文章编号:1004-0609(2010)02-0195-07

复合添加Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和

性能的影响

陈康华,方华婵,陈 祥

(中南大学 粉末冶金研究院,长沙 410083)

摘 要:

采用铸锭冶金法制备Al-Zn-Mg-Cu-Zr、Al-Zn-Mg-Cu-Cr-Pr和Al-Zn-Mg-Cu-Zr-Cr-Pr 3种合金,通过金相显微、扫描电镜和透射电镜观察以及拉伸性能、极化曲线、应力腐蚀和剥落性能的测试,研究复合添加Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和性能的影响。结果表明:复合添加Zr、Cr和Pr可有效抑制Al-Zn-Mg-Cu合金回复过程中亚晶的合并和长大,显著抑制再结晶,提高合金抗应力腐蚀和抗剥落腐蚀的性能;与单独添加Zr的合金相比,复合添加Zr、Cr和Pr的合金断裂韧性KⅠC从23.3 MPa?m1/2提高到29.3 MPa?m1/2,合金应力腐蚀开裂界限应力强度因子KⅠSCC由10.9 MPa·m1/2提高到24.5 MPa·m1/2,合金的抗拉强度、屈服强度及伸长率都略有提高。

关键词:

Al-Zn-Mg-Cu合金;微观组织;Pr;力学性能;腐蚀性能;

中图分类号:TG 146.4 文献标识码:A

Effects of Zr, Cr and Pr additions on microstructure

and properties of Al-Zn-Mg-Cu alloys

CHEN Kang-hua, FANG Hua-chan, CHEN Xiang

(Institute of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Three kinds of alloys Al-Zr-Mg-Cu-Zr, Al-Zn-Mg-Cu-Cr-Pr and Al-Zn-Mg-Cu-Zr-Cr-Pr were prepared by cast metallurgy. The effects of Zr, Cr and Pr additions on the microstructure and properties of Al-Zn-Mg-Cu alloys were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy, tensile test, polarization curve measurement, stress corrosion and exfoliation corrosion test. The results show that the combined additions of Zr, Cr and Pr to the Al-Zn-Mg-Cu alloys effectively retard the mergence and growth of the sub-grain during the recovery process, significantly inhibits the recrystallization of Al matrix, thus enhances the resistance to stress corrosion and exfoliation corrosion. Compared with the Al-Zn-Mg-Cu alloy added with Zr, the complex additions of Zr, Cr and Pr into the Al-Zn-Mg-Cu alloy remarkably increase the fracture toughness (KⅠC) from 23.3 MPa?m1/2 to 29.3 MPa?m1/2, and enhance the resistance to stress corrosion cracking (KⅠSCC) from 10.9 MPa·m1/2 to 24.5 MPa·m1/2, yield strength and elongation of the alloys all increase a little.

Key words: Al-Zn-Mg-Cu alloys; microstructure; praseodymium; mechanical properties; corrosion properties

由于Al-Zn-Mg-Cu合金具有较高的强度和较低密度,已被广泛应用于航空航天领域。研究其微观组织与性能的关系[1?2]及实现其强度与韧性、强度与耐蚀性能的良好结合一直是超高强铝合金研究的热点[3?9]。微合金化是调节合金微观组织获得优良综合性能最有效的方法之一。

在Al-Zn-Mg-Cu合金发展的前期,人们通过添加微量Cr和Mn形成铝化物弥散相抑制再结晶,但由于此类弥散相与基体不共格,且较粗大,因此,抑制再结晶效果不够理想。之后,人们采用添加微量Zr替代Cr和Mn,形成与基体共格的亚稳L12型Al3Zr相,提高了合金的抗再结晶阻力,提高合金的强度、韧性及抗腐蚀性能[10?11]。但由于Al3Zr弥散相在合金中的不均匀分布导致Zr的偏析[12],且经过一定时间处理Al3Zr弥散相会失去共格性而变成稳定的DO23型Al3Zr平衡相[13],因此抑制再结晶的效果有限。20 世纪60年代初,前苏联研究者发现在铝合金中添加微量Sc,能形成与基体共格的Al3Sc弥散相,细化晶粒并显著提高铝合金的强度[14?16]。进一步添加微量Zr,能形成比Al3Sc弥散相更细小且更稳定的Al3(Sc, Zr)弥散相,更大程度上保持抗再结晶效应和强化效应[17-19]。Sc和Zr微合金化是目前改善铝合金综合性能最有效的方法,受到国际材料界的重视, 引起各国研究者极大的兴趣,对其进行广泛而深入研究。但由于Sc的价格昂贵,使其在现阶段难以广泛应用。因此,人们一直致力于寻找新的有效元素来替代Sc。近年来,聂作仁等[20]通过添加微量Er,形成与基体共格的Al3Er弥散相,从而细化晶粒,显著抑制基体再结晶,提高合金的强度和综合性能。

稀土与过渡族元素在铝合金中可形成CeCr2Al20晶体结构(立方结构,点阵常数a=(1.27±0.05) nm,空间群为Fd3m)的化合物[21],起到弥散相作用。本课题组的前期研究[22]发现,在Al-Zn-Mg-Cu合金中复合添加过渡族元素Zr、Cr和稀土元素Yb,形成CeCr2Al20晶体结构的含Zr的YbCr2Al20新型多元铝化物弥散相,这种新型多元弥散相能显著抑制再结晶,提高Al-Zn-Mg-Cu合金强度、断裂韧性和应力腐蚀抗力。在铝中复合添加过渡族元素Zr、Cr和稀土元素La,也可形成含Zr的LaCr2Al20新型多元铝化物弥散相,显著抑制铝的再结晶[23]。本文作者采用稀土元素Pr替代Yb和La,研究复合添加Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和性能的影响。

1 实验

合金名义成分如表1所列。采用高纯铝(纯度为99.9%)、工业纯镁(纯度为99.9%)和工业纯Zn(纯度为99.9%)为原料,合金元素Cu、Zr、Cr和Pr以中间合金形式加入。熔炼温度为700~740 ℃,浇注在直径45 mm的铁模中,模具温度为220~240 ℃。铸锭经465 ℃均匀化处理24 h后,在500 t压机上热挤压成棒材,挤压比为12.2。挤压试样在电阻炉中进行固溶处理,采用逐步升温固溶,即450 ℃保温1 h,然后升温至470 ℃保温1 h,再升温至480 ℃保温2 h,冷水淬火,之后进行T6峰时效(130 ℃,24 h)。

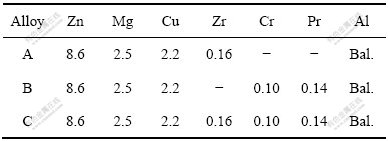

表1 铝合金的名义化学成分

Table 1 Nominal compositions of aluminum alloys (mass fraction, %)

样品机械抛光后用铬酸腐蚀,在光学金相显微镜下观察样品亚晶组织,经氟硼酸水溶液电解抛光复膜,置于偏振光下观察合金再结晶现象。采用双喷电解法(电解液为体积比1?3的硝酸甲醇溶液) 制备透射电镜试样,在透射电镜下观察合金微观组织。

拉伸实验参照国标GB228?87,在CSS?44100型电子拉伸机上进行试样(长向)拉伸试验。采用CHI600C电化学分析仪测量极化曲线,参比电极为饱和甘汞电极,辅助电极为铂电极,溶液体系为5.7%NaCl+1%H2O2(质量分数),实验在室温下进行。

应力腐蚀裂纹扩展速率测定采用双悬臂(DCB) 试样,按GB/T12445.1—1990 进行,裂纹扩展方向为试样 (L—T面) 长向,实验介质为3.5% NaCl 水溶液,溶液温度控制在(35±1) ℃,用读数显微镜跟踪测量并记录两表面裂纹扩展时的长度和相应的时间,由每个测量时间的平均裂纹长度a,再根据下式计算相应的KI。

![]()

式中:V为加载位移,mm;E为材料的弹性模量,GPa;h为字样的半高度,mm;l为平均裂纹长度,mm: KⅠ为裂纹尖端应力强度因子,MPa·m1/2。

剥落腐蚀采用航标HB5455?90,腐蚀溶液配比为NaCl 234 g/L,KNO3 50 g/L,HNO3 6.5 mg/L,其余为去离子水。样品除实验面外其余各面由环氧树脂密封,实验时间为48 h,实验温度为(25±1)℃。实验后样品在30%的硝酸溶液中清洗去除腐蚀产物,然后水洗吹干。对照HB5455?90标准,对腐蚀试样进行评级,评级代号如下:N为试样表面允许变色或腐蚀,但没有点蚀和剥蚀的迹象;P为不连续的腐蚀点,在点的边缘可能有轻微鼓起;EA~ED为剥蚀的等级;EA表示表面少量鼓泡裂开,呈薄片或粉末,有轻微的剥层;EB表示出现明显的分层并扩展到金属内部;EC表示剥蚀扩展到较深的金属内部;ED表示剥蚀扩展到比EC更深的金属内部,并有大量的金属层 剥落。

2 实验结果

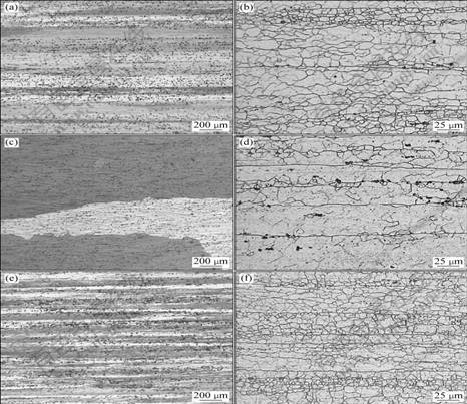

2.1 合金的金相组织

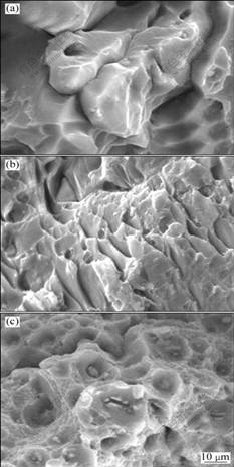

图1所示为合金的时效态组织。图1(a)、(c)和(e)所示为合金电解抛光覆膜后的组织。由图1(a)、(c)和(e)可知:复合添加Cr和Pr的合金B的组织十分粗大,发生明显的再结晶,且再结晶晶粒已经长大。单独添加Zr的合金A保持纤维状组织,复合添加Zr、Cr和Pr的合金C的纤维状特征明显。图1(b)、(d)和(f)所示为合金经铬酸腐蚀后的组织。从图1(b)、(d)和(f)中可以看出:合金A的亚晶已经长大,部分亚晶已经合并成为大晶粒;合金B的亚晶已经完全合并成大晶粒;而合金C仍保留了大量细小的亚晶组织。这说明复合添加Zr、Cr和Pr能显著抑制Al-Zn-Mg-Cu合金再结晶,阻碍亚晶粒的合并长大。

图1 经电解抛光覆膜和铬酸腐蚀处理后合金的金相组织

Fig.1 Optical microstructures of alloys by electro-polished and anodized and graff-sargent reagent etched: Electro-polished and anodized, alloy A (a), alloy B (b) alloy C (e); Graff-sargent reagent etched, alloy A (b), alloy D (d), alloy C (f)

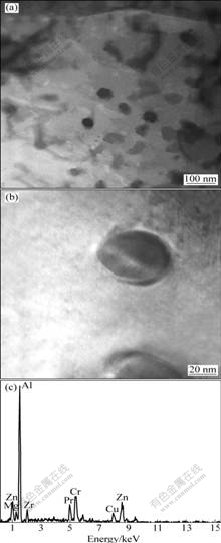

2.2 合金的微观组织

图2所示为复合添加微量Zr、Cr和Pr的Al-Zn-Mg-Cu合金T6时效态的TEM像。从图2(a)可以看出,合金的基体中析出颗粒状粒子,由EDX分析可知,弥散相中含Cr、Pr、Zr和Al。这些粒子细小弥散均匀分布于晶粒和晶界上,其粒径为20~50 nm,形状为球形。

图2 合金C在T6时效态时的TEM像和EDS谱

Fig.2 TEM images ((a), (b)) and EDS pattern (c) of fine spherical dispersoids in T6-tempered alloy C

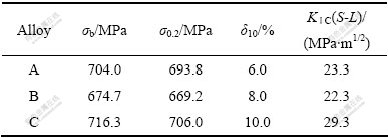

2.3 合金的力学性能

表2所列为合金的室温拉伸性能和断裂韧性。与合金A相比,合金C的抗拉强度稍微提高,伸长率由6%提高到10%;与合金B相比,合金C的抗拉强度提高41 MPa,伸长率由8%提高到10%。合金C的S-L方向的断裂韧性为29.3 MPa·m1/2,显著高于合金A(23.3 MPa?m1/2)和合金B的断裂韧性(22.3 MPa·m1/2)。

表2 合金的拉伸性能和断裂韧性

Table 2 Tensile properties and fracture toughness of tested alloys

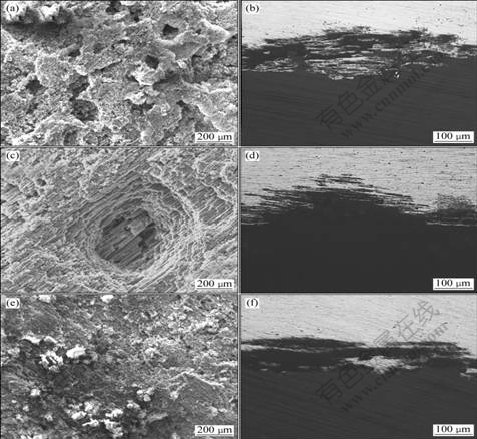

图3所示为3种合金拉伸断口的SEM像。由图3可知,合金A的断口呈冰糖状,表现为沿晶断裂特征。合金B的断口呈现细小的解离平台,表现为穿晶断裂特征。合金C的断口以韧窝为主,为延性断裂特征。结果表明,与单独添加Zr和复合添加Cr和Pr相比,复合添加Zr、Cr和Pr能显著提高Al-Zn-Mg-Cu合金的韧性。

图3 合金拉伸断口的SEM像

Fig.3 Fractural SEM images of alloys A (a), B (b) and C (c)

2.4 合金的腐蚀性能

2.4.1 应力腐蚀

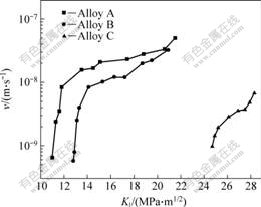

图4所示为3种合金应力腐蚀开裂扩展速率与应力场强度因子关系曲线。由图4可以看出,复合添加Zr、Cr和Pr的试样的抗应力腐蚀性能明显改善。仅添加Zr的合金A和复合添加Cr、Pr的合金B的应力腐蚀裂纹扩展速率很高,合金A的应力腐蚀开裂界限应力强度因子KⅠSCC为10.9 MPa·m1/2,合金B的KⅠSCC为12.8 MPa·m1/2。复合添加Zr、Cr和Pr的合金C的应力腐蚀裂纹扩展速率大大降低,KⅠSCC提高到24.5 MPa·m1/2。

图4 合金应力腐蚀开裂扩展速度与临界应力强度因子的关系

Fig.4 Relationships between stress corrosion crack growth rate v and stress intensity factor KⅠ of alloys

2.4.2 剥落腐蚀

按照HB5455?90评级标准对各试样清除腐蚀产物前后的表面进行评级。合金浸泡48 h后,清洗过腐蚀产物的样品表面的扫描照片和横截面金相形貌如图5所示。由图5可看出,3种合金经48 h浸泡后,产生不同程度的剥蚀。合金B的表层金属大块脱落,腐蚀侵入较深的金属内层,合金A的最表层金属已经剥落,合金B表面仍残存少量金属。从腐蚀产物来看,合金C的腐蚀产物为细小粉末,比合金A的腐蚀产物要细且少。而合金B的腐蚀产物为大量的金属碎片。从横断面可以看出,合金B的腐蚀层大多完全与基体脱离。而合金A和C的腐蚀层大多仍与基体相连,只有最表层的部分腐蚀层完全脱落。浸泡48 h后,合金A、B和C的腐蚀等级分别为EB+、ED和EA。说明复合添加Zr、Cr和Pr能显著提高Al-Zn-Mg-Cu合金的抗剥落腐蚀性能。

图5 样品在EXCO溶液中浸泡48 h后的表面SEM像和横断面OM像

Fig.5 SEM images of surfaces of alloys A (a), B (c) and C (e) and OM images of cross-section of alloys A (b), B (d) and C (f) after immersed 48 h in EXCO solution

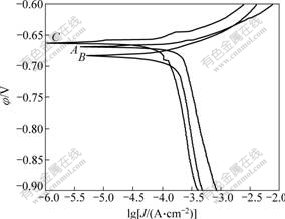

2.4.3 合金的极化曲线

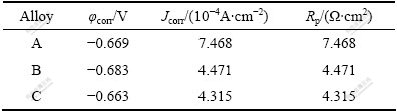

合金的电化学腐蚀极化曲线如图6所示,测量的电化学腐蚀参数列于表3。由图6和表3可以看出,与合金A和B相比,合金C的腐蚀电位升高,腐蚀电流密度减小,极化电阻变大。根据法拉第定律,腐蚀电流密度和电化学腐蚀率成正比,表明复合添加Zr、Cr和Pr的Al-Zn-Mg-Cu 合金的耐腐蚀能力增强,此结果反映的合金腐蚀倾向大小和剥落腐蚀和应力腐蚀的试验结果一致。

表3 合金的极化曲线腐蚀参数

Table 3 Corrosion parameters of polarization curves of alloys

图6 合金的电化学极化曲线

Fig.6 Potentiodynamic polarization curves of alloys

3 分析与讨论

从图1可以看出,复合添加Cr和Pr的合金组织已经发生明显的再结晶;单独添加Zr的合金虽然保持了纤维状组织,但亚晶已经长大,部分亚晶完全合并成为大晶粒;复合添加Zr、Cr和Pr的合金纤维状特征明显,且保留大量细小的亚晶组织,这是因为合金在均匀化处理和后续加工过程中,析出大量含Zr的PrCr2Al20新型多元弥散相,稳定变形组织的亚结构,阻碍亚晶界向大角度再结晶晶界转变,阻碍再结晶形核和长大过程,强烈抑制Al-Zn-Mg-Cu 合金的再结晶。这说明与PrCr2Al20和Al3Zr弥散相相比,含Zr的PrCr2Al20新型多元弥散相能更显著地抑制Al-Zn-Mg-Cu 合金的再结晶。

由于亚结构被大量保留,因此,弥散强化和亚结构强化是复合添加Zr、Cr和Pr的Al-Zn-Mg-Cu 合金的主要强化机制。同时大量亚晶界有利于分散应力,使变形均匀,从而在一定程度上提高合金的伸长率。含Zr的PrCr2Al20弥散相显著提高Al-Zn-Mg-Cu 合金的断裂韧性可能与保持形变回复组织、减少时效析出相在亚晶界富集,从而减少晶界(亚晶界)断裂有关。此外,晶内形成的这种弥散相,减少了共面滑移,避免位错在晶界(亚晶界)塞积,减少晶界(亚晶界)的应力集中,从而降低晶界断裂分数,提高Al-Zn-Mg-Cu合金的断裂韧性。

超高强铝合金由于晶界析出相增多,且容易在晶界呈连续状富集,造成晶界的应力集中,晶界断裂问题突出,而该系合金的腐蚀通常是沿晶界扩展,因此晶界的性质对合金抗应力腐蚀性能产生重要影响。一般而言,粗大的大角度再结晶晶粒晶界对合金的腐蚀性能产生不利影响,而亚晶界有很强的抗腐蚀能力。与单独添加Zr和复合添加Cr和Pr的合金相比,复合添加Zr、Cr和Pr能更有效地抑制合金基体的再结晶,保留大量细小的亚晶组织为主的未再结晶组织。由于亚晶界能量比大角度再结晶晶界低,时效析出相在亚晶界上的富集程度低于大角度再结晶晶界,不易形成连续状晶界析出相,有利于提高合金的抗腐蚀性能。

4 结论

1) 复合添加Zr、Cr和Pr可形成细小弥散含Zr的PrCr2Al20弥散相,稳定变形组织的亚结构,阻碍亚晶界向大角度再结晶晶界转变,显著提高Al-Zn-Mg-Cu合金的再结晶抗力。

2) 与单独添加Zr和复合添加Cr和Pr相比,复合添加Zr、Cr和Pr能提高Al-Zn-Mg-Cu合金的抗拉强度、屈服强度和断裂韧性,改善合金的塑性,Al-Zn-Mg-Cu-Zr、Al-Zn-Mg-Cu-Cr-Pr和Al-Zn-Mg-Cu- Zr-Cr-Pr合金在S-L方向上的KⅠC分别为23.3、22.3和29.3 MPa?m1/2。

3) 与单独添加Zr和复合添加Cr和Pr相比,复合添加Zr、Cr和Pr能显著提高Al-Zn-Mg-Cu合金的应力腐蚀抗力和剥落腐蚀抗力,Al-Zn-Mg-Cu-Zr合金的应力腐蚀临界应力强度因子KⅠSCC为10.9 MPa·m1/2,剥蚀等级为EB+;Al-Zn-Mg-Cu-Cr-Pr合金KⅠSCC为12.8 MPa·m1/2,剥蚀等级为ED;Al-Zn-Mg-Cu-Zr-Cr-Pr合金KⅠSCC为24.5 MPa·m1/2,剥蚀等级为EA。

4) 与单独添加Zr和复合添加Cr和Pr相比,复合添加Zr、Cr和Pr的Al-Zn-Mg-Cu合金的腐蚀电位升高,腐蚀电流密度减小,极化电阻变大。

[1] DIXIT M, MISHRA R S, SANKARAN K K. Structure-property correlations in Al 7050 and Al 7055 high-strength aluminum alloys[J]. Mater Sci Eng A, 2008, 478(1/2): 163?172.

[2] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy[J]. Mater Sci Eng A, 2003, 356(1/2): 326?336.

[3] CHEN Kang-hua, LIU Hong-wei, ZHANG Zhuo. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments[J]. Journal of Materials Processing Technology, 2003, 142 (1): 190?196.

[4] REDA Y, KARIM R A, ELMAHALLAWI I. Improvements in mechanical and stress corrosion cracking properties in Al-alloy 7075 via retrogression and reaging[J]. Mater Sci Eng A, 2008, (1/2): 468?475.

[5] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Mater Sci Eng A, 2008, 492(1/2): 1?10.

[6] FENG Chun, LIU Zhi-yi, NING Ai-lin. Retrogression and re-aging treatment of Al-9.99%Zn-1.72%Cu-2.5% Mg-0.13%Zr aluminum alloy[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1163?1170.

[7] ANDREATTA F, TERRYN H. Corrosion behaviour of different tempers of AA7075 aluminium alloy[J]. Electrochimica Acta, 2004, 49(17/18): 2851?2862.

[8] LI Zhi-hui, XIONG Bai-qing, ZHANG Yong-an. Investigation on strength, toughness and microstructure of an Al-Zn-Mg-Cu alloy pre-stretched thick plates in various ageing tempers[J]. Journal of Materials Processing Technology, 2009, 209(4): 2021?2027.

[9] HUANG Lan-ping, CHEN Kang-hua, LI Song. Influence of high-temperature pre-precipitation on local corrosion behaviors of Al-Zn-Mg alloy[J]. Scripta Materialia, 2007, 56(4): 305?308.

[10] WAGNER J A, SHENOY R N. The effect of copper, chromium, and zirconium on the microstructure and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Metallurgical Transactions A, 1991, 22: 2809?2818.

[11] YOSHIDA H, BABA Y. The role of zirconium to improve strength and stress-corrosion resistance of Al-Zn-Mg and Al-Zn-Mg-Cu alloys[J]. Transactions of the Japan Institute of Light Metals, 1982, 23(10): 620?630.

[12] ROBSON J D, PRANGNELL P B. Predicting recrystallized volume fraction in aluminium alloy 7050 hot rolled plate[J]. Materials Science and Technology, 2002, 18(6): 607?614.

[13] ROBSON J D, PRANGNELL P B. Dispersoid precipitation and process modeling in zirconium containing commercial aluminium alloys[J]. Acta Materialia, 2001, 49(4): 599?613.

[14] SINGH V, PRASAD K S. Effect of minor Sc additions on structure, age hardening and tensile properties of aluminium alloy AA8090 plate[J]. Scripta Materialia, 2004, 50(6): 903?908 .

[15] SUH D W, LEE S Y, LEE K H. Microstructural evolution of Al-Zn-Mg-Cu-(Sc) alloy during hot extrusion and heat treatments[J]. Journal of Materials Processing Technology, 2004, 155/156: 1330?1336.

[16] WU Yi-lei, FROES F H, LI Cheng-gong, ALEX A. Microalloying of Sc, Ni and Ce in an advanced Al-Zn-Mg-Cu alloy [J]. Metallurgical and Materials Transactions A, 1999, 30(4): 1017?1024.

[17] ZOU Liang, PAN Qing-lin, HE Yun-bin. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Trans Nonferrous Met Soc China, 2007, 17(2): 340?345.

[18] SENKOV O N, SHAGIEV M R , SENKOV S V. Precipitation of Al3(Sc,Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties[J]. Acta Materialia, 2008, 56(15): 3723?3738.

[19] HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1228?1235.

[20] XU Guo-fu, MOU Shen-zhou, YANG Jun-jun, JIN Tou-nan, NIE Zuo-ren, YIN Zhi-min. Effect of trace rare earth element Er on Al-Zn-Mg alloy[J]. Trans Nonferrous Met Soc China, 2006, 16(3): 598?603.

[21] SABINE N, WOLFGANG J.Ternary aluminides AT2Al20 (A=Rare Earth Elements and Uranium; T=Ti, Nb, Ta, Mo, and W) with CeCr2Al20-type structure[J]. Journal of Solid State Chemistry, 1995, 114(2): 337?341.

[22] CHEN Kang-hua, FANG Hua-chan, ZHANG Zhuo. Effect of of Yb, Cr and Zr additions on recrystallization and corrosion resistance of Al-Zn-Mg-Cu alloys[J]. Mater Sci Eng A, 2008, 497(1/2): 426?431.

[23] 周年润, 陈康华, 方华婵. 复合添加Zr、Cr和La对铝再结晶温度的提高作用[J]. 粉末冶金材料科学与工程, 2008, 13 (4): 208?213.

ZHOU Nian-run, CHEN Kang-hua, FANG Hua-chan. Effect of combined additions of Zr, Cr and La on improving recrystallization temperature of aluminum[J]. Materials Science and Engineering of Powder Metallurgy, 2008, 13 (4): 208?213.

基金项目:国家重点基础研究发展计划资助项目(2005CB623704);国家自然科学基金委员会创新研究群体科学基金资助项目(50721003);国家自然科学基金资助项目(50471057)

收稿日期:2009-03-01;修订日期:2009-09-02

通信作者:陈康华,研究员,博士;电话:0731-88830714;E-mail: khchen@mail.csu.edu.cn

摘 要:采用铸锭冶金法制备Al-Zn-Mg-Cu-Zr、Al-Zn-Mg-Cu-Cr-Pr和Al-Zn-Mg-Cu-Zr-Cr-Pr 3种合金,通过金相显微、扫描电镜和透射电镜观察以及拉伸性能、极化曲线、应力腐蚀和剥落性能的测试,研究复合添加Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和性能的影响。结果表明:复合添加Zr、Cr和Pr可有效抑制Al-Zn-Mg-Cu合金回复过程中亚晶的合并和长大,显著抑制再结晶,提高合金抗应力腐蚀和抗剥落腐蚀的性能;与单独添加Zr的合金相比,复合添加Zr、Cr和Pr的合金断裂韧性KⅠC从23.3 MPa?m1/2提高到29.3 MPa?m1/2,合金应力腐蚀开裂界限应力强度因子KⅠSCC由10.9 MPa·m1/2提高到24.5 MPa·m1/2,合金的抗拉强度、屈服强度及伸长率都略有提高。