Trans. Nonferrous Met. Soc. China 26(2016) 2162-2169

Deformation and densification behavior of discrete media filled thin-walled tubes during forward extrusion

Tong WEN1, Qing LIU1, Qian HUANG1, Wen-xue OU1, Jian-qing FENG2

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China

Received 16 June 2015; accepted 10 May 2016

Abstract:

Discrete media filled thin-walled hollow profiles are frequently used as integer structures for special purpose, e.g., in certain materials processing or architectural components. To understand the deformation of such composite structures which is a complicate mechanics process, involving coupled elastic-plastic deformation of dense metal, compaction of particle and interaction between the filler and the wall, the forward extrusion of Al 6061 tubes filled with various particles was studied. The analysis regarding internal volume variation of round tubes during forward extrusion indicates that with the diameter reduction the volume of tubes decreases commonly. The cavity shrinkage brings about triaxial pressure on the filler, resulted in compaction and densification of it. Loose powders filling leads to higher extrusion load. Due to dissimilar migration behaviors of the particles, the load-stroke curves of the tubes filled with fine powders and coarse balls are quite different. Small Lankford value of the tube wall material leads to higher hydrostatic pressure of the filler and then more powders are compacted.

Key words:

tube; forward extrusion; powder; deformation behavior; densification;

1 Introduction

Discrete or porous media filled thin-walled tubes can be utilized as integer structures for special purpose in the fields of manufacturing, construction, transportation, etc. For example, power-in-tube (PIT) technology is so far the main approach to produce superconducting MgB2 strands [1-3]. During the course, raw materials, namely a mixture of Mg and B powders, are enclosed in a non-reactive metallic tube in advance and drawn with the tube, shrinking the diameter, and finally reacted by sintering to form MgB2. In the bending of thin-walled tubes, sometimes the hollow workpiece is filled with discrete powders (e.g., sand) before forming, and then the tube wall is supported from inside during deformation and the section distortion can be alleviated to a large extent [4]. Furthermore, ZHAO et al [5] employed solid particles (steel balls) as pressure medium in the expansion of thin-walled tubes, while LEE et al [6] compared the microstructure and characteristics of bulk magnesium consolidated from Mg powder by equal channel angular extrusion (ECAE), with varying temperature and extrusion pass.

Due to special mechanical properties, the application of internally filled hollow profiles such as steel tube confined concrete (STCC) columns or concrete filled steel tubular (CFST) columns has been the interests of many structural engineers [7,8]. Moreover, DARVIZEH et al [9] studied the effect of low density, low strength polyurethane foam on the energy absorption characteristics of circumferentially grooved thick-walled circular tubes. MIRFENDERESKI et al [10] investigated the crushing behavior of empty and foam-filled thin-walled tubes under static and dynamic loading, while DUARTE et al [11] studied the dynamic and quasi-static bending behavior of aluminium foam filled thin-walled aluminium tubes.

The deformations of discrete medium filled profiles are coupled complicated mechanics processes involving multiple affecting factors along with their interactions. Besides the elastic-plastic deformation of dense metal, the filler undergoes different stages of deformation as it is compacted, including particle rearrangement, rotation and deformation, and all contribute to the macroscopic response to the structures. As well known in the field of powder metallurgy (PM), the response of the powder mass during compaction has a significant influence on the evolution of density during subsequent stages of the manufacturing process. Many studies have been devoted to understanding the flow and deformation rule of loose powder during compaction [12-14]. However, the studies regarding the frame of mechanics condition during the integral forming of powder filled tubes are very rare. In the preparation of superconducting materials by drawing and so on, it is frequently encountered that the processing parameters were inappropriately selected, resulted in fracture at interface and uneven distribution of microstructure. Therefore, it has theoretical and engineering significance to examine the coupled deformation of discrete medium filled tubes during various forming courses.

In the current study, forward extrusion of thin-walled tubes filled with different discrete particles, which is a typical deformation of these kinds of composite structures, was investigated by means of experiment and finite element method (FEM). The effect of processing and geometrical parameters on the variation of inner volume of tubes under varying extrusion conditions was analyzed, meanwhile, the deformation and densification behavior of the composite structures were examined.

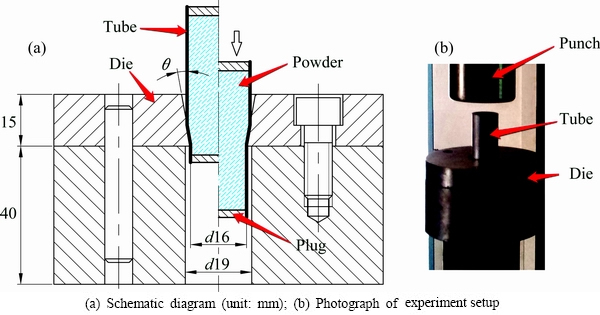

Fig. 1 Forward extrusion of thin-walled tube filled with loose particles

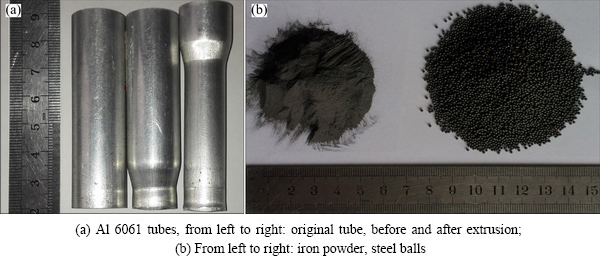

Fig. 2 Tubular samples and fillers in experiments

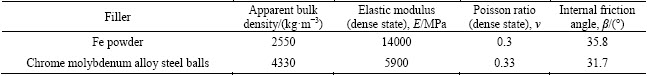

Table 1 Mechanical parameters of fillers

2 Experimental and numerical simulation methods

2.1 Experiment

Figure 1 shows the experiment setup for forward extrusion. The experiments were conducted on an SANS CMT 5105 universal material testing machine. The conical angle θ of the die is 15°. Al 6061 aluminum round tubes (d20 mm × 1.5 mm × 70 mm) were used, and the fillers are reduced iron powders (0.075 μm) and chrome molybdenum alloy steel balls ranging from 0.3 to 0.8 mm in diameter, as shown in Fig. 2. Basic performance parameters of the media are listed in Table 1. The friction angle was tested using a strain-controlled direct shear apparatus (model ZBQ-4) according to the ASTM standard D6128.

Before operation, bottom end of the tubes was reduced to a tapered step shape to fit the die cavity, as shown in Figs. 1 and 2, and then the fillers were encapsulated in the tubes with aluminum alloy plugs from the bottom. MoS2 was used as lubricant between the surfaces of the tube and die, and dry extrusions without the usage of lubrication were also conducted for comparison.

2.2 Numerical simulation

The FEM simulations were conducted with ABAQUS/Explicit . The dimensions of the specimen were the same as those in the experiment. The constitutive equation of Al 6061 is described by

. The dimensions of the specimen were the same as those in the experiment. The constitutive equation of Al 6061 is described by

σ=σs+Bεn=55+738.2ε0.44 (1)

The interface friction between the surfaces of the die and tubes was characterized by means of the Coulomb’s friction law, τ=μN. The friction coefficient μ is set to 0.1 and 0.25 for the conditions with or without lubrication, respectively. Elastic modulus of Al 6061 is 68.9 GPa.

A variety of theoretical models regarding the compaction of loose powders have been proposed in the field of powder metallurgy [15-19]. In the current study, flow behavior of powders under pressure is described by the Drucker-Prager (D-P) model. This yield function depends on the first and second invariants of the stress tensor, i.e. pressure and stress deviation. To represent the plastic compaction mechanisms, a strain hardening function was used to expand the yield function with increasing volumetric strain. The D-P model failure surface (Fs) can be written as [20]

Fs=t-ptan β-d=0 (2)

where t is the deviatoric stress, p is the equivalent effective pressure stress, β is the material’s friction angle and d is the material’s cohesion.

There are three different yield surface meridians in ABAQUS, namely the linear, hyperbolic and exponential function. The first one was used in the current study. In the FEM calculation, the dilatation angle and flow stress ratio of ferric iron oxide are 0 and 0.778, respectively. Other parameters are the same as those listed in Table 1.

3 Variation of internal volume of round tubes during forward extrusion

In a forming process such as extrusion or drawing of an empty tube, the volume of tube wall material keeps constant according to the volume reservation condition of plastic deformation. Nevertheless, the inner/outer diameters of the tubes are reduced; meanwhile the axial length might enlarge. The reduction of inner diameter makes the tube cavity diminish, while the increasing length makes the tube cavity enlarge. Overall variation of the internal volume of a formed tube depends on the combined actions. Decrease or shrinking tendency of tube cavity brings about tri-axial pressure on the filler inside and then the media will be compacted. The reduction degree of inner volume governs the densification of powders inside; thus, it is of importance to understand how the chamber changes during forming.

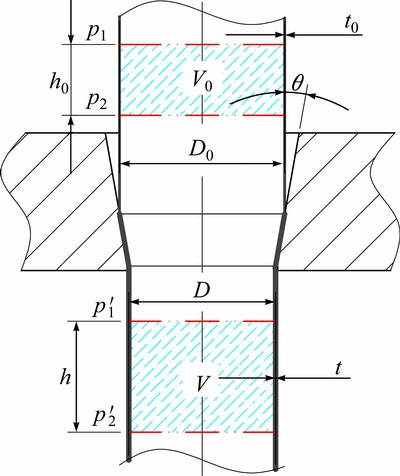

Figure 3 shows the geometrical parameters of a forward extruded round tube, including inner diameters D0 and D, wall thicknesses t0 and t. Cross-section of the tube remains round after extrusion, hence the distance between two referential points, p1 and p2, along with the corresponding diameters, can be utilized to calculate the internal volume of tubes.

Fig. 3 Schematic diagram of thin-walled round tube during forward extrusion

Volume (Vm) of the tube wall material is

Vm=π[(D0/2+t0)2-(D0/2)2]h0=Cons (3)

The initial reference volume (V0) within the tube before extrusion is

V0=π(D0/2)2h0 (4)

It is assumed that thickness variation of the wall is △t, then the thickness t after extrusion is t0+△t. According to the volume constancy condition, there is

V′m=π[(D/2+t0+Δt)2-(D/2)2]h=Vm (5)

So,

(6)

(6)

The internal volume (V) of the cavity after extrusion is

V=π(D/2)2h (7)

Variation ratio of the volume after extrusion is

[(t0/D0)+(t0/D0)2]/[(t0/D)+(t0/D)2+(Δt/D)+2(t0/D)(Δt/D)+(Δt/D)2] (8)

For round thin-walled tubes during extrusion,

D0>D>>t0>Δt (9)

Generally, tube wall thickness increases after extrusion, namely Δt>0. The amount of Δt relies on the initial thickness, material properties, extrusion ratio D0/D, and die geometry, etc. In conventional forming of thin-walled tubes, Δt is normally small compared with the overall sizes of part. If omit Δt, there is

(10)

(10)

It can be seen that internal volume of tubes is reduced after extrusion. The shrinkage of tube cavity brings about pressure on the inside particles, resulting in compaction and densification of the fillers.

The reduction ratio (K) of the inner volume between referential points p1 and p2 can be defined as

K=(V0-V)V0×100% (11)

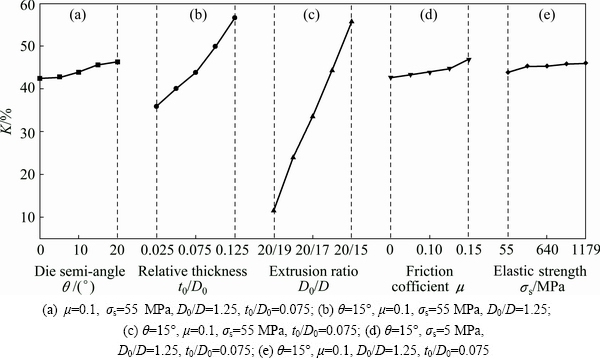

Figure 4 shows the FEM results of relationships between K and the die cone angle θ, relative thickness t0/D0, extrusion ratio D0/D, friction coefficient μ and yield strength σs of the tube wall material. Since the maximum deformation of the tubes is limited with the extrusion ratios (D0/D) ranging from 1.05 to 1.33, and no re-meshing operation was conducted during the calculation, the FEM nodes can be directly utilized as referential points for the identification of volume. It can be found that K is proportional to θ, t0/D0, D0/D, and μ. However, the influence of σs on K-value is no significant.

4 Characteristics of force and deformation

In the following, the force and deformation of particle filling Al 6061 tubes during forward extrusion will be investigated, especially with regard to the load, integer deformation and densification behavior of the fillers.

4.1 Extrusion load

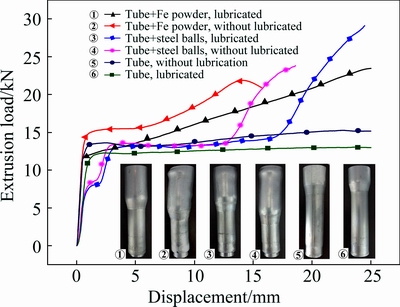

Figure 5 shows the experimental load-stroke curves of the tubes under various extrusion conditions: empty, filled with iron powders and steel balls, without lubrication and with MoS2 as lubrication between the die and outer surfaces of the tubes. It can be seen that all the loads increase rapidly at first, and then the loads of empty tubes keep almost constant after reaching a relatively steady deformation stage, whether using lubrication or not.

For the extrusion of iron powders filled tubes under good lubrication, the fillers are compacted continuously under the compressive stresses, and the load increases stably along a slope. When no lubrication was used, the large loads caused by fiction lead to axial collapse of the tubular structures. After extrusion, the loose powders inside the tube were compacted with a condensed state.

Fig. 4 Variation of internal volumes of empty tubes after forward extrusion under various conditions

Fig. 5 Experimental load curves of empty and various loose particles filled tubes during forward extrusion

As for the tubes filled with steel balls, the load curves present different forms. At the beginning of the process, the pressure applied on the balls increases gradually with the tube deformation. When the pressure reaches certain degree, the balance among the balls is suddenly broken and rearrangement of the balls takes place, resulting in an obvious fluctuation of the curve. After that, the loads vary slightly around 12 kN, which are close to those of empty tubes, indicating that the interactions among the migrating balls are very small during this stage and the loads are mainly caused by tube deformation. With the continuing reduction of tube diameters, the balls are finally completely compacted and the loads increase sharply, resulting in bulge and collapse of the structures, as the case 4 shown in Fig. 5. After forming, the balls are still in a loose state and no obvious deformation of the balls is observed; however, pits on the internal tube surface due to huge pressure during the course are clearly found.

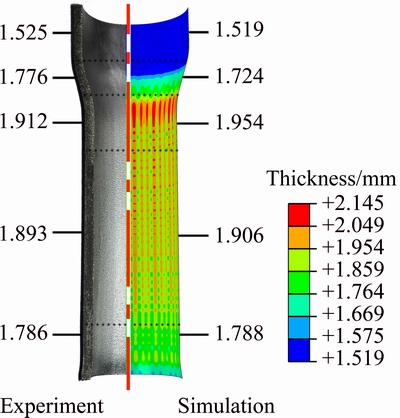

Fig. 6 Wall thickness distribution after extrusion (unit: mm)

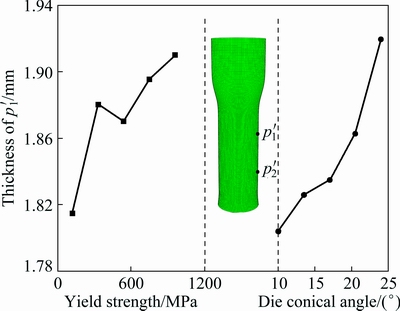

Fig. 7 Thickness vs yield strength and die geometry

4.2 Variation of tube wall thickness

Variation degree of wall thickness would have influence on the inner volume of tubes after forming. Figure 6 shows the experimental and simulated results of thickness distribution of the empty tubes along axial section after forward extrusion with lubrication. The FEM results agree with the experiment very well. Figure 7 shows the relationships between the thickness at the referential point and the yield strength and die conical angle. Obviously, wall thickness of the extruded tube increases when yield strength and die conical angle increase.

4.3 Densification of iron powders

During the forward extrusion of tubes filled with loose powder, complicate interaction exists between the tube wall and the filler. On one hand, the filler increases the forming load; on the other hand, the change of chamber shape makes the particles flow and compact.

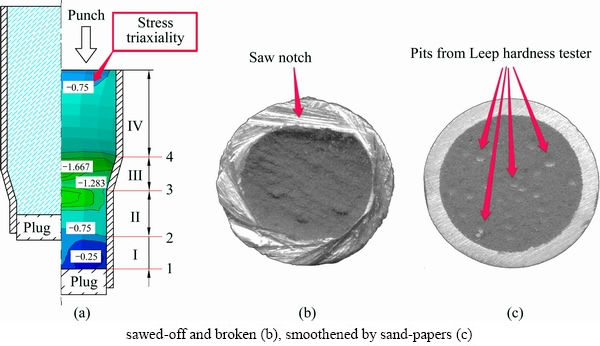

Figure 8(a) shows the stress triaxiality  of the iron powders filled in a tube during forward extrusion. Stress triaxiality is the ratio of hydrostatic pressure σm to von Mises equivalent stress

of the iron powders filled in a tube during forward extrusion. Stress triaxiality is the ratio of hydrostatic pressure σm to von Mises equivalent stress  , representing the energy ratio for volume and shape changes, or the combined influence of spherical tensor of stress and deviatoric tensor of stress on deformation [21,22]. It is positive in tensile state and negative in compression state. Figures 8(b) and (c) show the morphologies of the cross sections of the compacted iron powder beds. Figure 8(b) shows the natural state of the bed after separation and Fig. 8(c) shows the fracture surface smoothened by sand-papers.

, representing the energy ratio for volume and shape changes, or the combined influence of spherical tensor of stress and deviatoric tensor of stress on deformation [21,22]. It is positive in tensile state and negative in compression state. Figures 8(b) and (c) show the morphologies of the cross sections of the compacted iron powder beds. Figure 8(b) shows the natural state of the bed after separation and Fig. 8(c) shows the fracture surface smoothened by sand-papers.

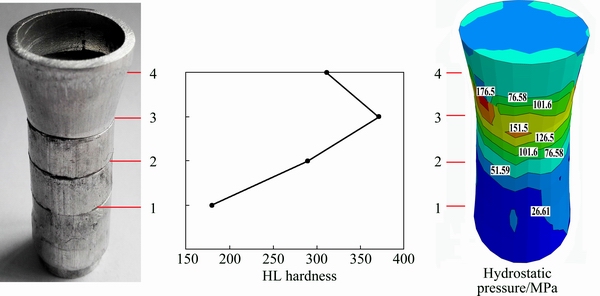

Hardness can be used to indirectly describe the densification degree of the compacted powder beds [19]. In the current study, the hardness was tested by a HL-1000B Leeb hardness tester. Figure 9 gives the average hardness distributions of the iron powder beds at different locations, along with the theoretical hydrostatic pressure. It can be found that the hardness increases first and then drops from the top to the bottom, which is consistent with the distribution of hydrostatic pressure. The maximum hardness locates in the conical zone of the tube, where the maximum three-dimensional compressive stress exists. Since Zone I is the preformed zone with less deformation, the powders in this zone are just slightly compacted. Powders in the unformed Zone IV remain loose.

Fig. 8 Stress triaxiality within filler during forward extrusion (a), light microscope images of cross sections of powder beds separating along section III

Fig. 9 Distribution of hardness and hydrostatic pressure of compacted iron powders (omitting Zone 4), extruded with lubrication

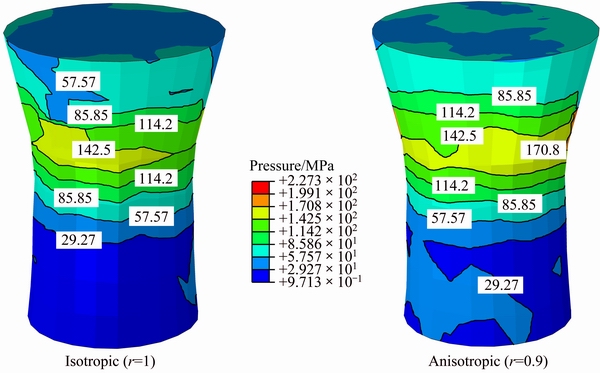

Fig. 10 Hydrostatic pressure distribution of iron powders filled in Al 6061 tubes during extrusion with different r-values of tube wall material (with lubrication, omitting Zone IV)

Generally, tube wall materials are anisotropic. Figure 10 shows the hydrostatic pressure of the powders filled in tubes with different r-values (Lankford value) during forward extrusion. Hill’s anisotropic yield criterion was used in the simulation [20,23]:

(12)

(12)

where σij is the stress components, F, G, H, L, M and N are constants obtained by tests of the material in different orientations. In the current study, only transverse anisotropy is considered.

It can be found that small r-value leads to higher hydrostatic pressure of the filler, since the tube wall is thicker after extrusion and the inner volume reduction K is higher, and then the more the powders are compacted.

5 Conclusions

1) Reduction of inner volume of thin-walled tubes during extrusion is a common phenomenon. The reduction degree increases with the increasing die conical angle θ, relative thickness t0/D0, extrusion ratio D0/D and friction coefficient μ, while the influence of yield stress σs of tube wall material on volume reduction is not significant.

2) During forward extrusion of tubes, the cavity shrinkage leads to compaction of inside powders, meanwhile complicate interaction exists between the tube wall and the fillers. The filler incurs increase of the forming loads, which could lead to axial collapse of the structures. Good lubrication between the tube wall and the die surface can decrease the load.

3) The load-stroke curves of the tubes filled with fine iron powders show a smooth progressive trend, while the curves of those filled with relatively large steel balls present obvious fluctuation during extrusion, caused by the unstable migration and rearrangement of the rigid balls under pressure.

4) Densification degree of the confined iron powders mostly relies on the three-dimensional compressive stress during extrusion. The higher the hydrostatic pressure is, the more the powders are compacted. The anisotropy of tube wall material has impact on wall thickness variation. Small r-value leads to higher hydrostatic pressure of the filler, and then more powders are compacted.

References

[1] SUSNER M A, DANIELS T W, SUMPTION M D, RINDFEISCH M A, THONG C J, COLLINGS E W. Drawing induced texture and the evolution of superconductive properties with heat treatment time in powder-in-tube in situ processed MgB2 strands [J]. Superconductor Science and Technology, 2012, 25(6): 1-13.

[2] WANG Q Y, JIAO G, LIU G, XIONG X, YAN S, ZHANG P, SULPICE A, MOSSANG E, FENG Y. Fabrication and properties of multifilamentary MgB2 wires by in-situ powder-in-tube process [J]. Physica C, 2010, 470(20): 1415-1418.

[3] TOMSIC M, RINDFLEISCH M, YUE J, MCFADDEN K, DOLL D, PHILLIPS J, SUMPTION D M, BHATIA M, BOHNENSTIEH S, COLLINGS E W. Development of magnesium diboride (MgB2) wires and magnets using in situ strand fabrication method [J]. Physica C, 2007, 456(1-2): 203-208.

[4] WEN T, JI X W. Deformation of thin-walled rectangular tubes during press bending and quality improvement of bended section [J]. Hot Working Technology, 2010, 39(19): 111-117. (in Chinese)

[5] ZHAO C, DONG G, XIAO H, WANG Y. New process of solid granule medium forming [J]. Journal of Plasticity Engineering, 2009, 45(8): 255-260. (in Chinese)

[6] LEE H, CHAO C, LIU T, LIN C, WANG H. Effect of temperature and extrusion pass on the consolidation of magnesium powders using equal channel angular extrusion [J]. Materials Transactions, 2013, 54(5): 765-768.

[7] SCHNEIDER S P. Axially loaded concrete-filled steel tube [J]. Journal of Structural Engineering, 1998, 124: 1125-1138.

[8] YU Q, TAO Z, LIU W, CHEN Z B. Analysis and calculations of steel tube confined concrete (STCC) stub columns [J]. Journal of Constructional Steel Research, 2010, 66(1): 53-64.

[9] DARVIZEH A, DARVIZEL M, ANSARI R, MESHKINZAR A. Effect of low density, low strength polyurethane foam on the energy absorption characteristics of circumferentially grooved thick-walled circular tubes [J]. Thin-Walled Structures, 2013, 71: 81-90.

[10] MIRFENDERESKI L, SALIMI M, ZIAEI-RAD S. Parametric study and numerical analysis of empty and foam-filled thin-walled tubes under static and dynamic loadings [J]. International Journal of Mechanical Sciences, 2008, 50(6): 1042-1057.

[11] DUARTE I, VESENJAK M, KRSTULOVIC'-OPARA L. Dynamic and quasi-static bending behaviour of thin-walled aluminum tubes filled with aluminum foam [J]. Composite Structures, 2014, 109: 48-56.

[12] HECKEL R W. Analysis of powder compaction phenomena [J]. Trans AIME, 1961, 221: 1001-1008.

[13] MCDONALD S A, SCHNEIDER L C R, COCKS A, WITHER P J. Particle movement during the deep penetration of a granular material studied by X-ray micro-tomography [J]. Scripta Materialia, 2006, 54(2): 191-196.

[14] WEN Tong, CHEN Xia, RUZIWA Walter, COCKS Alan. Deformation of a powder bed during deep penetration [J]. Journal of Advanced Manufacturing Systems, 2008, 7: 161-165.

[15] CYTERMANN R, GEVA R. Development of new model for compaction of powders [J]. Powder Metall, 1987, 30(4): 256-260.

[16] LEE K H, LEE J M, KIM B M. Densification simulation of compacted Al powders using multi-particle finite element method [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 68-75.

[17] FISCHEISTER H F, ARTZ E. A model for the compaction of ductile, spherical powders [C]//Proceedings of 7th International Powder Metallurgy Symposium. Dresden, 1981: 105-117.

[18] AZAMI A R, KHOEI A R. 3D computational modeling of powder compaction processes using a three-invariant hardening cap plasticity model [J]. Finite Elements in Analysis and Design, 2006, 42 (8): 792-807.

[19] CHTOUROU H, GUILLOT M, GAKWAYA A. Modeling of the metal powder compaction process using the cap model. Part I: Experimental material characterization and validation [J]. International Journal of Solids and Structures, 2002, 39(4): 1059-1075.

[20] HIBBITT R, KARLSSON D, SORENSEN C. ABAQUS User’s Manual (version 6.3) [M]. Pawtucket, RI, 2006.

[21] BREWIN P R, COUBE O, DOREMUS P, TWEED J H. Modelling of powder die compaction [M]. London: Springer-Verlag, 2008.

[22] TENG X. Numerical prediction of fracture in the Taylor test [J]. Solids and Structures, 2005, 42(9): 2929-2948.

[23] HILL R. A theory of the yielding and plastic flow of anisotropic metals [C]//Proceedings of the Royal Society of London, 1948: 281-297.

离散介质充填薄壁管正挤压过程的变形与致密化行为

温 彤1,刘 清1,黄 倩1,欧文学1,冯建情2

1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 西北有色金属研究院,西安 710016

摘 要:离散介质填充的中空薄壁型材常常作为整体结构用于一些特殊场合,如某些材料成型过程或建筑构件。这类复合结构的变形涉及致密金属的弹塑性耦合变形、松散颗粒压实以及管壁与填充物之间的相互作用。为认识其复杂力学行为,研究了填充不同粒度和材质的两种颗粒的Al 6061管正挤压过程。对圆管坯内腔体积变化的分析表明,随着正挤压时外径缩小,内腔容积通常减小,从而给填充物带来三轴压力并导致其致密化。填充使得挤压载荷增加;由于细粉和钢丸具有不同迁移与重排方式,二者的挤压力-行程曲线呈现不同形态。此外,较小的管材r值(Lankford值)使得填充介质静水压力增加并提高其致密化程度。

关键词:管材;正挤压;粉体;变形行为;致密化

(Edited by Xiang-qun LI)

Foundation item: Project (51575066) supported by the National Natural Science Foundation of China; Project (2012ZX04010-081) supported by the National Key Technologies R & D Program of China

Corresponding author: Tong WEN; Tel: +86-13018363383; E-mail: wentong@cqu.edu.cn

DOI: 10.1016/S1003-6326(16)64332-7

Abstract: Discrete media filled thin-walled hollow profiles are frequently used as integer structures for special purpose, e.g., in certain materials processing or architectural components. To understand the deformation of such composite structures which is a complicate mechanics process, involving coupled elastic-plastic deformation of dense metal, compaction of particle and interaction between the filler and the wall, the forward extrusion of Al 6061 tubes filled with various particles was studied. The analysis regarding internal volume variation of round tubes during forward extrusion indicates that with the diameter reduction the volume of tubes decreases commonly. The cavity shrinkage brings about triaxial pressure on the filler, resulted in compaction and densification of it. Loose powders filling leads to higher extrusion load. Due to dissimilar migration behaviors of the particles, the load-stroke curves of the tubes filled with fine powders and coarse balls are quite different. Small Lankford value of the tube wall material leads to higher hydrostatic pressure of the filler and then more powders are compacted.