J. Cent. South Univ. (2012) 19: 2022-2028

DOI: 10.1007/s11771-012-1240-x![]()

Grain crushing and its effects on

rheological behavior of weathered granular soil

CHEN Xiao-bin(陈晓斌)1,2, ZHANG Jia-sheng(张家生)1

1. School of Civil Engineering, Central South University, Changsha 410075, China;

2. National Engineering Laboratory for High Speed Railway Construction

(Central South University), Changsha 410075, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

To disclose the grain crushing effects on the weathered granular soil rheological behavior, a series of rheological tests (odometer compression and triaxial shearing) were carried out. At the same time, the sieving analysis tests of these specimens were also executed before and after tests, and the grain crushing degree, Br and n5, were collectively adopted to estimate the grain crushing. The grain crushing degree depends on the stress path, stress level, and load time, especially, the longer load time and more intensive gradient shearing path will increase the grain crushing quantity. The Hardin crushing degrees Br are 0.191, 0.118 and 0.085 in the ordinary compression, rheological compression and triaxial rheological shearing, respectively; The grain crushing degrees n5 are 1.9, 1.4 and 1.32, respectively. The strain softening phase indicates the grain crushing and diffusive collapse, and the strain hardening phase indicates the rearrangement of these crushed grains and formation of new bearing soil skeleton. The rheological deformation of granular soil can be attributed to the coarse grain crushing and the filling external porosity with crushed fragments.

Key words:

1 Introduction

The rheological behavior of soil depends on the stress conditions [1]. For instance, in the triaxial shearing test, when the principal stress difference reaches the yield limit, the rheological deformation speeds up or progressive failure occurs [2]. The grain breakage or crushing has important effect on the rheological deformation of granular soil. Many researches [3] have been executed to note or indicate the grain crushing effects on the granular soil behavior. TAVARES and NEVES [4] investigated the relationships among microstructure, fracture mechanism and mechanical response of rocks grain crushing under stressing in Brazil, and they analyzed the effects of microstructure on grain breakage and crushing response of rocks. The influence of the shape of limestone particles on crushing parameters was investigated by testing single particles in a high-resolution impact analyzer [5]. MARKETOS and BOLTON [6] used the discrete element models to simulate the attenuation particle bands during grain breakage. The experimental investigation of the elasto-plastic long-term behavior of granular soils under dynamic loading was conducted by KARG and HAEGEMAN [7]. LI et al [8] investigated the constitutive relationship of granular soil between macro-quantities, such as stresses and strains, and established a macro–micro relation (internal structure, the stress tensor and the strain tensor) in granular soil. Experimental studies revealed that principal elements of the mechanical behavior, like the angles of internal peak friction and dilatancy, are highly influenced by the density [9]. A novel approach to simulate triaxial tests with discrete element method (DEM) using circumferential periodic boundaries was developed by CATHERINE and LIANG [10]. TEJCHMAN and BAUER [11] investigated the volumetric strain change and the degradation of the granular soil shear resistance, and a mean grain diameter was used as the length of micro-structure. It was demonstrated that stress fluctuations are directly related to the intrinsic properties of granular soils leading to grain crushing [12]. SAWICKI and CHYBICKI [13] considered the problem of accuracy of predictions of pre-failure deformations of granular soils. LIU [14] analyzed the relationship between the grain breakage and deformation mechanisms of crushable granular materials. Plastic deformation of granular materials was investigated from the micromechanical viewpoint [15]. ALTUHAFI and BAUDET [16] indicated that as the sediment became better distributed during transport, breakage moved from the larger to the smaller particles, with the larger grain crushing.

FEDA [17] believed that the creep was the principal deformation model of granular soil, which had relationship with grain crushing, and grain crushing or debonding was the main reason for the creep. NAKATA and HYODO [18] detected that the crushing extent of granular soil increased if larger intensive shearing gradient was executed. Alluvial quartzy Zbraslav sand and granular silica gel were tested to demonstrate the effects of grain crushing by FEDA [19]. The grain fracture under two opposed contact forces was particularly explored [20-21]. Particle size distribution is an important mass-behavior characteristic of granular soil and HYSLIP [22] presented an evaluation of the applicability of fractal dimensioning techniques to quantify both physical particle roughness and grain size distribution of granular soil. The average grain size reduces with increasing stress level, and grain fracturing is the most effective in producing fine grains. Grain size reduction and porosity losses are higher in coarse-grained soil [23]. Before the grain crushing, there is consequently a high force on the grain contact, and the average inter-particle stress level will vary inversely with the number of inter-particle contact and be higher for the soil with larger particles [24]. CHENG et al [25-26] focused on the crushing of individual particles of which the medium was composed, and assumed that particles were made up of flawed agglomerates of bonded spheres. MARKETOS and BOLTON [27] used the data of DEM simulation to inform a statistical model of granular crushing.

To disclose the grain crushing effects on the rheological behavior of weathered granular soil, a series of rheological tests (odometer compression and triaxial shearing) were carried out. The granular soil specimens were made up with weathered red sand rock as coarse grain and clay as fine grain.

2 Materials preparation

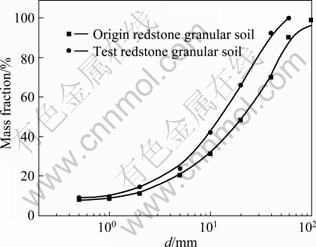

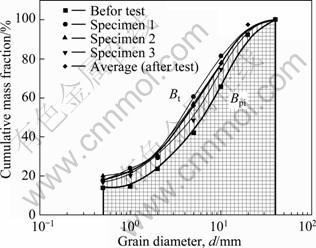

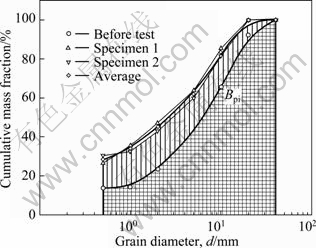

The raw granular soil for specimens was taken from highway embankment and its granulometrical curve is plotted in Fig. 1.

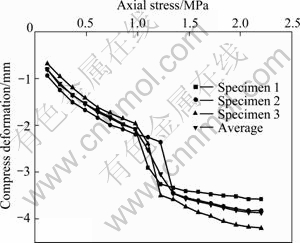

The physical parameters of the granular soil specimen are summarized in Table 1.

The granular soil specimens were respectively tested in Odometer rheological compression and tri-axial rheological shearing. The critical stress conditions in tri- axial rheological shearing were as follows: the confining pressure reached 150 kPa and the principal stress difference reached 1.0 MPa. In the odometer rheological test, the critical compression stress was about 2.0 MPa.

Fig. 1 Granulometrical curves of granular soil specimens

Table 1 Physical parameters of granular soil specimens

3 Quantification of grain crushing

The quantity of grains (d<0.5 mm) indicates the extent of crushing of the weathered granular soil. It is important to define a grain crushing degree to understand the rheological deformation behavior, when the particles of granular soil are crushed or broken.

There exist three kinds of grain crushing degrees, such as Bg [28], B60 [29] and Br [30]. The Bg and B60 cannot describe the change of whole grain size distributions before and after test. Among them, Bg is only used to estimate the given grain crushing extent. HARDIN (1985) analyzed rockfill-like materials and presented the new equations to estimate the grain crushing:

![]() (1)

(1)

![]() (2)

(2)

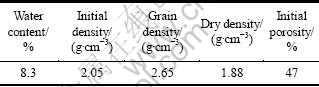

where Bpi is integral area enveloped by granulometrical curve and abscissa (dmin>0.074 mm) before test, Bpf is integral area enveloped by granulometrical curve and abscissa (dmin>0.074 mm) after test, and Bt is the difference between Bpi and Bpf . According to the particle size distribution properties of granular soil, the lower limit (dmin) of diameter of Hardin crushing degree was changed from 0.075 to 0.5 mm, then Bt, Bpi and Bpf were depicted in Fig. 2. Figure 2 shows that all the distribution changes of particle size could be depicted well by integral area of Bt, Bpi and Bpf after sieving analysis. So, the Hardin crushing degree (Br) could describe the change of whole grain size distributions of the granular soil before and after test. But, the change of the given particle size distribution cannot be depicted expediently in Hardin crushing degree.

Fig. 2 Integral area of Bt, Bpi and Bpf enveloped by granulometrical curve

Therefore, a crushing degree n5 for depicting the change of given particle size (d<5 mm) distribution was presented:

![]() (3)

(3)

where ![]() and

and ![]() are the percentages of the given particle size (d<5 mm) distribution on granulometrical curve before and after test, respectively.

are the percentages of the given particle size (d<5 mm) distribution on granulometrical curve before and after test, respectively.

The grain crushing degree Br and n5 were collectively adopted to define the grain crushing degree of granular soil. Through analyzing the difference of grain crushing degree before and after tests, the rheological deformation behavior could be detailedly understood.

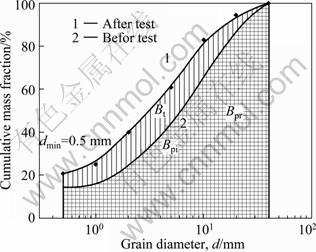

4 Compression rheological analysis

In the oedometer ordinary compression test, the specimen diameter is 7.9 mm and the specimen height is 50 mm. Figure 3 presents a series of oedometer compression curves of weathered red sandrock granular soil specimens. Figure 3 shows that the compression deformation of granular soil increases with the stress level, and the final average deformation reaches 4.0 mm (about 8% compression strain). The sieving analysis was carried out before and after the compression tests, and the integral areas of Bt, Bpi and Bpf on granulometrical curves are presented in Fig. 4. In the stress interval of 1.0-1.5 MPa, a sharp compression deformation step occurs by the coarse grain crushing, which could be testified and depicted by comparing the granulometrical curves in Fig. 4.

Fig. 3 Oedometrical compression deformation vs stress curves

Fig. 4 Granulometrical curves of oedometrical compression tests

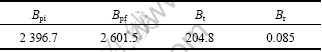

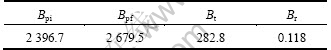

Figure 4 shows that the initial d5 is 42%, and after the test, d5 reaches 55.5%, so the crushing degree n5 is 1.32. The Hardin crushing degree Br and other coefficients are summarized in Table 2.

Table 2 Hardin grain crushing degree and coefficients of compression test

A series of oedometrical rheological compression tests were carried out under the constant stress of 1.0, 1.5 and 2.0 MPa, respectively. Figure 5 presents a series of oedometrical creep curves of weathered red sandrock granular soil specimens under constant stress of 2.0 MPa. The creep deformation increases with time non-linearly, and the final strain is about 9.86% when the time reaches 1 000 h. Figure 5 shows that collapse occurs as a displacement jump forms, for the most of grain crushing or breakage occurs at a short period of time. In 1968, BRAUN’s experiments showed the same rheological collapse behavior, and he indicated that collapse may occur only when the soil was loose enough. The collapse behavior shows that the initial porosity (47%) of weathered red sand rock granular soil specimen is loose enough.

Fig. 5 Oedometrical rheological deformation curves of specimens

The integral areas of Bt, Bpi and Bpf in granulometrical curves are plotted in Fig. 6 after sieving analysis. Then, the Hardin crushing degree Br and coefficients of oedometric creep tests are summarized in Table 3. The Hardin crushing degree Br and n5 are 0.118 and 1.4, respectively, which are all larger than the degrees in ordinary compression tests.

Fig. 6 Granulometrical curves of oedometrical rheological tests

Table 3 Hardin grain crushing degree and coefficients of compression rheological test

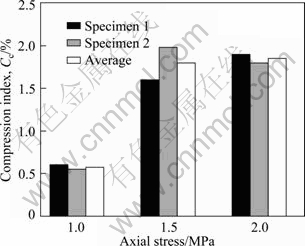

Figure 7 presents the coefficient of compression index (Cc) vs axial compress stress (σ) during the oedometer compression tests. Figure 7 shows that the compression index (Cc) obviously depends on the stress level.

Fig. 7 Coefficient of compression index of soil specimen

5 Shearing rheological analysis

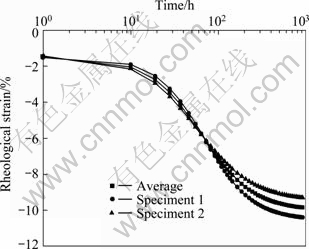

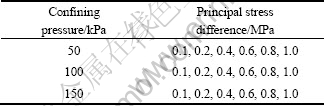

A series of triaxial rheological shearing tests with large dimension specimen of d300 mm×600 mm were carried out (Table 4). Figure 8 presents the creep curves of weathered red sand rock granular soil in the rheological shearing tests.

Table 4 Triaxial rheological test load plan for specimens

Fig. 8 Rheological deformation curves in triaxial tests

In Fig. 8, the stress level is defined as

![]() (4)

(4)

where σ1 and σ3 are the maximum and minimum principal stresses.

Figure 8 shows that the rheological characteristic curves depend on the principal stress difference level. Under the low stress level (S=0.1), rheological deformation is presented by a linear stress-strain relation (σ vs e), which means that the value of σ/e ratio is steady-going and there is neither strain hardening nor softening. Under the middle stress level of 0.2

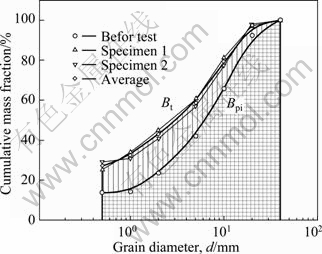

The sieving tests of the granular soil specimens were carried out before and after rheological tests. After sieving analysis, the integral areas of Bt, Bpi and Bpf in Hardin crushing degree are plotted in Fig. 9, and the coefficients are summarized in Table 5.

Fig. 9 Granulometrical curves of triaxial rheological tests

Table 5 Hardin grain crushing degree and coefficients of triaxial rheological tests

The Hardin crushing degree Br and n5 after triaxial rheological shearing tests are 0.191 and 1.9, respectively.

6 Results and discussion

It is shown that grain crushing in all stress conditions produces an abrupt collapse marked by the steep deformation curve, such as the oedometric ordinary compression abrupt collapse in Fig. 4, the oedometric creep abrupt collapse in Fig. 6, and the triaxial rheological shearing abrupt collapse in Fig. 9. By comparing these curves, the ordinary compression collapse curves are steeper (in Fig. 4), for the higher stress of 2.2 MPa and shorter load time. The grain crushing is an important aspect of rheological behavior for the granular soil. BRAUN [31] showed the same rheological behavior. BRAUN experiments indicated that the steep collapse may occur when the initial porosity is no less than 40%. At the same time, his conclusion was in accordance with NAKATA and HYODO [18].

The amount of grain crushing is affected by the load conditions and load time, and the grain crushing quantity increases with load time. The Hardin crushing degrees Br are 0.191, 0.118 and 0.085 for the oedometric ordinary compression, oedometric rheological compression and triaxial rheological shearing, respectively, the same as the coarse grain crushing degrees n5, which are 1.9, 1.4 and 1.32, respectively. On the other hand, experiments show that the quantity of grain crushing increases in the shearing path with more intensive gradient, which means that the coarse grain in the granular soil would be crushed more drastically in the long-term load (rheological load). FEDA [19] deemed that grain crushing would change the original response of granular soil to the load. According to the grain crushing study, it is deemed that the effects of angularity, density, grain size cannot be ignored in the rheological behavior analysis.

The strain hardening or strain softening phase in the shearing tests has intensive relationship with grain crushing in granular soil, as shown in Fig. 9. The strain softening phase indicates the grain crushing and diffusive collapse, and the strain hardening phase indicates the rearrangement of these crushed grains and formation of new bearing soil skeleton. In the deformation sharp collapse (in Fig. 4), grain crushing prevails under higher pressure, and particles in the original soil skeleton are debonded each other. In such a process, the rheological strain curve is garland-like, as shown in Fig. 6. The content of the crushed grain can be identified and quantified by sieving specimens before and after test, as shown in Fig. 5 and Table 2. BOHAC and FEDA [32] carried out some simulation experiments with granular silica and sugar balls arrays, and made some similar conclusions. The chalk and talc bars, glass beads, quartz particles were also used by TAKEI and HAYASHI [33] to simulate the grain crushing in the experiments.

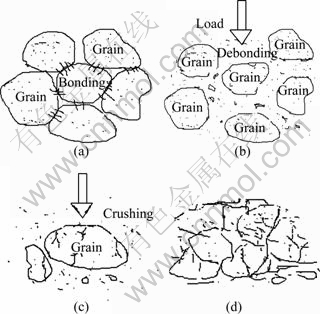

Through the grain crushing analysis, the rheological deformation of granular soil can be attributed to the coarse grain crushing and the filling external porosity with crushed fragments. In the course of granular soil rheological deformation, micro-structure of soil passes through four main stages repeatedly and circularly. Figure 10 roughly depicts the micro-structure changing of granular soil during the creep period. Figure 10(a) shows that the original grains are linked together by contact bonding, which is brittle and unrecoverable. When the load is over this bearing capacity of micro-structure, the contact bonding will fail, soil original structure collapses and the grain becomes disjunct, as shown in Fig. 10(b). Then, the high pressure would be tardily concentrated on the coarse grain face, which would cause the grain crushing, breakage or splitting, which is the strain softening process depicted in Fig. 10(c). In succession, the crushed fragments would fill the external porosity, which is the strain hardening process depicted in Fig. 10(d).

Fig. 10 Scheme of rheological behavior granular soil: (a) Original micro-structure; (b) Coarse grain debonding; (c) Grain crushing, breakage or splitting; (d) Filling porosity and rearrangement

7 Conclusions

1) The defined grain crushing degree Br and n5 are collectively adopted to understand the rheological deformation behavior, with the particles of granular soil crushed or broken.

2) The grain crushing of granular soil depends on the stress path, stress level, and load time, especially, the grain crushing quantity increases with load time and intensive gradient shearing step. The grain crushing causes a sharp collapse or stain hardening in the rheological deformation of granular soil.

3) In the rheological behavior granular soil, the strain softening phase indicates the grain crushing and diffusive collapse, and the strain hardening phase indicates the rearrangement of these crushed grains and formation of new bearing soil skeleton.

4) The rheological behavior of granular soil is attributed to coarse grain crushing and external porosity filling with the crushed fragments, in which the micro-structure passes through the steps of debonding- grain crushing-filling and rearrangement repeatedly.

References

[1] HOQUE E, TASUOKA F, SATO T. Measuring anisotropic elastic properties of and using a large triaxial specimen [J]. Geotechnical Testing Journal, 1996, 19(4): 411-420.

[2] CHEN Xiao-bin. The stress conditions effects on granular soil’s rheological properties in large triaxial rheological laboratory tests [J]. Journal of Central South University of Technology, 2008, 15(s1): 397-401.

[3] LI Qing-qi. Curve fitting method for creep parameter of soft rock [J]. Chinese Journal of Rock Mechanics and Engineering, 1998, 17(5): 559-564.

[4] TAVARES L M, das NEVES P B. Microstructure of quarry rocks and relationships to particle breakage and crushing [J]. International Journal of Mineral Processing, 2008, 87(4): 28-41.

[5] UNLAND G, AL-KHASAWNEH Y. The influence of particle shape on parameters of impact crushing [J]. Minerals Engineering, 2009, 22(3): 220-228.

[6] MARKETOS G, BOLTON M D. Compaction bands simulated in discrete element models [J]. Journal of Structural Geology, 2009, 31(5): 479-490.

[7] KARG C, HAEGEMAN W. Elasto-plastic long-term behavior of granular soils: Experimental investigation [J]. Soil Dynamics and Earthquake Engineering, 2009, 29(2): 155-172.

[8] LI X, YU H S, LI X S. Macro–micro relations in granular mechanics [J]. International Journal of Solids and Structures, 2009, 46(12): 4331-4641.

[9] ALI LASHKARI. On the modeling of the state dependency of granular soils [J]. Computers and Geotechnics, 2009, 36(9): 1237-1245.

[10] CATHERINE O'SULLIVAN, LIANG CUI. Micromechanics of granular material response during load reversals: Combined DEM and experimental study [J]. Powder Technology, 2009, 193(8): 289-302.

[11] TEJCHMAN J, BAUER E. FE-modeling of shear resistance degradation in granular materials during cyclic shearing under CNS condition [J]. Computers and Geotechnics, 2009, 36(2): 249-263.

[12] LI Y R, AYDIN A. Behavior of rounded granular materials in direct shear: Mechanisms and quantification of fluctuations [J]. Engineering Geology, 2010, 115(9): 96-104.

[13] SAWICKI A, CHYBICKI W. On accuracy of prediction of pre-failure deformations of granular soils [J]. Computers and Geotechnics, 2010, 36(7): 993-999.

[14] LIU En-long. Breakage and deformation mechanisms of crushable granular materials [J]. Computers and Geotechnics, 2010, 37(7): 723-730.

[15] NIELS P. KRUYT. Micromechanical study of plasticity of granular materials[J]. Comptes Rendus Mécanique, 2010, 338(3): 596603.

[16] ALTUHAFI F, BAUDET B A. A hypothesis on the relative roles of crushing and abrasion in the mechanical genesis of a glacial sediment [J]. Engineering Geology, 2011, 120(6): 1-9.

[17] FEDA J. Cataclasis compression of soils [J]. Acta Technnol, CSAV, 1999, 1(44): 255-237.

[18] NAKATA Y, HYODO M. Microscopic particle crushing of sand subjected to high pressure one dimensional compression [J]. Soil Found, 2001, 41(1): 69-82.

[19] FEDA J. Notes on the effect of grain crushing on the granular soil behavior [J]. Engineering Geology, 2002, 63(2): 93-98.

[20] TSOUNGUI O. Numerical model of crushing of grains inside two-dimensional granular materials [J]. Powder Technology, 1999, 105(4): 190-198.

[21] GHEZZEHEI T A. Rheological properties of wet soils and clays under steady and oscillatory stresses [J]. Soil Sci Soc Am, 2001, 65(6): 24-37.

[22] HYSLIP J P. Fractal analysis of the roughness and size distribution of granular materials [J]. Engineering Geology, 1997, 48(6): 231-244.

[23] CHUHAN F A, KJELDSTAD A. Porosity loss in sand by grain crushing experimental evidence and relevance to reservoir quality [J]. Marine and Petroleum Geology, 2009, 19(10): 39-53.

[24] HAGERTY M M, HITE D R, ULLRICH C R, HAGERTY D J. One dimensional high pressure compression of granular material [J]. Journal of Geotechnical Engineering, 1993, 119(7): 1-18.

[25] CHENG Y P, BOLTON M D, NAKATA Y. Crushing and plastic deformation of soils simulated using DEM [J]. Geotechnique, 2004, 54(2): 131-141.

[26] CHENG Y P, NAKATA Y, BOLTON M D. Distinct element simulation of crushable soil [J]. Geotechnique, 2003, 53(7): 633-641.

[27] MARKETOS G, BOLTON M D. Quantifying the extent of crushing in granular materials: A probability based predictive method [J]. Journal of the Mechanics and Physics of Solids, 2007, 55(3): 2142-2156.

[28] MARSAL R J. Large-scale testing of rockfill materials [J]. Journal of Soils Mechanics and Foundation Division American Society of Civil Engineering, 1967, 93(2): 27-43.

[29] BO J. Large strain viscoelastic constitutive models [J]. Solids Structures, 2001, 38(8): 2953-2968.

[30] HARDIN B. Crushing of soil particles [J]. Journal of Geotechnical Engineering, 1985, 111(10): 1177-1192.

[31] BRAUNS J. Modification of hydraulic conductivity in granular soils using waste materials [J]. Waste Management, 2004, 24(4): 491-499.

[32] BOHAC J, FEDA J. Modeling of grain crushing and debonding [C]// Proceedings of Sessions of Geo. Denver: ICSMGE, 2000: 43-46.

[33] TAKEI M, HAYASHI K O. Time-dependent behavior of crushable materials in one-dimensional compression test [J]. Soil Found, 2001, 41(1): 97-121.

(Edited by YANG Bing)

Foundation item: Project(50908233) supported by the National Natural Science Foundation of China; Project(200413) supported by Communication Science and Technology Fund of Hunan Province, China

Received date: 2011-05-12; Accepted date: 2011-09-23

Corresponding author: CHEN Xiao-bin, PhD; Tel: +86-731-82656563; E-mail: cxb528@163.com

Abstract: To disclose the grain crushing effects on the weathered granular soil rheological behavior, a series of rheological tests (odometer compression and triaxial shearing) were carried out. At the same time, the sieving analysis tests of these specimens were also executed before and after tests, and the grain crushing degree, Br and n5, were collectively adopted to estimate the grain crushing. The grain crushing degree depends on the stress path, stress level, and load time, especially, the longer load time and more intensive gradient shearing path will increase the grain crushing quantity. The Hardin crushing degrees Br are 0.191, 0.118 and 0.085 in the ordinary compression, rheological compression and triaxial rheological shearing, respectively; The grain crushing degrees n5 are 1.9, 1.4 and 1.32, respectively. The strain softening phase indicates the grain crushing and diffusive collapse, and the strain hardening phase indicates the rearrangement of these crushed grains and formation of new bearing soil skeleton. The rheological deformation of granular soil can be attributed to the coarse grain crushing and the filling external porosity with crushed fragments.