DOI:10.19476/j.ysxb.1004.0609.2017.12.03

高强高导Cu-Cr-Zr合金时效性能

丁宗业1,贾淑果1, 2,宁向梅1,宋克兴1, 2,刘 平1

(1. 河南科技大学材料科学与工程学院,洛阳 471023;

2. 河南省有色金属共性技术河南省协同创新中心,洛阳 471023)

摘 要:

摘 要:采用真空熔炼的方法制备Cu-Cr-Zr合金,研究合金的时效析出行为;借助高分辨透射电镜对合金时效析出相的组织形态进行分析,探讨合金的时效强化机制。结果表明:Cu-0.36Cr-0.03Zr合金经450 ℃时效4 h后获得较好综合性能,合金硬度和导电率分别达到为156 HV和82.62 %IACS;通过微观分析确定经450 ℃时效4 h后合金中析出相为面心立方Cr相,且与基体保持共格关系;当时效时间延长至8 h时,合金中面心立方Cr相转变为体心立方Cr相;经450 ℃时效4 h后合金强度与硬度的提高主要由共格应变强化所造成。

关键词:

文章编号:1004-0609(2017)-12-2420-06 中图分类号:TG146.1 文献标志码:A

铜合金材料具有较高的强度和优良的导电、导热性、及较高的再结晶温度等,是一种综合性能优良的功能材料,被广泛应用于连铸结晶器、电阻点焊电极、电力机车架空导线及触头材料等[1-5]。Cu-Cr-Zr系合金是高强高导铜合金的典型代表,属于时效析出强化型合金,可通过合理控制热处理工艺参数,促使Cr、Zr合金元素从过饱和固溶体中析出形成新相,并弥散分布于Cu基体中,实现合金强度及导电性等综合性能的大幅度提高[6-9]。目前有关Cu-Cr-Zr系合金经固溶时效后组织与性能变化的报道较多[10-13],但关于析出相微观结构与析出强化机理方面的文献较少,且对于该合金中析出相结构尚未存在统一认识[6-9]。本文作者对固溶态Cu-0.36Cr-0.03Zr合金在400~500 ℃时效0~8 h后的性能进行探讨,并对时效后的显微组织进行观察,分析合金的时效强化机制。

1 实验

试验用Cu-0.36Cr-0.03Zr合金,以纯铜、纯铬和Cu-50Zr中间合金为原料,在真空感应熔炼炉中进行熔炼,铁模浇铸,并锻造成型。合金棒料的固溶与时效处理在RJX-3-12型氮气保护管式炉中进行,控温精度为±5 ℃。电阻测量在ZY9987型数字式微欧计上进行;显微硬度测量使用国产HV1000数字显微硬度计,载荷设定为0.98 N,加载时间设定为10 s;抗拉强度的测量在SHIMADZU A-1250KV精密万能试验机上进行,拉伸速率为1 mm/min。显微组织观察分别在OLYMPUSPMG3金相显微镜、JEM-2100型高分辨透射电镜上进行,透射试样经电解双喷减薄,电解液配比为V(CH3OH):V(HNO3)=3:1,电解液工作温度为-30 ℃。

2 结果与分析

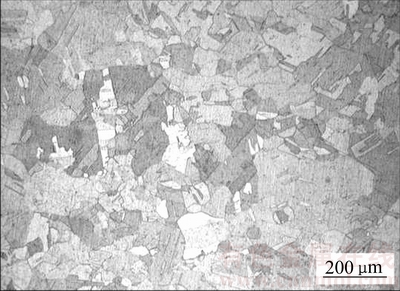

根据Cu-Cr及Cu-Zr相图,对Cu-0.36Cr-0.03Zr合金采用(950 ℃,1.5 h)的固溶处理,水淬,以保证合金元素溶入铜基体。图1所示为Cu-0.36Cr-0.03Zr合金经950 ℃固溶处理后的显微组织。从图1可以看出,合金经固溶处理后,组织均匀,晶粒细小。

2.1 时效对Cu-Cr-Zr合金性能的影响

Cu-0.36Cr- 0.03Zr合金经过(950 ℃,1.5 h)的固溶处理后,溶质原子溶入铜基体,形成过饱和固溶体,对其进行时效处理后,由于过饱和固溶体的分解,合金的性能会发生显著地变化。

图1 Cu-Cr-Zr合金在950 ℃固溶1.5 h后的显微组织

Fig. 1 Microstructure of Cu-Cr-Zr alloy after solution treatment at 950 ℃ for 1.5 h

图2所示为固溶处理后的Cu-0.36Cr-0.03Zr合金,经不同温度时效处理后,显微硬度与时效时间的关系曲线。从图2中可以看出,在时效初期,合金显微硬度迅速提高,且温度越高增加幅度越大;而后随着时效时间的延长,显微硬度达到峰值,随后缓慢降低,且温度越高达到峰值的时间越短。在450 ℃以下温度时效时,原子扩散能力较低,溶质原子析出速度慢,析出相较稳定,合金硬度呈一直上升趋势;当温度高于450 ℃时,合金显微硬度曲线出现峰值,且温度越高,达到峰值所需时间越短且峰值越低。如Cu-0.36Cr-0.03Zr合金在450 ℃时效 4 h达到硬度峰值156 HV,而在500 ℃ 时效2 h即达到硬度峰值154 HV。这是由于在时效初期,固溶体过饱和度较大,析出相析出速度较快,合金显微硬度迅速达到峰值;但随着时效时间的延长,析出相长大趋势增加,与基体共格关系遭到破坏,合金显微硬度降低。时效温度越高,原子扩散能力越强,析出速度越快,显微硬度越大,其达到峰值所需时间也越短。

图2 显微硬度随时效时间的变化曲线

Fig. 2 Curves of microhardness versus aging time

图3 导电率随时效时间的变化曲线

Fig. 3 Curves of conductivity versus aging time

图3所示为固溶处理后的Cu-0.36Cr-0.03Zr合金,经不同温度时效处理后,合金的导电率与时效时间的关系曲线。从图3可以看出,在时效初期,合金的导电率迅速增加,且温度越高增加幅度越大;随着时效时间的继续延长,导电率增大渐缓。材料的导电性受固溶在基体中合金元素的量关系极大,Cu-0.36Cr-0.03Zr合金经固溶处理后,合金元素固溶于铜基体中,固溶体发生弹性畸变程度较大,对电子的散射能力较强,导电率很低;合金在随后的时效处理过程中,由于时效初期基体的过饱和度大,固溶原子析出的动力大,析出速度很快,导致导电率在时效初期增幅较大;而温度越高,合金元素的扩散能力越大,而使得温度越高时效初期的导电性增幅越大;随着时效时间的增加,基体的过饱和度逐渐降低,溶质元素的析出速度渐慢,同时发生析出相的聚集粗化以及晶粒的长大等,使得导电率增幅趋缓。

综上所述,由图2及图3可知,Cu-0.36Cr-0.03Zr合金在450 ℃时效4 h,可以获得较好的综合性能,其显微硬度和导电率分别达到156 HV、82.62 %IACS。

2.2 合金显微组织分析

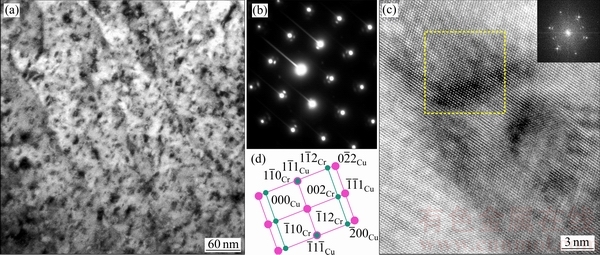

图4所示为Cu-0.36Cr-0.03Zr合金在450 ℃时效4 h后析出相形貌、电子衍射花样标定及HRTEM像。时效初期,析出相细小,有双叶花瓣状畸变衬度,可观察到零衬度线方向几乎完全一致,说明析出相与基体保持共格关系(见图4(a))。图4(b)所示为 晶带轴的选区电子衍射结果。从图4(b)可看出,除Cu基体衍射斑点外,并没有第二相的衍射斑点,可能此时析出相尺寸太小,且面心立方Cr相与面心立方Cu的晶格常数分别为0.368 nm和0.362 nm,相差极小,两者完全共格时,会使Cr相的衍射斑点被铜基体的掩盖,但铜基体的衍射斑点有明显拉长的迹象。由图4(c)中析出相的高分辨像可知,铜基体与析出相呈现晶格畸变,对其傅里叶变换图(FFT)进行标定,为面心立方Cr相,如图4(d)~(e)所示。图4(e)中红色箭头表示存在超晶格衍射斑点,表明在(022)面上存在着溶质富集,该现象与BATRA等[14]与CHENG等[15]的描述相一致。对HRTEM图进行反傅里叶转换,并测得纯铜d(111)为0.208 nm与计算所得的0.209 nm很接近,同时测量析出相(111)与(100)两晶面的晶面间距分别为0.218和0.185 nm,其晶面夹角为54.7°,与面心立方Cr相一致,可确定为面心立方Cr相。即由于由上述分析,Cu-0.36Cr- 0.03Zr合金在450 ℃时效4 h后析出相为面心立方Cr相,且与基体保持完全共格关系。

晶带轴的选区电子衍射结果。从图4(b)可看出,除Cu基体衍射斑点外,并没有第二相的衍射斑点,可能此时析出相尺寸太小,且面心立方Cr相与面心立方Cu的晶格常数分别为0.368 nm和0.362 nm,相差极小,两者完全共格时,会使Cr相的衍射斑点被铜基体的掩盖,但铜基体的衍射斑点有明显拉长的迹象。由图4(c)中析出相的高分辨像可知,铜基体与析出相呈现晶格畸变,对其傅里叶变换图(FFT)进行标定,为面心立方Cr相,如图4(d)~(e)所示。图4(e)中红色箭头表示存在超晶格衍射斑点,表明在(022)面上存在着溶质富集,该现象与BATRA等[14]与CHENG等[15]的描述相一致。对HRTEM图进行反傅里叶转换,并测得纯铜d(111)为0.208 nm与计算所得的0.209 nm很接近,同时测量析出相(111)与(100)两晶面的晶面间距分别为0.218和0.185 nm,其晶面夹角为54.7°,与面心立方Cr相一致,可确定为面心立方Cr相。即由于由上述分析,Cu-0.36Cr- 0.03Zr合金在450 ℃时效4 h后析出相为面心立方Cr相,且与基体保持完全共格关系。

图4 合金经450 ℃时效4 h后的析出相形貌、电子衍射花样、HREM像、FFT图与示意图及反傅里叶转变图

Fig.4 Precipitation morphology(a), SAED pattern(b), HREM image(c), FFT image(d) and a schematic diagram(e), Inverse FFT image(f)

图5所示为Cu-0.36Cr-0.03Zr合金经450 ℃时效8 h后的析出相形貌、电子衍射花样标定及HRTEM像。对比图4(a),由图5(a)可以看出,当时效时间达到8 h时,析出相已经明显长大,且发生聚集粗化。结合图2,随时效时间的延长,合金硬度降低。对合金在450 ℃时效8 h后的析出相进行选区电子衍射,发现其衍射斑点与图4(d)中傅里叶转变图相类似,说明该合金中存在面心立方Cr相,如图5(b)所示。对HRTEM图中较大尺寸析出相进行傅里叶转变,可得到不同的衍射斑点,经标定可确定析出相为体心立方Cr相(见图5(c)~(d)),且合金中体心立方Cr相与Cu基体存在N-W位向关系:

;

;

因此,Cu-0.36Cr-0.03Zr合金在450 ℃经8 h时间时效后,其析出相Cr由亚稳定的面心立方结构转变为稳定的体心立方结构,这与Cu-0.75Cr-0.13Zr合金时效过程中面心立方Cr相的变化一致[16]。

2.3 Cu-0.36Cr-0.03Zr合金时效析出强化机制

由图2可知,Cu-Cr-Zr合金经450 ℃时效4 h后,显微硬度达到峰值,其强度硬度的的提高主要来自于时效强化。时效强化的强化机制主要分为切过机制和绕过机制,在过时效之前,析出相尺寸极小且与基体保持共格关系(见图4),能被位错切过,位错切过时材料的表面能增加,使得材料强度增加。由共格弥散强化造成的切应力的增量为[17]:

(1)

(1)

式中:G是铜基体的切变模量; 是错配度

是错配度 的函数;r是析出相的平均半径;f是析出相的体积分数;b为位错的柏氏矢量大小;F是析出相钉轧位错的线张力,

的函数;r是析出相的平均半径;f是析出相的体积分数;b为位错的柏氏矢量大小;F是析出相钉轧位错的线张力, ;系数x的变化范围为2~3,通常取2.6。位错切过最大共格析出相的半径rmax为[18]:

;系数x的变化范围为2~3,通常取2.6。位错切过最大共格析出相的半径rmax为[18]:

(2)

(2)

可得到共格弥散强化产生的最大切应力:

(3)

(3)

由面心立方Cr的点阵常数 为0.368 nm,则:

为0.368 nm,则:

(4)

(4)

式中: 为面心立方基体铜的点阵常数,

为面心立方基体铜的点阵常数, =0.362 nm,可得

=0.362 nm,可得 为0.017。

为0.017。

根据:

(5)

(5)

式中: 为泊松比(0.303);Gp为析出相弹性常数42.1 GPa,得出

为泊松比(0.303);Gp为析出相弹性常数42.1 GPa,得出 为0.015,则可得共格析出相产生的最大强度增量:

为0.015,则可得共格析出相产生的最大强度增量:

(6)

(6)

且σmax=MτOA,得出:

(7)

(7)

Cu-0.36Cr-0.03Zr合金在450 ℃时效4 h(即硬度峰值状态)时的析出相体积分数f,可根据文献[19]计算为0.39,求得最大屈服强度增量为222 MPa,与经相同热处理工艺下纯铜的抗拉强度(137 MPa)之和为359 MPa,该值与实验值375 MPa相接近,从而验证该模型正确,即共格应变强化是Cu-0.36Cr-0.03Zr合金在450 ℃硬度峰值条件下的主要强化机制。

图5 合金在450 ℃时效8 h后的析出相形貌、电子衍射花样、HRTEM图及FFT衍射斑点标定

Fig. 5 Precipitation morphology(a), diffraction patterns(b), HRTEM image and FFT diffraction patterns indexing(c) and schematic diagram(d) in alloy aged at 450 ℃ for 8 h

3 结论

1) Cu-0.36Cr-0.03Zr合金经450 ℃时效4 h的时效处理,得到较好的综合性能。合金显微硬度达到156 HV,导电率增至82.62%IACS。

2) 经450 ℃时效4 h后,Cu-0.36Cr-0.03Zr合金中析出相为面心立方Cr相,呈双叶花瓣状且与Cu基体完全共格;随着时效时间延长至8 h时,面心立方Cr相转变为体心立方Cr析出相。

3) Cu-0.36Cr-0.03Zr合金经450 ℃时效4 h,达到硬度峰值的强化机制以共格应变强化为主。

REFERENCES

[1] PURCEK G, YANAR H, SARAY O, KARAMAN I, MAIER H J. Effect of precipitation on mechanical and wear properties of ultrafine-grained Cu-Cr-Zr alloy[J]. Wear, 2014, 311(1/2): 149-158.

[2] 李振亚, 杨丽景, 许 赪, 冒守栋, 宋振纶. 时效温度对镍铝青铜合金的硬质相演变的影响[J]. 中国有色金属学报, 2016, 26(4): 766-772.

LI Zhen-ya, YANG Li-jing, XU Cheng, MAO Shou-dong, SONG Zhen-lun. Effects of aging temperature on hard phase evolution of nickel aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 766-772.

[3] 贾淑果, 刘 平, 田保红, 郑茂盛, 周根树, 娄花芬. 高强高导Cu-0.1Ag-0.11Cr合金的强化机制[J]. 中国有色金属学报, 2004, 14(7): 1144-1148.

JIA Shu-guo, LIU Ping, TIAN Bao-hong, ZHENG Mao-sheng, ZHOU Gen-shu, LOU Hua-fen. Strengthening mechanism in high-strength and high-conductivity Cu-0.1Ag-0.11Cr alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1144-1148.

[4] 王庆娟, 周 晓, 梁 博, 周 滢. 超细晶Cu-Cr-Zr合金的高温拉伸性能及断裂机制[J]. 金属学报, 2016, 52(11): 1477-1483.

WANG Qing-juan, ZHOU Xiao, LIANG Bo, ZHOU Ying. High temperature tensile properties and fracture mechanism of ultra-fine grain Cu-Cr-Zr alloy[J]. Acta Metallurgica Sinica, 2016, 52(11): 1477-1483.

[5] ABIB K, LARBI F H, RABAHI L, ALILI B, BRADAI D. DSC analysis of commercial Cu-Cr-Zr alloy processed by equal channel angular pressing[J]. Transaction of Nonferrous Metals Society of China, 2015, 25: 838-843.

[6] 贾淑果, 刘 平, 宋克兴, 陈讲彪, 陈小红, 田保红, 任凤章. Cu-Cr-Zr原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1334-1338.

JIA Shu-guo, LIU Ping, SONG Ke-xing, CHEN Jiang-biao, CHEN Xiao-hong, TIAN Bao-hong, REN Feng-zhang. Microstructures and properties of Cu-Cr-Zr in-situ composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1334-1338.

[7] SU Juan-hua, LIU Ping, LI He-jun, REN Feng-zhang, DONG Qi-min. Phase transformation in Cu-Cr-Zr-Mg alloy[J]. Materials Letters, 2007, 61: 4963-4966.

[8] 钟江伟, 张 鸿, 陈彦旭. 稀土元素La、Ce含量对Cu-0.4Cr-0.2Zr-0.15Mg合金组织和性能的影响[J]. 中国有色金属学报, 2016, 26(5): 1092-1099.

ZHONG Jiang-wei, ZHANG Hong, CHEN Yan-xu. Effects of Ce and La contents in rare earth elements on microstructure and properties of Cu-0.4Cr-0.2Zr-0.15Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1092-1099.

[9] 杨 浩, 陈江华, 胡 特, 刘吉梓, 陈 刚, 赵新奇, 吴落义. Cu-Cr-Zr合金时效析出相的研究[J]. 电子显微学报, 2010, 29(4): 317-321.

YANG Hao, CHEN Jiang-hua, HU Te, LIU-Ji-zi, CHEN Gang, ZHAO Xin-qi, WU Luo-yi. A transmission electron microscopy study of hardening precipitates in CuCrZr alloys[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(4): 317-321.

[10] 余方新, 程建奕, 沈 斌. Cu-Cr-Zr-Mg合金早期时效析出贯序[J]. 中国有色金属学报, 2013, 23(12): 3360-3366.

YU Fang-xin, CHENG Jian-yi, SHEN Bin. Precipitation sequence of Cu-Cr-Zr-Mg alloy during early aging stage[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3360-3366.

[11] SU Juan-hua, LI He-jun, DONG Qi-min. Effect of cold working on the aging properties of CuCrZrMg alloy by artificial neural network[J]. Acta Metallurgica Sinica(English Letters), 2004, 17(5): 741-746.

[12] HUANG F X, MA J S. Analysis of phases in a Cu-Cr-Zr alloy[J]. Scripta Materialia, 2003, 48: 97-102.

[13] PAN Zhen-ya, CHEN Jiang-biao, LI Jin-fu. Microstructure and properties rare earth-containing Cu-Cr-Zr alloy[J]. Transaction of Nonferrous Metals Society of China, 2015, 25: 1206-1214.

[14] BATRA I S, DEY G K, KULKARNI U D, BANERJEE S. Precipitation in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2002, 356: 32-36.

[15] CHENG J Y, SHEN B, YU F X. Precipitation in a Cu-Cr-Zr-Mg alloy during aging[J]. Materials Characterization, 2013, 81: 68-75.

[16] WANG K, LIU K F, ZHANG J B. Microstructure and properties of aging Cu-Cr-Zr alloy[J]. Rare Metals, 2014, 33(2): 134-138.

[17] OROWAN E. Symposium on internal stress in metals and alloys[M]. London: Institute of Metals, 1948: 451-476.

[18] CORREIA J B, DAVIES H A, SELLARS C M. Strengthening in rapidly solidified age hardened CuCr and Cu-Cr-Zr alloys[J]. Acta Materialia, 1997, 45(1): 177-190.

[19] 苏娟华, 刘 平, 董企铭, 李贺军, 任凤章, 田保红. Cu-Cr-Zr 合金时效强化机理[J]. 材料热处理学报, 2005, 26(6): 62-65.

SU Juan-hua, LIU Ping, DONG Qi-ming, REN Feng-zhang, TIAN Bao-hong. The strengthening mechanism of aging precipitates in Cu-Cr-Zr alloy[J]. Transactions of Materials and Heat Treatment, 2005, 26(6): 62-65.

Aging properties of high-strength and high-conductivity Cu-Cr-Zr alloy

DING Zong-ye1, JIA Shu-guo1, 2, NING Xiang-mei1, SONG Ke-xing1, 2, LIU Ping1

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Henan Province Collaborative Innovation Center of Nonferrous Metals, Luoyang 471023, China)

Abstract: The Cu-Cr-Zr alloy was fabricated by vacuum melting, and the investigation on precipitation behavior was conducted. The morphology of precipitation was observed by means of high resolution transmission electron microscope (HRTEM), and the aging strengthening mechanism of alloy was discussed. The results show that a better comprehensive performance of the alloy aged at 450 ℃ for 4 h is obtained, the microhardness and electrical conductivity of the alloy are 156 HV and 82.62 %IACS, respectively. The face-centered cubic(FCC) Cr precipitates are found in the alloy aged at 450 ℃ for 4 h through the micro-analysis. As times increases to 8 h, the face-centered cubic Cr-phases transform into body-centered cubic(BCC) Cr-phases. The high strength of the alloy aged at 450 ℃ for 4 h mainly attributes to coherent strain strengthening mechanism.

Key words: Cu-Cr-Zr alloy; aging treatment; precipitate; coherent strain strengthening

Foundation item: Project(50571035) supported by the National Natural Science Foundation of China; Project (162300410049) supported by the Basic and Frontier Research Project of Henan Science and Technology Department, China; Project(14IRTSTHN007) supported by the Innovative Research Team (in Science and Technology) in University of Henan Province, China; Project(IRT1234) supported by the Changjiang Scholars and Innovative Research Team in University, China

Received date: 2016-09-02; Accepted date: 2017-03-20

Corresponding author: JIA Shu-guo; Tel: +86-379-64231269;E-mail: sgjia@haust.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(50571035);河南省科技厅基础与前沿技术研究项目(162300410049);河南省高校科技创新团队支持计划资助项目(14IRTSTHN007);长江学者和创新团队发展计划资助项目(IRT1234)

收稿日期:2016-09-02;修订日期:2017-03-20

通信作者:贾淑果,教授,博士;电话:0379-64231269;E-mail: sgjia@haust.edu.cn

[2] 李振亚, 杨丽景, 许 赪, 冒守栋, 宋振纶. 时效温度对镍铝青铜合金的硬质相演变的影响[J]. 中国有色金属学报, 2016, 26(4): 766-772.

[3] 贾淑果, 刘 平, 田保红, 郑茂盛, 周根树, 娄花芬. 高强高导Cu-0.1Ag-0.11Cr合金的强化机制[J]. 中国有色金属学报, 2004, 14(7): 1144-1148.

[4] 王庆娟, 周 晓, 梁 博, 周 滢. 超细晶Cu-Cr-Zr合金的高温拉伸性能及断裂机制[J]. 金属学报, 2016, 52(11): 1477-1483.

[6] 贾淑果, 刘 平, 宋克兴, 陈讲彪, 陈小红, 田保红, 任凤章. Cu-Cr-Zr原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1334-1338.

[8] 钟江伟, 张 鸿, 陈彦旭. 稀土元素La、Ce含量对Cu-0.4Cr-0.2Zr-0.15Mg合金组织和性能的影响[J]. 中国有色金属学报, 2016, 26(5): 1092-1099.

[9] 杨 浩, 陈江华, 胡 特, 刘吉梓, 陈 刚, 赵新奇, 吴落义. Cu-Cr-Zr合金时效析出相的研究[J]. 电子显微学报, 2010, 29(4): 317-321.

[10] 余方新, 程建奕, 沈 斌. Cu-Cr-Zr-Mg合金早期时效析出贯序[J]. 中国有色金属学报, 2013, 23(12): 3360-3366.

[19] 苏娟华, 刘 平, 董企铭, 李贺军, 任凤章, 田保红. Cu-Cr-Zr 合金时效强化机理[J]. 材料热处理学报, 2005, 26(6): 62-65.