Trans. Nonferrous Met. Soc. China 25(2015) 1353-1366

Microstructural approach to equal channel angular processing of commercially pure titanium—A review

Peiman Shahbeigi ROODPOSHTI, Nasim FARAHBAKHSH, Apu SARKAR, Korukonda Linga MURTY

North Carolina State University, USA

Received 3 September 2014; accepted 14 January 2015

Abstract:

A review on severe plastic deformation (SPD) technique of equal channel angular pressing (ECAP) process of commercially pure titanium (CP-Ti) alloys was presented with a major emphasize on the influence of ECAP parameters that include channel and curvature angles, processing route, temperature of operation, pressing speed, internal heating, number of pass through the die and back pressure. Various ECAP characteristics such as microstructure, strain inhomogeneity and mechanical properties are considered to achieve the maximum homogeneity, equilibrium grain refinement and mechanical improvement of CP-Ti. Investigations show that a pressing speed of 1-3 mm/s at 450 °C with route BC along with channel and curvature angles of 90° and 20° respectively with backpressure can lead to the most homogeneous ultrafine microstructure.

and 20° respectively with backpressure can lead to the most homogeneous ultrafine microstructure.

Key words:

equal channel angular pressing (ECAP); commercially pure titanium (CP-Ti); backpressure; channel angle; curvature angle; pressing speed;

1 Introduction

Titanium-based alloys with high specific strength play a significant role in various industries. Their excellent corrosion resistance, durability at elevated temperature, high specific strength, acceptable castability, good weldability, excellent biocompatibility [1] and lower density have introduced them as one of the ever-increasing interesting materials in automotive, aerospace and predominantly in biomedical as dental implants [1-8]. It is prevalent to add some alloying elements to hexagonal close packed (HCP) materials for improving their mechanical properties [9-14]; however, because most of the common alloying elements used in Ti alloys, such as Al and V in the popular Ti-6Al-4V alloy, are toxic [6,15] and may cause some illnesses, there is a high demand to use commercially pure (CP-Ti) Ti [3,16,17]. As a rule of thumb, the microstructure and mechanical properties of materials should meet some requirements to make them suitable for use as structural biomaterials to replace hard tissues[18-21]. Among all severe plastic deformation (SPD) methods [22-31], ECAP process (came to operation in Russia during the 1970s by SEGAL et al [32,33]) is conventional to produce homogeneous ultrafine grain microstructure with high angle grain boundaries [3,6,14,34-48], which helps to enhance the mechanical properties of materials and improve their adhesion to living cells and their proliferation [1,8,49]. Ultrafine-grained structure can result in lower friction coefficient and higher wear resistance. This is mainly due to the reduction of the adhesion component of friction coefficient [50]. Unlike many other ways of ultra-fine grain materials production [51], it can produce large bulk materials with acceptable density [22,35,52-57]. In ECAP process, one can apply various uniform strains on the material while preserving the original dimensions [36-38,58,59] reaching elevated strength and ductility [60]. Titanium, like other HCP metals [9], demonstrates low ductility, especially at lower temperatures due to their limited number of slip systems [6]. These alloys are categorized as difficult-to- work alloys [3,61-64]. Previous studies indicate that the ECAP processes of these alloys have been carried out at relatively high temperatures, low pressing speeds and high die angles. ECAP process is widely used for grain refinement of Ti, Cu, Ni, Mg, Al and Fe alloys [22,64-73].

It is conventional to develop nanostructure of CP-Ti for medical use by combining ECAP with a wide range of metal forming techniques including extrusion, rolling or forging [16,49,74]. VALIEV and RUSLAN [75] showed that a combination of ECAP and thermo mechanical treatment (TMT) on CP-Ti can lead to grain refinement from 300-400 nm to 100 nm after ECAP. This combination can improve the strength of material with the decreased ductility.

2 ECAP process

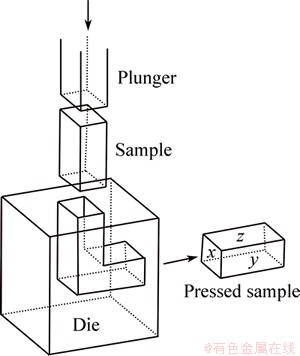

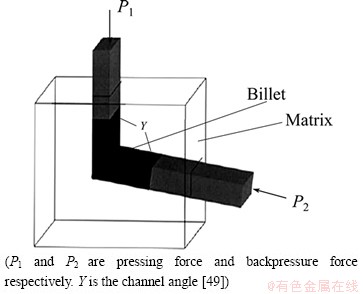

Although there are many reports of using the ECAP process for metallic powder consolidation [76-81], we emphasize here the grain refinement of solid metals. Figure 1 illustrates the principle of ECAP schematically. Two channels meet each other with a channel angle of f and curvature angle of Ψ. To avoid the grinding between each pass, it is conventional to design the entrance channel of the die bigger than its exit channel [82]. A sample, in the form of rod or bar can be pressed into the die [49]. The sample experiences a simple shear strain while passing through the mentioned angles. This process can be repeated several times to reach the desired microstructure.

Fig. 1 Schematic of ECAP process [83]

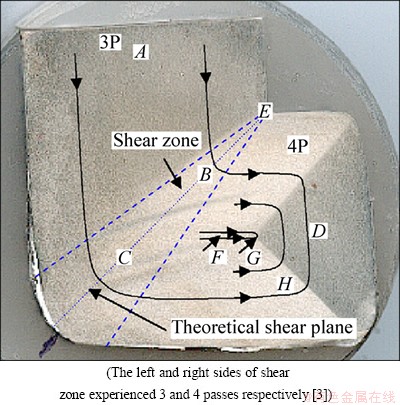

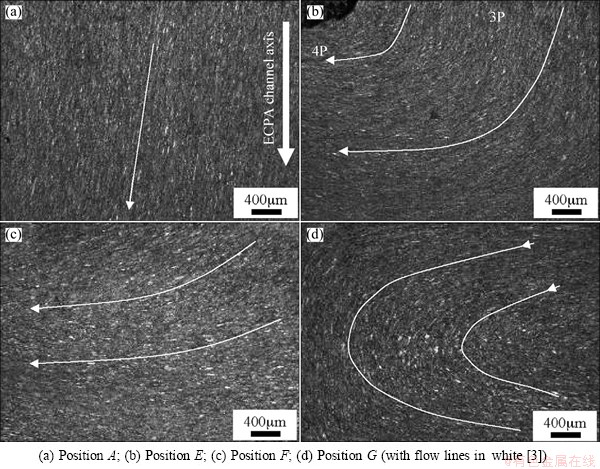

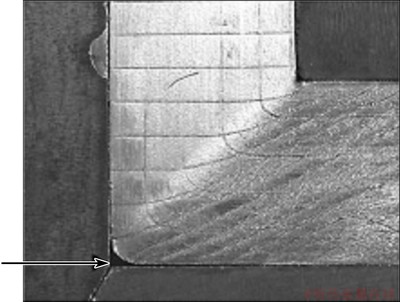

During the deformation process, some flow lines appear in the material with their direction highly dependent on the position of the specimen. Figure 2 shows a CP-Ti sample in the middle of the 4th pass (i.e., upper left side and lower right side of the sample experienced 3 and 4 passes respectively, 3P and 4P) and different parts of the sample are labeled by A to H. Figure 3 reveals the higher magnification of 4 different positions of the sample. White arrows help us to follow the direction of the flow lines. These lines show that the radius of the flow lines increases gradually from some parts near the channel angle (position E, Fig. 3(b)) to the center of the specimen (position F, Fig. 3(c)). It has a horizontal U shape at the position G [3]. Complicated flow lines appear close to the surface of the specimen due to the effect of friction. Further analysis shows that grain refinement (i.e., applied strain) strongly depends on these positions [58] with the center of the billet exhibiting the most homogeneous microstructure.

Fig. 2 Cross section of CP-Ti

3 Experimental

Experimental parameters play a critical role in altering the microstructure, strain inhomogeneity and mechanical properties of the ECAP-processed materials, as explained below [49,68,74,84].

3.1 Channel and curvature angles

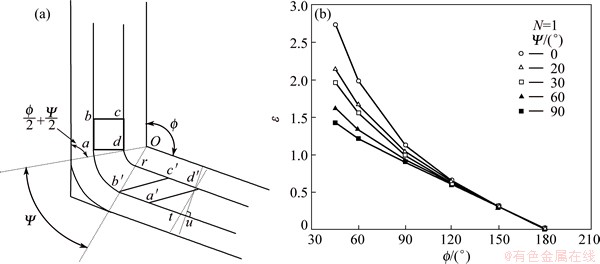

Channel angle (f) and curvature angle (Ψ), shown in Fig. 4(a), play a significant role in the total applied stress/strain during ECAP [49,68]. The lower the angles, the higher the imposed strain per pass [64,85]. The previous studies show that f=90°-120° and Ψ=0-20° are the most practical angles for various alloys such as titanium [6,59,65,86-88]. According to Eq. (1) [85], these angles result in an approximate strain of 0.5-1.0 in the first pass [68,85,89] (Fig. 4(b)).

(1)

(1)

where N is the number of pass and εN is the total amount of strain after N passes.

3.2 Processing routes

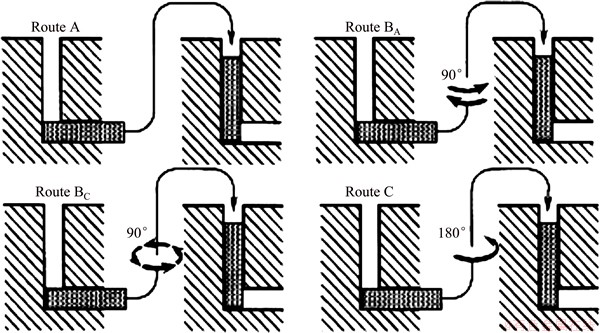

Processing routes can directly influence the microstructure [22,55,84,90]. During multiple ECAP passes, it is possible to rotate the sample along its longitudinal direction [35]. Among four different routes, demonstrated in Fig. 5, BC is the most conventional one to reach a homogeneous microstructure for most alloys [34,35,57,65,68,90-92], such as CP-Ti [5,16,35,59, 62,87,93,94], where the sample is rotated by 90° in the same direction between each passes [90]. In route A there is no rotation, BA has a rotation of 90° in alternate direction between passes and in route C the sample should experience a rotation of 180° between consecutive passes [49,85,92,94].

Fig. 3 Optical micrographs of 4 different positions

Fig. 4 Angles in ECAP (a) (f is the angle of intersection of two channels and Ψ is the angle subtended by the arc of curvature at the point of intersection [85] and variation of equivalent strain of single pass, with channel angles of 45°-180° and curvature angles of 0°-90°(b) [89]

Fig. 5 Four processing routes in ECAP [90]

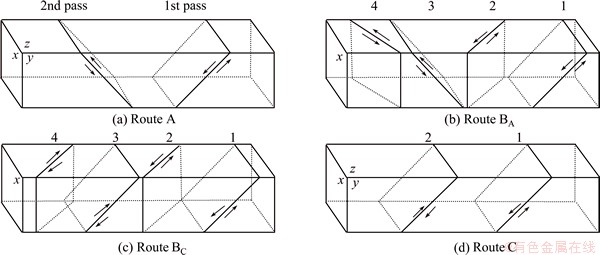

Previous studies show that various processing routes can activate different slip systems which lead to a wide range of microstructures. Figure 6 shows slip systems in X, Y and Z planes and the numbers 1, 2, 3 and 4 are related to the first, second, third and fourth passes respectively. It is clear that some routes are redundant strain processes. For example, in route C, the strain after every even number of process is restored. Route BC has similar situation and slip in the third and fourth passes can cancel the slip of the first and second passes respectively [49].

Fig. 6 Active slip system on X, Y and Z planes due to various processing routes [49]

Fig. 7 Optical microstructures of CP-Ti after first pass (a) and second pass (b) in route A, second pass in route B (c), and second pass in route C (d) [59]

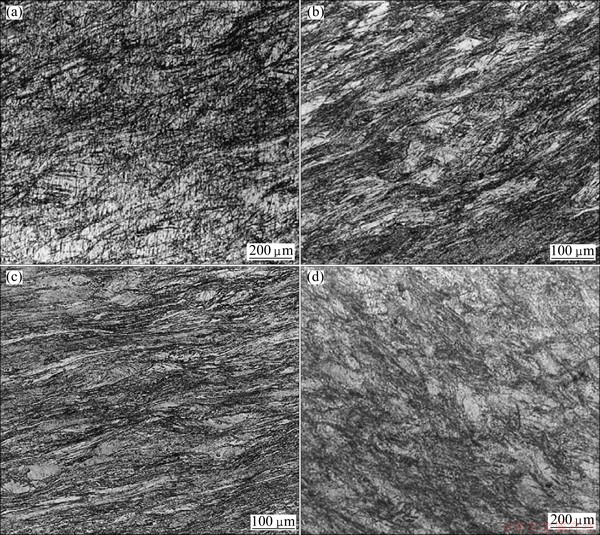

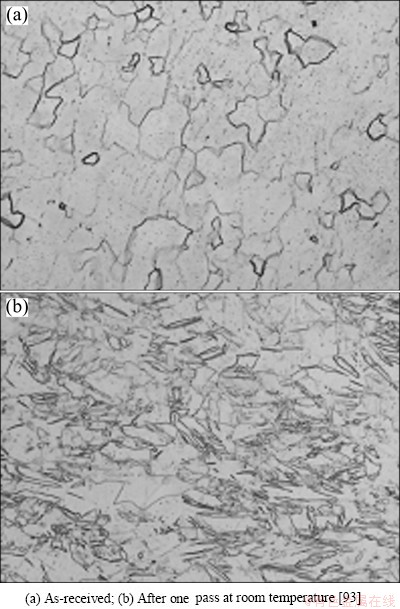

SHIN et al [59] revealed the dependency of processing routes on active slip systems in CP-Ti. They showed that  is the primary twinning deformation after the first pass [59,63]. By the end of the second pass in route A, deformation is controlled by basal slip and micro-twinning, and in route B, prism slip is active while in route C, there are prism and pyramidal slip systems with alternating twin bands. Figure 7(a) shows the microstructure of CP-Ti after the first pass. The flow line has an inclination of 30° to the longitudinal direction. After the second pass, the microstructure becomes highly dependent on the processing route. In route A, a higher amount of inclination with more homogeneous line space appears (Fig. 7(b)). Figure 7(c) demonstrates the micrograph of the material after the second pass with route B. Flow lines have essentially the same alignment as for the first pass although the line spacing is decreased. The second pass of route C produces more homogeneous microstructure because of the restoration of the shear deformation after every even pass (Fig. 7(d)) [59].

is the primary twinning deformation after the first pass [59,63]. By the end of the second pass in route A, deformation is controlled by basal slip and micro-twinning, and in route B, prism slip is active while in route C, there are prism and pyramidal slip systems with alternating twin bands. Figure 7(a) shows the microstructure of CP-Ti after the first pass. The flow line has an inclination of 30° to the longitudinal direction. After the second pass, the microstructure becomes highly dependent on the processing route. In route A, a higher amount of inclination with more homogeneous line space appears (Fig. 7(b)). Figure 7(c) demonstrates the micrograph of the material after the second pass with route B. Flow lines have essentially the same alignment as for the first pass although the line spacing is decreased. The second pass of route C produces more homogeneous microstructure because of the restoration of the shear deformation after every even pass (Fig. 7(d)) [59].

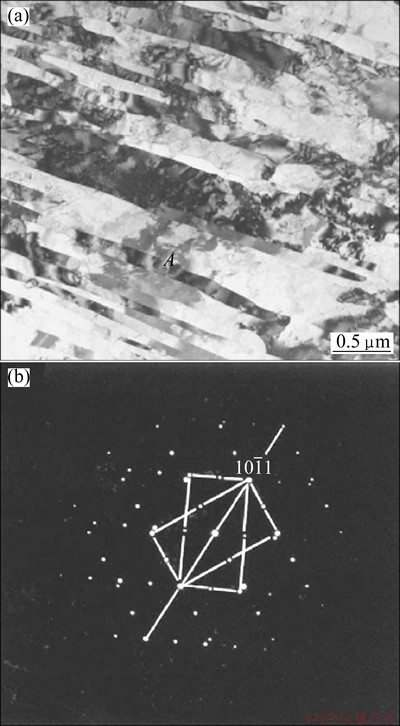

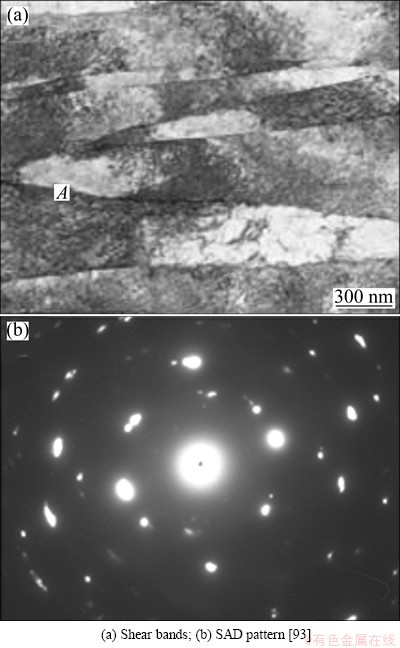

Figure 8 reveals the transmission electron microscopy (TEM) microstructure of CP-Ti after the first pass with corresponding selected area diffraction (SAD) pattern. Some parallel bands with a width of ~0.07 pm are clear. These bands are finer than slip bands appeared in cubic metals [59,67,95,96] and have lower dislocation density [59,95] . The SAD pattern (Fig. 8(b)) shows that the zone axis of  has a mirror spot with respect to the

has a mirror spot with respect to the  plane which introduces adjacent bands as twin structure of

plane which introduces adjacent bands as twin structure of  . This indicates that unlike cubic materials [59,94,97-99], the CP-Ti deforms primarily via twinning mechanism [59].

. This indicates that unlike cubic materials [59,94,97-99], the CP-Ti deforms primarily via twinning mechanism [59].

Fig. 8 TEM microstructure of CP-Ti after first pass (a) and corresponding SAD pattern (b) [59]

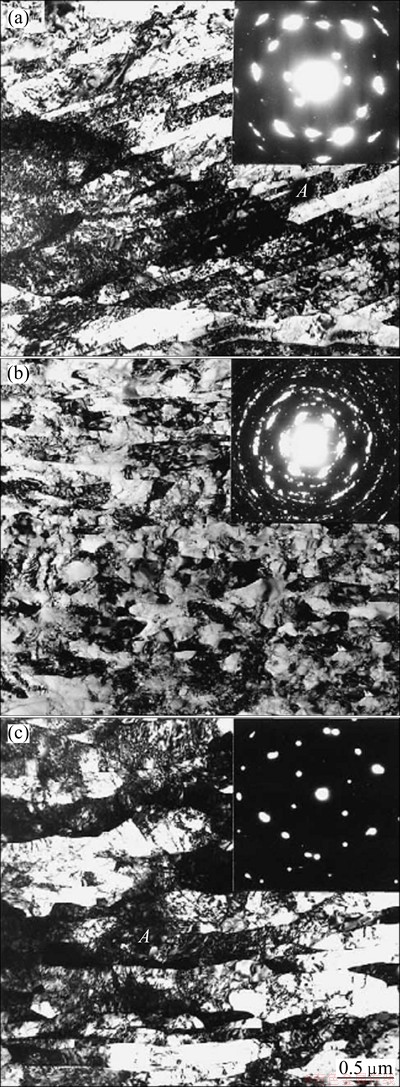

TEM microstructure of CP-Ti proves the evidence of some differences between various processing routes after the second pass. Figure 9(a) shows a reduction in the width of the twin band after the second pass by route A. Although the SAD pattern reveals a small rotation of the band after the second pass, the twin planes are still  . TEM microstructure of titanium after the second pass of route B is completely different (Fig. 9(b)) and instead of layers (mentioned in route A), there are some equiaxed grains with high dislocation density. The SAD pattern with clustered diffraction spots reveals that these grains have low angle grain boundaries [100]. After the second pass via route C, the

. TEM microstructure of titanium after the second pass of route B is completely different (Fig. 9(b)) and instead of layers (mentioned in route A), there are some equiaxed grains with high dislocation density. The SAD pattern with clustered diffraction spots reveals that these grains have low angle grain boundaries [100]. After the second pass via route C, the  twin plane is slightly misaligned (but less than that in route A) and dislocation density is highly increased (Fig. 9(c)) [59]. Various studies show that although there is always a mixture of low and high angle grain boundaries, the ratio of high angle to low angle grain boundaries increases with increased number of passes.

twin plane is slightly misaligned (but less than that in route A) and dislocation density is highly increased (Fig. 9(c)) [59]. Various studies show that although there is always a mixture of low and high angle grain boundaries, the ratio of high angle to low angle grain boundaries increases with increased number of passes.

Fig. 9 TEM microstructure with corresponding SAD pattern for CP-Ti after second pass via route A (a), route B (b) and route C (c) [59]

3.3 Temperature of operation

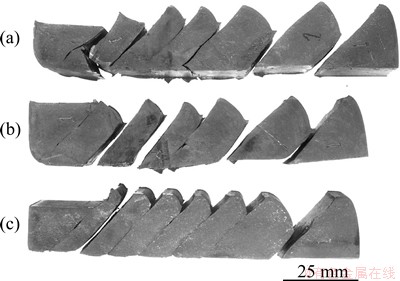

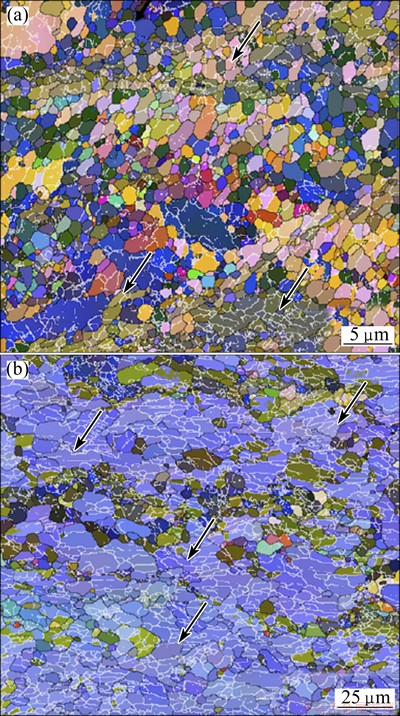

As a rule of thumb, ECAP is easier at elevated temperatures. However, higher temperatures can raise the rate of recovery and consequently, the dislocation annihilation will be more extensive leading to low angle grain boundary formation [91,101,102]. Increasing the temperature can increase the grain size as well [62,69,91, 101-103] and decrease the dislocation density which leads to lower strength improvement [16,93]. The maximum ultrafine grain microstructure is reachable at lower temperatures due to the inhibition of possible recrystallization [62]. The lower temperatures can easily provide smaller grain size [62] and high-angle grain boundaries [49] which result in superior mechanical properties [62]. Previous studies showed that, segmented failures can happen for CP-Ti under cold work condition [64]. SEMIATIN et al [64] showed that failure occurs at room temperature at all strain rates (i.e., from 0.025 to 25 mm/s) with a channel angle of 90° (Fig. 10). Although there are studies performed at room temperatures (with high channel angle and low pressing speed) [4,63,93, 104], various investigations show that carrying out ECAP at a temperature of 450 °C can lead to fully dense CP-Ti with ultrafine grains [16,17,87,100,105,106] (There is almost no recrystallization at this temperature) [106]. Figure 11 shows the influence of the temperature on the microstructure and grain size. CP-Ti processed at 450 °C for 8 passes has a grain size of 1.0 μm while at 590 °C a grain size of 4.8 μm is obtained.

Fig. 10 CP-Ti samples after ECAP process at room temperature and channel angle of 90° with different pressing speeds of 0.025 mm/s (a), 0.25 mm/s (b) and 25.0 mm/s (c) [64]

Fig. 11 EBSD microstructures of CP-Ti after 8 passes at 450 °C (a) and 590 °C (b) [106]

3.4 Pressing speed

Pressing speed can strongly influence the deformation mechanism of CP-Ti. Titanium alloys with HCP crystal structure can deform by twinning or slip mechanism depending on external conditions (such as strain, temperature and strain rate) and microstructure (such as grain size) [16,107]. KIM et al [107] showed that a decrease in the pressing speed from 2.8 mm/s to 0.8 mm/s on the ECAP process of pure Ti at 450 °C can increase dislocation density in the twin bands which makes a transition from twinning to dislocation slip mechanism. Figure 12 shows no evident of micro twins at low pressing speeds.

3.5 Internal heating

During ECAP, the internal temperature of the die increases. This effect is more prominent in stronger materials [49] and at higher pressing speeds [108]. The effect of internal heating on CP-Ti ECAP process has not been reported but it could result in in-situ annealing.

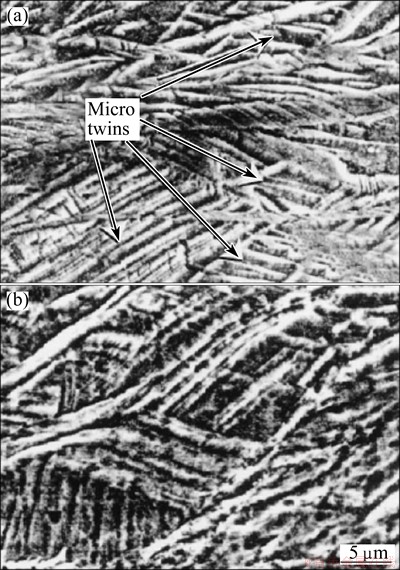

Fig. 12 SEM micrographs of CP-Ti samples after 1 pass with pressing speed of 2.8 mm/s (a) and 0.8 mm/s (b) [107]

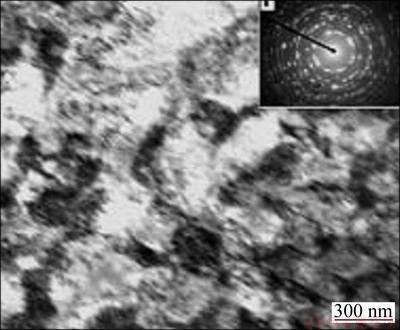

3.6 Number of passes through die

ECAP process has the advantage of increasing the amount of strain by increasing the number of passes while the original cross section remains unchanged [55]. Increasing the number of passes can lead to strong grain size refinement [74]. After the first pass, a pure shear deformation occurs in CP-Ti alloys and grains get elongated in longitudinal direction [93]. Investigations at different temperatures [88,93] show appearance of a large number of twins in the elongation direction after the first pass (Fig. 13) [93]. The existence of twinning depends on initial grain size, pressing speed and interstitial impurity of the material [6]. After some passes, ductility and strength increase simultaneously. This phenomenon is due to the increased fraction of high angle grain boundaries and the improved homogeneity of the microstructures [88,109]. Figure 14 depicts appearance of low angle bands after the first pass. By increasing the number of passes, the width of shear bands decreases [59,93]. In next steps, differently oriented shear bands meet each other and some cells appear, leading to sub-grain formation. Sub-grains wall contains a large number of dislocations and SAD patterns reveal that these new grains have high angle grain boundaries [93] (Fig. 15).

During high temperature deformation of high stacking fault metals, continuous dynamic recrystallization will occur, which is an important mechanism of grain refinement. Based on the previous studies, CP-Ti can reach its equilibrium grain refinement and saturated mechanical properties after 4 to 6 passes at temperatures of 200-450 °C [17,88] depending on the initial grain size, processing route and plane direction (transverse or longitudinal). It has been reported that grain coarsening appears after 8 passes [4,17,35, 106,107].

Fig. 13 Microstructures of CP-Ti

Fig. 14 TEM analysis of CP-Ti after one pass

It is conventional to lubricate samples with graphite [87,93] or MoS2 [6,16,63-65,74,87] between each pass or employing a die with movable wall to minimize friction between the billet and die walls [110-114].

Fig. 15 TEM microstructure and SAD pattern of CP-Ti after four passes [93]

3.7 Backpressure

Back pressure plays a critical role in ECAP process of low ductility alloys [56,57,115]. Although increasing the number of passes up to an optimum number can raise the total strain leading to improvement of mechanical properties, it is practically impossible to apply a large number of passes in difficult-to-work alloys [36]. In fact, during ECAP, after a few passes, cracks appear on the sample [6,60]. The number of passes depends upon the material. Increasing the temperature, because of the possible recrystallization, is not a practical solution [62]. It is also not recommended to increase the angle of the die corner, since it decreases the total amount of plastic deformation [58]. Application of back pressure during ECAP has been introduced as an alternative way to improve the properties of the materials. Under backpressure, materials have shown to be able to tolerate more passes. As soon as the billet passed the angles, the compressive mean stress changes to tensile (leading to crack initiation), while in the presence of backpressure, a negative (compressive) stress is applied during the whole process [115]. This compressive hydrostatic pressure causes a shear stress and by comparison, such a stress generates less damage [56,57] due to application of uniform stress-strain state in the material [116].

In summary, backpressure can influence the microstructure and final shape of the billet as follows:

1) Improve the uniformity of the material which leads to enhanced mechanical properties [58];

2) Increase the level of strain at each single pass and consequently improve the plastic deformation [58];

3) Enhance the workability (the total number of passes that the billet can tolerate without flaw initiation) [49,115];

4) Reduce the pore size and damage accumulation produced during the ECAP process [56,117];

5) Omit the corner gap (Dead zone, Fig. 16) [49,55, 58,115].

Fig. 16 Gap appearing between die and specimen in absence of backpressure [115]

In spite of the above advantages, high levels of backpressure may cause strain accumulation around the corner, which leads to a severe localized deformation and less strain uniformity [58].

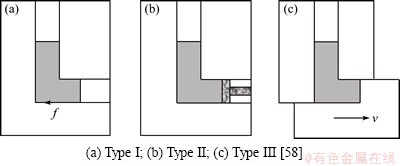

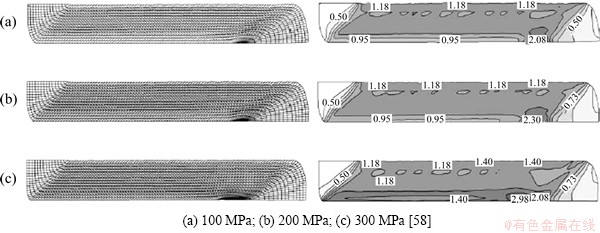

During last two decades, many numerical investigations have been done on the influence of a wide range of ECAP parameters on the final characteristics of the material [55,92,112,118-124]. SON et al [58] tried to simulate three types of applying backpressure (Fig. 17) on CP-Ti. In type I, type II and type III, a frictional force, a plunger and a movable die apply backpressure to the work-piece, respectively.

Fig. 17 Schematic illustration of three different types of backpressure

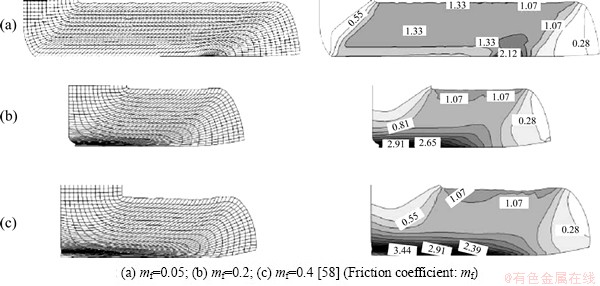

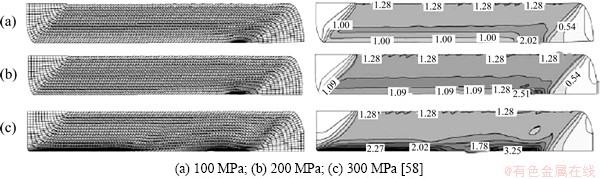

Figure 18 shows the influence of various amounts of frictional force on strain accumulation of the specimen. Although by increasing the severity of the frictional condition, there is almost no corner gap, a large amount of strain accumulation around the corner will appear, leading to inhomogeneity in the material [58]. The influence of various amounts of type II backpressure on strain distribution of CP-Ti is illustrated in Fig. 19, where it is clear that by increasing the amount of backpressure, there is still some strain accumulation; however, it is less than that in type I. Figure 20 shows the effect of type III backpressure on strain distribution of CP-Ti and it is clearly seen that this kind of backpressure has the advantage of more uniformity of the material. This strain homogeneity could be reachable due to a reduction in the friction force between the billet and die caused by die sliding [58].

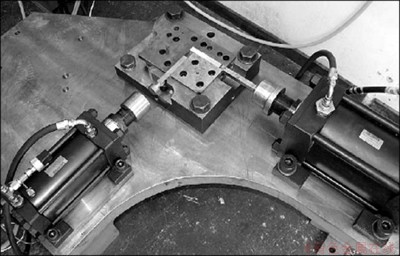

Previous studies show that it is more conventional to use the type II backpressure. Figure 21 shows a second punch method, where P1 is the pressing force and P2 (P2<P1) is backpressure. A computer controlled back pressure (Fig. 22) has been an area of research interest during the last decade [49]. This technology has the advantage of controlling forward and backward pressure and velocity of punches [49]. By contrast, employing plunger is superior to applying frictional force between the work-piece and die. It has been validated by numerical investigations [125].

4 Conclusions

During the last two decades, ECAP process, patented by SEGAL et al [32,33], developed rapidly in various industries. Nowadays, it is one of the most significant SPD methods of improving mechanical properties of CP-Ti, which leads to higher biocompatibility of titanium alloys.

Fig. 18 Strain distribution due to type I backpressure

Fig. 19 Strain distribution due to type II backpressure (φ=90°, Ψ=0° and mf=0.05)

Fig. 20 Strain distribution due to type III backpressure (φ=90°, Ψ=0° and mf=0.05)

Fig. 21 Schematic illustration of ECAP die with backpressure

Fig. 22 Computer control equipment to apply backpressure during ECAP process with die curvature angle of 90° [57]

Previous studies show that employing a die with channel angle of 90° and curvature angle of 0°-20°along with operation temperature of around 450 °C, pressing speed of 1-3 mm/s, route BC and an appropriate backpressure can lead to optimum mechanical properties and microstructural homogeneities in CP-Ti.

References

[1] ESTRIN Y, KASPER C, DIEDERICHS S, LAPOVOK R. Accelerated growth of preosteoblastic cells on ultrafine grained titanium [J]. Journal of Biomedical Materials Research (Part A), 2009, 90: 1239-1942.

[2] RACK H J, QAZI J I. Titanium alloys for biomedical applications [J]. Materials Science and Engineering C, 2006, 26: 1269-1277.

[3] CHEN Y J, LI Y J, WALMSLEY J C, DUMOULIN S, SKARET P C, ROVEN H J. Microstructure evolution of commercial pure titanium during equal channel angular pressing [J]. Materials Science and Engineering A, 2010, 527: 789-96.

[4] ZHAO Xi-cheng, YANG Xi-rong, LIU Xiao-yan, WANG Xing-yun, LANGDON TERENCE G. The processing of pure titanium through multiple passes of ECAP at room temperature [J]. Materials Science and Engineering A, 2010, 527: 6335-6339.

[5] HOSEINI M, HAMID POURIAN M, BRIDIER F, VALI H, SZPUNAR J A, BOCHER P. Thermal stability and annealing behaviour of ultrafine grained commercially pure titanium [J]. Materials Science and Engineering A, 2012, 532: 58-63.

[6] DHEDA S S, MOHAMED F A. Effect of initial microstructure on the processing of titanium using equal channel angular pressing. [J]. Materials Science and Engineering A, 2011, 528: 8179-8186.

[7] LONG M, RACK H J. Titanium alloys in total joint replacement—A materials science perspective [J]. Biomaterials, 1998, 19: 1621-1639.

[8] VALIEV R Z, SEMENOVA I P, LATYSH V V, RACK H, LOWE T C, PETRUZELKA J. Nanostructured titanium for biomedical applications [J]. Advanced Engineering Materials, 2008, 10: B15-B17.

[9] SHAHBEIGI ROODPOSHTI P, SARKAR A, MURTY K L. A review of the influence of production methods and intermetallic phase on the creep properties of AZ91 [J]. Magnesium Technology, 2014: 59-64.

[10] SHAHBEIGI ROODPOSHTI P, SARKAR A, MURTY K L. Microstructure development of high temperature deformed AZ31 magnesium alloys [J]. Materials Science and Engineering A, 2015, 626: 195-202.

[11] SHAHBEIGI ROODPOSHTI P, SARKAR A, MURTY K L. Fracture behavior of AZ31 Magnesium alloy during low stress high temperature deformation [J]. Metallography, Microstructure and Analysis, 2015: 4(2): 91-101.

[12] SHAHBEIGI ROODPOSHTI P, SARKAR A, MURTY K L. Creep deformation mechanisms and related microstructure development of AZ31 magnesium alloy [J]. Magnesium Technology, 2015, 10.1002/9781119093428.ch9.

[13] ZIAEI S, ZIKRY M A. Modeling the effects of dislocation–density interaction, generation, and recovery on the behavior of H.C.P. materials [J]. Metallurgical and Materials Transactions A, 2014, 10.1007/s11661-014-2635-0

[14] SONG Jie, WANG Li-ming, ZHANG Xiao-ning, SUN Xiao-gang, JIANG Hong, FAN Zhi-guo, XIE Chao-ying, WU M H. Effects of second phases on mechanical properties and martensitic transformations of ECAPed TiNi and Ti-Mo based shape memory alloys [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1839-1848.

[15] GEETHA M, SINGH A K, ASOKAMANI R, GOGIA A K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review [J]. Progress in Materials Science, 2009, 54: 397-425.

[16] STOLYAROV VLADIMIR V, ZHU YUNTIAN T, LOWE TERRY C, VALIEV RUSLAN Z. Microstructure and properties of pure Ti processed by ECAP and cold extrusion [J]. Materials Science and Engineering A, 2001, 303: 82-89.

[17] CHEN Y J, LI Y J, WALMSLEY J C, DUMOULIN S, GIREESH S, ARMADA S. Quantitative analysis of grain refinement in titanium during equal channel angular pressing [J]. Scripta Materialia, 2011, 64: 904-907.

[18] NIINOMI M. Mechanical biocompatibilities of titanium alloys for biomedical applications [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2008, 1: 30-42.

[19] FARAHBAKHSH N, SHAHBEIGI ROODPOSHTI P, AYOUB A, VENDITTI R A, JUR J S. Melt extrusion of polyethylene nanocomposites reinforced with nanofibrillated cellulose from cotton and wood sources [J]. Journal of Applied Polymer Science 2015, 10.1002/app.41857.

[20] ROOPAN S M, KAJBAFVALA A, BANADAKI A D, MADHUMITHA G, PILLAI K S. Bimetallic nanomaterials: Functional efficacy towards synthesis, photocatalytic degradation, and biomedical catalysts [J]. Journal of Nanomaterials, 2014, 2014: 1-3.

[21] DEHGHAN BANADAKI A, KAJBAFVALA A. Recent advances in facile synthesis of bimetallic nanostructures: An overview [J]. Journal of Nanomaterials, 2014, 2014: 1-28.

[22] SEGAL V M. Materials processing by simple shear [J]. Materials Science and Engineering A, 1995, 197: 157-64.

[23] ZHILYAEV A P, NURISLAMOVA G V, KIM B K,  M D, SZPUNAR J A, LANGDON T G. Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion [J]. Acta Materialia, 2003, 51: 753-765.

M D, SZPUNAR J A, LANGDON T G. Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion [J]. Acta Materialia, 2003, 51: 753-765.

[24] RICHERT M, LIU Q, HANSEN N. Microstructural evolution over a large strain range in aluminium deformed by cyclic-extrusion– compression [J]. Materials Science and Engineering A, 1999, 260: 275-283.

[25] CHU H S, LIU K S, YEH J W. Study of 6061-Al2O3p composites produced by reciprocating extrusion [J]. Metallurgical and Materials Transactions A, 2000, 31: 2587-2596.

[26] CHU H S, LIU K S, YEH J W. Aging behavior and tensile properties of 6061Al-0.3 μm Al2O3p particle composites produced by reciprocating extrusion [J]. Scripta Materialia, 2001, 45: 541-546.

[27] HUANG J Y, ZHU Y T, JIANG H, LOWE T C. Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening [J]. Acta Materialia, 2001, 49: 1497-1505.

[28] ZHU Y T, JIANG H, HUANG J, LOWE T C. A new route to bulk nanostructured metals [J]. Metallurgical and Materials Transactions Al, 2001, 32: 1559-1562.

[29] ZHAO X, JING T F, GAO Y W, ZHOU J F, WANG W. A new SPD process for spheroidal cast iron [J]. Materials Letters, 2004, 58: 2335-2339.

[30] SAITO Y, TSUJI N, UTSUNOMIYA H, SAKAI T, HONG R G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process [J]. Scripta Materialia, 1998, 39: 1221-1227.

[31] SAITO Y, UTSUNOMIYA H, TSUJI N, SAKAI T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process [J]. Acta Materialia, 1999, 47: 579-583.

[32] SEGAL V M. USSR Patent No. 575892 [P]. 1977.

[33] SEGAL V M, REZNIKOV V I, DROBYSHEVSKIY A E, KOPYLOV V I. Plastic working of metals by simple shear [J]. Russian Metallurgy, 1981, 1: 99.

[34] XU Cheng, XIA Ke-nong, LANGDON TERENCE G. Processing of a magnesium alloy by equal-channel angular pressing using a back-pressure [J]. Materials Science and Engineering A, 2009, 527: 205-211.

[35] STOLYAROV V V, ZHU Y T, ALEXANDROV I V, LOWE T C, VALIEV R Z. Influence of ECAP routes on the microstructure and properties of pure Ti [J]. Materials Science and Engineering A, 2001, 299: 59-67.

[36] MA Ai-bin, JIANG Jing-hua, NAOBUMI S, ICHINORI S, YUAN Yu-chun, YANG Dong-hui. Improving both strength and ductility of a Mg alloy through a large number of ECAP passes [J]. Materials Science and Engineering A, 2009, 513-514: 122-127.

[37]  Improvement of mechanical properties for Zn–Al alloys using equal-channel angular pressing [J]. Journal of Materials Processing Technology, 2005, 169: 242-248.

Improvement of mechanical properties for Zn–Al alloys using equal-channel angular pressing [J]. Journal of Materials Processing Technology, 2005, 169: 242-248.

[38] SEGAL V M. Equal channel angular extrusion: From macromechanics to structure formation [J]. Materials Science and Engineering A, 1999, 271: 322-333.

[39] HYUN C Y, KIM H K. Grain size dependence of flow stress in ECAPed Ti with constant texture [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S): s673-s677.

[40] ZHA Min, LI Yan-jun, MATHIESEN R,  R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2301-2306.

R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2301-2306.

[41] ZHANG Jing, ZHANG Ke-shi, WU Hwai-chung, YU Mei-hua. Experimental and numerical investigation on pure aluminum by ECAP [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1303-1311.

[42] YING Tao, HUANG Jian-ping, ZHENG Ming-yi, WU Kun. Influence of secondary extrusion on microstructures and mechanical properties of ZK60 Mg alloy processed by extrusion and ECAP [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1896-1901.

[43] JIANG Da-ming, NING Jiang-li, SUN Jian-feng, HU Zhi-min, HOU Yi. Annealing behavior of Al-Mg-Mn alloy processed by ECAP at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 248-254.

[44] WU Lai-zhi, CHEN Jun, DU Zhong-ze, WANG Jing-tao. Microstructures of ultra-fine grained FeCoV alloys processed by ECAP plus cold rolling and their evolutions during tempering [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 602-606.

[45] SONG Dan, MA Ai-bin, JIANG Jing-hua, LIN Pin-hua, YANG Dong-hui. Corrosion behavior of ultra-fine grained industrial pure Al fabricated by ECAP [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1065-1070.

[46] SHI Lei, YANG He, GUO Liang-gang, DANG Li, ZHANG Jun. Large-scale manufacturing of aluminum alloy plate extruded from subsize billet by new porthole-equal channel angular processing technique [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1521-1530.

[47] ZHANG Fan, ZHANG Ke-xiang, TAN Cheng-wen, YU Xiao-dong, MA Hong-lei, WANG Fu-chi. Microstructure and mechanical properties of Mg-Gd-Y-Zr alloy processed by equal channel angular pressing [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2140-2146.

[48] VENKATACHALAM P, RAMESH KUMAR S, RAVISANKAR B, THOMAS PAUL V, VIJAYALAKSHMI M. Effect of processing routes on microstructure and mechanical properties of 2014 Al alloy processed by equal channel angular pressing [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(10): 1822-1828.

[49] VALIEV RUSLAN Z, LANGDON TERENCE G. Principles of equal-channel angular pressing as a processing tool for grain refinement [J]. Progress in Materials Science, 2006, 51: 881-981.

[50] STOLYAROV V V, SHUSTER L S H, MIGRANOV M S H, VALIEV R Z, ZHU Y T. Reduction of friction coefficient of ultrafine-grained CP titanium [J]. Materials Science and Engineering A, 2004, 371: 313-317.

[51] ERTORER O, TOPPING T, LI Y, MOSS W, LAVERNIA E. Enhanced tensile strength and high ductility in cryomilled commercially pure titanium [J]. Scripta Materialia, 2009, 60: 586-589.

[52] VALIEV RUSLAN Z. Structure and mechanical properties of ultrafine grained metals [J]. Materials Science and Engineering A, 1997, 234-236: 59-66.

[53] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Progress in Materials Science, 2000, 45: 103-189.

[54] PURCEK G, ALTAN B S, MISKIOGLU I, OOI P H. Processing of eutectic Zn-5% Al alloy by equal-channel angular pressing [J]. Journal of Materials Processing Technology, 2004, 148: 279-287.

[55] KIM H S. Finite element analysis of deformation behaviour of metals during equal channel multi-angular pressing [J]. Materials Science and Engineering A, 2002, 328: 317-323.

[56] STOLYAROV V V, LAPOVOK R. Effect of backpressure on structure and properties of AA5083 alloy processed by ECAP [J]. Journal of Alloys and Compounds, 2004, 378: 233-236.

[57] STOLYAROV V V, LAPOVOK R, BRODOVA I G, THOMSON P F. Ultrafine-grained Al-5wt.% Fe alloy processed by ECAP with backpressure [J]. Materials Science and Engineering A, 2003, 357: 159-167.

[58] SON I H, LEE J H, IM Y T. Finite element investigation of equal channel angular extrusion with back pressure [J]. Journal of Materials Processing Technology, 2006, 171: 480-487.

[59] SHIN D H, KIM I, KIM J, KIM Y S, SEMIATIN S L. Microstructure development during equal-channel angular pressing of titanium [J]. Acta Materialia, 2003, 51: 983-996.

[60] VALIEV R Z, ALEXANDROV I V. Paradox of strength and ductility in metals processed by severe plastic deformation [J]. Journal of Material Research Society, 2002, 17: 5-8.

[61] FIGUEIREDO ROBERTO B, CETLIN PAULO R, LANGDON TERENCE G. The processing of difficult-to-work alloys by ECAP with an emphasis on magnesium alloys [J]. Acta Materialia, 2007, 55: 4769-4779.

[62] RAAB G I, SOSHNIKOVA E P, VALIEV R Z. Influence of temperature and hydrostatic pressure during equal-channel angular pressing on the microstructure of commercial-purity Ti [J]. Materials Science and Engineering A, 2004, 387-389: 674-677.

[63] ZHANG Yue, FIGUEIREDO ROBERTO B, ALHAJERI SALEH N, WANG Jing-Tao, GAO Nong, LANGDON TERENCE G. Structure and mechanical properties of commercial purity titanium processed by ECAP at room temperature [J]. Materials Science and Engineering A, 2011, 528: 7708-7714.

[64] SEMIATIN S L, DELO D P, SEGAL V M, GOFORTH R E, FREY N D. Workability of commercial-purity titanium and 4340 steel during equal channel angular extrusion at cold-working temperatures [J]. Metallurgical and Materials Transactions A, 1999, 30: 1425-1435.

[65] IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON TERENCE G. The process of grain refinement in equal-channel angular pressing [J]. Acta Materialia, 1998, 46: 3317-3331.

[66] NAKASHIMA K, HORITA Z, NEMOTO M, LANGDON TERENCE G. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing [J]. Acta Materialia, 1998, 46: 1589-1599.

[67] IWAHASHI Y, FURUKAWA M, HORITA Z, NEMOTO M, LANGDON TERENCE G. Microstructural characteristics of ultrafine-grained aluminum produced using equal-channel angular pressing [J]. Metallurgical and Materials Transaction A, 1998, 29: 2245-2252.

[68] OH-ISHI K, HORITA Z, FURUKAWA M, NEMOTO M, LANGDON TERENCE G. Optimizing the rotation conditions for grain refinement in equal-channel angular pressing [J]. Metallurgical and Materials Transaction A, 2011, 29: 2011-2013.

[69] IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON TERENCE G. Factors influencing the equilibrium grain size in equal- channel angular pressing: Role of Mg additions to aluminum procedures [J]. Metallurgical and Materials Transactions A, 1998, 29: 2503-2510.

[70] IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON T G. An investigation of microstructural evolution during equal-channel angular pressing [J]. Acta Materialia, 1997, 45: 4733-4741.

[71] KOCH C C, CAROLINA N. The synthesis and structure of nanocrystalline materials produced by mechanical attrition—A review [J]. Nanostructured Materials, 1993, 2: 109-129.

[72] KRASILNIKOV N A. Strength and ductility of copper subjected to equal-channel angular pressing with backpressure [J]. Russian Metallurgy, 2005, 2005: 220-226.

[73] SEGAL V M. Severe plastic deformation: Simple shear versus pure shear [J]. Materials Science and Engineering A, 2002, 338: 331-344.

[74] KANG D H, KIM T W. Mechanical behavior and microstructural evolution of commercially pure titanium in enhanced multi-pass equal channel angular pressing and cold extrusion [J]. Materials & Design, 2010, 31: s54-s60.

[75] VALIEV RUSLAN Z. Some new trends in SPD processing for fabrication of bulk nanostructured materials [J]. Materials Science Forum, 2006, 503-504: 3-10.

[76] XIANG S, MATSUKI K, TAKATSUJI N, TOKIZAWA M. Microstructure and mechanical properties of PM 2024Al-3Fe-5Ni alloy consolidated by a new process, equal channel angular pressing [J]. Journal of Materials Science Letters, 1997, 16: 1725-1727.

[77] MATSUKI K, AIDA T, TAKEUCHI T, KUSUI J, YOKOE K. Microstructural characteristics and superplastic-like behavior in aluminum powder alloy consolidated by equal-channel angular pressing [J]. Acta Materialia, 2000, 16: 2625-2632.

[78] PARASIRIS A, HARTWIG K T. Consolidation of advanced WC-Co powders [J]. International Journal of Refractory Metals and Hard Materials, 2000, 18: 23-31.

[79] HAOUAOUI M, KARAMAN I, MAIER H J, HARTWIG K T. Microstructure evolution and mechanical behavior of bulk copper obtained by consolidation of micro- and nanopowders using equal-channel angular extrusion [J]. Metallurgical and Materials Transactions, 2004, 35: 2935-2949.

[80] SENKOV O N, SENKOVA S V, SCOTT J M, MIRACLE D B. Compaction of amorphous aluminum alloy powder by direct extrusion and equal channel angular extrusion [J]. Materials Science and Engineering A, 2005, 393: 12-21.

[81] XIA K, WU X. Back pressure equal channel angular consolidation of pure Al particles [J]. Scripta Materialia, 2005, 53: 1225-1229.

[82] YAMASHITA A, HORITA Z, LANGDON TERENCE G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation [J]. Materials Science and Engineering A, 2001, 300: 142-147.

[83] BERBON PATRICK B, FURUKAWA M, HORITA Z, NEMOTO M, LANGDON TERENCE G. Influence of pressing speed on microstructural development in equal-channel angular pressing [J]. Metallurgical and Materials Transaction A, 1999, 30: 1989-1997.

[84] BOWEN J R, GHOLINIA A, ROBERTS S M, PRANGNELL P B. Analysis of the billet deformation behaviour in equal channel angular extrusion [J]. Materials Science and Engineering A, 2000, 287: 87-99.

[85] IWAHASHI Y, WANG J, HORITA Z, NEMOTO M, LANGDON TERENCE G. Principle of equal channel angular pressing for the processing of ultra fine grained materials [J]. Scripta Material, 1996, 35: 143-146.

[86] ZHAO Yan, GUO Hong-zhen, FU M W, NING Yong-quan, YAO Ze-kun. Fabrication of bulk ultrafine grained titanium alloy via equal channel angular pressing based thermomechanical treatment [J]. Materials & Design, 2013, 46: 889-894.

[87] KORSHUNOV A, KRAVCHENKO T, POLYAKOV L, SMOLYAKOV A, VEDERNIKOVA I, MOROZOV A. Effects of the number of equal-channel angular pressing passes on the anisotropy of ultra-fine titanium [J]. Materials Science and Engineering A, 2008, 493: 160-163.

[88] GUNDEROV D V, POLYAKOV A V, SEMENOVA I P, RAAB G I, CHURAKOVA A A, GIMALTDINOVA E I. Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing [J]. Materials Science and Engineering A, 2013, 562: 128-136.

[89] FURUNO K, AKAMATSU H, OH-ISHI K, FURUKAWA M, HORITA Z, LANGDON T G. Microstructural development in equal-channel angular pressing using a 60° die [J]. Acta Materialia, 2004, 52: 2497-2507.

[90] NAKASHIMA K, HORITA ZI, NEMOTO M, LANGDON TERENCE G. Development of a multi-pass facility for equal-channel angular pressing to high total strains [J]. Materials Science and Engineering A, 2000, 281: 82-87.

[91] YAMASHITA A, YAMAGUCHI D, HORITA Z, LANGDON TERENCE G. Influence of pressing temperature on microstructural development in equal-channel angular pressing [J]. Materials Science and Engineering A, 2000, 287: 100-6.

[92] FURUKAWA M, HORITA Z, LANGDON TERENCE G. Factors influencing the shearing patterns in equal-channel angular pressing [J]. Materials Science and Engineering A, 2002, 332: 97-109.

[93] YANG Xi-rong, ZHAO Xi-cheng, FU Wen-jie. Deformed microstructures and mechanical properties of CP-Ti processed by multi-pass ECAP at room temperature [J]. Rare Metal Materials and Engineering, 2009, 38: 955-7.

[94] SHIN D H, KIM I, KIM J, PARK K T. Grain refinement mechanism during equal-channel angular pressing of a low-carbon steel [J]. Acta Materialia, 2001, 49: 1285-92.

[95] SHIN D H, KIM B C, PARK K T, CHOO WUNG YONG. Microstructural changes in equal channel angular pressed low carbon steel by static annealing [J]. Acta Materialia, 2000, 48: 3245-52.

[96] FURUKAWA M, IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON TERENCE G. The shearing characteristics associated with equal-channel angular pressing [J]. Materials Science and Engineering A, 1998, 257: 328-32.

[97] FURUKAWA M, HORITA Z, NEMOTO M, LANGDON TERENCE G. Fabrication of bulk ultrafine-grained materials through intense plastic straining [J]. Metallurgical and Materials Transactions A, 1998, 29: 2237-43.

[98] SEMIATIN S L, SEGAL V M, GOETZ R L, GOFORTH R E, HARTWIG T. Workability of a gamma titanium aluminide alloy during equal channel angular extrusion [J]. Scripta Metallurgica et Materialia, 1995, 33: 535-40.

[99] ZHU Y T, LOWE TERRY C. Observations and issues on mechanisms of grain refinement during ECAP process [J]. Materials Science and Engineering A, 2000, 291: 46-53.

[100] STOLYAROV VLADIMIR V, ZHU Y T, ALEXANDROV IGOR V, LOWE TERRY C, VALIEV RUSLAN Z. Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling [J]. Materials Science and Engineering A, 2003, 343: 43-50.

[101] WANG Y Y, SUN P L, KAO P W, CHANG C P. Effect of deformation temperature on the microstructure developed in commercial purity aluminum processed by equal channel angular extrusion [J]. Scripta Materialia, 2004, 50: 613-617.

[102] GOLOBORODKO A, SITDIKOV O, KAIBYSHEV R, MIURA H, SAKAI T. Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP [J]. Materials Science and Engineering A, 2004, 381: 121-128.

[103] SHIN D H, PAK J J, KIM Y K, PARK K T, KIM Y S. Effect of pressing temperature on microstructure and tensile behavior of low carbon steels processed by equal channel angular pressing [J]. Materials Science and Engineering A, 2002, 323: 409-415.

[104] ZHAO Xi-cheng, FU Wen-jie, YANG Xi-rong, LANGDON TERENCE G. Microstructure and properties of pure titanium processed by equal-channel angular pressing at room temperature [J]. Scripta Materialia, 2008, 59: 542-545.

[105] LUO P, MCDONALD D T, XU W, PALANISAMY S, DARGUSCH M S, XIA K. A modified Hall–Petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing [J]. Scripta Materialia, 2012, 66: 785-788.

[106] LUO P, MCDONALD D T, ZHU S M, PALANISAMY S, DARGUSCH M S, XIA K. Analysis of microstructure and strengthening in pure titanium recycled from machining chips by equal channel angular pressing using electron backscatter diffraction [J]. Materials Science and Engineering A, 2012, 538: 252-258.

[107] KIM I, KIM J, HYUK D. Effects of grain size and pressing speed on the deformation mode of commercially pure Ti during equal channel angular pressing [J]. Metallurgical and Materials Transactions A, 2003, 34: 1555-1558.

[108] YAMAGUCHI D, HORITA Z, NEMOTO M, LANGDON TERENCE G. Significance of adiabatic heating in equal channel angular pressing [J]. Scripta Materialia, 1999, 41: 791-796.

[109] KUMAR P, XU C, LANGDON T G. Mechanical characteristics of a Zn-22% Al alloy processed to very high strains by ECAP [J]. Materials Science and Engineering A, 2006, 429: 324-328.

[110] SEGAL V M. Slip line solutions, deformation mode and loading history during equal channel angular extrusion [J]. Materials Science and Engineering A, 2003, 345: 36-46.

[111] SEGAL V M. Engineering and commercialization of equal channel angular extrusion (ECAE) [J]. Materials Science and Engineering A, 2004, 386: 269-276.

[112] SEMIATIN S L, DELO D P, SHELL E B. The effect of material properties and tooling design on deformation and fracture during equal channel angular extrusion [J]. Acta Materialia, 2000, 48: 1841-1851.

[113] SEMIATIN S L, DELO D P. Equal channel angular extrusion of difficult-to-work alloys [J]. Materials & Design, 2000, 21: 311-322.

[114] SHAN A, MOON I G, PARK J W. Estimation of friction during equal channel angular (ECA) pressing of aluminum alloys [J]. Journal of Materials Processing Technology, 2002, 122: 255-259.

[115] LAPOVOK R. The role of back-pressure in equal channel angular extrusion [J]. Journal of Materials Science, 2005, 40: 341-346.

[116] LAPOVOK R. Backpressure in equal-channel angular pressing [J]. Russian Metallurgy, 2004, 2004: 36-41.

[117] LAPOVOK R, TOMUS D, MANG J, ESTRIN Y, LOWE T C. Evolution of nanoscale porosity during equal-channel angular pressing of titanium [J]. Acta Materialia, 2009, 57: 2909-2918.

[118] PRANGNELL P B, HARRIS C, ROBERTS S M. Finite element modelling of equal channel angular extrusion [J]. Scripta Materialia, 1997, 37: 983-989.

[119] DELO D P, SEMIATIN S L. Finite-element modeling of nonisothermal equal-channel angular extrusion [J]. Metallurgical and Materials Transactions A, 1999, 30: 1391-1402.

[120] KIM H S, SEO M H, HONG S I. Plastic deformation analysis of metals during equal channel angular pressing [J]. Journal of Materials Processing Technology, 2001, 113: 622-626.

[121] LEE J H, SON I H, IM Y T. Finite element investigation of equal channel angular extrusion process [J]. Materials Transactions, 2004, 45: 2165-2171.

[122] DUMOULIN S, ROVEN H J, WERENSKIOLD J C, VALBERG H S. Finite element modeling of equal channel angular pressing: Effect of material properties, friction and die geometry [J]. Materials Science and Engineering A, 2005, 410-411: 248-251.

[123] XU Shu-bo, ZHAO Guo-qun, MA Xin-wu, REN Guo-cheng. Finite element analysis and optimization of equal channel angular pressing for producing ultra-fine grained materials [J]. Journal of Materials Processing Technology, 2007, 184: 209-216.

[124] SUO Tao, LI Yu-long, GUO Ya-zhou, LIU Yuan-yong. The simulation of deformation distribution during ECAP using 3D finite element method [J]. Materials Science and Engineering A, 2006, 432: 269-274.

[125] OH S J, KANG S B. Analysis of the billet deformation during equal channel angular pressing [J]. Materials Science and Engineering A, 2003, 343: 107-115.

工业用纯钛等径角挤压的显微组织控制方法综述

Peiman Shahbeigi Roodposhti, Nasim Farahbakhsh, Apu Sarkar, Korukonda Linga Murty

North Carolina State University, USA

摘 要:综述了工业用纯钛(CP-Ti)大塑性变形技术的等径角挤压工艺,主要集中在等径角挤压参数的影响,包括通道角和曲率角、挤压路径、挤压温度、挤压速度、内部产热、挤压道次和背压。为了获得CP-Ti的最大均匀性、晶粒细化和提高力学性能,对不同等径角挤压CP-Ti进行了表征,如显微组织、应力不均匀性和力学性能。研究表明,在挤压温度为450 °C,挤压速度为1~3 mm/s,挤压路径为BC,加载背压,通道角和曲率角分别为90°和20°的条件下能获得最均匀的超细组织。

关键词:等径角挤压;工业用纯钛;背压;通道角;曲率角;挤压速率

(Edited by Xiang-qun LI)

Foundation item: Project (DMR-0968825) support by National Science Foundation Through Grant

Corresponding author: Peiman Shahbeigi ROODPOSHTI; Tel: +1 919 757 7030, Fax: +1 919 515 5115; E-mail: pshahbe@ncsu.edu

DOI: 10.1016/S1003-6326(15)63734-7

Abstract: A review on severe plastic deformation (SPD) technique of equal channel angular pressing (ECAP) process of commercially pure titanium (CP-Ti) alloys was presented with a major emphasize on the influence of ECAP parameters that include channel and curvature angles, processing route, temperature of operation, pressing speed, internal heating, number of pass through the die and back pressure. Various ECAP characteristics such as microstructure, strain inhomogeneity and mechanical properties are considered to achieve the maximum homogeneity, equilibrium grain refinement and mechanical improvement of CP-Ti. Investigations show that a pressing speed of 1-3 mm/s at 450 °C with route BC along with channel and curvature angles of 90° and 20° respectively with backpressure can lead to the most homogeneous ultrafine microstructure.

and 20° respectively with backpressure can lead to the most homogeneous ultrafine microstructure.