Characterization and wear properties of nanoscaled TiN/TaN multilayer coatings

AN Jian(安 健)1, ZHANG Qing-yu(张庆瑜)2

1. Key Laboratory of Automobile Materials, Ministry of Education, Jilin University, Changchun 130025, China;

2. State Key Laboratory for Laser, Ion and Electron Beams, Dalian University of Technology, Dalian 116023, China

Received 20 April 2006; accepted 30 June 2006

Abstract:

The structural, morphological, mechanical and tribological characterization of nanoscaled multilayer TiN/TaN coatings deposited by magnetron sputtering technology were investigated by low angle X-ray diffractometry, high angle X-ray diffractometry, atomic force microscopy, microhardness, pin-on-disc testing and 3-D surface profiler. The results show that the TiN/TaN coatings exhibit good modulation period and sharp interface between TiN and TaN layers. In mutilayered TiN/TaN coatings, TiN layers have cubic structure, but hexagonal structure emerged among TaN layers besides cubic structure as modulation period is beyond 8.5 nm. The microhardness is affected by modulation period and the maximum hardness value of 31.5 GPa appears at a modulation period of 8.5 nm. The coefficient of friction is high and the wear resistance is improved for TiN/TaN coatings compared with those of TiN coating; the wear mechanism exhibits predominantly ploughing, material transfer and localized spallation.

Key words:

multilayer coatings; nitrides; physical vapor deposition; wear properties;

1 Introduction

Over the past 10 years, a considerable effort has been devoted to elaboration of multilayered coatings by various physical vapor deposition (PVD) techniques, for their enhanced mechanical properties [1]. Thin multilayered coatings, especially nitrides/nitrides, exhibit hardness enhancements that are significantly higher than those predicted by the rule of mixtures [2-4]. Multilayers consisting of very thin (2-10 nm) layers of nitride materials were deposited by magnetron sputtering have hardness in excess of 5 000 kg/mm2 [5]. This hardness is comparable to that of cubic-BN and is second only to diamond. Therefore, the potential for the development of new hard coatings for the machine industry is very large, using materials with good tribological properties as the individual layers of the multilayers. This special class of multilayers has been the subject of many recent studies to determine the mechanism that give rise to this high hardness. Several enhancement mechanisms have been proposed including, the effects of elastic anomalies, coherency strains, and elastic modulus differences between the superlattice layers [6-8].

PVD coating is suitable for improving the wear resistance of components in many engineering applications. Especially hard and wear resistant TiN coatings deposited by physical vapor deposition (PVD) or by plasma assisted chemical vapor deposition (PACVD) have gained increasing importance in industry, for example in protecting cutting tools, and its tribological properties and wear mechanism have been widely investigated. On the contrary, even though several coating studies have revealed that many nitride multilayers (TiAlN/VN [9], TiN/CrN [10], TiN/Nb [11], TiN/CrN [12] and CrN/NbN [13]) can outperform the single layered TiN in terms of wear resistance and corrosion resistance, little is known about the detailed wear behaviour of the nitride multilayered coatings.

This work is concerned with the structural, mech- anical and tribological characterization and establishment of correlations between hardness and tribological properties of TiN/TaN multilayered coatings deposited by the reactive magnetron sputtering technique.

2 Experimental

2.1 Deposition

The multilayers of TiN/TaN with modulation period of 2.8-14.1 nm and thickness of 1 ?m were deposited by reactive sputtering in a JPG450 magnetron sputtering system, which has three targets including one d. c. and two r. f. magnetron cathodes. The sputtering targets, pure Ti (99.9%) and Ta (99.9%), were mounted on each of the r. f. cathodes. The substrates, ground and polished single-crystal silicon (111) wafers, were chemically cleaned in an ultrasonic agitator in acetone, absolute alcohol before being mounted in the vacuum chamber. For good adherence to the substrate, a 20 nm thin Ti interlayer was deposited followed by a 200-nm-thick TiN layer. Multilayers were formed by rotating the substrate to the position above Ta and Ti targets alternately and were held stationary for different times to obtain compositionally-modulated structure. Typically, TiN/TaN multilayers were deposited under a base pressure of 4×10-4 Pa and a total Ar+N2 gas pressure of 5.0×10-1 Pa. Modulation ratio was obtained through exact control of the stopping times above the Ti and Ta targets. The modulation ratio lTaN/lTiN was fixed at 2∶1. The source power of Ti and Ta targets were 110 and 70 W, respectively. All the substrates were resistively heated to 723 K during deposition.

2.2 Characterization

The modulation periods of TiN/TaN multilayers were measured by the low-angle X-ray reflectivity method using Rigaku X-ray diffractometer (XRD) with Cu Kα radiation under condition of 40 kV and 30 mA. The coating crystallographic structures were characterized by high-angle X-ray diffraction (XRD) using Rigaku X-ray diffractometer (XRD diffraction angle range 30?-95?, 40 kV, Cu Kα radiation scan step 0.01?, counting time 4 s). The surface morphology and roughness of the coatings were examined with an atomic force microscope (AFM, NT-MDT Smena on a 5 mm2 area in contact mode). The hardness of the coatings was measured for 15 s at a load of 0.1 N using a DMH-2LS microhardness tester. A pyramidal Knoop diamond tip indenter was used.

Reciprocating ball-on-disc sliding experiments were performed in ambient air (60% RH) on a UMT-2 machine using 5 mm diameter hardened 52100 bearing steel balls (61HRC and 0.05 μm roughness) as the counterpart, and the coatings were tested as the disc. The sliding speed was 1.0 mm/s over a stroke (track) length of 10mm. Load 4.0 N was used. All the experiments were run for 180 cycles. A Newview 5022 3-D surface profiler was used to determine the depth profiles and hence cross-sectional areas of wear tracks. Based on the wear track diameter and depth profiles at several locations, the coating volume removed during the testing was obtained. The volume loss was used to evaluate the coating wear resistance. With this surface profiler the morphologies of wear surfaces of coatings were also examined.

3 Results and discussion3.1 Low angle X-ray diffraction and high angle X-ray diffraction

Low-angle X-ray reflectivity gives the reflection of X-rays from the interfaces between layers. The observed reflection peaks of different orders occur at the positions of 2 θ given by a modified form of Bragg’s law:

sin2θ=(mλ/2Λ)2+2δ (1)

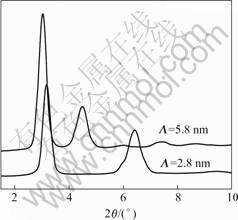

where m is the order of the reflection, λ is the X-ray wavelength, Λ is the modulation period (bilayer period), and δ is the real part of the average reflective index of the coating. The low-angle reflective patterns from TiN/TaN multilayers are shown in Fig.1. The strong superlattice reflections indicate that the multilayered coatings deposited have well-defined periodicity and abrupt interfaces. By plotting sin2θ vs m2 curve and fitting to a straight line, Λ can be determined very accurately. All modulation periods calculated using this method are listed in Table 1.

Fig.1 Low-angle XRD patterns of multilayered TiN/TaN coatings

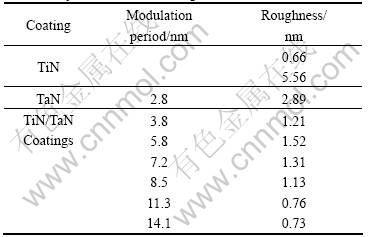

High-angle XRD patterns shown in Fig.2 (a) and (b) reveal that the monolayered TiN coating exhibits cubic structure with lattice constants of 0.424 nm, displays a (200) preferential orientation. TaN coating mainly shows cubic structure with lattice constants of 0.434 nm besides a little amount of h-TaN phase, and displays (111) preferential orientation. High-angle X-ray diffraction spectra of TiN/TaN multilayers with different modulation

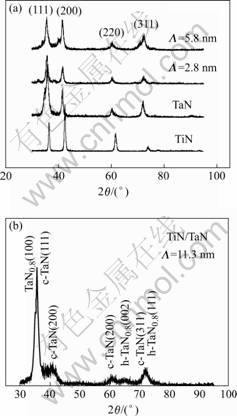

Table 1 Modulation periods and surface roughness of TiN, TaN and multilayered TiN/TaN coatings.

Fig.2 High-angle X-ray diffraction spectra of single-layered TiN, TaN coatings and multilayered TiN/TaN coatings: (a) TiN, TaN, Λ=2.8 nm, Λ=5.8 nm; (b) Λ=11.3 nm

periods show that as modulation period is less than 11.3 nm, the TiN/TaN multilayers are formed with a cubic structure and with increasing modulation period the relative XRD intensity of peak (111) to that of peak (200) decreases considerably. The (100) preferential orientation of hexagonal TaN0.8 becomes more evident as the modulation period is at 11.3 nm. The fraction of cubic phase of TaN decreases dramatically and large amount of hexagonal TaN0.8 is formed. NORDIN et al [14] observed the similar phenomenon in study of growth characteristics of multilayered PVD TiN/TaNx on HSS substrates. As the lamella of TaNx is grown thicker than 6 nm, the fraction of cubic phase decreases and (100) oriented hexagonal TaN0.8 appears, which are resulted from the stabilization of TaNx phase.

3.2 Evolutions of surface morphology and hardness

Surface morphologies of the single-layered TiN, TaN coatings and multilayered TiN/TaN coatings were measured by atomic force microscopy (AFM). Fig.3 shows the topography typical of columnar growth. There are two patterns seen in the lumps. The first is where the lateral size decreases with increasing modulation period. The second is where the surface height (peak to valley) markedly decreases with increased modulation period and the coatings become denser and smoother. The surface roughness of multilayers is listed in Table 1. The surface roughness of multilayers is intermediate between those of the constituent single-layered TiN and TaN coatings. The roughness value of the TiN/TaN coatings at the modulation period of 2.8 nm is much higher than that of single-layered TiN coating, but smaller than that of single-layered TaN coating. At larger modulation periods, the surface roughness of the multilayers gradually approaches that of single-layered TiN coating. The surface evolution of multilayered TiN/TaN coatings is controlled by three interacting factors, i.e. surface diffusion, shadowing effect and grain growth or crystallographic orientation effect. At small modulation period TaN lamella can “remember’ its base material of TiN for some nm. This can result in an epitaxial relationship between the lamella materials in each column for a few nm and in the whole lamella if the thickness is kept small. This can be confirmed from the fact that high-angle XRD diffraction pattern exhibits superlattice structure and (200) preferential orientation of TiN single layer. However, combinations of low surface diffusion and strong shadowing effect due to high sputtering rate of TaN cause less smoothing effect provided by the top TiN lamella. As the modulation period increases, the preferential orientation factor decreases, single TaN phase transforms into multi-phase, moreover, the top TiN lamella thickness increases, leading to a strong smoothing effect and a remarkable decrease of surface roughness.

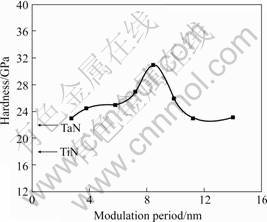

The Knoop microhardness values for TiN and TaN single layers are 18.0 and 22.0 GPa, respectively. When the TiN/TaN multilayered coatings are formed, their hardness increases considerably. The curve of hardness value vs modulation period is shown in Fig.4, and exhibits the hardness anomaly for TiN/TaN multilayers, and a maximum value of 31.5 GPa occurs at a modulation period of 8.5 nm. The maximum hardness value is 52% higher than that suggested by a simple rule for mixture obtained from the hardness (H) and the

Fig.3 AFM images of single-layered TiN, TaN and multilayered TiN/TaN coatings: (a) TiN; (b) TaN; (c) Λ=2.8 nm; (d) Λ=11.3 nm

Fig.4 Hardness of multilayered TiN/TaN coatings vs modul- ation period

lamellas thickness (t) of TiN and TaN, respectively, which can be written as

Hmultilayer=HTiNtTiN/Λ+HTaNtTaN/Λ (2)

The hardness enhancement around modulation period of 8.5 nm may result from the coherency strain of lattice mismatch at the interface. According to the lattice constants of TiN and TaN, it can be calculated that lattice mismatch of TiN/TaN is about 2.3%. XU et al[15] obtained similar results by comparing TaN/TiN with TaWN/TiN superlattice films deposited by magnetron sputtering. The elastic modulus of TiN and TaN are 590.0 GPa and 587.0 GPa, respectively. Hence, it is deduced that the anomalous increase of hardness is not the contribution of elastic modulus difference because the modulus difference is very small between TiN and TaN. While the interfacial coherency strain of TiWN/TiN film is larger than that of TaN/TiN film, the former produce large alternating stress fields, leading to larger hardening. The hardness enhancement hence is believed to originate from the lattice mismatch.

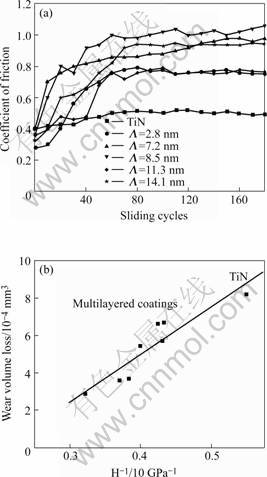

3.3 Wear properties of multilayered coatingsThe friction coefficients of TiN/TaN multilayered coatings are shown in Fig.5 (a). The single-layered TiN coatings experience short running-in stage, however, the TiN/TaN multilayered coatings run about 40 cycles till steady stage. This may be related to the higher hardness of TiN/TaN multilayered coatings. The coefficient of friction for TiN/TaN coatings is higher than that of TiN coating at the steady stage, and varies in a range of 0.7-1.0. The coefficient of friction increases with increasing modulation period, reaches up to about 1.0 at a modulation period of 8.5 nm, then decreases.

Variation of wear loss with the inverse hardness

Fig.5 Variation of coefficient of friction with sliding cycles(a) and variation of wear volume loss with hardness (b)

illustrated in Fig.5 (b) indicates that multilayered coatings exhibit better wear resistance than TiN coating, and the wear volume increases with the decreasing hardness and exhibits a linear relationship with the inverse hardness. This is characteristic of wear behavior of most materials sliding couples that obey the Archard relationship in which wear volume loss is inversely proportional to the hardness of the worn surface.

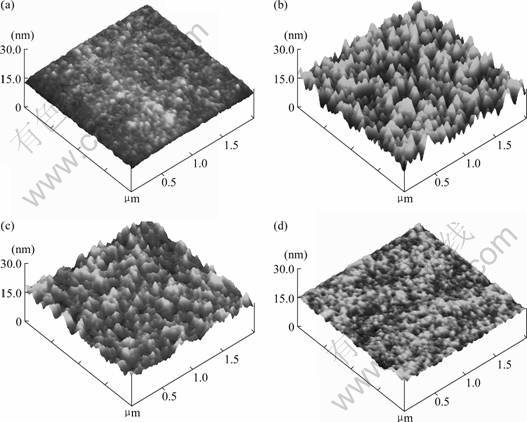

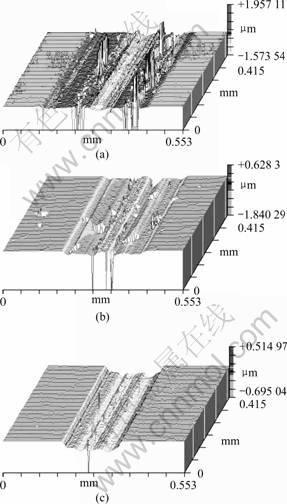

Morphologies of worn surfaces of the TiN/TaN mutilayered coatings with various modulation periods were analyzed using Newview 5022 3-D surface profiler. Fig.6 shows 3-D maps of worn surfaces of TiN/TaN mutilayered coatings. It can be seen that the wear track mainly consists of groves, and the width of wear track decreases with increase of hardness. A little amount of outshoots besides grooves can be observed on the worn track of the TiN/TaN coating with small modulation period; EDS analysis indicates material transferred from the sliding couple (Fig.6(a)). As the modulation period increases, on the worn surface localized spallation of coating, it can be clearly observed (Fig.6 (b)) that the

Fig.6 3-D maps of worn surface of multilayered TiN/TaN coatings with different modulations: (a) 2.8 nm; (b) 7.2 nm; (c) 8.5 nm

spallation, to a certain extent, degrades the wear resistance. This may be ascribed to high compressive stresses developed in the coating. NORDIN et al [11] revealed that the TiN/TaN coating exhibited the highest compressive stress among TiN/CrN, TiN/NbN and TiN/TaN coatings with modulation periods of about 10nm, hence, made it surfer poor adhesion to the substrate. The worn surfaces become smooth (Fig.6 (c)) with increasing modulation period further. The above observation results indicate that the dominant mechanisms are ploughing, material transfer and localized spallation.

4 Conclusions1) Within the modulation period range of 2.8-8.5 nm, the mutilayered TiN/TaN coatings deposited by magnetron sputtering have cubic structure. Beyond that range, a large amount of hexagonal TaN0.8 phase develops.

2) The surface roughness of multilayers is intermediate between single-layered TiN and TaN coatings and it closes to the roughness of the smooth TiN coating at larger modulation period. Multilayers exhibit significant hardness enhancement and a maximum hardness value of 31.5 GPa occurs at 8.5 nm of modulation period.

3) The coefficient of friction of multilayered TiN/TaN coatings is higher than that of single-layered TiN coating, but the wear resistance of the former is considerably better than that of the latter. Analysis of worn surfaces reveals that the wear mechanism mainly includes ploughing, material transfer and spallation.

Reference

[1] MUSIL J. Hard and superhard nanocomposite coatings [J]. Surf Coat Technol, 2000, 125: 322-330.

[2] SPROUL W D. New routes in the preparation of mechanically hard films [J]. Science, 1996, 273: 889-892.

[3] ZENG X T. TiN/NbN superlattice hard coatings deposited by unbalanced magnetron sputtering [J]. Surf Coat Technol, 1999, 113: 75-79.

[4] WONG M S, HSIAO G Y, YANG S Y. Preparation and characterization of AlN/ZrN andAlN/TiN nanolaminate coatings [J]. Surf Coat Technol, 2000, 133-134: 160-165.

[5] HELMERSSON U, TODOROVA S, BARNETT S A. Growth of single-crystal TiN/VN strained-layer superlattices with extremely high mechanical hardness [J]. J Appl Phys, 1987, 62(2): 481-487.

[6] KOEHLER J S. Attempt to design a strong solid [J]. Phys Rev B, 1970, 2 (2): 547-551.

[7] ANDERSON P M, LI C. Hall-petch relation for multilayered materials [J]. Nanostructure Mater, 1995, 5(3): 349-362.

[8] CAMMARATA R C, SCHLESINGER T E, KIM C. Nanoindentation study of the mechanical properties of copper-nickel multilayered films [J]. Appl Phys Lett, 1900, 56, 1862-1864.

[9] HOVSEPIAN P, LEWIS D B, MUNZ W D. Recent progress in large scale manufacturing of multilayer/superlattice hard coatings [J]. Surf Coat Technol, 2000, 133-134: 166-171.

[10] NORDIN M, LARSSON M, HOGMARK S. Mechanical and tribological properties of multilayered PVD TiN/CrN [J]. Wear, 1999, 232: 221-225.

[11] NORDIN M, LARSSON M, HOGMARK S. Mechanical and tribological properties of multilayered PVD TiN/CrN, TiN/MoN, TiN/NbN and TiN/TaN coatings on cemented carbide [J]. Surf Coat Technol, 1998, 106: 234-241.

[12] NORDIN M, HERRANEN M, HOGMARK S. Influence of lamellae thickness on the corrosion behaviour of multilayered PVD TiN/CrN coatings [J]. Thin solid film, 1999, 348: 202-209.

[13] BEMPORAD E, PECCHIO C, ROSSI S D. Characterisation and wear properties of industrially produced nanoscaled CrN/NdN multilayer coating [J]. Surf Coat Technol, 2004, 188-189: 319-330.

[14] NORDIN M, ERICSON F. Growth characteristics of multilayered physical vapour deposited TiN/TaNx on high speed steel substrate [J]. Thin Solid Film, 2001, 385(1-2): 174-181.

[15] XU J, LI G, GU M. The microstructure and mechanical properties of TaN/TiN and TaWN/TiN superlattice films [J]. Thin Solid Film, 2000, 370: 45-49.

Foundation item: Project (20050509) supported by the National Science Foundation of Jilin Province, China

Corresponding author: AN Jian; Tel: +86-431-5095874; Fax: +86-431-5095874; E-mail: anjian@jlu.edu.cn