DOI: 10.11817/j.issn.1672-7207.2021.01.003

质子交换膜燃料电池热管理问题的研究进展

侯健1,杨铮1,贺婷1,李强1,王倩2,张建胜1

(1. 清华大学 能源与动力工程系,热科学与动力工程教育部重点实验室,北京,100084;

2. 暨南大学 能源与电力研究中心,广东 珠海,519070)

摘 要:

前人类社会面临的主要挑战,清洁能源高效利用技术是实现人类社会可持续发展的重要保障,其中,氢燃料电池特别是质子交换膜燃料电池(PEMFC)因其具有高效环保等特点备受青睐。PEMFC在发电过程中产生大量的热,产热与散热的平衡决定电池的温度,电池对温度的要求很苛刻,只允许稍微偏离设计点的温度,因此,通过热管理将电池的温度均匀地控制在设计点温度附近非常重要。本文从产热、传热和热管理策略(冷却策略、余热利用、控制策略)等方面综述PEMFC的热管理问题,重点介绍PEMFC组件在导热系数和冷却策略方面的研究现状,并提出了需要进一步研究的问题。

关键词:

中图分类号:TM911.4 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)01-0019-12

Research progress on thermal management of proton exchange membrane fuel cells

HOU Jian1, YANG Zheng1, HE Ting1, LI Qiang1, WANG Qian2, ZHANG Jiansheng1

(1. Key Laboratory for Thermal Science and Power Engineering of the Ministry of Education, Department of Energy and Power Engineering, Tsinghua University, Beijing 100084, China;

2. Energy and Electricity Research Center, Jinan University, Zhuhai 519070, China)

Abstract: The balance of energy demanding and environmental protection are the main challenges of human society at present. Efficient and clean utilization of energy are the key to achieve sustainable development. Hydrogen fuel cell technology, especially proton exchange membrane fuel cell (PEMFC), is favored because of its high efficiency and environmental protection. A large amount of heat will be generated in the power generation of PEMFC. The temperature of the battery is determined by the balance of heat generation and heat dissipation. The battery is very sensitive to the temperature, which allows only a small deviation from the design temperature. Therefore, it is significant to control the temperature of the battery uniformly close to the design point through thermal management. The thermal management of PEMFC in the aspects of heat generation, heat transfer and thermal management strategies(cooling strategy, waste heat utilization, control strategy) was summarized. The research status of thermal conductivity of PEMFC modules and cooling strategies were introduced. The problems that need to be further studied were proposed.

Key words: proton exchange membrane fuel cell; thermal management; thermal conductivity; cooling strategy

随着能源与环境问题的日益严重,清洁能源技术受到了世界各国的关注与重视[1]。氢燃料电池特别是质子交换膜燃料电池(PEMFC)具有能源转换效率高、排放无污染、燃料来源广、操作温度低和启停迅速等特点,可应用在交通运输、便携式发电、固定电站等领域[2]。PEMFC的结构组成从其中心至两侧分别为质子交换膜、催化剂层(CL)、微孔层(MPL)、气体扩散层(GDL)、双极板(BPP)等(如图1所示)[3],发电的原理很简单,氢气在阳极失去电子被氧化,氧气在阴极与穿过质子交换膜而来的氢离子以及外电路传输而来的电子结合生成水,并放出大量的热,如何处理好这部分热,是PEMFC商业化的最重要问题之一[4]。PEMFC的能量转换效率为50%左右,意味着有50%的能量以热能形式释放出来,若散热效果不好,则会造成最高温度超过膜的设计点温度(常用的Nafion膜最高耐受温度为80 ℃[5])以及温度不均匀,而温度分布会影响气体的供应、电化学反应、质子交换膜的传输特性以及水管理,对PEMFC的总效率与稳定性造成影响[4]。所以,PEMFC中热管理的主要目的是确保电堆在可靠高效的温度附近运行,并保证内部温度的均匀分布,避免产生局部高温[6]。本文作者综述了近年来PEMFC中热管理问题的研究进展。

图1 PEMFC运行过程中不同组件的温度分布、产热和热性能[3]

Fig. 1 Temperature distribution, heat generation and thermal performance of different components during PEMFC operation[3]

1 温度对PEMFC电堆性能的影响

热管理问题之所以重要,就在于它深刻地影响着PEMFC电堆的效率与稳定性。许多学者对PEMFC电堆性能的影响因素(运行温度、入口气体的温湿度、流量与电池冷却条件等)进行了研究[7-9]。YU[7]认为入口气体温度的影响大于湿度的影响,入口气体温度与电堆最佳工作温度的温差越大,电堆的性能越低,这意味着可以通过预热入口气体来提高电池性能。另外,电池温度、电压、反应气体的流量之间的交互作用对电池性能有显著影响,这说明操作参数对电池性能的影响并不是独立的,其中,交互作用也需要考虑在内[8]。PANDIYAN等[9]发现电极的内阻会随温度的升高而升高,所以,可以通过优化电极的生产工艺来降低电极内阻,从而获得更高的电效率。

除此之外,温度升高可增大膜的电导率、交换电流密度、催化剂的催化活性且有利于气体扩散,从而提高电池的性能[10]。但是过高的温度和电流密度容易造成阳极侧膜脱水,这与膜内的电渗透效应有关[11],过高的电流密度还会造成电池内温度分布不均匀[12],而局部高温是许多降解机制的驱动力,如湿热变形、蠕变、铂溶解和双极板腐蚀[13]。这些都表明电池的温度会极大地影响电池的性能,所以,需要对电池内的产热与传热有更深入的认识。

2 PEMFC的产热与传热

2.1 产热

PEMFC的能量转换效率为50%左右,这意味着一半的化学能以热能的形式释放出来,电池中的产热包括化学反应熵热、电化学反应不可逆热、焦耳热、冷凝热以及反应气体显热(可忽略)[14]。一般情况下,熵热、不可逆反应热和焦耳热的总和相当于质子交换膜燃料电池的输出功率,粗略计算,它们分别占总放热量的55%,35%和10%[15-16]。

在某些情况下,水的相变在加湿电堆的热平衡分析中也是不可忽视的。LIU等[17]通过分析PEMFC电堆加湿后水的相变对热平衡的影响,发现在冷却水带走的热量中,水蒸气冷凝放出的热量占30%~40%。

2.2 传热

如果不能及时散热,电池的温度会升高,水蒸气的饱和压力上升,极有可能发生膜脱水和降解等现象[9],这极大地损坏了膜性能,降低了电池发电效率,所以,需要详细地了解电池的传热特性,从而选择合适方式进行散热。PEMFC内的散热方式主要为导热与对流换热(见图1),由于GDL的孔径小于100 μm,没有形成强烈的对流,所以,其内部对流换热一般可忽略。导热系数是材料的固有性质。在PEMFC中,一旦几何形状与热源被确定,电池内的温度分布就将由导热系数决定[18],所以,PEMFC组件的导热系数受到了广泛研究。

电解质膜与双极板的结构比较简单,其导热系数能被很精确地测量(见图1)。但GDL和MPL结构复杂,学者们对它们的有效导热系数进行了大量研究。CL是由催化剂组分、疏水物质和电解质离聚体组成的三维多孔结构[19],是膜电极中最活跃的一层,为电子、质子、反应物和产物的传输提供了途径,同时促进了电化学反应的进行[20]。CL的结构不像GDL和MPL那样复杂,它的导热系数几乎不受压缩、测量方法和基材的影响,为0.22 W·m-1·K-1左右[21]。

2.3 与水管理的耦合

PEMFC中的质子交换膜(这里主要指Nafion膜)对水含量有着近乎苛刻的要求,若水含量小,则容易使膜的离子电导率下降,因为氢离子在膜中的传导需要以水分子作为介质,这意味着水分子会随着氢离子的传导从阳极一起运输到阴极,这种现象称为电渗透效应。电渗透效应会导致阳极比阴极更容易缺水,往往需要给反应气体加湿,以保持膜充足的水含量,但是,如果加湿过度又会造成阴极积水现象,因为水会在阴极产生,加上电渗透效应运输过来的水分,非常容易使阴极被液态水淹没,阻碍氧气在阴极的传输与反应,最终导致电池性能降低。所以,PEMFC的水管理与热管理一样是PEMFC商业化最重要的问题之一[22]。

在PEMFC中水分的传输与热量的传输通常是耦合在一起的,这表现在:水蒸气饱和压力随温度呈指数增长[16],这意味着高温时膜更容易脱水;水蒸发和冷凝的过程分别伴随着潜热的吸收和释放;由于热管效应(温度梯度引起水的相变和净传质),水和热传输同时发生[15]。

3 气体扩散层与微孔层的导热系数

仿真是研究PEMFC热管理问题的常用手段,仿真精确度会受到物性参数精确度的影响。目前人们对双极板、催化层、质子交换膜的导热系数进行了深入研究,但由于GDL与MPL内部结构比较复杂,对于它们的有效导热系数的研究还存在一些问题,所以有必要对它们进行更多研究。

3.1 气体扩散层(GDL)

GDL是PEMFC中一种重要的纤维多孔介质,它管理着电子、热量以及流体的传输[23-24]。由于GDL是各向异性的多孔介质,其有效导热系数分为面内有效导热系数和通面有效导热系数,一般用通面有效导热系数(keff)来表征它的导热能力。在室温条件下,ELAT GDL的keff为0.2 W·m-1·K-1,Sigracet GDL的keff为0.3~0.4 W·m-1·K-1,Toray GDL的keff为0.3~0.8 W·m-1·K-1[25]。

keff的研究可分为实验测量和模型预测两部分,keff的实验测量分为原位与非原位测量。原位测量是指通过测量运行中PEMFC内部的温度分布得到keff,这种方法由于需要插入热电偶而对电池造成不可避免的干扰,影响测量精度。非原位测量技术有测量瞬态导热系数的激光闪光辐射测量技术和测量稳态导热系数的可压缩热流法,此外,还有最近才用于keff非原位测量的光纤布拉格光栅传感技术等,其中热流法因其测量精度高、适用性广得到了普遍使用[26-27]。

3.1.1 实验测量

理论上,GDL的keff应该是固体纤维与孔隙内流体导热系数的简单函数,但由于GDL复杂的、各向异性的微观结构,以及其内部涉及的多相物质运输,使得模型对GDL的keff的预测存在一定的局限性,同时,keff的原位测定也变得很困难,学者们大多研究某几个因素对keff的影响,这些因素包括压缩率、含水量、聚四氟乙烯(PTFE)含量、温度、非均匀孔隙度等[28]。

CHEN等[29]采用光纤布拉格光栅传感技术研究了PTFE含量以及压缩率对keff的影响,发现当PTFE含量较高时,keff会随着压缩率的增大而减小,当PTFE含量较低时,keff会随着压缩率的增大而增大。这是因为压缩GDL时过多的PTFE会减少碳纤维之间的接触面,从而使keff减少,他们认为对于特定含量的PTFE,存在一个与之对应的压缩率,使得keff最大。通过测量GDL的孔中氢气、空气、氩气时的导热系数,BOCK等[30]得出通氢气的GDL导热系数会比通空气的高15%~20%,这是氢气的导热系数比空气的导热系数高7倍造成的结果。通过仿真研究膜电解质组件(MEA)的温度分布,发现由于阳极GDL内气体的导热系数发生了改变,通过MEA的温度分布发生了较大改变(2 ℃左右)。在微米级的GDL厚度下,2 ℃意味着温度梯度非常大,因此,在对PEMFC建立热模型时,需要考虑通入气体的导热系数,以免得出错误的结果。

3.1.2 模型预测

模型可分为仿真模型与解析模型,仿真模型可用来研究实验测量中难以操作的问题,解析模型可用于研究相关因素对GDL导热系数的影响。导热系数可以用单一的解析关联式来估计,但不能准确地表示。

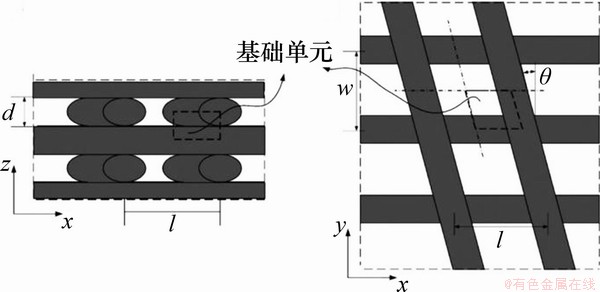

YABLECKI等[31]采用格子玻尔兹曼方法仿真研究了含水量对keff的影响,认为keff会随着液态水饱和度的增加而增加,因为液态水的导热系数较高。SADEGHI等[32]对PEMFC建立了1个GDL的简化几何(见图2)与传热模型,用于预测GDL的keff。他们通过与其他文献中的实验结果对比验证了模型的合理性,然后用该模型预测了GDL中几何参数与操作参数对keff的影响,预测结果表明keff与碳纤维之间的堆叠角θ成反比,与双极板对GDL的压力、模型基础单元的纵横比(w/l=1时keff最大)成正比,还发现碳纤维的直径d与操作温度对keff的影响比较小。SADEGHIFAR等[33]以此模型为基础,研究了14个GDL与微孔层(MPL)在不同压缩条件下的通面导热系数,认为GDL中加入PTFE或者MPL都会增加接触热阻从而降低keff。YABLECKI等[34]提出了一种确定keff的解析模型,热模型只考虑碳纤维接触点处的热收缩与扩散热阻,其输入信息是由X线计算机断层成像实验提供的,并利用该模型研究了非均匀孔隙率分布、GDL压缩率和聚四氟乙烯含量对4种东丽碳纸的keff的影响,得出keff与孔隙率成反比例关系以及keff会随着双极板对GDL的压力增加而增加,但当孔隙率不变时,增加GDL的厚度可以增加keff。AZIZAN[35]等在前人的基础上提出了一种修正后的分形方程,利用扫描电子显微镜的图片确定GDL多孔介质中的弯曲和孔隙分形维数,从而可以得到与实验值吻合较好的keff,为GDL中的导热系数确定提供了一种新的思路。

图2 GDL几何模型的正视图和俯视图[32]

Fig. 2 Front view and top view of GDL geometric model[32]

3.1.3 面内有效导热系数

面内有效导热系数受到压缩、温度、PTFE含量、MPL涂层和纤维方向等多种因素的影响,是通面有效导热系数的5~10倍(取决于压实压力)[36-39]。

3.2 微孔层(MPL)

PEMFC中往往会在GDL与催化层之间再加上一层MPL。MPL由炭黑粉末和疏水剂(PTFE)组成,可以防止GDL中的液态水回流,又可以促使阴极生成的水蒸气进入GDL中,对水热管理非常重要[40-42]。虽然MPL本身会增加电池中的热阻,但是它的存在会使电池中的温度分布更加均匀,改善了PEMFC的热管理。这是因为GDL与CL之间的接触热阻占GDL热阻的40%[43],而MPL由于具有较高的接触表面积,大大降低了这种接触热阻,从而改善了电池的传热[44-45]。BURHEIM等[46]研究了PTFE含量与压力对MPL有效导热系数的影响,发现当压力从400 kPa变化到1 600 kPa时,导热系数从0.05 W·m-1·K-1增加到0.12 W·m-1·K-1,但与PTFE的含量关系不大。

3.3 GDL-MPL复合区

GDL与MPL通常被视为单独的层。然而,在2种不同材料的融合处存在相当大的界面区域,是由MPL侵入GDL形成的GDL-MPL复合区。此区域的属性与其组成的任一材质都不同。表1所示为GDL-MPL复合区域的研究进展[47-49],表明其对PEMFC内部的传热有影响,但影响程度还有待进一步研究。

表1 GDL-MPL复合区域的研究进展

Tabel 1 Research Progress of GDL-MPL composite region

4 PEMFC的热管理策略

为了保证PEMFC的高效运行,除了电池本身外还需要一些配套系统,一般分为氧化剂子系统、燃料子系统、冷却子系统、电气子系统以及控制子系统共5个配套系统[50]。

4.1 常用的冷却方式

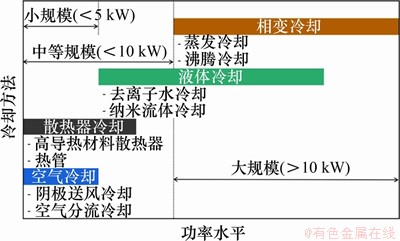

PEMFC一般工作温度为80 ℃左右,与环境的温差比较小,同时,电池本身的辐射以及自由对流换热量很小,所以,PEMFC电堆中产生的热主要通过冷却介质带走。冷却介质的流动需要耗费泵功率,该功率需要尽可能地小,必须在优化传热的同时将泵功率最小化,使系统功率最高[9]。常用的冷却方式有空气冷却、散热器冷却、相变冷却和液体冷却等,可以根据电池功率等技术和经济指标来选择合适的冷却方式[40, 51-52],如图3所示[53]。

图3 PEMFC的冷却方式与功率水平的关系[53]

Fig. 3 Relationship between cooling mode and power level of PEMFC[53]

4.1.1 空气冷却

对于小功率(<100 W)的电堆,可通过增加阴极送风来实现冷却。这种冷却方法的优点之一是结构简单,缺点是与阳极侧相比,电堆的阴极侧需要相对较大的流场尺寸,因此,增加了电堆的体积。这种冷却方法没有足够的温度控制,冷却在很大程度上取决于环境空气的温度和湿度。

除此之外,还可采用空气分流冷却。空气分流冷却需设置单独的冷却流道,由于空气的散热能力较差,使其冷却功率受到了限制,一般要求电堆的功率不超过5 kW。在这种冷却方式中,必须使用风机进行空气循环,但这种冷却方式容易造成电堆电池之间的温度不均匀(最高8 ℃),从而导致电池之间电压的差别很大,降低了整个电堆的总功率[54]。近年来,空气冷却PEMFC受到了广泛关注,因为该电池系统可将冷却子系统与氧化剂子系统集成在一起,从而降低了燃料电池的质量、体积和成本,并且降低了控制复杂度[55]。

4.1.2 散热器冷却

散热器冷却又称被动冷却或边缘冷却,利用散热器(高导热材料或热管)通过热传导的方式将热量从中心区域移至PEMFC的边缘,然后排放到大气中[56]。与液体冷却相比,散热器冷却可降低冷却系统的复杂性,提高系统的可靠性。

高导热材料散热器冷却的缺点是散热量小,要求散热器具有很高的导热系数。散热器的材料一般为石墨基材料,因为石墨的导热系数高,密度低[57]。WEN等[58]对PEMFC中热解石墨片(PGS)的热性能进行了实验研究,PGS有效降低了电池内部的温度,提高了传热速率,在有PGS的电池中,温度分布也比没有PGS的电池中的温度分布更均匀。WEN等[59]发现PGS的加入使电堆的最大功率提高了15%以上,显著改善了电堆的性能,缓解了低阴极流量下的积水问题。

另一种散热器是热管。热管具有非常高的导热系数,液体在蒸发段蒸发,将热量带到冷凝段排出,再通过毛细作用等回流到蒸发段。热管的特点有对重力不敏感、可在不增加功率输入的情况下进行长距离传热、端与端之间的温降小、设计制造简单等。根据燃料电池功耗,可采用不同类型的热管(微型热管(1~100 W)、环路热管、脉动热管、吸附式热管(100~1 000 W)等)[60-61]。采用仿真方法可以对U型脉动热管内的对流和沸腾换热速率进行研究,该热管的两端为蒸发器,中间部分为冷凝器,ARABNEJAD等[62]发现随着蒸发器温度的升高,管内对流沸腾换热速率也随之增大。VASILIEV等[63]提出了一种带多孔涂层微通道的微型被动式直接甲醇燃料电池(DMFC)冷却系统,利用热管效应强化了系统的冷却,冷却介质为丙烷。模拟结果表明该冷却系统的换热量是热虹吸式沸腾冷却系统的换热量7~8倍。

4.1.3 相变冷却

目前大型的PEMFC电堆多采用液体冷却,与之相比,相变冷却有许多特点,如降低冷却剂流量、简化系统布局和取消冷却剂泵等。液体冷却利用的是液体的显热变化,而相变冷却利用的是冷却剂的相变潜热,大大提高了系统的散热能力,所以,只需少量的冷却剂即可满足散热的要求。相变冷却有蒸发冷却与沸腾冷却2种方式。

蒸发冷却要求冷却剂(常用水)的沸腾温度高于PEMFC电堆的温度,这是为了使冷却剂在需要的地方蒸发而不是提前蒸发。由于液体的蒸发,两相传热具有比单相传热明显更高的散热能力,采用该方式可减小冷却系统的尺寸。蒸发冷却通过阳极气流将冷却介质输送到燃料电池,通过膜传输(电渗透效应),然后蒸发到阴极气流中,这样可在不对PEM燃料电池的性能造成不利影响的情况下冷却PEMFC[64]。由于质子交换膜燃料电池的工作温度在60~80 ℃之间,常用水作为冷却剂工质,但水需要被很好地雾化,这与阳极气体加湿有很大的区别,因为只有雾化水才能在氢气中均匀分布,水滴才能在不阻碍氢气流动的情况下通过气体扩散层,才不会影响电池的性能[65]。SNYDER[65]提出了一种超声雾化技术,可有效提高PEMFC的整体效率。

在沸腾冷却时,冷却剂的沸腾温度必须低于PEMFC电堆的温度,从而能在冷却流场内保持沸腾,这就需要选择合适的冷却剂。沸腾冷却具有很强的冷却能力,广泛应用于高热流密度设备的制冷领域,如计算机芯片、激光二极管等,也可应用于质子交换膜燃料电池电堆的冷却[66]。与传统液体冷却方式类似,沸腾冷却需设计独立的冷却液流道,其本质上涉及两相流和不断变化的流型。理想的配置将使用沸腾温度比最佳PEM电堆工作温度低10~20 ℃的冷却介质。因此,当PEM电堆上升到其设计的工作温度时,将有足够的过热用于沸腾,并导致自然驱动的流动[67]。所以,沸腾冷却不仅可以省去冷却泵,而且有利于PEMFC电堆工作温度的稳定和均匀[66]。SOUPREMANIEN等[68]通过实验对单相流和沸腾流中的冷却剂进行了比较,发现无论选择哪种几何形状的冷却流场,沸腾流的冷却效果都比单相流的好。

4.1.4 液体冷却

在大型的PEMFC电堆(功率>10 kW)中的冷却方式一般以液体冷却为主,冷却液常用去离子水、纳米流体等,液体冷却的效果虽好,但由于增加了循环泵与散热器,增加了寄生功率。并且冷却流场中液体的流动方式会影响PEMFC电堆中的温度分布,冷却剂的分布越均匀,温度分布就越均匀[69],所以,热管理的一个核心就在于流场的优化。流场有平行流场、蛇形流场以及高成本的仿生流场等,单条流道有C型、V型、U型和三维流道等[70-72]。

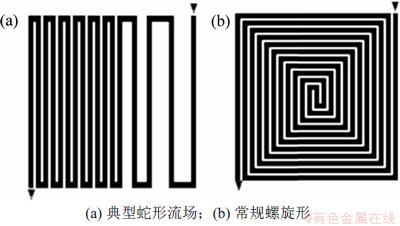

CHEN等[73-74]对蛇形流场和平行流场进行了比较,得出采用蛇形流场可获得更好的冷却性能。图4所示为2种典型的冷却流场。GHASEMI等[75]对6种带蛇形流场的PEMFC进行了研究后发现常规螺旋形流场(图4(b))具有较好的温度分布与性能,但压降较大,若同时要求流场的压降不能太大,则可选择典型蛇形流场(图4(a))。CASTELAIN等[76]测量了混沌几何(V形、C形)流道和直流道等的热性能,测量结果表明与直流道相比,混沌几何流道的内部对流换热系数有较大的提高。C型流道换热增强的最多,但同时考虑换热增强与压力损失时V型流道最好[77]。这些优化的核心思想都是在保证PEMFC电堆中温度分布良好的条件下,尽可能地降低寄生功率,从而提高总的能量利用效率。

图4 2种典型的冷却流场[75]

Fig. 4 Two typical cooling flow fields[75]

冷却剂的热物理特性对燃料电池液体冷却方式的效率有显著影响,除了使用去离子水作为冷却介质外,人们发现纳米流体是非常好的一种冷却介质。由于固体的导热系数通常高于液体的导热系数,因此,可以通过将微小或较大尺寸的固体颗粒悬浮在流体中强化传热[78],目前的挑战是如何研制出一种导热系数高但电导率严格限制在2 μS/cm以下的纳米流体冷却剂[79]。SAROJINI等[80]对含有不同体积分数的金属和陶瓷颗粒(Cu,Al2O3和CuO)的纳米流体的导电性进行了实验评估,发现在水和乙二醇基纳米流体中,电导率都随着颗粒浓度的增加和颗粒粒径的减小而增大,且只有当乙二醇的体积分数小于0.05%才能满足电导率在2 μS/cm以下的要求。除此之外,与基础流体相比,Al2O3纳米流体的电导率随体积分数的增加而增加,随温度的升高而增加[81]。

4.2 系统余热利用

PEMFC的能量转换效率一般在50%左右,反应中一半的化学能都以热能的形式释放出来,若能对这些释放出来的余热加以利用,如用于热电联产系统、温差发电系统等,则会大大提高总的能量利用效率。

采用热电发电装置可将PEMFC排放的一部分废热利用起来。KWAN等[82]发现在余热利用的同时可有效降低散热器的面积。DENG等[83]对有轨电车中的PEMFC和基于热电材料的余热发电装置(WHUS)的联合系统进行了研究,发现热电材料产生的电量可供给外部或者内部耗能装置如Li离子电池、水泵、冷却风扇等,同时因为分流了一部分电池堆出口冷却水用于热电发电,还可降低风扇的冷却压力。但该余热发电装置的热电转化效率并不高,当电堆功率为159 kW时,只能够产生1.11 kW热电功率。由于热电材料的成本较高,将其商业化应用于PEMFC-WHUS联合系统还有很多困难,可能随着热电材料的研究在成本方面取得新的突破,这种情况会有所改善。

4.3 控制策略

传统的冷却方法可进行有效散热,但在响应速度、稳定性等方面还需采取控制策略来解决[84]。良好的控制策略可帮助PEMFC电堆将运行温度控制在一个稳定高效的区间内,从而提高电堆的寿命与能量转化效率。

经典的比例、积分和微分(PID)控制器通常用于调节氢气流量和空气流量的反馈电压控制和前馈电流控制。自整定PID控制器或滑模控制器适应不断变化的动态响应,响应速度更快。自适应控制器(AC)如负载调节器和极值搜索控制器不断更新控制动作。模型预测控制(MPC)使用PEMFC模型来预测系统行为和更新控制器动作。近年来,人工智能如神经网络控制(NNC)、模糊逻辑控制(FLC)和FLC-PID控制被广泛应用于PEMFC系统的控制,因为它们实现起来更简单、成本更低,不需AC和MPC那样的繁重计算,且效果更好[85-86]。

与PI控制相比,自适应控制策略的波动小,收敛速度快,即动态响应性能更好。HUANG等[87]发现自适应控制策略能很好地将PEMFC运行温度控制在(343±1) K的最佳温度内,在冷启动中也能使电池堆迅速地达到工作温度并保持稳定。ZHAO等[88]提出了水冷PEMFC系统的半经验热管理模型,可用于指导水冷PEMFC控制系统的设计和优化。为了使传感器在发生故障的情况下,仍能高精度地将PEMFC电堆的温度保持在参考值,YAN等[89]提出了一种主动容错控制策略来解决这个问题。

5 热管理问题的仿真研究

对PEMFC中各组件导热系数的研究都是为了更好地对热管理问题进行仿真。由于仿真研究比实验研究成本更低,操作更简单,且可用于优化系统等,在PEMFC的热管理研究中,大量的研究者采用了仿真与实验相结合的方法,一般先用FLUENT,MATLAB或COMSOL等软件建立模型,然后用实验数据验证模型的正确性,从而使模型可用于指导PEMFC的设计与优化。

如对于气液两相流模型,因为PEMFC中的能量、物质运输在时间和空间尺度上都存在差异,建模时,对于宏观尺度,一般采用VOF方法;对于介观尺度,采用格子玻尔兹曼方法(LBM);对于微观尺度,采用分子动力学或量子力学方法。由于受到气液两相流耦合困难和计算量的限制,在建模时,考虑所有尺度上的气液两相流运输是不切合实际的。只能依据一些假设和简化来建立特定维度和尺度的模型,这些模型的预测能力也受到了限制[90]。JIA等[91]建立了PEMFC的动态传热模型,通过实验验证了该模型的准确性,发现当电流从2 A突变到17 A时,电堆的温升速率会不断减小到0。

仿真模型从一开始的一维模型逐渐发展为二维、三维的模型,仿真的对象也从单电池逐渐变成了电池堆系统。仿真模型通过不断优化,变得越来越精确,但目前对仿真模型的输入参数如PEMFC中GDL的导热系数等物性参数还需要进行更加精准的原位测量,因为GDL是一种各向异性的材料,使得现在许多文献中测量的导热系数不一致,所以,在物性测量方面还需要做更多的工作。

6 结论与展望

PEMFC的热管理与水管理是2个核心的问题,水管理往往与热管理耦合在一起,因为电堆的温度分布对水分的运输影响极大,所以,不考虑热传输就无法研究电池的性能。热管理的核心目的是将PEMFC电堆的工作温度保持在最合适的区间内,避免出现局部高温,从而使电池稳定高效地运行。

随着PEMFC的商业化发展,热管理问题日益突出,以下问题有待进一步研究:

1) 原位精确测量电池组件的导热系数等物性参数,关注各向异性材料(GDL等)的特性。

2) 深入了解PEMFC中的水热传输机理与耦合效应,可通过建立专门的模型来实现。

3) 进一步优化冷却流场,寻找新的纳米流体冷却介质,并优化生产工艺。

4) 开发合适的控制算法,建立更精确的模型,更好地研究电池堆的动态特性。

参考文献:

[1] POLLET B G, STAFFELL I, SHANG Jin lei. Current status of hybrid, battery and fuel cell electric vehicles: from electrochemistry to market prospects[J]. Electrochimica Acta, 2012, 84: 235-249.

[2] NOLAN J, KOLODZIEJ J. Modeling of an automotive fuel cell thermal system[J]. Journal of Power Sources, 2010, 195(15): 4743-4752.

[3] KANDLIKAR S G, LU Zijie. Fundamental research needs in combined water and thermal management within a proton exchange membrane fuel cell stack under normal and cold-start conditions[J]. Journal of Fuel Cell Science and Technology, 2009, 6(4): 044001.

[4] SHIMOI R, MASUDA M, FUSHINOBU K, et al. Visualization of the membrane temperature field of a polymer electrolyte fuel cell[J]. Journal of Energy Resources Technology, 2004, 126(4): 258-261.

[5] FREIRE T J P, GONZALEZ E R. Effect of membrane characteristics and humidification conditions on the impedance response of polymer electrolyte fuel cells[J]. Journal of Electroanalytical Chemistry, 2001, 503(1/2): 57-68.

[6] 石瑶. 质子交换膜燃料电池的高效热管理研究[D]. 长春: 吉林建筑大学市政与环境工程学院, 2015: 1-2.

SHI Yao. Study on efficient thermal management of proton exchange membrane fuel cell[D]. Changchun: Jilin Construction University. College of Municipal and Environmental Engineering, 2015: 1-2.

[7] YU S. Thermal modeling of proton exchange membrane fuel[D]. Ann Arbor: University of Michigan. College of Mechanical Engineering, 2006: 78-79.

[8] PATTAMARAT K, HUNSOM M. Testing of PEM fuel cell performance by electrochemical impedance spectroscopy: optimum condition for low relative humidification cathode[J]. Korean Journal of Chemical Engineering, 2008, 25(2): 245-252.

[9] PANDIYAN S, JAYAKUMAR K, RAJALAKSHMI N, et al. Thermal and electrical energy management in a PEMFC stack: an analytical approach[J]. International Journal of Heat and Mass Transfer, 2008, 51(3/4): 469-473.

[10] SANTARELLI M G, TORCHIO M F. Experimental analysis of the effects of the operating variables on the performance of a single PEMFC[J]. Energy Conversion and Management, 2007, 48(1): 40-51.

[11] TSUSHIMA S, TERANISHI K, HIRAI S. Magnetic resonance imaging of the water distribution within a polymer electrolyte membrane in fuel cells[J]. Electrochemical and Solid-State Letters, 2004, 7(9): A269.

[12] YAN W M, CHEN Falin, WU H Y, et al. Analysis of thermal and water management with temperature-dependent diffusion effects in membrane of proton exchange membrane fuel cells[J]. Journal of Power Sources, 2004, 129(2): 127-137.

[13] NANDJOU F, POIROT-CROUVEZIER J P, CHANDESRIS M, et al. Correlation between local temperature and degradations in polymer electrolyte membrane fuel cells[J]. ECS Transactions, 2015, 66(25): 1-12.

[14] 李容, 谢晓峰, 齐亮, 等. PEMFC热管理的研究进展[J]. 电池, 2007, 37(1): 70-72.

LI Rong, XIE Xiaofeng, QI Liang, et al. Research progress in thermal management of PEMFC[J]. Battery 2007, 37(1): 70-72.

[15] KANDLIKAR S G, LU Zijie. Thermal management issues in a PEMFC stack: a brief review of current status[J]. Applied Thermal Engineering, 2009, 29(7): 1276-1280.

[16] JU H, WANG Chaoyang, CLEGHORN S, et al. Nonisothermal modeling of polymer electrolyte fuel cells[J]. Journal of the Electrochemical Society, 2005, 152(8): A1645.

[17] LIU Zhichun, SHEN Jun, PEI Houchang, et al. Effect of humidified water vapor on heat balance management in a proton exchange membrane fuel cell stack[J]. International Journal of Energy Research, 2015, 39(4): 504-515.

[18] BURHEIM O S. PEMFC materials' thermal conductivity and influence on internal temperature profiles[J]. ECS Transactions, 2017, 80(8): 509-525.

[19] MAJLAN E H, ROHENDI D, DAUD W R W, et al. Electrode for proton exchange membrane fuel cells: a review[J]. Renewable and Sustainable Energy Reviews, 2018, 89: 117-134.

[20] BURHEIM O S, SU Huaneng, HAUGE H H, et al. Study of thermal conductivity of PEM fuel cell catalyst layers[J]. International Journal of Hydrogen Energy, 2014, 39(17): 9397-9408.

[21] AHADI M, TAM M, SAHA M S, et al. Thermal conductivity of catalyst layer of polymer electrolyte membrane fuel cells: Part 1. Experimental study[J]. Journal of Power Sources, 2017, 354: 207-214.

[22] CAO Taofeng, LIN Hong, CHEN Li, et al. Numerical investigation of the coupled water and thermal management in PEM fuel cell[J]. Applied Energy, 2013, 112: 1115-1125..

[23] NIBLETT D, NIASAR V, HOLMES S. Enhancing the performance of fuel cell gas diffusion layers using ordered microstructural design[J]. Journal of the Electrochemical Society, 2020, 167(1): 013520.

[24] ELKHAROUF A. Understanding GDL properties and performance in polymer electrolyte fuel cells[D]. Birmingham: University of Birmingham. School of Chemical Engineering, 2014: 15-16.

[25] BOCK R, SHUM A, KHOZA T, et al. Experimental study of thermal conductivity and compression measurements of the GDL-MPL interfacial composite region[J]. ECS Transactions, 2016, 75(14): 189-199.

[26] YABLECKI J. Modeling the effective thermal conductivity of an anisotropic and heterogeneous polymer electrolyte membrane fuel cell gas diffusion layer[D]. Toronto: University of Toronto. Department of Mechanical and Industrial Engineering, 2012: 5-6.

[27] KHANDELWAL M, MENCH M M. Direct measurement of through-plane thermal conductivity and contact resistance in fuel cell materials[J]. Journal of Power Sources, 2006, 161(2): 1106-1115.

[28] ALHAZMI N E. Thermal conductivity of proton exchange membrane fuel cell components[D]. Leeds: University of Leeds. School of Technology, Environment and Materials Engineering, 2014: v-vi.

[29] CHEN Tao, LIU Shihua, ZHANG Jiwei, et al. Study on the characteristics of GDL with different PTFE content and its effect on the performance of PEMFC[J]. International Journal of Heat and Mass Transfer, 2019, 128: 1168-1174.

[30] BOCK R, HAMRE B, ONSRUD M A, et al. The influence of argon, air and hydrogen gas on thermal conductivity of gas diffusion layers and temperature gradients in PEMFCS[J]. ECS Transactions, 2019, 92(8): 223-245.

[31] YABLECKI J, HINEBAUGH J, BAZYLAK A. Effect of liquid water presence on PEMFC GDL effective thermal conductivity[J]. Journal of the Electrochemical Society, 2012, 159(12): F805-F809.

[32] SADEGHI E, BAHRAMI M, DJILALI N. Analytic determination of the effective thermal conductivity of PEM fuel cell gas diffusion layers[J]. Journal of Power Sources, 2008, 179(1): 200-208.

[33] SADEGHIFAR H, DJILALI N, BAHRAMI M. Effect of polytetrafluoroethylene(PTFE) and micro porous layer(MPL) on thermal conductivity of fuel cell gas diffusion layers: modeling and experiments[J]. Journal of Power Sources, 2014, 248: 632-641.

[34] YABLECKI J, BAZYLAK A. Determining the effective thermal conductivity of compressed PEMFC GDLs through thermal resistance modelling[J]. Journal of Power Sources, 2012, 217: 470-478.

[35] AZIZAN M F, KHALID A, MANSHOOR B, et al. A comprehensive fractal approach in determination of the effective thermal conductivity of gas diffusion layers in polymer electrolyte membrane fuel cells[J]. Advanced Science Letters, 2017, 23(5): 4045-4049.

[36] TEERTSTRA P, KARIMI G, LI X. Measurement of in-plane effective thermal conductivity in PEM fuel cell diffusion media[J]. Electrochimica Acta, 2011, 56(3): 1670-1675.

[37] SADEGHI E, DJILALI N, BAHRAMI M. A novel approach to determine the in-plane thermal conductivity of gas diffusion layers in proton exchange membrane fuel cells[J]. Journal of Power Sources, 2011, 196(7): 3565-3571.

[38] ZAMEL N, LITOVSKY E, SHAKHSHIR S, et al. Measurement of in-plane thermal conductivity of carbon paper diffusion media in the temperature range of -20 ℃ to +120 ℃[J]. Applied Energy, 2011, 88(9): 3042-3050.

[39] ALHAZMI N, ISMAIL M S, INGHAM D B, et al. The in-plane thermal conductivity and the contact resistance of the components of the membrane electrode assembly in proton exchange membrane fuel cells[J]. Journal of Power Sources, 2013, 241: 136-145.

[40] BVUMBE T J, BUJLO P, TOLJ I, et al. Review on management, mechanisms and modelling of thermal processes in PEMFC[J]. Hydrogen and Fuel Cells, 2016, 1(1): 1-20.

[41] GOSTICK J T, IOANNIDIS M A, FOWLER M W, et al. On the role of the microporous layer in PEMFC operation[J]. Electrochemistry Communications, 2009, 11(3): 576-579.

[42] DEEVANHXAY P, SASABE T, TSUSHIMA S, et al. Effect of liquid water distribution in gas diffusion media with and without microporous layer on PEM fuel cell performance[J]. Electrochemistry Communications, 2013, 34: 239-241.

[43] UNSWORTH G, ZAMEL N, LI Xianguo. Through-plane thermal conductivity of the microporous layer in a polymer electrolyte membrane fuel cell[J]. International Journal of Hydrogen Energy, 2012, 37(6): 5161-5169.

[44] NANADEGANI F S, LAY E N, SUNDEN B. Effects of an MPL on water and thermal management in a PEMFC[J]. International Journal of Energy Research, 2019, 43(1): 274-296.

[45] THOMAS A, MARANZANA G, DIDIERJEAN S, et al. Thermal and water transfer in PEMFCs: investigating the role of the microporous layer[J]. International Journal of Hydrogen Energy, 2014, 39(6): 2649-2658.

[46] BURHEIM O S, SU Huaneng, PASUPATHI S, et al. Thermal conductivity and temperature profiles of the micro porous layers used for the polymer electrolyte membrane fuel cell[J]. International Journal of Hydrogen Energy, 2013, 38(20): 8437-8447.

[47] BURHEIM O S, CRYMBLE G A, BOCK R, et al. Thermal conductivity in the three layered regions of micro porous layer coated porous transport layers for the PEM fuel cell[J]. International Journal of Hydrogen Energy, 2015, 40(46): 16775-16785.

[48] WONG A, BAZYLAK A. Investigating the effect of non-uniform microporous layer intrusion on oxygen transport in dry and partially saturated polymer electrolyte membrane fuel cell gas diffusion layers[J]. ECS Transactions, 2017, 80(8): 175-186.

[49] BOCK R, SHUM A D, XIAO X, et al. Thermal conductivity and compaction of GDL-MPL interfacial composite material[J]. Journal of the Electrochemical Society, 2018, 165(7): F514-F525.

[50] DE LAS HERAS A, VIVAS F J, SEGURA F, et al. Air-cooled fuel cells: keys to design and build the oxidant/cooling system[J]. Renewable Energy, 2018, 125: 1-20..

[51] ZHANG Guangsheng, KANDLIKAR S G. A critical review of cooling techniques in proton exchange membrane fuel cell stacks[J]. International Journal of Hydrogen Energy, 2012, 37(3): 2412-2429..

[52] RAMEZANIZADEH M, ALHUYI NAZARI M, HOSSEIN AHMADI M, et al. A review on the approaches applied for cooling fuel cells[J]. International Journal of Heat and Mass Transfer, 2019, 139: 517-525.

[53] CHOI E J, PARK J Y, KIM M S. Two-phase cooling using HFE-7100 for polymer electrolyte membrane fuel cell application[J]. Applied Thermal Engineering, 2019, 148: 868-877.

[54] ADZAKPA K P, RAMOUSSE J, DUBE Y, et al. Transient air cooling thermal modeling of a PEM fuel cell[J]. Journal of Power Sources, 2008, 179(1): 164-176.

[55] DE LAS HERAS A, VIVAS F J, SEGURA F, et al. How the BoP configuration affects the performance in an air-cooled polymer electrolyte fuel cell. Keys to design the best configuration[J]. International Journal of Hydrogen Energy, 2017, 42(17): 12841-12855.

[56] BURKE K A, JAKUPCA I, COLOZZA A, et al. Demonstration of passive fuel cell thermal management technology[J]. NASA/TM, 2012-217421

[57] WEN C Y, LIN Yusheng, LU C H, et al. Thermal management of a proton exchange membrane fuel cell stack with pyrolytic graphite sheets and fans combined[J]. International Journal of Hydrogen Energy, 2011, 36(10): 6082-6089.

[58] WEN C Y, HUANG Guowei. Application of a thermally conductive pyrolytic graphite sheet to thermal management of a PEM fuel cell[J]. Journal of Power Sources, 2008, 178(1): 132-140.

[59] WEN C Y, LIN Yusheng, LU C H. Performance of a proton exchange membrane fuel cell stack with thermally conductive pyrolytic graphite sheets for thermal management[J]. Journal of Power Sources, 2009, 189(2): 1100-1105.

[60] VASILIEV L, VASILIEV L Jr. Heat pipes in fuel cell technology[C]// Mini-Micro Fuel Cells. Dordrecht, Netherlands: Springer, 2008: 117-124.

[61] VASILIEV L L, FILATOVA O S, VASILIEV L. Heat pipes-good tool for fuel cells thermal management[C]// Proceedings of International Symposium on Convectice Heat and Mass Transfer in Sustainable Energy. Hammamet, Tunisia: Begell House Inc, 2009: 1-8.

[62] ARABNEJAD S, RASOULIAN R, SHAFII M B, et al. Numerical investigation of the performance of a U-shaped pulsating heat pipe[J]. Heat Transfer Engineering, 2010, 31(14): 1155-1164.

[63] VASILIEV L, VASILIEV L Jr. Heat transfer enhancement in confined spaces of mini-micro fuel cells[C]// Mini-Micro Fuel Cells. Dordrecht, Netherlands: Springer, 2008: 125-132.

[64] WOOD D L, YI J S, NGUYEN T V. Effect of direct liquid water injection and interdigitated flow field on the performance of proton exchange membrane fuel cells[J]. Electrochimica Acta, 1998, 43(24): 3795-3809.

[65] SNYDER L E. A feasibility study of internal evaporative cooling for proton exchange membrane fuel cells[D]. Card City: Texas A & M University. School of Mechanical Engineering, 2004: 30-31.

[66] KANDLIKAR S G. Heat transfer and fluid flow in minichannels and microchannels[M]. Amsterdam: Elsevier, 2014: 221-293.

[67] GARRITY P T, KLAUSNER J F, MEI Renwei. A flow boiling microchannel evaporator plate for fuel cell thermal management[J]. Heat Transfer Engineering, 2007, 28(10): 877-884.

[68] SOUPREMANIEN U, LE PERSON S, FAVRE-MARINET M, et al. Tools for designing the cooling system of a proton exchange membrane fuel cell[J]. Applied Thermal Engineering, 2012, 40: 161-173.

[69] AMIRFAZLI A, ASGHARI S, SARRAF M. An investigation into the effect of manifold geometry on uniformity of temperature distribution in a PEMFC stack[J]. Energy, 2018, 145: 141-151.

[70] CHEN Tao, XIAO Yong, CHEN Tiezhu. The impact on PEMFC of bionic flow field with a different branch[J]. Energy Procedia, 2012, 28: 134-139.

[71] SHIMPALEE S, VAN ZEE J W. Numerical studies on rib & channel dimension of flow-field on PEMFC performance[J]. International Journal of Hydrogen Energy, 2007, 32(7): 842-856.

[72] 陈思彤, 李微微, 王学科, 等. 相变材料用于质子交换膜燃料电池的热管理[J]. 化工学报, 2016, 67(S1): 1-6.

CHEN Sitong, LI Weiwei, WANG Xueke, et al. Phase change materials are used in thermal management of proton exchange membrane fuel cells [J]. Journal of Chemical Engineering, 2016, 67(S1): 1-6.

[73] CHEN F C, GAO Z, LOUTFY R O, et al. Analysis of optimal heat transfer in a PEM fuel cell cooling plate[J]. Fuel Cells, 2003, 3(4): 181-188.

[74] RAHGOSHAY S M, RANJBAR A A, RAMIAR A, et al. Thermal investigation of a PEM fuel cell with cooling flow field[J]. Energy, 2017, 134: 61-73.

[75] GHASEMI M, RAMIAR A, RANJBAR A A, et al. A numerical study on thermal analysis and cooling flow fields effect on PEMFC performance[J]. International Journal of Hydrogen Energy, 2017, 42(38): 24319-24337.

[76] CASTELAIN C, LASBET Y, AUVITY B, et al. Experimental study of the thermal performance of chaotic geometries for their use in PEM fuel cells[J]. International Journal of Thermal Sciences, 2016, 101: 181-192.

[77] LASBET Y, AUVITY B, CASTELAIN C, et al. Thermal and hydrodynamic performances of chaotic mini-channel: application to the fuel cell cooling[J]. Heat Transfer Engineering, 2007, 28(8/9): 795-803.

[78] WANG Xiangqi, MUJUMDAR A S. Heat transfer characteristics of nanofluids: a review[J]. International Journal of Thermal Sciences, 2007, 46(1): 1-19.

[79] ZAKARIA I A, MICHAEL Z, WAN MOHAMED W A N. Nanofluid as cooling medium in polymer electrolyte membrane(PEM) fuel cell: a study on potentials and possibilities[J]. Advanced Materials Research, 2015, 1109: 319-323.

[80] SAROJINI K G K, MANOJ S V, SINGH P K, et al. Electrical conductivity of ceramic and metallic nanofluids[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2013, 417: 39-46.

[81] MINEA A A, LUCIU R S. Investigations on electrical conductivity of stabilized water based Al2O3 nanofluids[J]. Microfluidics and Nanofluidics, 2012, 13(6): 977-985.

[82] KWAN T H, WU Xiaofeng, YAO Qinghe. Multi-objective genetic optimization of the thermoelectric system for thermal management of proton exchange membrane fuel cells[J]. Applied Energy, 2018, 217: 314-327.

[83] DENG Wenli, DAI Chaohua, GUO Ai, et al. Waste heat utilization in fuel cell trams with thermoelectric generators[C]// Chinese Automation Congress. Jinan: IEEE, 2017: 1992-1997.

[84] 张宝斌, 刘佳鑫, 李建功, 等. 燃料电池冷却方法及热管理控制策略进展[J]. 电池, 2019, 49(2): 158-162.

ZHANG Baobin, LIU Jiaxin, LI Jiangong, et al. Development of fuel cell cooling method and thermal management control strategy[J]. Battery, 2019, 49(2): 158-162.

[85] HAN Zhe, HE Li, NIU Zhuo, et al. A review and prospect for temperature control strategy of water-cooled PEMFC[C]// 2017 36th Chinese Control Conference(CCC). Dalian, China. IEEE, 2017: 9062-9068.

[86] DAUD W R W, ROSLI R E, MAJLAN E H, et al. PEM fuel cell system control: a review[J]. Renewable Energy, 2017, 113: 620-638.

[87] HUANG Lianghui, CHEN J, LIU Zhiyang, et al. Adaptive thermal control for PEMFC systems with guaranteed performance[J]. International Journal of Hydrogen Energy, 2018, 43(25): 11550-11558.

[88] ZHAO Xingqiang, LI Yankun, LIU Zhixiang, et al. Thermal management system modeling of a water-cooled proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2015, 40(7): 3048-3056.

[89] YAN Chizhou, CHEN Jian, LIU Hao, et al. Model-based fault tolerant control for the thermal management of PEMFC systems[J]. IEEE Transactions on Industrial Electronics, 2020, 67(4): 2875-2884.

[90] ZHANG Guobin, JIAO Kui. Multi-phase models for water and thermal management of proton exchange membrane fuel cell: a review[J]. Journal of Power Sources, 2018, 391: 120-133.

[91] JIA Qiuhong, HAN Ming, CHAM Y T, et al. Proton exchange membrane fuel cell(PEMFC) heat transfer model and dynamic heat response analysis[J]. Advanced Materials Research, 2011, 236/237/238: 2713-2716.

(编辑 杨幼平)

收稿日期: 2020 -09 -27; 修回日期: 2020 -12 -13

基金项目(Foundation item):中国博士后科学基金资助项目(2020M680538)(Project(2020M680538) supported by the Postdoctoral Science Foundation of China)

通信作者:张建胜,教授,博士生导师,从事煤气化、燃料电池研究;E-mail: zhang-jsh@tsinghua.edu.cn

引用格式: 侯健, 杨铮, 贺婷, 等. 质子交换膜燃料电池热管理问题的研究进展[J]. 中南大学学报(自然科学版), 2021, 52(1): 19-30.

Citation: HOU Jian, YANG Zheng, HE Ting, et al. Research progress on thermal management of proton exchange membrane fuel cells[J]. Journal of Central South University(Science and Technology), 2021, 52(1): 19-30.

摘要:能源与环境是目前人类社会面临的主要挑战,清洁能源高效利用技术是实现人类社会可持续发展的重要保障,其中,氢燃料电池特别是质子交换膜燃料电池(PEMFC)因其具有高效环保等特点备受青睐。PEMFC在发电过程中产生大量的热,产热与散热的平衡决定电池的温度,电池对温度的要求很苛刻,只允许稍微偏离设计点的温度,因此,通过热管理将电池的温度均匀地控制在设计点温度附近非常重要。本文从产热、传热和热管理策略(冷却策略、余热利用、控制策略)等方面综述PEMFC的热管理问题,重点介绍PEMFC组件在导热系数和冷却策略方面的研究现状,并提出了需要进一步研究的问题。