Effects of titanium coating on property of diamond

ZHANG Xiao-fu(张小福), LU An-xian(卢安贤)

School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 20 October 2006; accepted 5 March 2007

Abstract:

The titanium film was coated on the surface of diamond crystal in order to improve the chemical properties of diamond and the effect of titanium coating on the property of diamond was discussed. The anti-impacting strength, the oxidization process and the soakage property between vitrified bond and diamond were investigated. It is found that, when the titanium film is coated on the surface of diamond crystal, the soakage angle between vitrified bond and diamond decreases from 39.5? to 34.5? at 993 K, and the oxidization degree on the surface of diamonds is lowered greatly.

Key words:

diamond; titanium coating; soakage property;

1 Introduction

Diamond has many excellent properties such as high hardness, high strength and abrasion, and it is often used as the tools or made into grinding wheels to process other hard materials such as tungsten carbide, polycrystalline diamond compacts or ceramics[1]. Natural diamond is very rare, very expensive and hard to meet the demand of industry. Now diamonds used in industry are synthesized by graphite at high temperature and high pressure (1 773 K and 5-6 GPa) with iron or cobalt as the catalyst[2]. As the grains of synthesized diamond are very small, it is necessary that the diamond grains are mixed with certain kind of bond to manufacture grinding products[3]. Among all kinds of different bond grinding products, vitrified bond diamond products have very good application prospect[4] because of their high longevity, high efficiency, good rigidity and low processing cost. However, the diamond is easily oxidized at high temperature over 1 023 K in the air, whereas the sintered temperature of vitrified bond diamond products is usually beyond 1 473 K in order to get high bonding strength between diamond grains and ceramics cement. As a result, the vitrified bond diamond products are difficult to be obtained[5]. Now many high property materials with high strength or high toughness appear. These materials are all very difficult to be processed by tools[6]. The disadvantage of the current tools is high processing cost, low processing efficiency and great noise pollution[7]. So high property vitrified bond diamond products are urgently expected. Now the research and development work is focused on two aspects: one is the development of high strength vitrified bond with low sintering temperature; the other is to coat protecting film on the surface of diamond crystal in order to delay the oxidization of diamond[8]. There are some reports about coating metals such as nickel or titanium on the metal bonded diamond products[9] and on the vitrified bonded cubic boron nitride(CBN) products[10]. It is reported that the titanium coating on the surface of diamonds can prevent diamonds from oxidization below 1 173 K, and reinforce the bonding strength between vitrified bond and diamonds[11]. In this study, the effect of titanium coating on the property of diamond is mainly discussed.

2 Experimental

2.1 Preparation of titanium coating on diamond

In the experiment, the titanium film was coated on the diamond crystals by physical vapor deposition method. The thickness of titanium film is 3 μm and the mass increase of the coated diamond is about 0.3%.

2.2 Preparation of vitrified bond

The vitrified bond is a Li2O-ZnO-SiO2-Al2O3-B2O3 system glass-ceramics with wide range of thermal expansion coefficient[12-13]. The basic glass was prepared by conventional melt quenching technology and using two-step thermal treatment route. The composition of glass-ceramics is listed in Table 1.

Table 1 Composition of Li2O-ZnO-SiO2 glass-ceramics (molar fraction, %)

![]()

2.3 Measurement of impacting strength

In the impacting strength testing, a few gram of standard diamond sample is put into a special apparatus and impacted at 2 400 r/min for 0.5 min by 5 mm- diameter steel ball. Then the sample is sieved in a standard boult. The anti-impacting strength is defined as the ratio of unsifted sample mass to primary sample mass[14]. The apparatus type for testing anti-impacting strength of diamond is CYCJ-04A made in Zhengzhou Research Institute for Abrasive and Grinding, China.

2.4 Comparison of oxidization difference

The apparatus for XRD is D/Max 2500 18 kW made in Rigaku Company, Japan, and for SEM testing, the apparatus is KYKY 2800 digital Scan Electron Microscope, made in Chinese Academy of Sciences.

2.5 Effect of vitrified bond on soakage property

The contact angle is used to indicate the soakage property between the vitrified bond and diamond. The smaller the contact angle is, the better the soakage property is. The apparatus for testing the contact angle between diamond and vitrified bond is JC 2000x type made in Shanghai Zhongchen Digital Technic Co Ltd, China.

3 Results and discussion

3.1 Effect of coating on anti-impacting strength of diamond

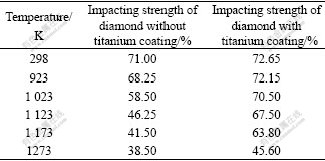

Table 2 lists the result of the impacting strength of the diamond with titanium coating and the diamond without titanium coating at different temperatures. It can be seen that, when coating titanium on the surface of diamond, the decreasing degree of impacting strength of the diamond is smaller than that of diamond without titanium coating from 1 023 K to 1 273 K. This fact indicates that the titanium coating improves the anti- impacting property of the diamond. This can be attributed to the chemical reaction between titanium and oxygen in the air when the temperature is higher than 993 K:

6Ti+5O2→2Ti3O5 (1)

Table 2 Impacting strength of diamond at different temperatures

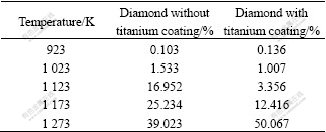

The oxide Ti3O5 on the surface of diamond is very compact and inert, and wraps the diamond crystal, which prevents titanium and diamond from oxidization. So the anti-impacting strength of diamond with titanium coating only decreases a little in the temperature range from 298 K to 1 173 K, while the anti-impacting strength of diamond without titanium coating is only 60% as that at 298 K. With the increasing of temperature, Ti3O5 turns into TiO2, and TiO2 can escape from diamond crystal. At 1 230 K, Ti8C5 begins to be oxidized, no Ti8C5 wraps the diamond crystals and diamond is oxidized at 1 273 K, so the anti-impacting strength greatly decreases. This can also be confirmed by the mass change of two kinds of diamond at different temperatures, as listed in Table 3.

Table 3 Mass loss of two kinds of diamonds at different temperatures

The mass loss of the diamond with titanium coating is only about 3.356% at 1 123 K. While the escaping of TiO2 from diamond crystal occurs, the mass loss at 1 173 K increases to 12.916%. At 1 173 K there is still Ti8C5 that wraps diamond crystal, so the anti-impacting strength of diamond with titanium is 63.80%. For diamond without titanium coating, the mass loss is 25%, and the anti-impacting strength is 41.50%. This means that titanium coating can protect diamond at 1 173 K. When the temperature continues to increase to 1 273 K, the mass loss of diamond with titanium coating increases rapidly, and the impacting strength decreases apparently. This means that titanium cannot protect diamond from being oxidized at 1 273 K.

3.2 Change of oxidization process

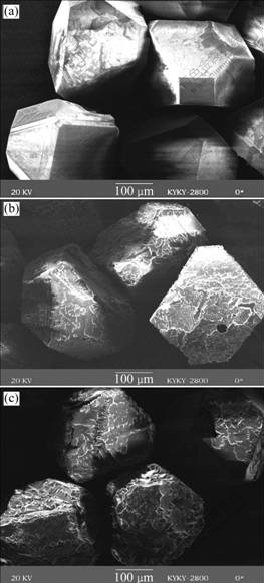

When temperature is higher than 1 023 K, the carbon atoms on the surface of diamond begin to act with the oxygen in the air, and the carbon dioxide is produced, which forms many holes on the surface of diamond crystal and greatly decreases the anti-impacting and abrasion property of diamond. The change on the surface of diamond crystal at high temperature can be seen in Fig.1.

Fig.1 Change on surface of diamond crystalline at high temperatures: (a) 298 K; (b) 1 073 K; (c) 1 173 K

When the surface of diamond is coated with titanium, Ti8C5 is formed by a chemical reaction between titanium and diamond, which produces a strong combination between diamond and titanium:

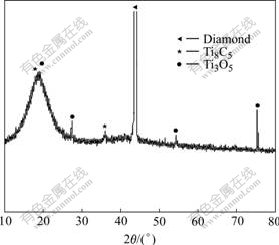

5C+8Ti→TiC5 (2)

Because of the oxidization of titanium on the surface of diamond and the chemical reaction between titanium and diamond, the texture on the surface of diamond crystal at 1 173 K is C-Ti8C5-Ti3O5, as shown in Fig.2. With the increase of temperature, Ti3O5 turns into TiO2. TiO2 escapes from the surface of diamond crystal, and more and more titanium is oxidized. At 1 173 K, no diffraction peak of Ti can be seen on the XRD spectrum, which means that most titanium has been oxidized at this time. When the temperature continues to increase to 1 230 K, Ti8C5 begins to be oxidized[15]:

Fig.2 XRD pattern of diamond with titanium coating at 1 173 K

Ti8C5+13O2→8TiO2↑+5CO2↑ (3)

So no Ti8C5 wraps the diamond crystals and diamond begins to be oxidized at 1 273 K. The mass loss of diamond plating titanium increases rapidly, and the anti-impacting strength decreases apparently at 1 273 K.

3.3 Soakage property between vitrified bond and diamond crystal at high temperature

The effect of vitrified bond on the soakage property of the diamond with titanium coating and without titanium coating at high temperature can be seen from the change of the contact angle.

Fig.3 shows the effect of vitrified bond on the contact angle change between vitrified bond and diamond without coating titanium. It can be seen that the contact angle gets small with the increase of temperature. When the temperature increases further, the movement of atom in the melting vitrified bond becomes more quickly, the force between atoms gets small, the viscosity of vitrified bond melt decreases, and the contact angle gets small.

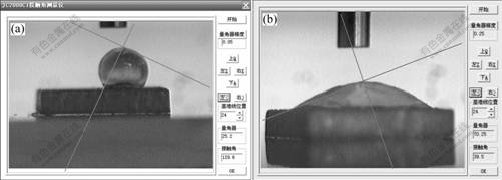

Fig.3 Effect of temperature on contact angle between glass-ceramics and diamond without coating titanium: (a) 963 K (129.6?);(b) 993 K (39.5?)

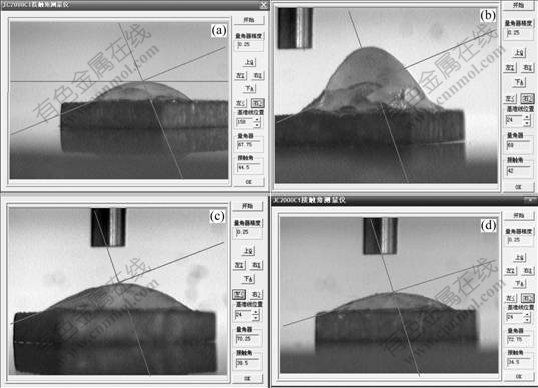

Fig.4 shows the effect of the titanium coating on the contact angle. When diamond surface is coated with a titanium film, the titanium atom on the surface will be oxidized at high temperature and forms oxide Ti3O5 with similar structure of Al2O3?TiO2, which produces a chemical combination between titanium and vitrified bond. Therefore the contact angle between vitrified bond and diamond with coating titanium gets smaller than that between vitrified bond and diamond without coating titanium.

Fig.4 Effect of titanium coating on contact angle: (a) 983 K (44.5?); (b) 983 K (42?); (c) 993 K (39.5?); (d) 993 K (34.5?)

4 Conclusions

1) When the temperature is below 1 173 K, titanium coatings on the surface of diamond can prevent diamond from being oxidized, the anti-impacting strength of the diamonds hardly decreases, and the combination between titanium and diamonds is very strong.

2) The contact angle between vitrified bond and diamond decreases with the increase of temperature. Titanium coatings on the surface of diamond crystal can improve the soakage property between vitrified bond and diamond at high temperature.

3) When diamond surface is coated with a titanium film, the titanium atom on the surface will be oxidized at high temperature and form oxide Ti3O5 with similar structure of Al2O3?TiO2. A chemical reaction takes place between the surface C atom in diamond crystal and Ti atom in the titanium coatings to form Ti8C5, which reinforces the bonding strength between glass-ceramics and diamond.

References

[1] ROBERT L, PATRICK D. Property of large single crystal diamond [J]. Diamond and Related Materials, 1999, 8(3): 909-915.

[2] CHOUDHARY D, BELLARE J. Manufacture of gem quality diamond: A review [J]. Ceramic International, 2000, 26: 73-85.

[3] HANSKURT T, THOMAS F. In-process dressing of fine diamond wheels for tool grinding [J]. Precision Engineering, 2000, 24(1): 58-61.

[4] ZHANG Xi-ming, WANG Ming-zhi, WANG Yan-hui. Effect of different stuffs which can make pores in grinding wheel on the properties of vitrified bond [J]. Diamond and Abrasive Engineering, 2002, 131(5): 19-22. (in Chinese)

[5] GUO Zhi-min, ZHANG Xiang-hong, ZANG Jian-bin, WANG Yan-hui. Effect of coating outside of super hard abrasives on the strength of vitrified bond super hard grinding wheel [J]. Super Hard Materials Engineering, 2005, 14(1): 18-21. (in Chinese)

[6] WAN Long, DING Xiao-ping, LIU Xiao-pan. Super hard materials and tools [M]. Beijing: Chemical Industry Press, 2000. (in Chinese)

[7] LUO S Y, LIAO Y S, CHOU C C. Analysis of the wear of a resin-bonded diamond wheel in the grinding of tungsten carbide [J]. Journal of Materials Processing Technology, 1997, 69(1/3): 289-296.

[8] WANG Yan-hui. Preparation of titanium film on the surface of diamond: Properties and application [D]. Qinhuangdao: Yanshan University, 2000. (in Chinese)

[9] WANG Y H, ZANG J B, WANG H X, WANG M Z. Effect of Ti coating on the wear stages of diamond in tools [J]. Key Engineering Materials, 2001, 202/203: 199-202.

[10] ALESHIN V G, VESNA V T, MALOV V P, FILIPPOVICH A G. Gas-phase deposition of titanium coating on grains of cubic boron nitride [J]. Soviet Powder Metallurgy and Metal Ceramics, 1991, 30(4): 297-300.

[11] BREVAL E, CHENG J P, AGRAWAL D K. Development of titanium coatings on particulate diamond [J]. Journal of the American Ceramic Society, 2000, 83(8): 2106-2108.

[12] OMAR A A, EL-SHENNAWI A W, EL-GHANNAM A R. Crystallization of some spodumene-lithium zinc orthosilicate glasses [J]. J Mater Sci, 1991, 26: 3366-3373.

[13] OMAR A A, SHENNAWI A, GHANNAM A R. Thermal expansion of Li2O-ZnO-Al2O3-SiO2 glasses and corresponding glass-ceramics [J]. Mater Sci, 1991, 26: 6049-6056.

[14] Committee of Chinese Abrasives Standardization Technology. A compilation of standards of china machinery industry—Abrasives [M]. Beijing: China Standard Press, 2003.

[15] JI Mu-wen ping. Technology of nonmetals[M]. Beijing: Science Press, 1982.

Corresponding author: ZHANG Xiao-fu; Tel: +86-13874832384; E-mail: smzxf@vip.sina.com