文章编号:1004-0609(2011)08-1841-06

改进型ECAP路径对Al-Mg2Si原位复合材料

组织与力学性能的影响

边丽萍,梁 伟,马 建,张文利,薛晋波,王红霞,赵兴国

(太原理工大学 材料科学与工程学院,太原 030024)

摘 要:

采用一种结合BC、BA路径特点的改进型路径BC-UD2、在250 ℃对铸造Al-10.9%Mg2Si原位复合材料进行等通道转角挤压(ECAP)来细化组织、改善Mg2Si增强相形态及分布状态,考察其对力学性能的影响。结果表明:经BC-UD2路径8道次ECAP挤压后,复合材料基体由约100 μm发达的树枝晶组织细化为约1.5 μm的细晶粒组织;原先粗大的汉字状共晶Mg2Si相被细化为约0.85 μm的多边形状颗粒,趋于均匀分布状态,较常规BC路径中Mg2Si颗粒沿基体晶界聚集分布状态有很大改善;经BC-UD2路径挤压后复合材料的抗拉强度由铸态的166.9 MPa增大到331.8 MPa,伸长率由铸态的0.43%增加到23.6%,分别提高了99%和5 400%;同时也比BC路径挤压材料的抗拉强度(297.3 MPa)提高了12%,伸长率(15.15%)提高了56%,综合力学性能显著提高。

关键词:

Al-Mg2Si原位复合材料;等通道转角挤压;晶粒细化;颗粒分散;力学性能;

中图分类号:TB 331 文献标志码:A

Effect of modified ECAP route on microstructure and mechanical property of Al-Mg2Si in-situ composite

BIAN Li-ping, LIANG Wei, MA Jian, ZHANG Wen-li, XUE Jin-bo, WANG Hong-xia, ZHAO Xing-guo

(College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China)

Abstract: A modified equal channel angular pressing (ECAP) route BC-UD2 combining with the characteristics of routes BC and BA was employed to process an as-cast Al-10.9%Mg2Si in-situ composite at 250 ℃ to refine the microstructure and modify the morphology and distribution of Mg2Si reinforcements. The results show that after 8-pass ECAP processing the matrix is significantly refined from its original developed dendrites of about 100 μm in the as-cast state to equiaxed grains of about 1.5 μm, and the eutectic Mg2Si from coarse Chinese script cells to fine discrete polygonal particles of about 0.85 μm which are redistributed more homogeneously than those by the conventional route BC, where the refined Mg2Si particles still congregate seriously along the matrix grain boundary. Accordingly, the ultimate tensile strength and the elongation of the composite processed by route BC-UD2 are enhanced from 166.9 MPa and 0.43% in the as-cast state to 331.8 MPa and 23.46%, increased by 99% and 5 400%, respectively, and further increased by 12% and 56% when compared to those by route BC, and thus the comprehensive mechanical properties are enhanced remarkably.

Key words: Al-Mg2Si in-situ composites; equal channel angular pressing/extrusion; grain refinement; particle redistribution; mechanical property

以Mg2Si颗粒增强的Al基、Mg基复合材料具有低密度、高耐磨性和良好的铸造性等特点,在近年来已被列入新一类型颗粒增强金属基复合材料(PMMCs)[1]。在Al-Mg2Si复合材料中,Mg2Si不但是Al、Mg和Ti基体中常用颗粒增强体中密度最低的增强相,而且以Mg2Si增强的PMMCs呈现出比常规Al-Si合金更高的高温强度,因而有望取代传统Al-Si合金,在汽车和航天等领域得到应用[2]。然而,在常规熔炼铸造的Al-Mg2Si复合材料中,不仅初生Mg2Si颗粒尺寸粗大[3],而且由于存在粗大的Mg2Si共晶团、其共晶胞晶界构成了潜在的裂纹增殖途径[1],因而材料的力学性能不高,尤其是塑性较差,从而大大制约其在结构材料方面的应用。因此,粗大的Mg2Si相需要细化、并改善其形貌及分布,才能进一步提高材料的力学性能。目前,粗大Mg2Si增强相的细化方法主要如下:1) 添加晶粒细化剂,如混合稀土[4]、钠盐[5]、磷[6]、过剩Si[2];2) 通过先进的加工技术,如热挤 压[7]、快速凝固[8]和机械合金化[9]。然而,前者细化效果有限(迄今为止,文献报道的最小初生Mg2Si颗粒尺寸约为6 μm[1]),力学性能仍不令人满意(已报道的最高伸长率为8.3%[2]),后者成本过高,限制了其工程实际应用。

等通道转角挤压(Equal channel angular extrusion/ pressing, ECAP/ECAE)是一种低成本的能够显著细化组织[10]、并能在一定程度上改善增强相颗粒分布[11]、获得亚微米/超细晶块体材料的方法[12]。LIANG等[13]提出了一种晶粒细化效果好、颗粒分散明显、有别于常规4种ECAP挤压路径的新型路径BC-UD2,然而利用这一路径对Al-Mg2Si复合材料进行挤压的相关试验研究还未见报道。本文作者利用这一新型ECAP路径BC-UD2来挤压普通重力铸造Al-10.9%Mg2Si原位复合材料,以改善Mg2Si颗粒的大小、形貌及其分布,同时细化基体组织,通过与常规BC路径进行对比,考察其对材料组织细化、Mg2Si颗粒分散及其力学性能的影响。

1 实验

实验采用纯Al(99.9%)、纯Mg(99.8%)、Al-24%Si (质量分数)中间合金熔炼制备Al-10.9%Mg2Si原位复合材料(名义成分为Al-10%Mg-4%Si)。合金熔炼采用SXZ-5-2电阻炉,熔炼温度为740 ℃,保温20 min后,在700 ℃时浇铸入d 20 mm×150 mm的圆柱形金属模中。

将棒料用电火花线切割机加工成10 mm×10 mm×55 mm的试样,利用WDW-100KN型电子万能试验机在250 ℃、分别以BC-UD2路径[13](每2道次BC路径挤压后,试样倒转后再按BC路径挤压,即BC—BC—倒转+BC—BC—倒转+BC—BC—倒转+BC—BC)、BC路径(试样每第二次挤压时沿相同方向旋转90°(逆时针或顺时针方向))进行8道次等通道转角挤压(ECAP)。挤压速率为0.5 mm/s,挤压采用具有背压作用的自制模具[14],模具参数为Φ=90?,Ψ=20?。

将熔炼制备及经ECAP挤压后的Al-10.9%Mg2Si复合材料试样沿料棒纵截面加工成尺寸为15 mm×3.5 mm×2 mm的拉伸试样,在室温下进行拉伸试验。采用JSM-6700F型场发射扫描电子显微镜(FESEM)和H-800透射电子显微镜(TEM)对铸态及ECAP挤压态复合材料试样进行微观组织和断口形貌观察。SEM观察试样沿挤压试样3个相互垂直面X、Y和Z[12]截取。TEM观察试样沿挤压试样横截面方向切取。

2 结果与讨论

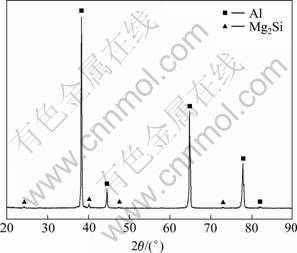

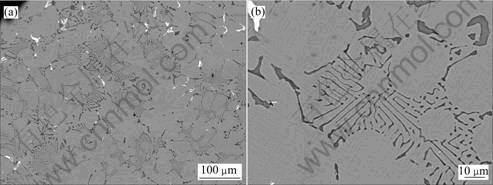

图1所示为铸态Al-10.9%Mg2Si复合材料的XRD像。分析可知,铸态Al-10.9%Mg2Si 复合材料由α(Al)和Mg2Si两相组成。如图2所示,初生α(Al)(浅灰色)约为100 μm的发达树枝晶组织,粗大的共晶Mg2Si(深灰色)呈汉字状沿α(Al)枝晶晶界分布(见图2(b))。白色物质为杂质铁形成的化合物。

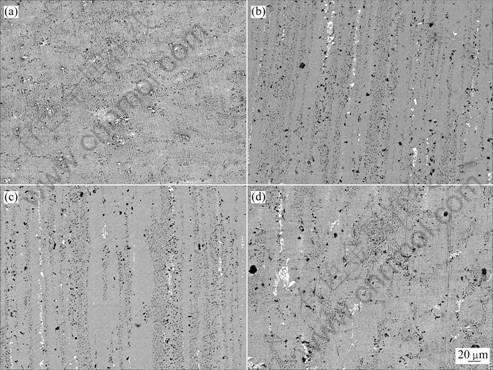

图3所示为Al-10.9%Mg2Si复合材料经不同路径ECAP 8道次挤压细化后Mg2Si颗粒的分布情况。如图3(a)~(c)所示, 经BC-UD2 路径挤压后,原先粗大的汉字状Mg2Si被显著细化,并在强烈变形过程中伴随着变形发生了较大程度的分散迁移,在X面上呈现较为均匀的分布状态,在Y和Z面Mg2Si颗粒趋于均匀分布,且在流变方向上具有一定的方向性。而经BC路径挤压后(见图3(d)),尽管粗大的Mg2Si增强相在强烈应变作用下破碎细化为小颗粒,但由于BC路径的冗余应变(Redundant strain,每4次挤压应变回复一次)特性,细化后的Mg2Si颗粒在X、Y和Z 3个面上均沿晶界呈聚集分布状态[15](因3个面上Mg2Si分布情况相同,简化起见,此处仅提供X面)。由两种路径所导致的Mg2Si颗粒分散程度不同,原因在于改进型路径BC-UD2开动的滑移系更为分散、每4次挤压后(一个循环周期)剪切面不具重复性[13]。

图1 铸态Al-10.9%Mg2Si合金的XRD谱

Fig.1 XRD pattern of as-cast Al-10%Mg2Si alloy

图2 铸态Al-10.9%Mg2Si合金的SEM像

Fig.2 SEM images of as-cast Al-10.9%Mg2Si alloy

图3 合金分别经BC-UD2和BC ECAP挤压后在X、Y和Z面Mg2Si颗粒分布的SEM像

Fig.3 SEM images of ECAP samples in three orthogonal planes X, Y and Z by routes BC-UD2 ((a)-(c)) and BC (d): (a) X plane; (b) Y plane; (c) Z plane; (d) X plane

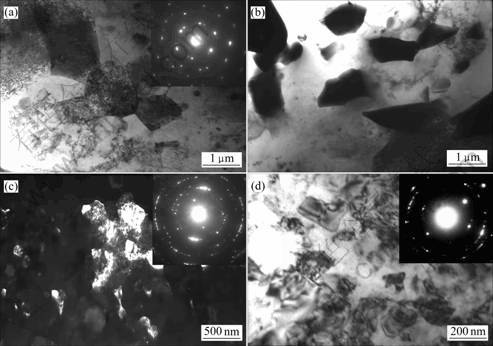

图4所示为复合材料经ECAP挤压后的TEM像及相应的选区衍射(SAD)谱。由图4可知:经BC-UD2路径挤压后,铸态时枝晶状α(Al)基体被细化约为1.5 μm的等轴晶粒,如图4(a)所示,晶内存在高密度位错,而原先粗大的汉字状Mg2Si相被破碎细化约为0.85 μm的多边形状小颗粒,同时在复合材料基体上也可观察到一定数量的纳米级Mg2Si小粒子,这是由于在高温强变形过程中Mg2Si颗粒发生的回溶与析出反复进行所致。经BC路径挤压后,α(Al)基体被细化约为231 nm的等轴晶(见图4(c)),Mg2Si相被细化至约为 151 nm的等轴颗粒(见图4(d))。从选取衍射斑点看,BC路径中基体晶粒取向更为分散,呈现大角度晶界特征(见图4(c)),而BC-UD2路径中基体晶粒呈现小角度晶界特征(见图4(a))。

图4 合金分别经路径BC-UD2和进行ECAP挤压后的TEM像及相应的SAD谱

Fig.4 TEM images and corresponding SAD patterns of ECAP alloys by route BC-UD2 ((a), (b)) and route BC ((c), (d)): (a), (c) α(Al)-rich region; (b), (d) Mg2Si-rich region

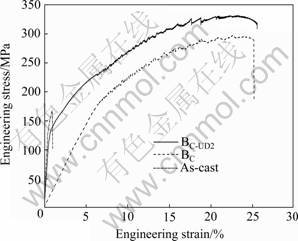

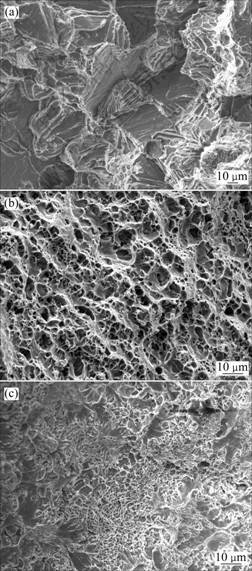

图5所示为复合材料在铸态及经不同路径进行ECAP挤压后的室温拉伸曲线。如图所示,经8道次ECAP挤压后,BC-UD2 路径力学性能最佳,抗拉强度σb达331.8 MPa,伸长率ε为23.6%,相比于铸态(σb= 166.9 MPa,ε=0.43%),抗拉强度提高了98.8%,伸长率提高了54倍;相比于BC路径(σb=297.3 MPa,ε=15.15%),抗拉强度提高了12%,伸长率提高了56%;同时也比文献[2]报道的通过压铸含更高含量Mg2Si的Al-15%Mg2Si-8%复合材料的力学性能(σb=329 MPa,ε=8.3%)有很大提高,伸长率是其2.84倍(见表1)。此外,从工程应力—应变曲线所围面积也可看出,BC-UD2路径中复合材料韧性相比于BC路径的也有很大提高。BC-UD2路径挤压导致复合材料强度、尤其是塑性的显著提高,其原因在于基体组织及增强相显著细化为微米/亚微米级晶粒组织;同时,由于Mg2Si小颗粒的相对均匀分散有效克服了BC路径中Mg2Si颗粒的沿晶界聚集状态,大大降低了颗粒团聚所引起的增强相与基体界面应力集中[16]、继而引发裂纹的早期形成倾向,Mg2Si颗粒增强基体作用得以充分发挥,从而进一步提高复合材料的强度和塑韧性。因此,尽管BC-UD2路径晶粒细化效果略低于BC路径的,但由于具有类似BA路径的能对细化后的Mg2Si颗粒进行有效的几何再分配[15],迫使在共晶组织中形核的裂纹在韧性α(Al)基体中扩展,避免晶界应力集中,基体塑性与增强相增强作用得以充分发挥,由此力学性能较BC-UD2 路径显著提高。

图5 Al-10.9%Mg2Si合金在铸态及经BC-UD2、BC路径8道次ECAP挤压后的工程应力—应变曲线

Fig.5 Engineering stress—strain curves of as-cast and 8-pass ECAP Al-10.9%Mg2Si alloys by routes BC-UD2 and BC, respectively

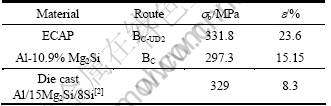

断口分析结果也表明,铸态复合材料由于粗大共晶Mg2Si相呈汉字状沿晶界分布,断口呈沿晶脆性断裂特征(见图6(a));而经BC-UD2 路径挤压后,复合材料断口呈韧性断裂,韧窝大而深,表现出很好的塑韧性(见图6(b));经BC路径挤压的复合材料断口,韧窝浅而细小,除主要的韧性断裂特征外,由于Mg2Si颗粒的偏聚分布,局部还可观察到河流状花样、呈现解理断裂特征(见图6(c))。

表1 Al-Mg2Si复合材料的室温拉伸性能

Table 1 Tensile properties of Al-Mg2Si composites at room temperature

图6 合金在铸态及BC-UD2路径和BC路径ECAP挤压态的室温拉伸断口形貌

Fig.6 Fractographs of Al-10.9%Mg2Si alloys in as-cast state (a) and through 8-pass ECAP processing by routes BC-UD2 (b) and BC (c)

3 结论

1) 经8道次BC-UD2路径挤压后,复合材料基体α(Al)由铸态时尺寸约为100 μm的树枝晶细化至尺寸约为1.5 μm的等轴晶;原先沿α(Al)枝晶晶界分布的粗大的汉字状共晶Mg2Si相被细化至尺寸约为0.85 μm的多边形状颗粒,细化后的Mg2Si颗粒伴随变形发生了较大程度的分散,在X、Y、Z 3个面趋于均匀化分布,明显改善了常规BC路径中Mg2Si增强相虽被细化、但沿晶界偏聚的分布状态。

2) 室温拉伸结果表明,经改进型路径BC-UD2挤压后,复合材料抗拉强度为331.8 MPa,伸长率为23.6%;相比于铸态,抗拉强度提高了98.8%,伸长率提高了约54倍;相比于BC路径,复合材料抗拉强度提高了12%,伸长率提高了56%。

3) 改进型ECAP路径BC-UD2在晶粒细化方面仅次于 BC路径,但其具有类似于 BA 路径的颗粒再分散功能,大大提高了Mg2Si颗粒分布的均匀性。因而,经BC-UD2路径挤压后的复合材料呈现出比BC路径挤压材料更高的综合力学性能,室温抗拉强度和伸长率较BC路径挤压材料分别提高了12%和56%,塑性的提高更为显著。

REFERENCES

[1] HADIAN R, EMAMY M, VARAHRAM N, NEMATI N. The effect of Li on the tensile properties of cast Al-Mg2Si metal matrix composite[J]. Mater Sci Eng A, 2008, 490(1/2): 250-257.

[2] ZHANG Jian, WANG Yu-qing, YANG Bing. Effects of Si content on the microstructure and tensile strength of an in situ Al/Mg2Si composite[J]. J Mater Res, 1999, 14(1): 68-74.

[3] MABUCHI M, KUBOTA K, HIGASHI K. Tensile strength, ductility and fracture of magnesium-silicon alloys[J]. J Mater Sci, 1996, 31(6): 1529-1535.

[4] ZHANG J, FAN Z, WANG Y Q, ZHOU B L. Microstructural development of Al-15wt.%Mg2Si in situ composite with mischmetal addition[J]. Mater Sci Eng A, 2000, 281(1/2): 104-112.

[5] ZHANG J, FAN Z, WANG Y, ZHOU B. Microstructural refinement in Al-Mg2Si in situ composites[J]. J Mater Sci Lett, 1999, 18(10): 783-784.

[6] LI Chong, LIU Xiang-fa, WU Yu-ying. Re?nement and modi?cation performance of Al-P master alloy on primary Mg2Si in Al-Mg-Si alloys[J]. J Alloys Compd, 2008, 465(1/2): 145-150.

[7] MABUCHI M, KUBOTA K, HIGASHI K. Effect of hot extrusion on mechanical properties of a Mg-Si-Al alloy[J]. Mater Lett, 1994, 19: 247-250.

[8] MABUCHI M, HIGASHI K. Strengthening mechanisms of Mg-Si alloys[J]. Acta Mater, 1996, 44(11): 4611-4618.

[9] FROMMEYER G, BEER S, von OLDENBURG K. Microstructure and mechanical properties of mechanically alloyed intermetallic Mg2Si-Al alloys[J]. Z Metallkde, 1994, 85(5): 372-377.

[10] 张 郑, 王经涛, 赵西成. 7475铝合金ECAP的晶粒细化极限[J]. 中国有色金属学报, 2004, 14(5): 741-745.

ZHANG Zheng, WANG Jing-tao, ZHAO Xi-cheng. Microstructure and grain refinement limit of 7475 aluminum alloy after equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 741-745.

[11] SABIROV I, KOLEDNIK O, VALIEV R Z, PIPPAN R. Equal channel angular pressing of metal matrix composites: Effect on particle distribution and fracture toughness[J]. Acta Materialia, 2005, 53(18): 4919-4930.

[12] VALIEV RUSLAN Z, LANGDON TERENCE G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[13] LIANG Wei, BIAN Li-ping, XIE Guo-yin. Transformation matrix analysis on the shear characteristics in multi-pass ECAP processing and predictive design of new ECAP routes[J]. Mater Sci Eng A, 2010, 527(21/22): 5557-5564.

[14] WANG Shun-qi, LIANG Wei, WANG Yu, BIAN Li-ping, CHEN Ke-hua. A modified die for equal channel angular pressing [J]. J Mater Process Technol, 2009, 209(7): 3182-3186.

[15] GARC?A-INFANTA J M, ZHILYAEV A P, CEPEDA- JIM?NEZ C M, RUANO O A, CARRE?O F. Effect of the deformation path on the ductility of a hypoeutectic Al-Si casting alloy subjected to equal-channel angular pressing by routes A, BA, BC and C[J]. Scripta Materialia, 2008, 58(2): 138-141.

[16] LLOYD D J. Aspects of fracture in particulate reinforced metal matrix composites[J]. Acta Metall Mater, 1991, 39(1): 59-71.

(编辑 龙怀中)

基金项目:大学生创新创业专项基金资助项目(08122067, 07010727);山西省留学人员基金资助项目(2007-25);山西省自然科学基金资助项目(2006011051)

收稿日期:2010-08-16;修订日期:2011-01-20

通信作者:边丽萍,讲师,博士研究生;电话/传真:0351-6018398;E-mail: bianliping_724@126.com.