J. Cent. South Univ. (2012) 19: 842-849

DOI: 10.1007/s11771-012-1081-7![]()

Variation of biological and hydrological parameters and

nitrogen removal optimization of modified Carrousel oxidation ditch process

ZHANG Zhi(张智)1, 2, LI Bo-lin(李柏林)1, 2, XIANG Xin-yi(相欣奕)2, 3,ZHANG Chi(张驰)1, 2, CHAI Hua(柴华)1, 2

1. Faculty of Urban Construction and Environmental Engineering, Chongqing University, Chongqing 400045, China;

2. Key Laboratory of The Three Gorges Reservoir Region’s Eco-Environment, Ministry of Education,Chongqing University, Chongqing 400045, China;

3. School of Geographical Sciences, Southwest University, Chongqing 400715, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

To enhance the nitrogen removal, a systemic monitoring of the biological and hydrological parameters of Carrousel oxidation ditch in Chongqing Jingkou Wastewater Treatment Plant was carried out to study the feasibility of simultaneous nitrification and denitrification (SND). The variation and distribution of parameters such as flow velocity, concentration of dissolved oxygen (DO) and mixed liquor suspended solids (MLSS) in oxidation ditch were monitored and analyzed, which were major control factors for SND. The results showed that, the dimensional distribution of flow velocity, DO and MLSS were affected significantly by the operation condition of the aeration wheels. With all the four aeration wheels being in operation, DO and flow velocity were higher and the mixing of MLSS was sufficient. With three aeration wheels being in operation, the flow velocity in most of the bottom areas was enough to meet the basic requirements of no deposition, and the anaerobic region and aerobic region could exist simultaneously in one oxidation ditch, which was helpful to the process of SND. According to spatial distribution characteristics of the flow velocity, DO and soluble components under optimized condition, different functional zones of biochemical reaction in the Carrousel oxidation ditch system were defined, which might contribute to the optimization control and SND of Carrousel oxidation ditch.

Key words:

1 Introduction

Oxidation ditch system, which was originated from Netherlands, has many advantages such as simple operation, easy management, and flexible operation mode, which has been widely used and studied world-wide [1].

Typical oxidation ditch is composed of some vertical channels and curved channels, with water surface aeration wheels and underwater plug-flow equipment jointly used to realize the function of plug-flow and oxygen supply acting as the source for the uneven spatial distribution of flow pattern and dissolved oxygen in the oxidation ditch [2]. It provides a good occurrence conditions for simultaneous nitrification and denitrification (SND) process [3-4], but may also lead to deposition problem. Coordinating the relationship between the two aspects plays an important role for the realization of stable operation and improvement of nitrogen removal of oxidation ditch system.

Some scholars studied the flow pattern, the characteristics of dissolved oxygen distribution and the SND in the oxidation ditch. YANG et al [5] and LUO et al [6] studied the characteristics of flow pattern of the integrated oxidation ditch by using the method of monitoring and numerical simulation, and put forward the research of optimization of flow distribution and correction of deposition problem. HELEN et al [7] built a numerical model of oxidation ditch by using the momentum calculation and analysis of the effect of the operation mode of aeration wheel on the flow pattern and distribution of dissolved oxygen. YANG et al [8-9] established the model of flow pattern and dissolved oxygen distribution in oxidation ditch, and proposed the optimal operation mode of aeration wheel and the underwater propeller. By their work, the nitrogen removal efficiency of the system was improved, and the goal of steadily meeting the discharge standards and energy saving was achieved. LIU et al [10] studied the relationship between dissolved oxygen, influent load and the SND in a small test system of the oxidation ditch and a pilot system of the oxidation ditch and the optimal operation mode was obtained. Studies showed that by regulating the operation mode of aeration equipment and plug-flow equipment, the flow pattern and the distribution of dissolved oxygen in oxidation ditch could be optimized, which was able to promote the process of SND, improve the nitrogen removal effect, and correct the deposition problem.

The operating mode of aeration equipment and plug-flow equipment could not only affect the flow velocity and spatial distribution of dissolved oxygen, but also had an impact on other characteristic parameters of the oxidation ditch (such as sludge concentration, and soluble components). These characteristic parameters interacted with each other, which had close relation with the SND process. The current research work was devoted to studying the relationship of the characteristic parameters distribution and the impact of them on SND process in oxidation ditch, etc. In addition, how to control the micro-environment by regulating the distribution of characteristic parameters of the oxidation ditch to improve the efficiency of SND and the dynamics of SND process by considering the effect of influent water is the research focus currently.

In this work, the modified Carrousel oxidation ditch system of the wastewater treatment plant named Jingkou in Chongqing, China, was taken for an example. The SND process of the oxidation ditch system and the distribution and variation of the feature parameters in the trench (flow velocity, sludge concentration, dissolved oxygen and dissolved components) were analyzed. Mechanisms of the effect of feature parameters on SND process and the occurrence conditions conducive to SND process were investigated, and the countermeasures to enhance nitrogen removal function in the oxidation ditch were analyzed.

2 Materials and methods

2.1 General condition of waste water treatment plant

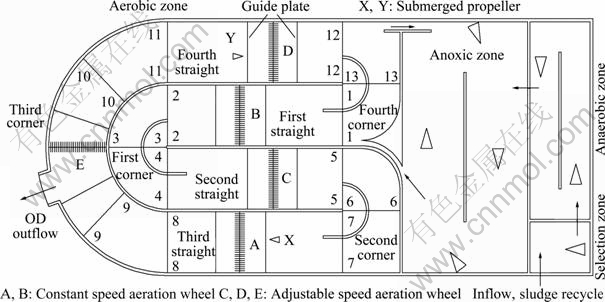

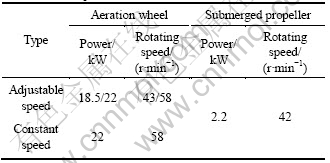

The modified Carrousel oxidation ditch process is in operation in Jingkou Wastewater Treatment Plant (WWTP) in Chongqing, China, with single-cell design capacity being 10 000 m3/d. The effluent water quality should meet the first level B criteria specified in the discharge standard of pollutants for municipal wastewater treatment plant (GB 18918—2002). Layout plan of the WWTP is shown in Fig. 1. The device parameters of Carrousel oxidation ditch are listed in Table 1.

2.2 Experimental methods

By monitoring and analysis of flow velocity, dissolved oxygen, sludge concentration and distribution of dissolved components in different working conditions of the oxidation ditch, the variation of the feature parameters in the oxidation ditch was studied, based on which, different function regions of biochemical reaction inside the oxidation ditch were divided. In addition, the condition conducive to achieve nitrogen removal process by simultaneous nitrification and denitrification (SND) was studied.

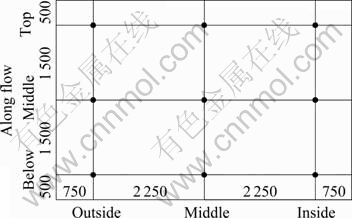

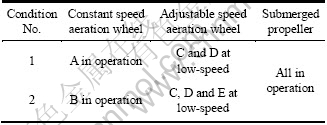

The monitoring sections of the feature parameters of the trench in the oxidation ditch are shown in Fig. 1, and the distribution of monitoring points in each section is shown in Fig. 2. Two different testing conditions are listed in Table 2.

Fig. 1 Layout plan and distribution of flow velocity monitoring section of modified Carrousel oxidation ditch

Table 1 Device parameters of Carrousel oxidation ditch

Fig. 2 Distribution diagram of monitoring points (Unit: mm)

Table 2 Operating conditions of Carrousel oxidation ditch

3 Results and discussion

3.1 Flow velocity distribution in oxidation ditch

Change of flow velocity has a certain impact on nitrogen removal process of the oxidation ditch, with its plug-flow effect and flow velocity as the variables to control total nitrogen removal efficiency [11]. Flow velocity could not only affect the sludge deposition, but also affect the hydraulic cycle time of the oxidation ditch, the proportion of the residence time of aerobic and anoxic environment, dissolved oxygen, organic matter, and the distribution of sludge concentration directly. In addition, flow velocity was also a direct reflection of the extent of disturbance in the trench, playing an important role in the shape and size of sludge floc directly, which was the key factor of the occurrence of SND process in the oxidation ditch.

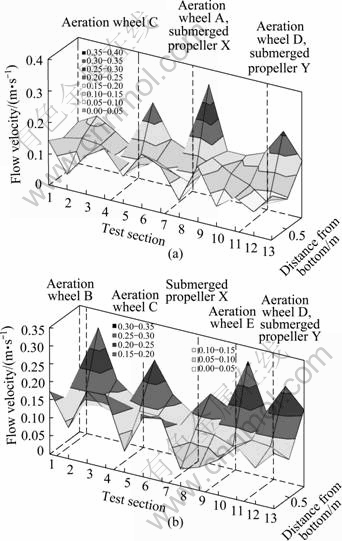

As can be seen from Fig. 3, flow velocity of the oxidation ditch was affected by the aeration and the changes of spatial location significantly, with the average velocity (0.140 m/s) in the trench of operating Condition 2 (opening four aeration wheels) being higher than the mean velocity (0.124 m/s) in Condition 1 (with three aeration wheels in operation). The velocity variations in the horizontal and vertical directions were also obvious, with the average velocity at the bottom, middle, upper part being 0.172, 0.122 and 0.127 m/s, which were significantly higher than the values (0.150, 0.106 and 0.115 m/s) under Condition 1. In the two kinds of operating conditions, the flow velocity in the first corner (outside of the diversion wall in cross section 3, and the inside of cross section 4) and inside of the cross section 11 was low and there showed the evidence of sludge deposition. Overall, the flow velocity in most of the regions in the two operating conditions of the oxidation ditch was in the range of 0.1-0.2 m/s, with the flow velocity in most of the bottom area generally meeting the requirements of no-deposition flow velocity (0.15 m/s [12]). The power density (18.87 W/m3) in operating Condition 1 was smaller than that in operating Condition 2 (24.38 W/m3) with less energy consumption.

Fig. 3 Spatial distribution of flow velocity: (a) Condition 1; (b) Condition 2

The lower flow velocity in the oxidation ditch was more conducive to nitrogen removal by SND [11]. There was a higher flow velocity region under the operating Condition 2, which was not only a waste of energy, but also led to the uniform distribution of the concentration of organic matter and dissolved oxygen in trench. And this made the alternating cycle time of aerobic and anoxic shorter, which was not good for the occurrence of SND process. Therefore, we should minimize the number of the opening aeration wheels under the premise of meeting the aeration demand and reduction of the sludge deposition, in order to promote the occurrence of SND process in the oxidation ditch.

3.2 Distribution of mixed liquor suspended solids (MLSS) in oxidation ditch

The size of activated sludge floc is an important factor which affects the SND process. Generally, the size of activated sludge floc is 20-2 000 μm [13]. When the size of activated sludge floc is 50-110 μm, highly efficient SND process can be obtained, while the floc size is mostly in the range of 60-80 μm and upwards [14]. In the same condition, the higher the sludge concentrations and the smaller the perturbation of the sludge, the more conducive to the formation of larger activated floc is, which is helpful for the SND process.

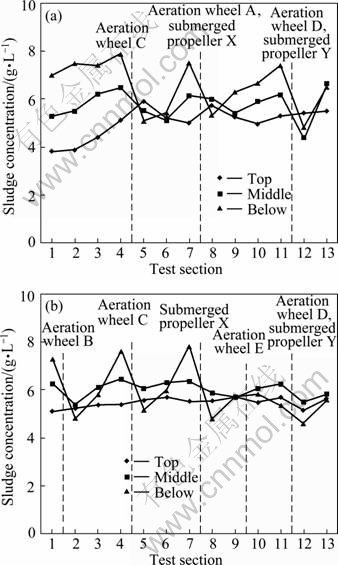

From Fig. 4, it was shown that when four aeration wheels were in operation (operating Condition 2), variations of MLSS in length, width and depth were all relatively small and the degree of mixture was high in the entire trench, which indicated that the disturbance was relatively large, and the proportion to form a large size sludge flocs should be reduced. When opening three aeration wheels (operating Condition 1), the variations of MLSS both along the flow path and in the vertical direction were larger, such as 1-4 cross section, and the MLSS difference between the neighboring two vertical layers was greater than 1 g/L. Degree of sludge mixture in ditch became worse, but the disturbance was smaller and more conducive to the formation of large particle flocs, which might promote the occurrence of SND process.

Fig. 4 MLSS variations along corridor: (a) Condition 1; (b) Condition 2

Considering different influent loadings, by increasing the concentration of sludge and minimizing the number of opening aeration wheels, disturbance of the trench could be reduced, which was more conducive to the process of SND occurrence. However, the increase of sludge concentration would also cause sludge deposition or aggravate the problem of deposition. In the practical operation, it was required to consider the various factors comprehensively and determine the appropriate concentration of sludge.

3.3 Distribution of dissolved oxygen (DO) in oxidation itch

Dissolved oxygen was the most important parameter to control the SND process occurrence in the oxidation ditch, which could directly affect the changes of aerobic-anoxic zone and the proportion of the spatial distribution. Controlling a relatively low concentration of dissolved oxygen was more conducive to the formation of aerobic and anoxic environment in the body of floc [15-16], thus creating the condition for the occurrence of SND.

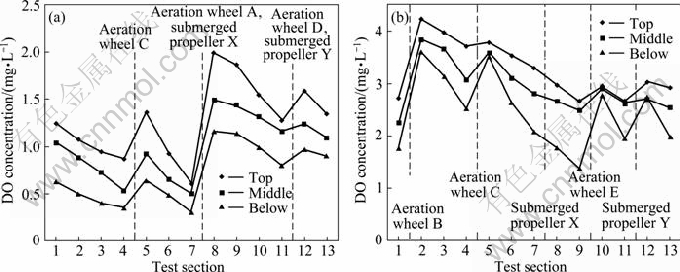

It can be seen from Fig. 5 that when the mixture was realized through the aeration wheel, the dissolved oxygen concentration increased. When the flow went far away from the aeration wheel downstream, the dissolved oxygen concentration decreased, but aeration wheel has very small impact on the dissolved oxygen concentration upstream. Studies have shown that, SND process occurred only when c(DO)<0.8 mg/L [4, 17]. With the four aeration wheels being in operation, the entirely dissolved oxygen concentration in the trench was generally greater than 2.5 mg/L, the aerobic state was almost in the best condition, and SND condition was destroyed. With three aeration wheels being in operation, the dissolved oxygen concentration in the cross-sections in trench of the oxidation ditch was roughly in the range of 0.5-1.5 mg/L, which indicated uneven distribution along the flow direction and the formation of a large area of anoxic-aerobic alternating zone, creating an ideal condition for the occurrence of SND process.

3.4 Distribution of soluble components in oxidation ditch

Based on the traditional nitrogen removal theory

[18], it is considered that dissolved oxygen condition for nitrification and denitrification processes is contradictory. The higher the concentration of dissolved oxygen within the reactor is, the more conducive to nitrification process. However, under low dissolved oxygen condition, the growth rate of nitrifying bacteria is low. In this condition, the lower the dissolved oxygen concentration, the more conducive to the denitrification process. Therefore, in the simultaneous nitrification and denitrification process, the supply of the dissolved oxygen should be optimized.

As can be seen from Fig. 6(a), under the operation Condition 1, along with the advancing of nitrifying process, the NH4+ concentration reduced gradually. To the end of the oxidation ditch system (sections 8-13), the dropping trend slowed down. This indicated that nitrification was almost completed (NH4+ concentration tended to be 2 mg/L) without being inhibited. As can be seen from Fig. 6(b), under the operation Condition 1, along the flow direction, TN concentration decreased. In some low DO regions, such as sections 1-4, sections6-7, and the lower part of the outer ditch, denitrifying bacteria consumed organic matter in water as the carbon source, taking nitrate and nitrite as electron acceptor, and then the nitrate nitrogen was reduced to the gaseous nitrogen to complete the denitrification process. To the end of the oxidation ditch system (sections 8-13), the dropping trend slowed down. This indicated that denitrification was almost completed (TN concentration tended to be 6 mg/L).

Fig. 5 DO variations along corridor: (a) Condition 1; (b) Condition 2

Fig. 6 NH4+ (a), TN ((b) and (d)) and ![]() (c) variations along corridor: (a) Under Condition 1; (b) Under Condition 1; (c) Under Condition 2; (d) Under Condition 2

(c) variations along corridor: (a) Under Condition 1; (b) Under Condition 1; (c) Under Condition 2; (d) Under Condition 2

As can be seen from Figs. 6(c) and 6(d), under the operation Condition 2, the TN concentration reduced appreciably in the front of the oxidation ditch under the influence of dilution of circulation water. With the flow of water, TN and ![]() concentrations were essentially unchanged, indicating that there was no denitrification basically in the oxidation ditch system. The results proved that high DO concentration was destructive to SND.

concentrations were essentially unchanged, indicating that there was no denitrification basically in the oxidation ditch system. The results proved that high DO concentration was destructive to SND.

3.5 Functional zones division of biochemical reaction in oxidation ditch

In the surface aeration oxidation ditch system, uneven distribution of DO led to the co-existence of aerobic and anoxic situations in three dimensions. The distribution of pollutant concentration was thought to be the result from fluxion and biochemical reaction. On the basis of the spatial distribution of DO and soluble components, it was hold that the channel of oxidation ditch could be divided into several different functional zones from the aspect of biochemical reaction. The detailed division is shown as follows.

1) Sections 1-4

The flow velocity was on the low side in these areas (average flow velocity was 0.10 m/s). Except for the higher DO concentration of the top of section 1 (1.25 mg/L), most of the DO concentrations in other areas ranged from 0.4 to 0.9 mg/L. So, the top of section 1 should be defined as nitration reaction zone and other areas should be defined as denitrification reaction zone.

2) Section 5

The wastewater flowed toward section 5 from section 4. In this process, the DO concentration increased with the operation of aeration wheel C and guiding plate. Finally, the DO concentrations at the top, middle and bottom part of section 5 were 1.4, 0.9 and 0.5 mg/L. So, the top of section 5 should be defined as nitration reaction zone, while the middle and bottom parts of section 5 should be defined as denitrification reaction zone.

3) Sections 6-7

The DO concentrated on the low side in these areas (DO concentration ranged from 0.3 to 0.9 mg/L), so these areas could be defined as denitrification reaction zone.

4) Sections 8-10

The flow velocity was on the high side in these areas (average flow velocity was 0.15 m/s) and the DO concentration increased under the action of aeration wheel A. So, these areas could be defined as nitration reaction zone.

5) Sections 11-13

From the top to the bottom of these sections, the DO concentration decreased gradually. So, the top and middle of these areas could be defined as nitration reaction zone and the bottom as denitrification reaction zone.

Under the operation Condition 1, when three aeration wheels were in operation, the anaerobic region and aerobic region could occur simultaneously in one oxidation ditch, which was helpful for the process of SND.

The division of functional zones of biochemical reaction in the Carrousel oxidation ditch system could contribute to the theory basis to the optimization control and SND of Carrousel oxidation ditch.

3.6 Environmental stability of DO

Wastewater treatment is a dynamic changing process, and both quantity and quality of wastewater show considerable fluctuation even in one day. Variations in different seasons were introduced by such factors as water consumption of residents and rainfall. In low temperature period (winter), fewer water consumption and rainfall led to the high influent concentration and fluctuation. On the contrary, in high temperature period (summer), more water consumption and rainfall led to the low influent concentration and fluctuation.

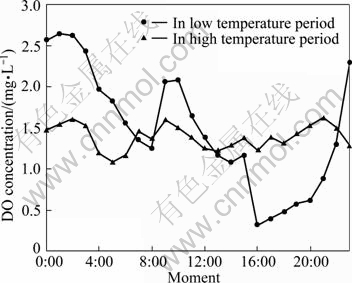

The capacity of dilution buffering makes oxidation ditch system have higher resistance against concussive loading. With low fluctuation of influent, the DO concentration has no significant change within one day. As can be seen from Fig. 7, the DO concentration of section 9 ranged from 1.08 to 1.63 mg/L in high temperature period. On the contrary, with high fluctuation of influent, the DO concentration changed significantly in a day. At certain time in a day, the DO concentration was on the high side and it made the whole oxidation ditch become completely aerobic zone. At other time in a day, the DO concentration was on the low side and it made the whole oxidation ditch become complete anoxic zone. Because of these changes, the process of SND could not occur simultaneously and steadily in oxidation ditch. So, in an enhanced SND control technology, we should take various elements into the comprehensive consideration when deciding the strategy to control, such as influent load, aeration condition and reaction process.

Fig. 7 DO concentration vs time of section 9

3.7 Optimization control of DO and enhanced nitrogen removal

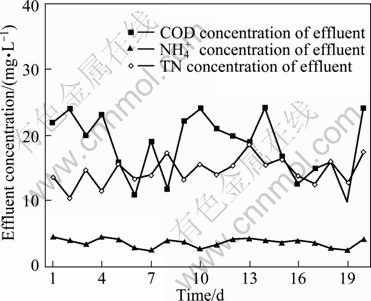

Under the condition of stable influent concentration, too low DO concentration had adverse effect on nitration reaction, and too high DO concentration introduced negative effect on denitrification reaction. In this work, when three aeration wheels were in operation, the anaerobic region and aerobic region could be obtained simultaneously in one oxidation ditch, which was helpful for the process of SND. Under the operation Condition 1, the oxidation ditch system showed good removal performance and the effluent concentration (COD, NH4+ and TN) could meet the first level B criteria specified in GB 18918—2002 steadily (60, 8 and 20 mg/L) (Fig. 8).

Fig. 8 Effect of modified Carrousel oxidation ditch operation under Condition 1

4 Conclusions

1) The spatial distribution of flow velocity, DO and MLSS were affected markedly by the operation condition of the aeration wheels. Different distribution patterns of biological and hydrological parameters of two operation conditions in Carrousel oxidation ditch system were investigated, and impact factors of biological and hydrological parameters for SND were analyzed. The results showed that when three aeration wheels were in operation, the anaerobic region and aerobic region could occur simultaneously in one oxidation ditch, which was helpful for the process of SND.

2) On the basis of the spatial distribution of DO and soluble components, it was hold that the channel of oxidation ditch could be divided into several different functional zones of biochemical reaction, which might contribute to the theory basis for optimization control and SND of Carrousel oxidation ditch.

3) Under high fluctuation of influent, the DO concentration changed significantly within a day, which introduced adverse effect on the stable environmental condition of SND. So, considering the changing influent, some dynamic control methods should be implemented to realize the stable and efficient SND.

References

[1] DENG Rong-sen. Oxidation ditch wastewater treatment theory and technology [M]. Beijing: Chemical Industry Press, 2006: 1-8. (in Chinese)

[2] OU Yue-zhou, HU Yong-you. Oxidation ditch sewage treatment technology and projects [M]. Beijing: Chemical Industry Press, 2005: 6-30. (in Chinese)

[3] HAO X D, DODDEMA H J, GROENESTIJN J W. Conditions and mechanism affecting simultaneous nitrification and denitrification in a Passveer oxidation ditch [J]. Bioresource Technology, 1997, 59(1): 207-215.

[4] KLANGDUEN P, JURG K. Study of factors affecting simulataneous nitrification and denitrification [J]. Water Science and Technology, 1999, 39(6): 61-68.

[5] YANG Hua-zhan, WANG Tao, DENG Rong-sen. Research on flow characteristic of curve channel of integrated oxidation ditch [J]. Journal of Chongqing Jianzhu University, 2007, 29(3): 106-109. (in Chinese)

[6] LUO N, LI W M, DENG R S. Numerical simulation of a combined oxidation ditch flow using 3D k-ε turbulence model [J]. Journal of Environment Science, 2005, 17(5): 808-812.

[7] HELEN X L, GLEN T D, PETER F S. Application of computational fluid dynamics to closed-loop bioreactors: I. Characterization and simulation of fluid-flow pattern and oxygen transfer [J]. Water Environment Research, 2007, 79(6): 600-612.

[8] YANG Yin, YANG Jia-kuan, ZUO Jiao-lan, LI Ye, HE Shu, YANG Xiao, ZHANG Kai. Study on two operating conditions of a full-scale oxidation ditch for optimization of energy consumption and effluent quality by using CFD model [J]. Water Research, 2011, 45(11): 3439-3452.

[9] YANG Yin, WU Ying-ying, YANG Xiao, ZHANG Kai, YANG Jia-kuan. Flow field prediction in full-scale Carrousel oxidation ditch by using computational fluid dynamics [J]. Water Science and Technology, 2010, 62(2): 256-265.

[10] LIU Y C, SHI H C, XIA L. Study of operational conditions of simultaneous nitrification and denitrification in a Carrousel oxidation ditch for domestic wastewater treatment [J]. Bioresource Technology, 2010, 101(3): 901-906.

[11] ABUSAM A, KEESMAN K J, SPANJERS H. Effect of oxidation ditch horizontal velocity on the nitrogen removal process [EB/OL]. [2011-05-30]. http:// www.ewaonline.de, 2007-02-10/.

[12] DENG Rong-sen, KUANG Li, LI Yuan. Research and experiment on mixed liquor of Orbal oxidation ditch [J]. Journal of Chongqing Jianzhu University, 2007, 29(2): 86-89. (in Chinese)

[13] HOLLEY K S. Simultaneous nitrification and denitrification in Activated sludge floc [D]. Rolla, USA: University of Missouri-Rolla, 2003.

[14] ANDREADAKIS A D. Physical and chemical properties of activated sludge flocs [J]. Water Research, 1993, 27(12): 1707-1714.

[15] ZENG Wei, ZHANG Yue, LI Lei. Simultaneous nitrification denitrification via nitrite under limited aeration [J]. Journal of Beijing University of Technology, 2010, 36(9): 1263-1270. (in Chinese)

[16] YAN Jun, WANG Shu-ying, GAO Shou-you. Simultaneous nitrification and denitrification of wastewater with low C/N ratio under low DO [J]. China Water and Wastewater, 2007, 23(3): 44-48. (in Chinese)

[17] KATIE A T, NATAITE B, RALF C R. Simultaneous nitrification and denitrification using stored substrate (PHB) as the electron Donor in an SBR [J]. Biotechnology and Bioengineering, 2003, 83(6): 706-720.

[18] PAUL E P, LISSON S S, MAURET M C. Process state evaluation of alternating oxic-anoxic activated sludge using ORP, pH and DO [J]. Water Research and Technology, 1998, 38(3): 299-306

(Edited by YANG Bing)

Foundation item: Project(2009ZX07315-002-01) supported by the Water Pollution Control and Management of Major Special Science and Technology, China; Project(CDJXS11210001) supported by the Scientific and Technical Innovation Project of Chongqing University Graduation Foundation, China

Received date: 2011-07-26; Accepted date: 2011-11-14

Corresponding author: ZHANG Zhi, Professor, PhD; Tel: +86-23-65120811; E-mail: zhangzhicq@126.com

Abstract: To enhance the nitrogen removal, a systemic monitoring of the biological and hydrological parameters of Carrousel oxidation ditch in Chongqing Jingkou Wastewater Treatment Plant was carried out to study the feasibility of simultaneous nitrification and denitrification (SND). The variation and distribution of parameters such as flow velocity, concentration of dissolved oxygen (DO) and mixed liquor suspended solids (MLSS) in oxidation ditch were monitored and analyzed, which were major control factors for SND. The results showed that, the dimensional distribution of flow velocity, DO and MLSS were affected significantly by the operation condition of the aeration wheels. With all the four aeration wheels being in operation, DO and flow velocity were higher and the mixing of MLSS was sufficient. With three aeration wheels being in operation, the flow velocity in most of the bottom areas was enough to meet the basic requirements of no deposition, and the anaerobic region and aerobic region could exist simultaneously in one oxidation ditch, which was helpful to the process of SND. According to spatial distribution characteristics of the flow velocity, DO and soluble components under optimized condition, different functional zones of biochemical reaction in the Carrousel oxidation ditch system were defined, which might contribute to the optimization control and SND of Carrousel oxidation ditch.