- Abstract:

- 1 Introduction▲

- 2 System of robot▲

- 3 Dynamics analysis▲

- 4 Controller design▲

- 5 Simulation and experime...▲

- 6 Conclusions▲

- References

- Figure

- Fig.1 Relationship between robot and weld seam

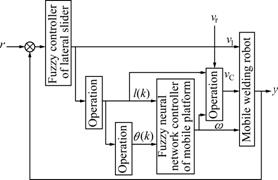

- Fig.2 Schematic diagram of principle of coordinate controller

- Fig.3 Schematic diagram of fuzzy-gaussian neural network controller

- Fig.4 Results of tracking curve-line

- Fig.5 Errors of torch position

- Fig.6 Errors of heading angle of robot

- Fig.7 Results of welding curve line: (a) Actual tracking results of welding curve line; (b) Torch position errors; (c) Lateral slider position; (d) Heading angle (θ) of robot

- Fig.8 Results of welding pipeline: (a) Actual tracking results of welding pipeline; (b) Torch position errors; (c) Lateral slider position; (d) Heading angle (θ) of robot

J. Cent. South Univ. Technol. (2010) 17: 1320-1326

DOI: 10.1007/s11771-010-0637-7![]()

Seam tracking control for mobile welding robot based on vision sensor

ZHANG Ting(张庭)1, LI Kai(李慨)1, YANG Jing(杨静)2

1. Department of Mechanical Engineering, Hebei University of Technology, Tianjin 300130, China;

2. Department of Chemical Engineering, Hebei University of Technology, Tianjin 300130, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract:

To solve the seam tracking problem of mobile welding robot, a new controller based on the dynamics of mobile welding robot was designed using the method of backstepping kinematics into dynamics. A self-turning fuzzy controller and a fuzzy-Gaussian neural network (FGNN) controller were designed to complete coordinately controlling of cross-slider and wheels. The fuzzy-neural control algorithm was described by applying the Gaussian function and back propagation (BP) learning rule was used to tune the membership function in real time by applying the FGNN controller. To make the tracking more quickly and smoothly, the neural network controller based on

Key words:

mobile welding robot; seam tracking; fuzzy-Gaussian neural network; dynamic model; Lyapunov function;

1 Introduction

Welding automation has been widely used in several manufacturing fields, and one of the most complex applications is welding system based on autonomous robots. Some special welding robots can provide several benefits in certain welding applications. Among them, mobile welding robot used in line welding can generate perfect movements at a certain travel speed, which makes it possible to produce a consistent weld penetration and weld strength.

In practice, various robotic welding systems have been developed recently, such as crawling welding machine based on structured light for a storage tank or oil pipeline welding [1], wheeled welding robot for welding in the lattice region of egg boxes inside the ship bottom [2]. The intelligent mobile welding robot has the function of auto-searching weld line for ship deck welding [3-5]. Wheel welding mobile robot is a typical non-holonomic bond system and does not satisfy feedback stabilization [6]. So, it cannot use smooth state feedback to realize system asymptotic stability. The continuous state feedback in the modern control theory plays a dominant role, and many mature results cannot be used in the non-holonomic mobile welding robot, which has been widely interested by both academic circle and research institution in resent years. SEONG et al [7] and GAO et al [8] applied adaptive controller based on the backstepping method to the mobile welding robot for seam tracking control. GAO et al [9] and WANG et al [10] designed controllers for mobile platform and cross-slider based on the fuzzy control algorithm.

The fuzzy neural network control combines the reasoning and induction ability of fuzzy control with self-learning and self-adaptive ability for network weight and threshold of neural network. The fuzzy neural network control can improve the tracking accuracy and stability because fuzzy reasoning is realized and fuzzy control rule is optimized by using neural network, and it is an ideal method that uses neural network to design seam tracking controller [11]. ZHANG et al [12] designed controllers for mobile platform based on the fuzzy- Gaussian neural network control algorithm.

The majority of the existing methods only consider kinematics models, and less consider dynamics. In real welding environments, however, due to the external disturbance or the perturbation of structural parameters, such as actual vehicle dynamic inertia and the power limits of actuators and localization errors, the method of the linear control theory based on the kinematics model could not result in good performance, especially in the aspects of stability and robustness. Therefore, in order to address this problem, nonlinear controls such as sliding mode control was employed for a welding mobile robot [13]. Though there are many researches on tracking control based on the dynamic model for the nonholonomic constraints mobile robot [14-16], there have been relatively few studies on seam tracking control in practice.

At present, the dynamics control problem of nonholonomic mobile manipulator has two processing methods. One is input-output linearization; the other is backstepping kinematics into dynamics. Mobile welding robot is nonholonomic mobile manipulator application to welding field. DUNG et al [17] and ZHANG [18] designed a sliding mode controller based on dynamic model of two-wheeled welding mobile robot by the method of input-output linearization. LI and ZHANG [19] derived the dynamic behaviors of left and right driving wheels and the body of the welding mobile robot to the welding torch point based on the Newton-Euler method. In order to realize the combined control of robot body and sliders, and further research on the dynamic behaviors of sliders, a systematic and a complete dynamic model for robot was constructed. In order to verify the effectiveness of the above model, a sliding mode tracking control method was proposed and simulated.

A prototype of mobile welding robot with welding torch positioned at one side of welding robot was developed, and a new controller based on the dynamics and kinematics models of the mobile welding robot was designed by the method of backstepping kinematics into dynamics. First, self-turning fuzzy controller and fuzzy- Gaussian neural network (FGNN) controller were designed to complete coordinately controlling of cross- slider and wheels, and exactly welding seam tracking was realized by using the controller. The fuzzy-neural control algorithm was described by applying a Gauss function as a membership function, and a specialized learning architecture was used so that membership function would be tuned in real time by applying the FGNN controller. Also self-learning neural network was used to deal with unmodeled disturbances, making the tracking more quickly and smoothly. At the same time, the online learning time was reduced, and the real-time ability was improved. The controller can not only solve kinematics redundancy problem of cross-slider and mobile platforms to complete coordinately controlling of cross-slider and wheels, but also ensure the tracking velocity of each axis to make the mobile welding robot stable and robust.

2 System of robot

The mobile welding robot includes mobile platform, cross-slider, welding torch, visual tracking system and intelligent micro-computer control system. The hardware framework of control system includes PC, NI-PCI7344, NI-DAQ6015 and image capture card. The software framework of measurement and control system are based on LabVIEW.

The wheels are driven and controlled by AC servo motor. The cross-slider is controlled by step motor, and four motors are controlled by a four-axis motion controller. The integration grade and control precision are improved greatly.

3 Dynamics analysis

The dynamic model of the mobile welding robot, which is constrained with nonholonomic constraint, can be expressed as follows:

![]() (1)

(1)

where q represents a there-dimensional generalized coordinate vector; M(q)![]() R3×3 represents the system inertia matrix; C(q,

R3×3 represents the system inertia matrix; C(q,![]() R3×3 represents the centripetal force matrix that refers to position and speed; F(

R3×3 represents the centripetal force matrix that refers to position and speed; F(![]() R3 represents the surface friction; G(q)

R3 represents the surface friction; G(q)![]() R3×3 represents the gravity; τd

R3×3 represents the gravity; τd![]() R3 represents the unknown disturbance; B(q)

R3 represents the unknown disturbance; B(q)![]() R3×3 represents the input transformation matrix; τ

R3×3 represents the input transformation matrix; τ![]() R3×1 represents the input moment vector; A(q)

R3×1 represents the input moment vector; A(q)![]() R1×3 represents the constraint matrix; and λ

R1×3 represents the constraint matrix; and λ![]() R1 represents the binding force vector.

R1 represents the binding force vector.

Nonholonomic constraint is described as follows:

![]() (2)

(2)

![]() (3)

(3)

where θ represents the heading angle of the mobile welding robot.

According to the matrix theory, the dynamic model of the robot can be rewritten to the following form:

![]() (4)

(4)

where![]()

![]()

![]()

![]()

![]() S is the matrix that make A(q)S(q)=0; q=[ν ω ν1]T, ν represents the slip velocity of mobile robot; ω represents the rotary angular velocity of mobile platform relative to its centroid, and

S is the matrix that make A(q)S(q)=0; q=[ν ω ν1]T, ν represents the slip velocity of mobile robot; ω represents the rotary angular velocity of mobile platform relative to its centroid, and ![]() represents the slip velocity of lateral slider. ZHANG et al [20-21] proposed the accurate values of mobile welding robot dynamic parameters.

represents the slip velocity of lateral slider. ZHANG et al [20-21] proposed the accurate values of mobile welding robot dynamic parameters.

4 Controller design

4.1 Compromise control tactic design

The position error between the front-end of the current welding torch and the goal is described as follows [19-20]:

(5)

(5)

where l(k) represents the lateral slider position at time k; ν(k-1) represents the moving velocity of mobile platform at time k-1; e1, e2 and e3 represent tracking error of X direction (xe), tracking error of Y direction (ye) and tracking error of angle θe, respectively.

Suppose the initial pose position of the torch is p= [x y θ]T, the pose position of the tracking goal is p1= [x1 y1 θ1] and given welding velocity is q′=[ν′ ω′]T. Then, seam tracking problem can be stated as: find the

appropriate q=[ν ω ν1]T to make ![]() where T

where T

represents control cycle.

In this system, vision sensor was used. Some hypotheses are as follows: Firstly, the extended line of lateral slider crosses throughout with the welding seam, so xe=0; secondly, reference velocity ν′ and θ′ are known.

Fig.1 shows the relationship between the robot and weld seam, where C(k) represents mobile robot’s centre of mass. From Fig.1, it can be seen that the error between the moving direction of mobile platform and the trend of weld seam is θk [9-10],

![]() (6)

(6)

Fig.1 Relationship between robot and weld seam

To keep the welding speed of the welding torch front-end, moving speed of centroid was calculated as follows:

![]() (7)

(7)

For controller of lateral slider, the weld seam deviation and its changing rate of seam deviation are the inputs of control system; slip velocity of lateral slider is the output. For controller of mobile platform, the inputs are the weld seam deviation and the extended length of lateral slider, and the output is ω. Fig.2 shows the control schematic diagram, where r and y represent reference and actual track, respectively; vr and vc represent reference welding velocity and mobile robot’s velocity, respectively.

Fig.2 Schematic diagram of principle of coordinate controller

The controller of lateral slider uses a kind of fuzzy algorithm [9-10], and the controller of mobile platform uses fuzzy-Gaussian neural network control algorithm. Fig.3 shows the schematic diagram of fuzzy-Gaussian neural network controller, where ωC represents the output of the FGNN controller and ![]() represents the network weight.

represents the network weight.

Fig.3 Schematic diagram of fuzzy-gaussian neural network controller

The first layer introduced inputs into neural network.

![]() (8)

(8)

where i and j represent the ith layer and jth nerve cell, respectively; ![]() and

and ![]() respectively represent the inputs and outputs of neural network; and xi represents the input of fuzzy neural network controller.

respectively represent the inputs and outputs of neural network; and xi represents the input of fuzzy neural network controller.

In the second layer, the inputs of FGNN are fuzzed. Each input has three fuzzy language collections, which is {N, Z, P} = {“negative”, “zero”, “positive”}, and the membership function uses Gaussian function.

![]() (9)

(9)

where ![]() is the language collection,

is the language collection, ![]() aij and bij respectively represent the central value and width of

aij and bij respectively represent the central value and width of![]()

The function of the third layer represents ‘and’ operation, where multiplication is used instead of min algorithm.

![]() (10)

(10)

The function of the fourth layer is de-fuzzy, which uses weighted average method.

![]() (11)

(11)

(12)

(12)

The network uses BP to learn rules, and the learning rules include off-line learning and on-line learning.

In the process of off-line learning, the network is trained by means of a group of sample data. The trained values include ![]() and parameters aij and bij of Gauss function, and the trained target function is shown as follows:

and parameters aij and bij of Gauss function, and the trained target function is shown as follows:

![]() (13)

(13)

where ![]() represents the desired output of network; and y represents the actual output of network.

represents the desired output of network; and y represents the actual output of network.

Iterative formula of weight is adjusted as follows:

![]() (14)

(14)

![]() (15)

(15)

![]() (16)

(16)

where η1, η2 and η3 are learning rates.

In the process of on-line learning, the trained target functions are as follows:

![]() (17)

(17)

where θd and θ represent the anticipant and actual bending angles of the mobile welding robot (WMR), respectively.

4.2 Dynamic control law

Towards to the above velocity ![]() a tracking error ec is defined as:

a tracking error ec is defined as:

![]()

![]() (18)

(18)

where ![]() and

and ![]() represent the anticipant and actual velocities of the mobile platform, respectively.

represent the anticipant and actual velocities of the mobile platform, respectively.

The dynamic equation of the robot under the velocity error is described as follows:

![]() (19)

(19)

![]() (20)

(20)

where K1 represents the positive diagonal gain matrix; and τNN represents the moment item of the monolayer neure and γ represents the compensation of the non- modeling disturbance quantity of the system.

The output of this neure can be defined as follows:

![]() (21)

(21)

where W represents the connection weight matrix of the monolayer neure and ![]() represents the input of neure.

represents the input of neure.

Substituting Eq.(20) to Eq.(19), and uniting with Eq.(21), the closed loop dynamic equation of the error can be got:

![]() (22)

(22)

where ![]() represents the vector including mass and intertia of mobile welding robot;

represents the vector including mass and intertia of mobile welding robot; ![]() denotes the error of estimate of

denotes the error of estimate of ![]() . Using

. Using ![]() to replace

to replace ![]() , the above equation can be simplified as follows:

, the above equation can be simplified as follows:

![]() (23)

(23)

To compensate the non-modeling, choose the disturbance quantity as follows:

![]() (24)

(24)

where ![]() represents a positive diagonal matrix, and min(diag(kd))>bd.

represents a positive diagonal matrix, and min(diag(kd))>bd.

4.3 Learning rules and stability analysis of neural network

Lyapunov theory is used to judge the stability of the system. The Lyapunov function (L) form is as follows:

![]() (25)

(25)

where Γ is symmetric positive definite constant matrix. From Eq.(25), it can be seen that L≥0, and L=0 only when e1, e2, e3, ec and ![]() are 0. Derivate the two sides of Eq.(25), we can get the following equation:

are 0. Derivate the two sides of Eq.(25), we can get the following equation:

![]()

![]() (26)

(26)

It can be seen that ![]() is a skew-symmetric matrix from Eq.(17), let

is a skew-symmetric matrix from Eq.(17), let ![]() and instead of γ, Eq.(26) can be rewritten to the following form:

and instead of γ, Eq.(26) can be rewritten to the following form:

![]()

![]() ≤

≤![]()

![]() (27)

(27)

where K1min and kdmin are the smallest singular values of K1 and kd, respectively. Substituting Eq.(5) to Eq.(27), and the equation can be got as follows:

![]() ≤

≤![]()

![]()

![]() (28)

(28)

Substitute ![]() into Eq.(16), and then

into Eq.(16), and then

![]() ≤

≤![]()

![]()

![]() (29)

(29)

We can obtain kdmin≥bd from Eq.(29), so ![]() <0. From Lyapunov theory, it can be seen that the control algorithm is globally asymptotically stable and converges to 0.

<0. From Lyapunov theory, it can be seen that the control algorithm is globally asymptotically stable and converges to 0.

From derivation process, it can be seen that

![]() (30)

(30)

Derivate two sides of Eq.(30), we can get the following equation:

![]() (31)

(31)

Eq.(31) is the learning rule of neural network controller. The self-learning and self-adaptive ability of neural network controller is realized by adjusting weight coefficient. The adjustment of W is realized by supervised Hebb learning rule.

5 Simulation and experiment

5.1 Simulation

The experiment is implemented in Matlab to prove the availability of the algorithm. The parameters of the controller are as follows: m0=50 kg, m1=4 kg, J0= 1.417 kg?m2, J1=0.03 kg?m2, R=0.6 m, r=0.08 m, K1= 20I2, k2=0.5, k3=0.25, Γ=I3, where Ik is a k×k unit matrix, and kd=[5 5 5].

Figs.4-6 show that the error is eliminated by the motion of both cross-slider and mobile platforms when tracking curve-line, which can avoid that cross-slider reaches limit position and welding seam is pressed by robot. After the tracking process enters into stable state, the cross-slider always does small amplitude adjustment near the center position, and the tracking error is within ±0.4 mm.

Fig.4 Results of tracking curve-line

Fig.5 Errors of torch position

Fig.6 Errors of heading angle of robot

5.2 Welding experiment

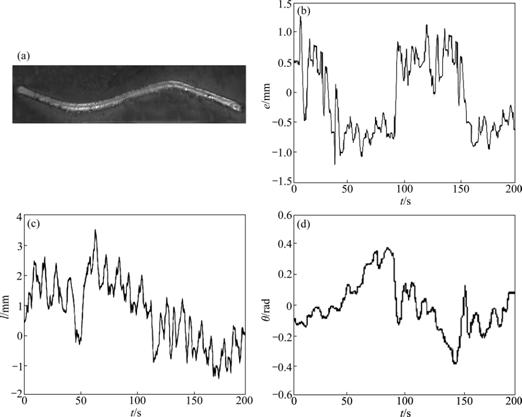

The parameters of welding in experiment are the same as those used in the simulation experiment. The welding experiment results of track fold line and pipe line are shown in Figs.7 and 8, respectively.

The actual tracking results of tracking a curve line and welding pipeline are respectively shown in Fig.7(a) and Fig.8(a). Fig.7(b) and Fig.8(b) show the tracking errors of tracking a curve line and welding pipeline detected by vision sensor, respectively. The lateral slider positions are shown in Fig.7(c) and Fig.8(c). The robot orientation errors are shown in Fig.7(d) and Fig.8(d). The adaptive fuzzy controller and the FGNN controller can solve kinematics redundancy problem of both cross-slider and mobile platforms; the FGNN controller combines the reasoning and induction ability of fuzzy control with self-learning and self-adaptive for network weight and threshold ability of the neural network. The FGNN controller can improve the tracking accuracy and stability because fuzzy reasoning is realized and fuzzy control rule is optimized by using neural network; and the dynamic controller ensures velocity tracking of each axis.

Fig.7 Results of welding curve line: (a) Actual tracking results of welding curve line; (b) Torch position errors; (c) Lateral slider position; (d) Heading angle (θ) of robot

Fig.8 Results of welding pipeline: (a) Actual tracking results of welding pipeline; (b) Torch position errors; (c) Lateral slider position; (d) Heading angle (θ) of robot

6 Conclusions

(1) A prototype of mobile welding robot with welding torch positioned at one side of welding robot is developed.

(2) A systematic and complete dynamic model for mobile welding robot is constructed, which contains the dynamics coupling between the mobile platform and the cross-slider.

(3) The self-turning fuzzy control algorithm and FGNN control algorithm are adopted to design coordination control strategy between the mobile platform and the cross-slider.

(4) The dynamic controller is designed by the control algorithm of the monolayer nerve cell network, which can compensate the dynamic coupling, the partial uncertainty and the disturbances of the parameters of the robot dynamic model on-line. The velocity tracking is realized and the mobile welding robot has good stability and robustness.

References

[1] MA Zhi-wei, ZHANG Hua, ZHENG Guo-yun. Structure design of mobile welding robot based on rotating arc sensor for bending weld [J]. Transactions of China Welding Institution, 2005, 26(11): 51-54. (in Chinese)

[2] KAM B O, JEON Y B, KIM S B. Motion control of two wheeled welding Mobile Robot with seam tracking sensor [C]// Proceedings of EEE International Symposium on Industrial Electronics. Pusan: IEEE, 2001: 851-856.

[3] JIANG Li-ping, JIAO Xiang-dong, L? Xue-qing. Key points of high efficient automatic welding technique for large scale spherical steel tank [J]. Chinese Journal of Mechanical Engineering, 2003, 39(8): 146-150. (in Chinese)

[4] ZHANG Ke, L? Xue-qin, WU Yi-xiong. Algorithm for the entrance angle calculation of a welding mobile robot during auto-searching weld line [J]. Journal of Shanghai Jiaotong University, 2006, 39(6): 941-944. (in Chinese)

[5] ZHANG Ke, WU Yi-xiong, JIN Xing, L? Xu-qing. Study on welding mobile robot with the function of auto-searching welding line [J]. China Welding, 2006, 15(1): 68-69.

[6] RENW, SUN J S, BEARD R W. Nonlinear tracking control for nonholonomic mobile robots with input constraints: An experimental study [C]// Proceedings of the 2005 American Control Conference. Piscataway: IEEE, 2005: 4923-492.

[7] SEONG J M, SUN J S, BEARD R W. Nonlinear tracking control of a welding robot based on adaptive backstepping method [C]// Proceedings of International Symposium on Electronics & Electronics Engineering. Vietnam: IEEE, 2005: 43-51.

[8] GAO Yan-feng, ZHANG Hua, MAO Zhi-wei. Curved seam tracking control of a wheeled welding mobile robot [J]. Robot, 2007: 439-451. (in Chinese)

[9] GAO Yan-feng, ZHANG Hua, MAO Zhi-wei. Coordinate control of broken-line welding seam tracking for wheeled robot [J]. Transactions of the China Welding Institution, 2008, 29(5): 33-37. (in Chinese)

[10] WANG Hai-dong, ZHANG Hua, XU Jian-ning. Compromise control tactic for wheeled welding robot [J]. Transactions of the China Welding Institution, 2004, 25(3): 4-6. (in Chinese)

[11] CHENG Shan-ben, LOU Ya-jun, ZHAO Song-bing. Fuzzy-neural network modeling and control of pool dynamic process in pulsed GTAW [J]. Acta Automatica Sinica, 2002, 28(1): 74-82.

[12] ZHANG Ke, WU Yi-xiong, JIN Xing. Real-time seam tracking based on fuzzy-Gaussian neural network for welding mobile robot [J]. Transactions of China Welding Institution, 2004, 28(9): 17-22. (in Chinese)

[13] CHWA D. Sliding mode tracking control of nonholonomic wheeled mobile robots in polar coordinates [J]. IEEE Transaction on Control System Technology, 2004, 12(4): 637-644.

[14] XIAO Beng-xian, ZHANG Song-can. Tracking control of nonholonomic mobile robots based on dynamics model [J]. Journal of System Simulation, 2006, 18(5): 1263-1266. (in Chinese)

[15] ZHANG Shuo-sheng, YU Da-tai. Robust following controller design of wheeled mobile manipulator [J]. Journal of University of Science and Technology Beijing, 2003, 25(1): 69-73.

[16] TAN L C, TRONG H B. Sliding mode control of two-wheeled mobile robot for tracking smooth curved welding path [J]. KSME International Journal, 2004, 7(18): 1094-1106.

[17] DUNG N M, DUY V H, PHUONG N T, KIM S B, OH M S. Two-wheeled welding mobile robot for tracking a smooth curved welding path using adaptive sliding-mode control technique [J]. International Journal of Control, Automation and Systems, 2007, 3(5): 283-294.

[18] ZHANG Ke. Dynamic modeling and simulation for nonholonomic welding mobile robot [J]. Journal of Central South University of Technology, 2007, 14(5): 679-684.

[19] LI Kai, ZHANG Ting. Seam tracking control of welding mobile robot based on dynamics model [C]// Proceedings of the Second International Conference on Modeling and Simulation. Manchester, 2009: 1403-1409.

[20] ZHANG Ting, LI Kai, YANG Jing. Compromise control tactic for intelligent mobile welding robot [C]// Proceedings of the 9th International Conference on Electronic Measurement & Instruments. Beijing: IEEE, 2009: 836-839.

[21] ZHANG Ting, LI Kai, DAI Shi-jie, XIAO Shu-mei. Research on seam tracking controller of mobile welding robot [C]// Proceedings of International Conference on Automation and Logistics. Shenyang: IEEE, 2009: 1042-1045.

Foundation item: Project(2007309) supported by the Scientific Research Project of Hebei Provincial Education Office, China; Project(2007AA04Z209) supported by the National High-Tech Research and Development Program of China

Received date: 2009-06-12; Accepted date: 2010-01-04

Corresponding author: LI Kai, PhD, Associate professor; Tel: +86-22-26582598; E-mail: tingzhang1117@163.com

- Seam tracking control for mobile welding robot based on vision sensor