文章编号:1004-0609(2008)12-2233-12

球磨条件下Fe合金化改善MgH2 体系性能的机理

周惦武1,张 健1, 2,彭 平2,刘金水2

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 材料科学与工程学院,长沙 410082)

摘 要:基于密度泛函理论的第一原理方法,通过计算清洁、空位缺陷Mg(0001)表面吸附氢分子(H2)前后以及Fe合金化镁氢化合物(MgH2)体系的能量与电子结构,对球磨条件下Fe合金化改善MgH2体系性能的原因进行初步探讨。结果表明:与清洁Mg表面相比,由于球磨改变了Mg颗粒的表面结构,使Mg表面产生较多缺陷,而缺陷的存在增强了H2的物理吸附能力,并且Mg表面向H2转移的电荷数增多,因而体系球磨后具有较好的吸氢性能;而在Fe合金化MgH2体系中,Fe固溶于MgH2中形成(MgFe)H2固溶体和合金化形成少量Mg2FeH6相,MgH2系结构稳定性均降低,对应体系解氢性能增强。分析电子结构发现:空位缺陷有助H2吸附于Mg表面,与Mg(0001)表面最上层与H2直接产生吸附作用的金属原子在费米能级(EF)附近s轨道的成键电子数密切相关;在Fe合金化MgH2体系中,与合金化元素Fe近邻的H原子形成空位的难度增加,H原子较难释放;与Mg近邻的H原子形成空位的难度减少,H原子容易释放;Fe合金化导致Mg-H之间存在较弱的成键作用,因此,MgH2体系的解氢性能得到提高。

关键词:

中图分类号:TG 146.2 文献标识码: A

Mechanism of improved properties of MgH2 systems with ball milling and iron addition

ZHOU Dian-wu1, ZHANG Jian1, 2, PENG Ping2, LIU Jin-shui2

(1.State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

2. School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The energy and electronic structure of the adsorption of H2 on the clean, vacancy defective Mg (0001) surfaces and iron alloying magnesium hydride were calculated by using a first-principles plane-wave pseudopotential method, the mechanism of improved properties on MgH2 systems were analyzed with milling and iron addition. The results show that the vacancy defect system benefits enhancing the physical sorption between Mg surface and H2 compared with the clean Mg (0001) surface, because the quantity of the charges transferring from Mg surface to H2 adsorbed may be increased significantly, the H2 adsorption properties are improved after ball milling. The structure stability of the alloying system is reduced when a little iron dissolves into the magnesium hydride, and is further reduced when the iron additions form Mg2FeH6 compound. The analyses of electronic structures shows that the catalytic reactivities for H2 adsorption of the different surfaces are dependent on the numbers of s orbital bonding electrons around Fermi level for the uppermost layer metal atoms which interact directly with H2. It is easy to form vacancy for hydrogen atoms next to iron atom, which indicates that hydrogen atom cannot be escaped, but it is difficult to from vacancy for hydrogen atoms next to magnesium atom, which indicates that hydrogen atom can be escaped. Hence it is thought that the change of dehydrogenating properties of MgH2 with or without a little iron addition attributes to the weakened bonding between magnesium and hydrogen.

Key words: magnesium hydride; Mg(0001) surface; adsorption; formation heat

随着化石能源的逐渐枯竭和环境污染的日益严重,开发一种替代化石能源的清洁的新能源,是一个紧迫的课题。氢能作为洁净的能源载体成为被关注的焦点。储氢材料是氢能利用技术所需的关键材料之一,近年来国内外众多研究人员为发展高性能储氢材料开展了广泛的研究。衡量储氢材料性能的两个重要参数是储氢量和吸放氢动力学。镁氢化合物(MgH2)理论储氢量(7.6%,质量分数)大于国际能源机关(IEA)确定未来新型储氢材料的标准5.0%,其作为储氢材料进行应用最具诱惑力,然而该体系吸放氢性能差,限制了其实际应用。为提高其较差的吸氢动力学,人们采用球磨技术替代传统的高温熔炼技术,由于球磨改变了Mg颗粒的表面结构,使表面产生较多缺陷,因而球磨法制备的Mg纳米晶,比传统镁粉具有更快的吸氢动力学[1?2]。为改善MgH2较差的解氢动力学,目前大多数工作集中在向体系内加入少量添加物,其中过渡金属Fe合金化方法被证明是一种有效方法。实验发现:对MgH2 进行Fe合金化,当Fe与MgH2摩尔比为8?100[3]或质量比为1?10 [4]时,在一定温度和压力下,在氩气的气氛中球磨20 h,吸氢后最终产物为β-MgH2+Fe;而球磨达到6 h后[5],析出了新的分离相Mg2FeH6。HIGHTOWER等[6]在采用Fe合金化MgH2制备Mg2FeH6的过程中发现,Fe与Mg晶格互相固溶,而HUOT等[5]发现Mg2FeH6生成的同时,合金化体系中保留了未反应的Mg,而MgH2相却消失了。最近本文作者和李松林等[7]采用第一原理计算与高能球磨相结合的方法,在采用实验XRD谱确定体系相组成的基础上建立计算模型,基于理论计算方法对纳米晶Mg2FeH6的形成过程进行初步研究,并在实验DSC测试的合金形成热与理论计算的合金形成热在变化趋势一致的前提下,通过实验初步制备出纳米Mg2FeH6储氢合金。本文作者在实验DSC分析时发现:所有取样粉末均显示仅有1个吸热峰,即使Mg2FeH6和MgH2两相共存,也为1个吸热峰;此外球磨粉末均在不超过300 ℃的条件下解氢,由此可见,对MgH2进行Fe合金化可以改善体系解氢性能。

通常Mg吸氢动力学与其表面结构密切相关,为此人们对H2吸附Mg表面开展了大量工作。如SPLUMMER等[8]采用能量损失谱(EELS)和热力学脱附光谱(TDS)研究了H2分子、H原子与Mg之间的相互作用,发现H2在Mg表面的吸附需要活化,并且Mg表面存在较强的化学吸附H原子的表面氢化物层;N?RSKOV等[9]采用从头算法研究了H2在Mg(0001)表面的吸附,发现H2在Mg表面的吸附方式为化学吸附;VEGGE等[10]却发现Mg表面吸附H2的过程仅为物理吸附。关于Fe合金化改善MgH2解氢性能的理论研究,SONG等[11]采用全势线性平面波(FLAPW)方法,认为合金元素Fe改善MgH2体系解氢性能的主要原因在于,Fe的加入引起了体系费米能级附近Mg和H成键电子数的变化。

综上所述,为提高MgH2体系较差的吸氢性能,人们虽然采用球磨替代传统的高温熔炼开展了一定的实验研究,对H2在Mg表面的吸附也作了一些理论探讨,但吸附的方式观点却不一致,并且对H2在改性(如空位缺陷)Mg表面吸附的理论研究很少见到文献报道;本文作者球磨制备Mg2FeH6初期仅出现唯一氢化相MgH2[7],其很可能是球磨Mg表面产生较多缺陷,有助H2首先容易被Mg表面吸附,进而Mg和H2反应形成MgH2,但缺乏理论依据。此外Mg2FeH6晶体结构目前缺乏完整的数据,SONG等[11]没有比较MgH2、不同Fe含量(MgFe)H2固溶体的结构稳定性以及Mg2FeH6对MgH2体系解氢性能的影响,为此,本文作者采用基于密度泛函理论的第一原理计算方法,通过计算清洁、空位缺陷Mg(0001)表面吸附氢分子(H2)前后以及Fe合金化MgH2体系的能量与电子结构,探讨球磨条件下Fe合金化改善MgH2体系吸放氢性能的微观机理,期望为设计新型镁基储氢材料提供理论指导。

1 计算方法

为研究球磨改变Mg颗粒表面结构,使Mg表面产生较多缺陷,有助H2被Mg表面吸附,进而改善MgH2吸氢性能的机理,本研究中计算体系的能量与电子结构时,采用基于密度泛函理论的Dmol 4.1程序,电子交换关联能函数采用GGA近似的PW91形式[12],势函数取全电子位势,电子波函数采用DND基 组[13?14],经测试K点网格数取4×2×1较合理。体系优化时,其精度设置为:能量 ≤2.0×10?5 Ha,应力≤0.004 Ha,位移≤0.005 ?;研究Fe合金化改善MgH2体系解氢性能,本研究中计算体系的能量与电子结构时,使用的是CASTEP(Cambridge Serial Total Energy Package)总能计算软件包[15?16]。交换关联能采用广义梯度近似(GGA)中的Perdew-Burke-Ernzerhof形式[17?18], 交换关联能的计算在最小化的快速傅立叶变换(Fast-Tourier-Transform, FFT)网格上进行,采用对正则条件进行驰豫的超软(Ultrasoft)赝势[19]作为平面波基集[20],采用自洽迭代(SCF)方法进行计算,计算时,采用结合Broyden-Flecher-Goldfarb-Shanno(BFGS)共轭梯度方法[21]的Pulay密度混合方案[22]处理电子驰豫。先对模型的晶体结构进行完全的几何优化,以求得它们的局域最稳定结构;再计算优化后模型的单点能。优化结束时,体系总能量的收敛值取2.0×10?5 eV/atom, 每个原子上的力低于0.05 eV/?, 公差偏移小于2.0×10?3 ?,应力偏差小于0.1 GPa。平面波展开的截止能量Ecut为310.0 eV,FFT网格为24×24×80,采用的K空间为0.50 nm?1。根据Monkhorst-Pack算法,得到K点网格为(4, 4, 1),计算在倒易空间进行。通过收敛性的检验,发现这些设定参数足以保持计算所需要的精度。

2 计算结果与分析

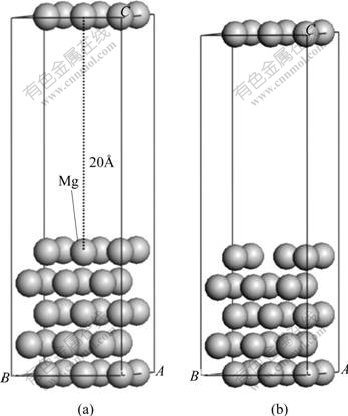

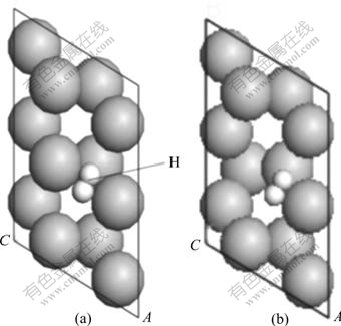

为从理论上探讨球磨改善MgH2体系吸氢性能的微观机理,经过较好测试,本研究中构建了5层Mg(0001)清洁表面模型,其结构示意图如图1(a)所示。考虑边界效应及计算费用,其超胞大小设为p(2×3),为避免层晶之间的相互干扰,真空层厚度取20 ?;空位缺陷Mg(0001)表面模型示意图如图1(b)所示。计算模型体系优化时,表面的上两层Mg原子、H2分子或H原子允许自由驰豫,而底3层Mg原子被固定。

图1 5层Mg(0001)表面模型示意图

Fig.1 Schematic diagram of models of Mg(0001) surfaces: (a) Clean; (b) vacancy defective sufaces

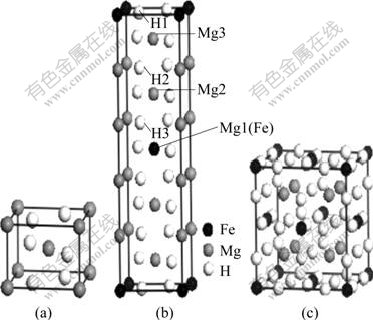

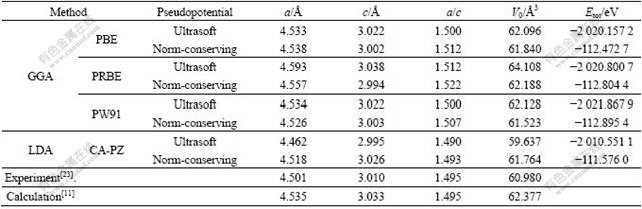

MgH2的晶体结构示意图如图2(a)所示,它由晶格常数a和c决定,空间群为P42/mnm(NO.136)。晶胞中各原子坐标为:+2Mg(0, 0, 0);+4H(0.304, 0.304, 0)[23]。由于实际测量的a和c一般不能用于密度泛函计算,用于密度泛函理论计算的a和c必须经过相应的计算方法进行优化。而交换关联能和赝势数据的品质对于优化a和c有决定的作用,因此,本计算就从优化a和c开始。在MgH2晶体结构的计算中,对交换关联能广义梯度近似(GGA)的3种形式(PBE、PRB、EPW91)和局部密度近似(LDA)的CA-PZ形式都采用了两种不同的赝势:Ultrasoft和Norm-conserving,分别计算了晶格常数a、c和a/c的值,并与实验值以及他人的计算结果进行了比较,结果列于表1。

图2 空位缺陷Mg(0001)表面模型MgH2和Mg2FeH6的晶体结构示意图

Fig.2 Schematic diagram of crystal structures for MgH2 and Mg2FeH6: (a) MgH2; (b) Five-times unit of MgH2; (c) Mg2FeH6

表1 MgH2晶格常数(a, c, a/c)的比较

Table 1 Lattice parameters(a, c, a/c)of MgH2 by GGA, LDA, experiment and calculation

从表1可见,与其他交换关联能和赝势的计算结果比较,交换关联能采用广义梯度近似(GGA)的PBE形式,赝势取倒易空间表述的超软(Ultrasoft)赝势,MgH2的平衡晶格常数a和c分别为4.533和3.022 ?,与实验值[23] (a=4.501 ?和c=3.010 ?)最接近,并与SONG等[11]的计算结果(a=4.535 ?和c=3.033 ?)符合得很好,这进一步验证了计算方法中选择交换关联能和赝势的准确性。

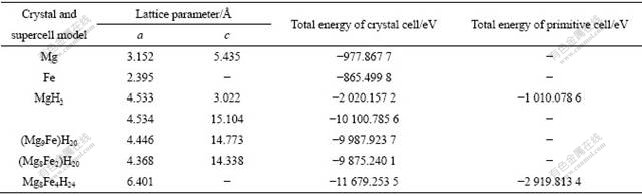

为研究Fe合金化改善MgH2体系解氢性能的微观机理,假定Fe固溶于MgH2中形成(MgFe)H2固溶体,其超胞模型结构如图2(b)所示。考虑到与H原子相比,Fe原子与Mg原子大小更接近,用1个Fe原子替代图2(b)模型中心的1个Mg1原子,得到(Mg9Fe)H20超胞,此时对应Fe在MgH2中的固溶浓度(摩尔分数)为5.0%;用2个Fe原子替代中心和8个顶点各1个Mg1原子,得到(Mg8Fe2)H20超胞,此时对应Fe的固溶摩尔分数为10.0%。计算MgH2超胞模型的平衡晶格常数如表2所列。由表2可知,Fe合金化后,平衡晶格常数a和c均减少。

表2 晶体和超胞模型的平衡晶格常数(a)、(c)以及总能量

Table 2 Equilibrium lattice constant (a), (c) and total energies of crystal and supercell model

Mg2FeH6的晶胞结构(Mg8Fe4H24)如图2(c)所示,为反CaF2结构,仅由晶格常数a决定,空间群为Fm3m (NO.225),晶胞中各原子坐标为:+8Mg(0.25, 0.25, 0.25);+4Fe(0, 0, 0);+24H(x, 0, 0),x为(0~0.240)[24]。由于实验未检测出Mg2FeH6晶胞结构(Mg8Fe4H24)中H原子的位置,为此,选择实验值附近不同的晶格常数和不同的x值进行了一系列的计算,发现Mg2FeH6晶体的平衡晶格常数 (6.401?)与实验值 (6.443?[24],6.444 ?[5],6.442 ?[25],6.429 ?[26])符合得较好,同时对应x=0.240时,Mg2FeH6晶胞的总能量(?11 679.253 5 eV)为最低值。由于总能量越低,对应晶胞结构越稳定,为此确定Mg2FeH6晶胞结构中H原子的坐标为(0.240, 0, 0)。

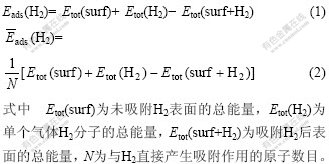

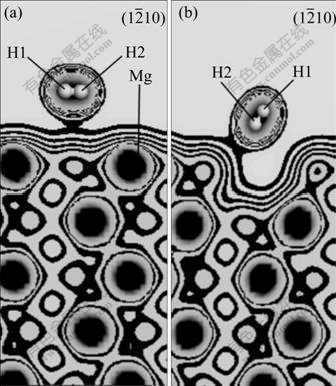

为探讨球磨Mg是否有助H2被Mg表面吸附,从而改善MgH2体系的吸氢性能,本研究中计算了H2在清洁、空位缺陷Mg(0001)表面的吸附能。计算时将H2的初始吸附位均定于Mg(0001)表面最利于H2解离桥位的正上方[27],并且距Mg表面的吸附高度均为3 ?, 如图3所示。为便于比较,也计算了表面对H2的平均吸附能。吸附能Eads(H2)及平均吸附能![]() (H2)的计算公式如下[28]:

(H2)的计算公式如下[28]:

计算结果列于表3。

图3 H2在Mg(0001)表面的初始吸附位

Fig.3 Initial positions of H2 on Mg (0001) surfaces during process of H2 adsorption: (a) Clean surface; (b) Vacancy defective surface

表3 H2在清洁、空位缺陷Mg(0001)表面稳定吸附的吸附能(Eads(H2))及平均吸附能![]() (H2)

(H2)

Table 3 Adsorption energy (Eads(H2)) and average adsorption energy (![]() (H2)) of clean and vacancy defective Mg (0001) surface during H2 adsorption process

(H2)) of clean and vacancy defective Mg (0001) surface during H2 adsorption process

由表3可见,吸附能均为正值,表明吸附过程释放能量,H2在Mg(0001)表面的吸附可以进行。由于受表层原子种类及数目的影响,发现清洁Mg(0001)表面对H2的吸附能Eads(H2) (0.025 0 Ha)明显高于空位缺陷的对应值(0.023 1 Ha)。然而,若仅考虑与H2直接产生吸附作用的金属原子时,则发现空位缺陷Mg(0001)表面对H2的平均吸附能(0.004 6 Ha/atom)大于清洁Mg(0001)表面(0.004 2 Ha/atom),这表明:空位缺陷的存在有利增强Mg表面对H2的吸附能力,因而球磨有助H2被Mg表面吸附,进而促进Mg和H2反应形成MgH2,因而球磨制备Mg2FeH6初期仅出现唯一氢化相MgH2[7];此外球磨改变了镁颗粒的表面结构,使表面产生较多缺陷,因而球磨法制备的镁纳米晶,比传统镁粉具有更快的吸氢动力学[1?2]。

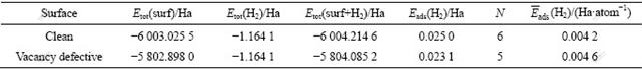

图4所示为H2稳定吸附于Mg(0001)表面的电子密度图。由图4(a)可见,H2稳定吸附于清洁Mg(0001)表面时,H2轴线仍与表面保持平行,整个吸附过程中,H2只是在垂直于表面方向上下平移,此时,H2与Mg表面间几乎无电子云重叠,且体系中H原子与表面最近邻Mg原子间距为3.937 8 ?,远大于H?(1.54 ?)与Mg2+(0.66 ?)的离子半径之和2.20 ?,表明H2在清洁Mg(0001)表面呈物理吸附,吸附后的H2键长为0.748 9 ?,与自由H2键长(0.747 6 ?)相比,变化很小。H2稳定吸附于空位缺陷Mg(0001)表面时,由于Mg原子空位的存在,H2发生扭转并逐渐向空位处靠近,其轴线与表面呈一定夹角(见图4(b)),此时,H2与Mg表面间相对清洁表面情形而言,具有较大程度的电子云重叠,H原子与表面最近邻Mg原子间距为3.601 5 ?,虽仍大于H+ (1.54 ?)与Mg2+(0.66 ?)的离子半径之和2.2 ?,但与清洁Mg(0001)表面相比,其间距减小近0.346 3 ?;与此同时,吸附后的H2键长也伸长为0.755 6 ?,表明H—H键得到一定程度的削弱,这似乎预示着:Mg表面空位缺陷的存在,增强了H2在镁表面的物理吸附能力。

图4 H2在清洁、缺陷Mg(0001)表面稳定吸附构型的电子密度

Fig.4 Electron density contours of Mg (0001) surfaces during process of H2 adsorption: (a) Clean surface; (b) Vacancy defective surface

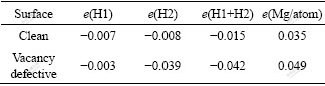

表4进一步给出了Mg(0001)表面稳定吸附构型的Mulliken原子布居。发现H2稳定吸附于清洁Mg(0001)表面时,电子由Mg表面向H2上产生极少量转移,吸附后的H2带有极少量的负电荷(?0.015),而表面Mg原子则带有少量的正电荷(0.035);当H2稳定吸附于空位缺陷Mg(0001)表面时,与清洁表面相比,H2从Mg表面得到的电子数却有所增多(?0.042)。

表4 H2在清洁及缺陷Mg(0001)表面稳定吸附构型的Mulliken布居分析

Table 4 Mulliken population of clean and vacancy defective Mg (0001) surfaces during H2 adsorption process

2.5 Fe合金化MgH2体系的解氢性能

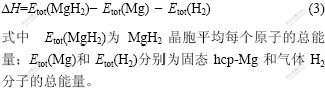

通常MgH2体系吸放氢动力学采用p—c—T曲线表示,一定温度(T)和压力(p)下,合金形成热?H的高低决定着解氢平台压的大小。一般而言,?H为负值,其值越负,解氢平台压越低,MgH2体系解氢越难,而?H的绝对值越小,越容易解氢[29?30]。基于此,本研究采用MgH2体系的总能量与镁以及氢分子总能量的差值来表示氢在镁中固溶或形成氢化物的合金形成热,计算公式如下:

Fe在MgH2中固溶形成(MgFe)H2固溶体的合金形成热[31?32]由下式计算:

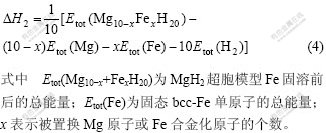

晶态单原子能量计算采用与计算晶胞总能量相同的赝势,Mg和Fe晶体单原子能量的计算值列于表2。由式(3)和(4)计算得到MgH2、Mg10H20、(Mg9Fe)H20、(Mg4Fe2)H12、(Mg8Fe2)H20晶胞的总能量列于表2中,合金形成热的计算结果见图5。从图5可看出,MgH2的合金形成热的计算值(–62.30 kJ/mol)稍大于实验值((–76.15±9.2) kJ/mol)[33]。其差异的主要原因在于本研究中的计算值为0 K时的值,而实验值则为温区670.7~707.9 K的测定值。而Fe合金化后,即Fe固溶于MgH2中,MgH2体系的负合金形成热却降低。

图5 MgH2与(MgFe)H2的合金形成热

Fig.5 Formation heat of MgH2 and (MgFe)H2 systems

关于计算多元合金氢化物ABnH2m的合金形成热,MIEDEMA等[34]给出了下述的近似关系式:

其两项之和则几乎为常数,因此如果?H(ABn)越负,ABnH2m的稳定性越低。但对Mg2FeH6而言,实验中并未发现Mg2Fe[5?7],因此,采用式(5)不宜计算其合金形成热,本研究中采用下式进行计算 [31?32]:

计算发现Mg2FeH6合金形成热的计算值(?124.87 kJ/mol)与实验值[24] (?79.2 kJ/mol)相比略偏大,但与SONG等[11]的计算值(?124.15 kJ/mol)十分 接近。

为考查少量Mg2FeH6相对MgH2体系结构稳定性的影响,本研究中引入稳定性参量ΔEr′,用它来表示Fe合金化MgH2与未合金化MgH2的合金形成热的变化值,其计算公式为

![]()

根椐式(7),ΔEr′(Mg2FeH6)的计算结果为45.358 7 kJ/mol。

分析上述计算的合金形成热,发现不同含量Fe固溶于MgH2中形成 (MgFe)H2固溶体,与未进行Fe合金化MgH2体系相比,体系?H的绝对值减小,其结构稳定性变差[29?30],表明Fe合金化MgH2体系解氢性能提高,与Fe合金化球磨粉末均不超过300 ℃(573 K)的条件下解氢的实验结果相符[7];而Mg2FeH6相的负合金形成热(?124.87 kJ/mol)大于MgH2(?62.30 kJ/mol),其结构更稳定,这与新的分离相Mg2FeH6[5, 7]相符;式(7)的计算值(45.3587 kJ/mol)为正,表明少量、结构更稳定的Mg2FeH6相的存在,造成MgH2体系的结构稳定性进一步降低。由于Mg2FeH6和MgH2两相共存体系中,MgH2仍为主体相(即使Fe固溶于MgH2中)[7],Mg2FeH6的量相对较少,因此少量、稳定存在的Mg2FeH6相起催化剂作用,使MgH2体系解氢性能进一步增强,这较好解释了本文作者最近报道的实验结果,即Mg2FeH6和MgH2两相共存粉末在所有粉末中有最窄的温度范围,解氢量较大,并显示最快的解氢速率约为0.0384%/℃[7]。

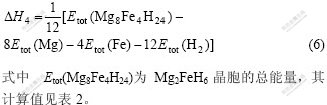

球磨Mg表面产生较多缺陷,有助于H2被Mg表面吸附,进而改善MgH2吸氢性能。探讨其微观机理,本研究中计算了清洁、空位缺陷表面的表层Mg原子在吸附H2前后的总态(DOS)及分波态密度(PDOS),如图6所示。由图6(a)可见,H2吸附前,清洁Mg(0001)表面表层平均每个Mg原子的成键峰主要集中在费米能级EF到?7 eV能量区间,其中,在?6~0 eV区间,成键电子主要来自各层Mg(s)及Mg(p)的贡献,而在?7~?6 eV区间, 成键电子则主要来自各层Mg(s)的贡献;与清洁表面相比,空位缺陷表面表层平均每个Mg原子的成键峰高度及能量分布区间并明显变化(见图6(b))。H2吸附后,与H2直接产生相互作用的Mg原子态密度相对于吸附前的发生了显著变化(见图6(c)和(d))。对于清洁与空位缺陷表面而言,其总态密度在?7.5~?6.3 eV的低能级区均出现一新成键峰(见6(c)和(d)),其主要来自H(s)与少量Mg(s)的贡献,预示着H2与表层Mg原子间具有较弱程度的吸附作用。同时,由于受吸附H2分子的影响,清洁与空位缺陷表面表层Mg(s)的分波态密度与未吸附H2的情形相比,均略向低能级区方向移动,而Mg(p)的分波态密度变化则不太明显。进一步比较与H2直接产生相互作用的Mg原子在H2吸附后的总态密度时发现(见图6(e)),体系态密度按清洁、空位缺陷表面的顺序逐渐向低能级方向移动,且费米能级以下的成键峰高度也按该顺序依次增大,这或许就是Mg(0001)表面对H2吸附能力逐渐增强的主要原因[35?36]。

图6 H2吸附于清洁、缺陷Mg(0001)表面前后与H2直接产生相互作用Mg原子平均每个原子的总态密度及分波态密度

Fig.6 Total and partial densities of states of clean and vacancy defective Mg (0001) surfaces during process of H2 adsorption: (a), (b) Densities of states between metal atom and Mg (0001) surface before H2 adsorption; (c), (d) Densities of states between metal atom and Mg (0001) surface after H2 adsorption; (e) Total density of states between metal atom and Mg (0001) surface after H2 adsorption; (f) Partial density of states between metal atom and Mg (0001) surface before H2 adsorption

由上述分析发现,H2吸附于Mg(0001)表面前后,与H2直接产生相互作用的Mg原子的态密度变化主要是由其s轨道的分波态密度变化所引起,预示着金属Mg原子的s轨道电子对H2吸附性能影响较大。为此,进一步比较了Mg(0001)表面未吸附H2时的最表层Mg原子s轨道的分波态密度,如图6(f)所示。在?7~?4 eV能量区间,清洁表面Mg(s)的分波态态密度明显高于空位缺陷表面的,而在?4~0 eV区间,情形却截然相反。对空位缺陷Mg表面而言,低能级区较多的成键电子向费米能级EF处转移,使费米能级处参与成键的电子数明显增多,进而能够提高Mg的表面活性[37],这很可能就是空位缺陷的存在增强了Mg表面对H2吸附能力的主要原因。

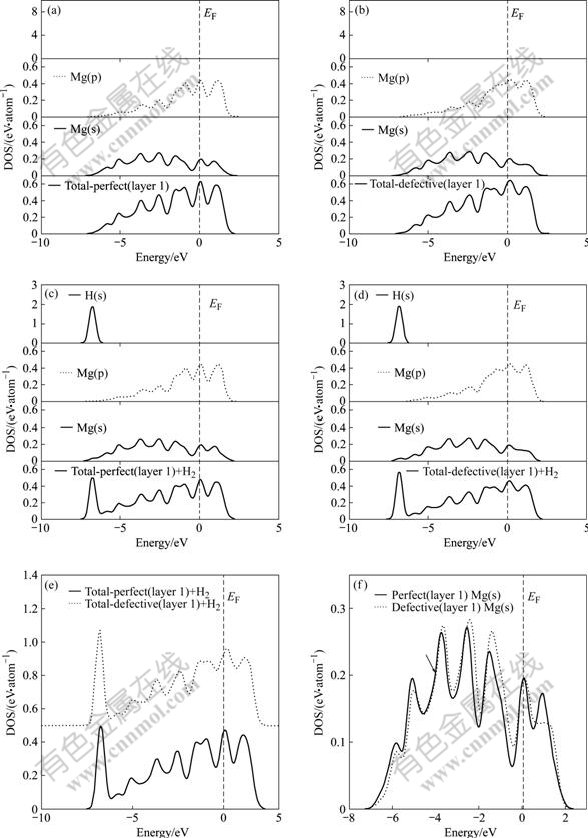

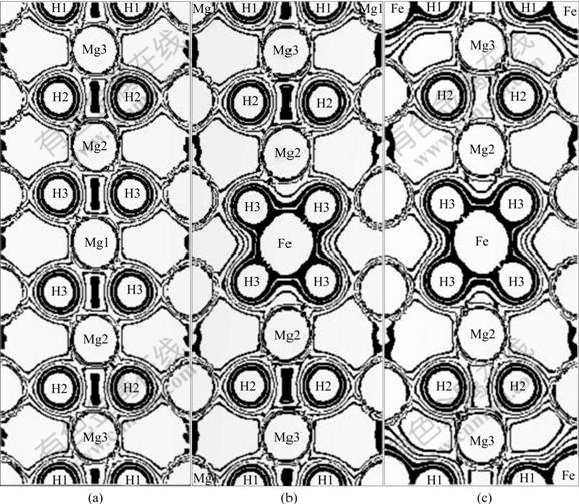

为研究Fe合金化改善MgH2体系解氢性能的原因,本研究中计算了Fe固溶于MgH2五倍单胞模型的总态密度及相应原子的分波态密度。在计算模型中,Mg、H和Fe分别占据不同的不等价原子位置,其标记如图2(b)所示。Fe未固溶时,MgH2在费米能级(EF)至?7.0 eV的能量范围内,成键电子存在几个主要的成键峰(见图7(a))。在0~?3.0 eV区间,其成键峰主要为H(s)、Mg(p)以及少量Mg(s) 的贡献;在?3.0 eV~ ?4.0 eV区间,成键峰主要来自H(s)、Mg(s)以及少量Mg(p) 的贡献;而在?4.0 eV~?7.0 eV区间,成键峰则主要是H(s)和Mg(s)贡献的结果。在0~3.0 eV的能量范围内,有1个很宽的能隙,其左右两边分别为成键峰和反成键峰。Fe固溶于MgH2中,其态密度发生了明显的改变(如图7(b)和7(c)所示),其变化有:1) 能隙出现在费米能级(EF)以下?2.0~?1.0 eV区间,宽度明显变窄; 2) 在?1.0~0.5 eV范围,主要表现为Fe(d)的电子特性,对Fe固溶量5.0%而言,Mg2(p)、H3(s)有少量的贡献;而固溶量10.0%时,除Mg2(p)、H3(s)少量贡献外,Mg3(p)、H1(s)与H2(s)也有少量贡献;3) Fe固溶量为5.0%时,在?4.0~?6.0 eV区间,H3的成键峰高度增加,Fe固溶量为10.0%时,在同一区间,H1、H3的成键峰高度均增加;4) EF附近,Mg(s)、Mg(p)与H(s)的分波态密度的高度有所降低。以上态密度的分析结果表明:Fe固溶于MgH2中,Fe原子与其第一近邻的H原子之间存在着强烈的成键作用,而Mg原子与其近邻的H原子之间的成键作用则有所减弱。

图7 Mg10H20 (a)、(Mg9Fe)H20 (b)和(Mg8Fe2)H20 (c)的总态密度与分波态密度

Fig.7 Total and partial densities of states of Mg10H20 (a), (Mg9Fe)H20 (b) and (Mg8Fe2)H20(c)

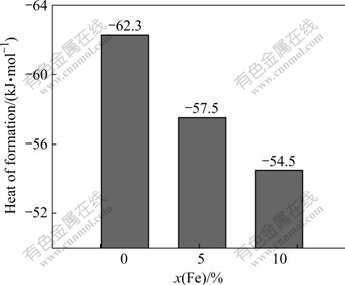

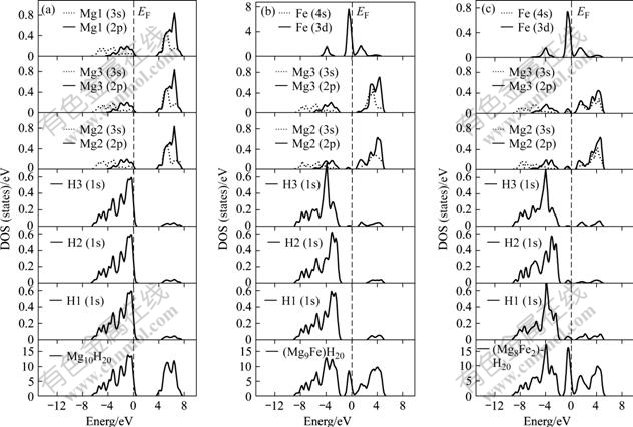

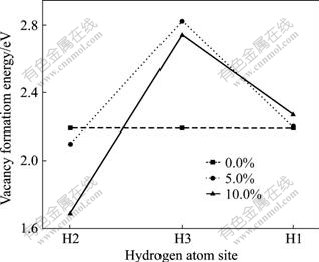

为进一步研究Fe原子与其近邻的H原子的相互作用,计算了与Fe邻近的H1、H3原子以及与Mg近邻的H2原子(如图2(b))的双氢空位的平均空位形成能。Fe在MgH2中固溶量为0.0%、5.0%、10.0%时,H1、H2、H3原子双氢空位的平均空位形成能δE(2H)分别由下式计算[38]:

如:Fe在MgH2中固溶量为0.0%时,n=0,固溶量为5.0%时,n=1, 固溶量为10.0%时,n=2;Etot(Mg10?nFenH18)为形成双氢空位后Mg10?nFenH18 晶胞的总能量; Etot(Mg10?nFenH20)为未形成双氢空位后Mg10?nFenH20 晶胞的总能量,计算结果如图8所示。从图8可见,Fe合金化后,MgH2体系中与Fe邻近的H1、H3原子的双氢空位的平均空位形成能比对应的未合金化时H1、H3的空位形成能大,这表明形成H1、H3空位的难度增加,H原子较难释放;而H2原子的双氢空位的平均空位形成能在进行Fe合金化后,却小于合金化前的,这表明形成H2空位的难度减小,Fe合金化后,H原子容易释放。但随着Fe合金化浓度的增加,与Fe邻近的H1、H3原子,H原子释放的难易程度有所改变,H3原子较易

图8 不同位置H原子的空位形成能

Fig.8 Vacancy formation energy of hydrogen atom in different kinds of sites

图9所示为Fe固溶于MgH2前后超胞模型(110)面的电子密度分布。比较图9(a)、(b)和(c)可见,Fe固溶于MgH2中,固溶1个Fe原子时,MgH2中Fe-H3之间存在较强的相互作用, Mg3-H2, Mg3-H1之间的相互作用没有明显变化,而Mg2-H2,Mg2-H3之间的相互作用减弱;固溶2个Fe原子时,MgH2中Fe-H3,Fe-H1之间均存在较强的相互作用,Mg3-H2之间的相互作用变化不明显,但Mg2-H2,Mg2-H3, Mg3-H1之间的相互作用减弱。

图9 Mg10H20、(Mg9Fe)H20和(Mg8Fe2)H20在(110)面的电子密度分布

Fig.9 Charge distributions on (110) plane of Mg10H20(a), (Mg9Fe)H20(b) and (Mg8Fe2)H20(c)

3 结论

1) H2在清洁Mg(0001)表面呈现较微弱的物理吸附,电荷由Mg表面向H2产生了少量转移,Mg(0001)表面存在空位缺陷,对H2的物理吸附能力增强,并且Mg表面向H2转移的电荷数增多;Fe固溶于MgH2中形成(MgFe)H2固溶体和合金化时形成少量Mg2FeH6相,MgH2体系的结构稳定性均降低,体系解氢性能对应增强。

2) 空位缺陷有助H2吸附于Mg表面,与Mg(0001)表面最上层与H2直接产生吸附作用的金属原子在费米能级(EF)附近s轨道的成键电子数密切相关。

3) MgH2体系中,与合金化元素Fe近邻的H原子形成空位的难度增加,H原子较难释放;而与Mg近邻的H原子形成空位的难度减小,H原子容易释放;Fe合金化MgH2体系解氢性能增强的主要原因在于Mg—H之间存在较弱的成键作用。

[1] ZALUSKA A, ZALUSKI L, STR?M-OLSEN J O. Nanocrystalline magnesium for hydrogen storage[J]. J Alloys Comp, 1999, 288(1/2): 217?225.

[2] JURCZYK M, SMARDZ L, OKONSKA I, JANKOWSKA E, NOWAK M, SMARDZ K. Nanoscale Mg-based materials for hydrogen storage[J]. Int J Hydrogen Energy, 2008, 33(1): 374?380.

[3] SHANG C X, BOUOUDINA M, SONG Y, GUO Z X. Mechanical alloying and electronic simulations of (MgH2+M) systems (M=Al, Ti, Fe, Ni, Cu and Nb) for hydrogen storage[J]. In J Hydrogenenergy, 2004, 29(1): 73?80.

[4] LIANG G, HUOT J, BOILY S, VAN NESTE A, SCHULZ R. Catalytic effect of transition metals on hydrogen sorption in nanocrystalline ball milled MgH2-Tm (Tm=Ti, V, Mn, Fe and Ni) systems[J]. J Alloys Comp, 1999, 292(1/2): 247?252.

[5] HUOT J, BOILY S, AKIBA E, SCHULZ R. Direct synthesis of Mg2FeH6 by mechanical alloying[J]. J Alloys Comp, 1998, 280(1/2): 306?309.

[6] HIGHTOWER A, FULTZ B, BOWMANN R C. Mechanical alloying of Fe and Mg[J]. J Alloys Comp, 1997, 252(1/2): 238?244.

[7] ZHOU D W, LI S L, VARIN R A, PENG P, LIU J S, YANG F. Mechanical alloying and electronic simulations of 2Mg-Fe mixture powers for hydrogen storage[J]. Mater Sci Eng A, 2006, 427(1/2): 306?315.

[8] SPRUNGER P T, PLUMMER E W. The interaction of hydrogen with simple metal surfaces[J]. Surf Sci, 1994, 307/309(1): 118?123.

[9] N?RSKOV J K, HOUM?LLER A, JOHANSSON P K, LUNDQUIST B I. Adsorption and dissociation of H2 on Mg surfaces[J]. Phys Rev Lett, 1981, 46(4): 257?260.

[10] VEGGE T. Locating the rate-limiting step for the interaction of hydrogen with Mg(0001) using density-functional theory calculations and rate theory[J]. Phys Rev B, 2004, 70(3): 035412?035418.

[11] SONG Y, GUO Z X, YANG R, Influence of selected alloying elements on the stability of magnesium dihydride for hydrogen storage applications: A first-principles investigation[J]. Phys Rev B, 2004, 69(1): 094205?094215.

[12] PERDEW J P, WANG Y. Accurate and simple analytic representation of the electron-gas correction energy[J]. Phys Rev B, 45(23): 13244-13249.

[13] DELLEY B. Analytic energy derivatives in the numerical local-density-functional approach[J]. J Chem Phys, 1991, 94 (11): 7245?7250.

[14] PACK J D, MONKHORST H J. Special points for brillouin-zone integrations—A reply[J]. Phys Rev B, 16(4): 1748?1749.

[15] PAYNE M C, TETER M P, ALLAN D C. Iterative minization techniques for Ab initio total energy calculations: molecular dynamics and cojugate gradients[J]. Rev Mod Phys, 1992, 64(1/2): 1045?1097.

[16] SEGALL M D, LINDAN P L D, PROBERT M J, PICKARD C J, HASNIP P J, CLARK S J, PAYNE M C. First-principles simulation: ideas, illustrations and the CASTEP code[J]. J Phys: Condens Matter, 2002, 14(11): 2717?2743.

[17] MARLO M, MILMAN V. Density-functional study of bulk and surface properties of titanium nitride using different exchange-correlation functionals[J]. Phys Rev B, 2000, 62(4): 2899?2907.

[18] WHITE J A, BIRD D M. Implementation of gradient-corrected exchange-correlation potentials in car-parrinello total-energy calculations[J]. Phys Rev B, 1994, 50(1): 4954?4957.

[19] VANDERBILT D. Soft self-consistent pseudopotentitals in a generalized eigenvalue formalism[J]. Phys Rev B, 1990, 41(11): 7892?7895.

[20] FRANSCIS G P, PAYNE M C. Finite basis set corrections to total energy pseudopotential calcaulations[J]. J Phys: Condens Matter, 1990, 19(2): 4395?4404.

[21] MONKHORST H J, PACK J D. Special points for Brillouin-zone integrations[J]. Phys Rev B, 1976, 13(1): 5188?5192.

[22] HAMMER B, HANSEN L B, NORKOV J K. Improved adsorption energetics withen density-functional theory using revised perdew-burke-ernzerhof functionals[J]. Phys Rev B, 1999, 59(11): 7413?7421.

[23] BORTZ M, BERTHEVILLE B, BOTTQER G, YVON K. ![]() Structure of the high pressure phase γ-MgH2 by neutron powder diffraction[J]. J Alloys Comp, 1999, 287(1/2): L4?6.

Structure of the high pressure phase γ-MgH2 by neutron powder diffraction[J]. J Alloys Comp, 1999, 287(1/2): L4?6.

[24] DIDISHEIM J J, ZOLLIKER P, YVON K, FISCHER P, SCHEFER J, GUBELMANN M, WILLIAMS A F. Dimagnesium iron(II) hydride, Mg2FeH6, containing octahedral FeH64? anions[J]. Inorg Chem, 1984, 23(1/2): 1953.

[25] HUOT J, HAYAKAWA H, AKIBA E. Preparation of the hydrides Mg2FeH6 and Mg2CoH5 by mechanical alloying followed by sintering[J]. J Alloys Comp, 1997, 248(1/2): 164?167.

[26] SELVAM P, YVON K. Synthesis of Mg2FeH6, Mg2CoH5 and Mg2NiH4 by high-pressure sintering of the elements[J]. In J Hydrogenenergy, 1991, 16(1): 615?631.

[27] BIRD D M, CLARCKE L J, PAYNE M C, STICH I. Dissociation of H2 on Mg(0001)[J]. Chem Phys Lett, 1993, 212(5): 518?524.

[28] JENSEN P, BLAS? X, ORDEJ?N P. First principles study of gold adsorption and diffusion on graphite[J]. Surf Sci, 2004, 564(1): 173?178.

[29] ZHOU D W, PENG P, LIU J S. First-principles calculations of dehydrogenating properties of MgH2-V systems[J]. Science in China: Series E, 2006, 49(2): 129?136.

[30] 周惦武, 彭 平, 刘金水. MgH2-Ti体系的第一原理计算[J]. 中国有色金属学报, 2005, 15(9): 1403?1410.

ZHOU Dian-wu, PENG Ping, LIU Jin-shui. First-principles calculation of dehydrogenating properties of MgH2-Ti systems[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1403?1410.

[31] MEDVEDEVA M I, GORNOSTYREV Y N, NOVIKOV D L, MRYASOV O N, FREEMAN A J. Ternary site preference energies, size misfits and solid solution hardening in NiAl and FeAl[J]. Acta Mater, 1998, 46(10): 3433?3442.

[32] SAHU B R. Electronic structure and bonding of ultralight LiMg[J]. Mater Sci Eng B, 1997, 49(1/2): 74?78.

[33] BOGDANOV?? B, BOHMHAMMEL K, CHRIST B, REISER A, SCHLICHITE K. Thermodynamic investigation of the magnesium-hydrogen system[J]. J Alloys Comp, 1999, 282(1/2): 84?92.

[34] MIEDEMA A R. The electronegativity parameter for transition metals: heat of formation and charge transfer in alloys[J]. J Less-Common Met, 1973, 32(1/2): 117?152.

[35] IMAI Y, MUKAIDA M, TSUNODA T. Comparison of density of states of transition metal disilicides and their related compounds systematically calculated by a first-principle pseudopotential method using plane-wave basis[J]. Intermetallics, 2000, 8(4): 381?390.

[36] VAKHNEY A G, YARESKO A N, ANTONOV V N, NEMOSHKALENKO V V. The effect hydrogen on the electronic structure and cohesive properties of iron-based alloys doped by chromium and nickel[J]. Int J Hydrogen Energy, 2001, 26(5): 453?456.

[37] EALET B, GONIAKOWSKI J, FINOCCHI F. Water dissociation on a defective Mg(100) surface: Role of divacancies. Phys Rev B, 2004, 69(19): 195413?195421.

[38] KELLOU A, FERAOUN H I, GROSDIDIER T, CODDET C, AOURAG H. Energetics and electronic properties of vacancies, anti-sites, and atomic defects(B, C, and N ) in B2-FeAl alloys[J]. Acta Mater, 2004, 52(11): 3263?3271.

基金项目:国家自然科学基金资助项目(50771044);国家重点基础研究发展计划资助项目(2006CB605104)

收稿日期:2008-04-23;修订日期:2008-07-08

通讯作者:周惦武,副教授,博士;电话:13017297124;E-mail: zdwe_mail@yahoo.com.cn