DOI:10.11817/j.ysxb.1004.0609.2020-39448

搅拌摩擦加工制备石墨烯/Al复合材料的界面微观结构

傅 强,夏 春,黄春平,柯黎明,缪 宇

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:

以纯净石墨烯为原料,采用搅拌摩擦加工法制备石墨烯/Al复合材料,主要通过透射电镜等手段观察分析复合材料石墨烯-Al的两种界面,即石墨烯平面-Al、石墨烯边缘-Al的界面微观结构,并对界面形成机制进行了分析。结果表明:石墨烯平面-Al界面清晰,是典型的机械结合界面;而石墨烯边缘-Al界面存在过渡,且在其附近偶尔还发现Al4C3的分布,此区域主要以扩散结合并可能具有部分反应(扩散+部分反应)的界面形式存在。复合材料的界面形成机制与石墨烯不同位置的C原子活性有关,平面内C原子的大π共轭结构使其高度惰性,形成机械结合界面;而搅拌摩擦加工过程对石墨烯的破坏主要发生在边缘,由于C—C键合被破坏,石墨烯边缘活泼的C原子与Al基通过C—Al原子的相互作用而形成扩散+部分反应的过渡界面。

关键词:

搅拌摩擦加工;石墨烯/Al复合材料;界面;机械结合;扩散;反应结合;

文章编号:1004-0609(2020)-01-0026-07 中图分类号:TB333 文献标志码:A

石墨烯是由碳原子按六边形晶格整齐排布而成的二维晶体物质,具有极高的强度与刚度、优异的传热导电性、很好的自润滑和稳定性等优点[1-2]。可以预期,将石墨烯与铝基体复合有可能很大程度提高铝及铝合金力学、耐磨性能的同时给材料的热、电等物理性能带来突破[3-5],在航空航天、电子信息等领域有迷人的应用前景。目前,石墨烯/Al复合材料的主要制备方法包括粉末冶金法、熔体铸造法、原位合成法和搅拌摩擦加工法(Friction stir processing,FSP)等。其中,FSP是在搅拌摩擦焊技术的基础上发展起来的一种材料加工制备新方法,其核心是利用搅拌头所造成加工区金属材料的剧烈热塑性变形,使之与增强相混合,并通过晶粒的破碎和焊合实现微观结构的致密化、均匀化和细化。通过这样的摩擦搅拌作用,有利于机械合金化和晶粒的细化而获得强-塑性配合良好的复合材料,被认为是一种制备金属基复合材料的理想方法[6-7]。JEON等[8]将氧化石墨烯以水溶胶的形式涂覆至5052-H32铝板表面后进行搅拌摩擦加工。结果表明,FSP过程的热作用使水分完全蒸发、氧化石墨烯还原,复合材料的伸长率和热导率较基体分别提高50%和15%以上。KHODABAKHSHI等[9-10]以AA5052铝合金为基体采用FSP法制备石墨烯/Al复合材料,研究了FSP不同区域的组织与织构以及石墨烯添加对复合材料力学性能的影响。结果表明,石墨烯加入量3%(体积分数)时,较未添加石墨烯的试样,复合材料的硬度提高了53%,屈服强度提高了3倍以上;通过与不同理论模型的比对,他们认为复合材料力学性能的提高很大归因于石墨烯添加附带产生的冶金强化。DIXIT等[11]将鳞片石墨与铝粉混合后填充于铝板的沟槽中,经多达7道次的FSP,最终石墨被原位剥离为片层厚度约6 nm的多层石墨烯,复合材料的强韧性皆得到大幅度提高。ZHANG等[12]以2009铝合金为基体,在粉末冶金法制得烧结胚体并经锻造获得板材后再进行FSP处理,认为这种方式能高效地分散石墨烯且石墨烯与基体界面结合良好,复合材料抗拉和屈服强度较基体分别提高了23.3%和30.5%。

界面是复合材料中极其重要的部分,从本质上影响复合材料整体对荷载的响应,并严重影响复合材料的所有性质。国内外研究对石墨烯/Al复合材料的FSP制备、性能和组织结构进行了一些研究,但界面方面并未深入。由石墨物理插层和剥离的方式获得的纯净石墨烯,因不含氧化过程,避免了强氧化剂对石墨烯电子结构和晶格完整性的破坏,其本征性能更优,更有利于得到综合性能良好的复合材料[13-14]。为此,本文作者以纯净石墨烯为原料,采用FSP制备石墨烯/Al复合材料,重点对复合材料的界面进行观察与分析并探讨其界面形成机制。

1 实验

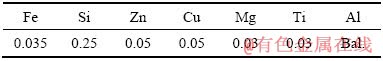

实验材料为工业纯铝1060板材,试样尺寸为180 mm×60 mm×5 mm,表1所列为其化学成分。增强相为南京吉仓纳米科技有限公司通过物理法制备的纯净石墨烯纳米片,片径20~80 μm,厚度4~7 nm,纯度99.7%,其SEM像如图1所示。由图1可见,大小不同的片径且具有典型的皱褶结构特征。

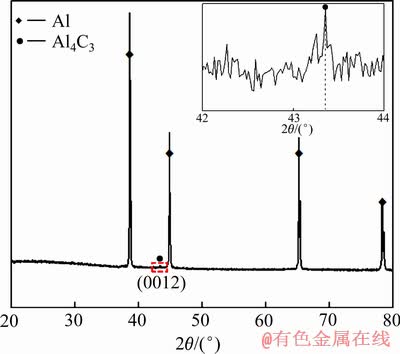

表1 纯铝 1060 化学成分

Table 1 Chemical composition of pure aluminum 1060 (mass fraction, %)

图1 石墨烯原料的SEM像

Fig. 1 SEM image of graphene raw materials

在1060铝板表面加工直径d 3 mm、深度2.5 mm的盲孔,添加石墨烯并压实,通过控制相邻孔中心距离控制复合材料中石墨烯的体积含量约2.0%。将两块已添加石墨烯的铝板层叠在一起,在自制的搅拌摩擦加工设备上进行实验。搅拌头倾斜角设置为2°,旋转速度为950 r/min,行进速度为37.5 mm/min,为获得较均匀的复合材料,进行4道次FSP实验。

将制备好的复合材料试样沿横截面截取成金相试样,用5%(体积分数)的HF腐蚀,观察复合材料横截面的宏观形貌和微观分散情况;利用LabRAM HR型显微激光拉曼光谱仪分析石墨烯的结构;用D8 ADVANCE型X射线衍射仪分析复合材料的物相;采用Talos F200X型场发射透射电子显微镜观察复合材料的界面微观结构。将复合材料切块投入HCl(37%,质量分数)中以萃取出其中的石墨烯,随后进行反复漂洗、真空干燥后通过Axis Ultra DLD型X射线光电子能谱仪分析其元素种类及价态。

2 结果与分析

图2所示为FSP制备的石墨烯/Al复合材料横截面宏观形貌。由图2可见,采用FSP可制备出致密的、无明显宏观缺陷、具有较好成形的石墨烯/Al复合材料,在搅拌摩擦中心区(Center of friction stir zone,A区)呈比较均匀的颜色变化,表明石墨烯与Al基在宏观上能比较均匀地混合。

图2 石墨烯/Al复合材料的横截面宏观形貌

Fig. 2 Macroscopic morphology from thickness cross-section of FSPed graphene/Al composites

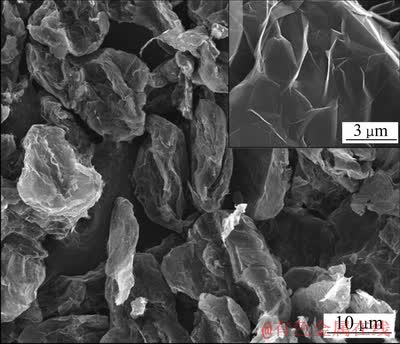

图3所示为搅拌摩擦中心区复合材料的微观形貌与元素分布,进一步表明经4道次FSP后石墨烯能较均匀地分散于Al基中。

图4所示为石墨烯原料和FSP制备石墨烯/Al复合材料的拉曼光谱图。石墨烯的拉曼光谱由若干峰组成,比较明显的有1350 cm-1、1580 cm-1和2700 cm-1附近的特征峰,分别对应D峰、G峰和2D峰。通常,通过D峰与G峰的衍射强度比值(ID/IG)判断石墨烯的缺陷程度。由图4可发现,石墨烯原料没有明显的D峰,表明其晶格结构较为完整;而石墨烯/Al复合材料的D峰相当明显,ID/IG=1.36,说明FSP过程中石墨烯晶格发生明显破坏以及片径的大规模减小[15]。I2D/IG通常被用来估计石墨烯的层数,比值越低表明石墨烯的堆垛使其层数增加[16]。从图4中可发现,复合材料与石墨烯原料的I2D/IG比较接近,也说明复合材料未出现明显的石墨烯团聚,与图3的结果一致。

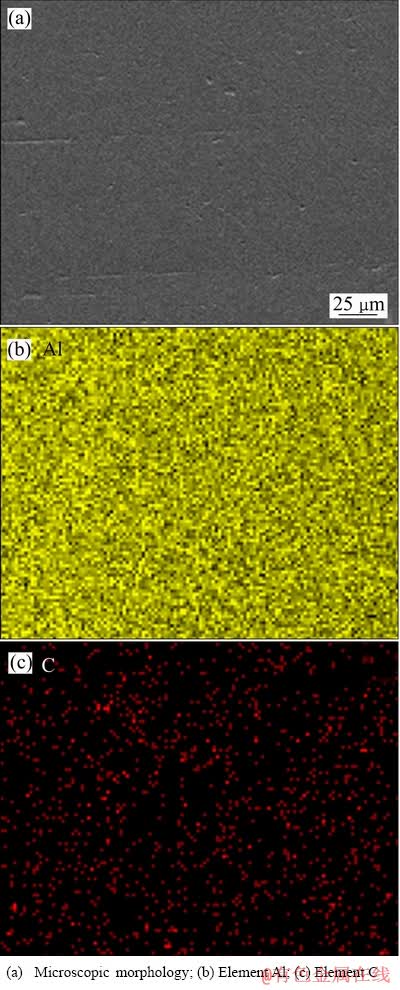

图5所示为FSP制备石墨烯/Al复合材料的XRD谱。除了Al特征峰,在2θ=43.435°处还检测到微弱的对应晶面指数为(0012)的Al4C3衍射峰,表明FSP过程中石墨烯与Al基发生了轻微的反应。由于近无缺陷的纯净石墨烯具有高度反应惰性,这种C—Al反应可能优先发生在石墨烯边缘以及无定形碳等位置[17]。

图3 石墨烯/Al复合材料的微观形貌与元素分布

Fig. 3 Microscopic morphology and corresponding element distributions of graphene/Al composites

图4 石墨烯原料与石墨烯/Al复合材料的拉曼光谱图

Fig. 4 Raman spetra of graphene raw materials and graphene/Al composites

图5 石墨烯/Al复合材料的XRD谱

Fig. 5 XRD patterns of graphene/Al composites

图6所示为FSP制备石墨烯/Al复合材料的典型界面特征。图6(a)所示为其TEM像,通过EDS分析C元素的分布(见图6(b))可明显判断出石墨烯分布情况。从图6(a)中可发现,呈皱褶和弯曲形态的石墨烯分布于Al基中,这是由于FSP复杂的塑性流动所造成的。图6(a)还可完整地看到石墨烯平面结构,其片径约250~350 nm,相比原始石墨烯,其片径很大程度地减小,与复合材料的拉曼光谱(见图4)相对应,说明FSP过程致使较大片径的石墨烯打断或破碎,结果在石墨烯边缘留下大量的结构缺陷。石墨烯作为一种二维结构的材料,与基体存在两种界面,即石墨烯平面-基体、石墨烯边缘-基体[18]。从图6(a)中可同时观察到两种界面(界面Ⅰ和Ⅱ)。图6(c)所示为石墨烯平 面-Al(界面Ⅰ)的典型HRTEM像,该界面清晰,为明显的机械结合界面;由于FSP过程的大塑性形变使石墨烯与基体有更好的物理接触,结果形成无微小孔洞等缺陷的结合良好的界面。图6(d)所示为界面Ⅱ的典型HRTEM像。与界面Ⅰ不同的是,石墨烯边缘-Al存在明显的界面过渡。事实上,多名研究者利用合金化(如机械合金化[19]、搅拌摩擦合金化[11])方法制备石墨烯/Al复合材料也观察到界面过渡的存在,推测其是由C—Al原子的相互扩散而形成的。在石墨烯边缘-Al界面过渡区附近偶尔还能观察到长度约10 nm的针状Al4C3(见图6(e)),表明轻微的Al—C反应发生在石墨烯边缘-Al。为分析复合材料的界面形式,本文采用Digital Micrograph软件,分别对图6(d)、(e)中4个区域进行傅里叶变换(FFT)像分析,a1的4对斑点倒易点阵总长为17.5(1/nm),其晶面间距为0.23 nm,与Al的(111)晶面接近;相应地,a2的晶面间距0.34 nm,对应石墨的(002)晶面;a3则反映为C和Al衍射斑点的重合,很可能为C—Al原子间相互扩散的结果;a4的晶面间距0.204 nm,可以对应上Al4C3的(0012)晶面,与XRD谱检测结果一致。

图6 石墨烯/Al复合材料的界面特征

Fig. 6 Interface characteristics of graphene/Al composites and corresponding FFT patterns recorded in a1, a2, a3 and a4

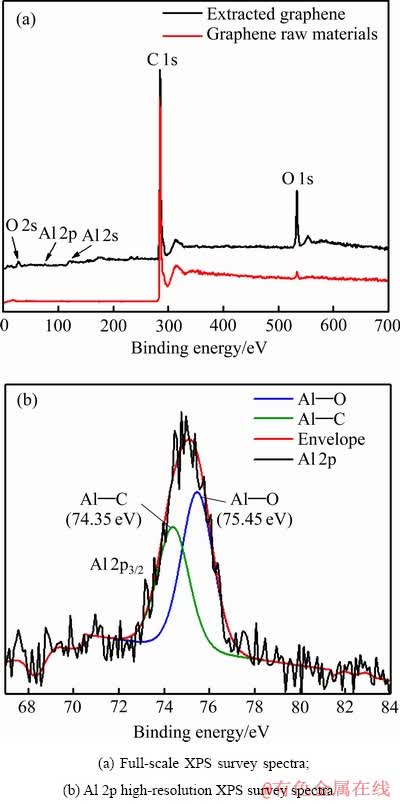

为进一步判断复合材料FSP制备过程是否发生原子扩散,本文对复合材料中的石墨烯进行萃取。图7所示为石墨烯原料与萃取的石墨烯的XPS分析:原料主要为C s峰,由于空位少量吸附氧有微弱的O s峰;萃取的石墨烯较原料多了Al 2s和Al 2p峰(见图7(a)),高分辨率XPS显示Al 2p主要为Al—C(74.35 eV)和Al—O(75.45 eV)(见7(b)),说明复合材料FSP制备中基体的Al向石墨烯扩散并至少部分Al与石墨烯的活泼C以Al—C共价键的形式结合,形成石墨烯的铝掺杂。

图7 石墨烯原料与复合材料萃取的石墨烯XPS谱

Fig. 7 XPS survey spectra of graphene and extracted graphene from composites

根据以上分析,可对复合材料的界面及其形成机制进行描述与分析。FSP过程中,因承受摩擦、碾压和搅拌等作用,石墨烯被打断或破碎为较小片径的石墨烯,在石墨烯平面内C原子的大π共轭结构使其高度惰性,与基体仅形成机械结合界面。被打断或破碎的石墨烯边缘由于C—C键合的破坏[20],C原子有很大的活性,一方面,基体中的Al原子向石墨烯扩散形成石墨烯的铝掺杂;另一方面,石墨烯中活泼的C原子向基体扩散并在一定的条件下发生界面反应,结果在石墨烯边缘-Al形成扩散为主并可能有部分反应的界面过渡。这种界面过渡有利于改善石墨烯-Al的浸润性,从而有利于载荷传递与位错运动的阻碍而提高复合材料的性能。

依据界面错配度( )公式:

)公式:

(1)

(1)

式中:d1、d2为晶面间距,且d2>d1。经计算Al基与石墨烯间界面错配度为0.32,错配度>0.25,为非共格界面;同理可知,Al4C3与石墨烯的界面错配度为0.40,也为非共格界面。而Al基与Al4C3的界面错配度为0.11,在0.05~0.25之间,为半共格界面。0点阵理论认为,两者界面上出现的晶格错配应该通过“错配位错”来进行协调,半共格或非共格界面处的点阵畸变较大,形成的点阵畸变应力场会阻碍位错运动而有利于复合材料性能的提高。

3 结论

1) 以纯净石墨烯为原料,采用搅拌摩擦加工制备石墨烯/Al复合材料,石墨烯-Al的两种界面中,石墨烯平面-Al为机械结合界面,而石墨烯边缘-Al主要为扩散结合界面并可能发生部分界面反应。

2) 复合材料的界面形成与石墨烯不同位置的C原子活性有关,平面内C原子活性低,形成机械结合界面;搅拌摩擦加工过程对石墨烯的破坏主要发生在边缘,石墨烯边缘活泼的C原子与Al基发生相互扩散而形成过渡界面,有利于改善石墨烯-Al的界面浸润性。

3) 石墨烯-Al、石墨烯-Al4C3是非共格界面,而Al-Al4C3为半共格界面。

REFERENCES

[1] GEIM A K. Graphene: Status and prospects[J]. Science, 2009, 324: 1530-1534.

[2] MOGHADAM A D, OMRANI E, MENEZES P L, ROHATGI P K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and grapheme—A review[J]. Composites B, 2015, 77: 402-420.

[3] SABOORI A, PAVESE M, BADINI C, FINO P. Microstructure and thermal conductivity of Al-graphene composites fabricated by metallurgy and hot rolling techniques[J]. Acta Metallurgica Sinica (English Letters), 2017, 30(7): 675-687.

[4] 李多生, 吴文政, QIN Qing-hua, 周贤良, 左敦稳, 鲁世强, 郜友彬. 石墨烯/Al复合材料的微观结构及力学性能[J]. 中国有色金属学报, 2015, 25(6): 1498-1504.

LI Duo-sheng, WU Wen-zheng, QIN Qing-hua, ZHOU Xian-liang, ZUO Dun-wen, LU Shi-qiang, GAO You-bin. Microstructure and mechanical properties of graphene/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1498-1504.

[5] 肖伯律, 刘振宇, 张星星, 马宗义. 面向未来应用的金属基复合材料[J]. 中国材料进展, 2016, 35(9): 666-673.

XIAO Bo-lü, LIU Zhen-yu, ZHANG Xing-xing, MA Zong-yi. Metal matrix composites for future applications[J]. Progress in China Materials, 2016, 35(9): 666-673.

[6] MISHRA R S, MA Z Y. Friction stir welding and processing Ⅱ[J]. Materials Science and Engineering R, 2005, 50(1): 1-78.

[7] ARORA H S, SINGH H, DHINDAW B K. Composite fabrication using friction stir processing-a review[J]. The International Journal of Advanced Manufacturing Technology, 2012, 61: 1043-1055.

[8] JEON C H, JEONG Y H, SEO J J, TIEN H N, HONG S T, YUM Y J, HUR S H, LEE K J. Material properties of graphene/aluminum metal matrix composites fabricated by friction stir processing[J]. International Journal of Precision Engineering and Manufacturing, 2014, 15(6): 1235-1239.

[9] KHODABAKHSHI F, ARAB S M, SVEC P, GERLICH A P. Fabrication of a new Al-Mg/graphene nanocomposite by multi-pass friction-stir processing: Dispersion, microstructure, stability, and strengthening[J]. Materials Characterization, 2017, 132: 92-107.

[10] KHODABAKHSHI F, NOSKO M, GERLICH A P. Effects of graphene nano-platelets (GNPs) on the microstructural characteristics and textural development of an Al-Mg alloy during friction-stir processing[J]. Surface and Coatings Technology, 2018, 335: 288-305.

[11] DIXIT S, MAHATA A, MAHAPATRA D R, KAILAS S V, CHATTOPADHYAY K. Multi-layer graphene reinforced aluminum-manufacturing of high strength composite by friction stir alloying[J]. Composites B, 2018, 136: 63-71.

[12] ZHANG Z W, LIU Z Y, XIAO B L, NI D R, MA Z Y. High efficiency dispersal and strengthening of graphene reinforced aluminum alloy composites fabricated by powder metallurgy combined with friction stir processing[J]. Carbon, 2018, 135: 215-223.

[13] LI Wei-ping, LI De-long, FU Qiang, PAN Chun-xu. Conductive enhancement of copper/graphene composites based on a high- quality graphene[J]. RSC Advances, 2015, 5(98): 80428-80433.

[14] JIANG Rong-rong, ZHOU Xu-feng, FANG Qi-le, LIU Zhao-ping. Copper-graphene bulk composites with homogeneous graphene dispersion and enhanced mechanical properties[J]. Materials Science and Engineering A, 2016, 654: 124-130.

[15] LI Min, GAO Hai-yan, LIANG Jia-miao, GU Sun-wang, YOU We-ren, SHU Da, WANG Jun, SUN Bao-de. Microstructure evolution and properties of graphene nanoplatelets reinforced aluminum matrix composites[J]. Materials Characterization, 2018, 140: 172-178.

[16] CHEN Fan-yan, YING Jia-min, WANG Yi-fei, DU Shi-yu, LIU Zhao-ping, HUANG Qing. Effects of graphene content on the microstructure and properties of copper matrix composites[J]. Carbon, 2016, 96: 836-842.

[17] RASHAD M, PAN Fu-sheng, TANG Ai-tao, ASIF M. Effect of graphene nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method[J]. Progress in Natural Science (Materials International), 2014, 24(2): 101-108.

[18] ZHANG Dan-dan, ZHAN Zai-ji. Experimental investigation of interfaces in graphene materials/copper composites from a new perspective[J]. RSC Advances, 2016, 6: 52219-52226.

[19] PErez-Bustamante R, BolaNos-Morales D, Bonilla-MartInez J, ESTRADA-GUEL I, MARTINEZ- SANCHEZ R. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying[J]. Journal of Alloys and Compounds, 2014, 615: S578-S582.

[20] JEON I Y, SHIN S H, CHOI H J, YU S Y, JUNG S M, BAEK J B. Heavily aluminated grapheme nanoplatelets as an efficient flame-retardant[J]. Carbon, 2017, 116: 77-83.

Interface microstructure of graphene/Al composites prepared by friction stir processing

FU Qiang, XIA Chun, HUANG Chun-ping, KE Li-Ming, MIAO Yu

(National Defense Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The graphene/Al composites were prepared by friction stir processing used pristine graphene as the raw materials. The interface between graphene and the matrix could be divided into two types, namely graphene plane-Al and graphene edges-Al, graphene materials exhibit a unique two-dimension structure. Two types of interface microstructure were mainly observed by TEM and the interface formation mechanisms were analyzed. The results show that it is clean and well bonded in the graphene plane-Al, illustrating a mechanical bonding. Nevertheless, a transition zone, Al4C3 occasionally detects near the zone, which is found in the graphene edge-Al, this zone is estimated to exist as an interface combined with diffusion and partial reaction bonding. The interface formation mechanisms are related to the activity of C atoms in different graphene locations. The C atoms in the graphene plane are highly inert for the large conjugated π bond structure, and therefore, the mechanical bonding interface forms here. However, the C atoms at the graphene edge are active owing to C—C bonds dissociation in friction stir processing, and diffusion and partial reaction bonding with interface transition forms as the result of atomic-scale interaction between C and Al.

Key words: friction stir processing; graphene/Al composites; interface; mechanical bonding; diffusion; reaction bonding

Foundation item: Projects(51874179, 51465044) supported by the National Natural Science Foundation of China; Project(GJJ160690) supported by Science and Technology Project of Department of Education of Jiangxi Province, China; Project(YC2017014) supported by Graduate Innovation Fund of Nanchang Hangkong University, China

Received date: 2019-01-08; Accepted date: 2019-04-24

Corresponding author: XIA Chun; Tel: +86-791-83953312; E-mail: xiachun2002@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51874179,51465044);江西省教育厅科技项目(GJJ160690);南昌航空大学研究生创新基金资助项目(YC2017014)

收稿日期:2019-01-08;修订日期:2019-04-24

通信作者:夏 春,副教授,博士;电话:0791-83953312;E-mail:xiachun2002@163.com

摘 要:以纯净石墨烯为原料,采用搅拌摩擦加工法制备石墨烯/Al复合材料,主要通过透射电镜等手段观察分析复合材料石墨烯-Al的两种界面,即石墨烯平面-Al、石墨烯边缘-Al的界面微观结构,并对界面形成机制进行了分析。结果表明:石墨烯平面-Al界面清晰,是典型的机械结合界面;而石墨烯边缘-Al界面存在过渡,且在其附近偶尔还发现Al4C3的分布,此区域主要以扩散结合并可能具有部分反应(扩散+部分反应)的界面形式存在。复合材料的界面形成机制与石墨烯不同位置的C原子活性有关,平面内C原子的大π共轭结构使其高度惰性,形成机械结合界面;而搅拌摩擦加工过程对石墨烯的破坏主要发生在边缘,由于C—C键合被破坏,石墨烯边缘活泼的C原子与Al基通过C—Al原子的相互作用而形成扩散+部分反应的过渡界面。