能

(Edited by YNAG Hua)

Foundation item: Project (50725413) supported by the National Natural Science Foundation of China; Project (2007CB613704) supported by the National Basic Research Program of China; Projects (2010AC4085, 2009AB4134 and 2006AA4012-9-6) supported by the Science and Technology Program of Chongqing, China; Project (2010CSTC-HDLS) supported by the Program for Hundreds of Distinguished Leading Scientists of CQ CSTC, China

Corresponding author: YANG Ming-bo; Tel: +86-23-62563176; E-mail: yangmingbo@cqut.edu.cn

DOI: 10.1016/S1003-6326(11)60990-4