DOI: 10.11817/j.ysxb.1004.0609.2021-37854

激光选区熔化铝合金及铝基复合材料的研究进展

蔡志勇1, 2,刘海江1,王日初1, 2, 3,彭超群1, 2

(1. 中南大学 材料科学与工程学院,长沙 410000;

2. 湖南省电子封装与先进功能材料重点实验室,长沙 410083;

3. 中南大学 轻质高强结构材料国防科技重点实验室,长沙 410083)

摘 要:

铝合金及铝基复合材料具有密度小、比强度高、耐腐蚀性能优异等特点,将激光选区熔化技术应用于制备结构-功能一体化铝合金及铝基复合材料精密复杂构件,在航空航天、交通运输、电子器件等领域具有广阔的应用前景。本文主要介绍国内外激光选区熔化铝合金及铝基复合材料的研究、开发及应用情况。首先,阐述激光选区熔化技术的基本原理;其次,分析激光选区熔化的主要工艺参数、铝合金及铝基复合材料的微观组织、宏观性能以及后处理工艺等,并概述激光选区熔化铝合金及铝基复合材料的主要应用情况;最后,阐述激光选区熔化铝合金及铝基复合材料面临的主要问题并进行展望。

关键词:

文章编号:1004-0609(2021)-xx-- 中图分类号:TG146.21 文献标志码:A

引文格式:蔡志勇, 刘海江, 王日初, 等. 激光选区熔化铝合金及铝基复合材料的研究进展[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37854

CAI Zhi-yong, LIU Hai-jiang, WANG Ri-chu, et al. Progress in aluminum alloys and composites fabricated by selective laser melting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37854

铝合金是使用量仅次于钢的一种重要金属材料,具有密度小、比强度高、耐腐蚀性能优异等特点,通过引入增强体形成的铝基复合材料可进一步提高其强度、耐热性和耐磨性。铝合金及铝基复合材料的传统制备方法包括熔铸、锻造和粉末冶金等,近年来,在这些传统制备方法的基础上,众多新型铝合金及复合材料制备方法应运而生,并在国内外学术界和产业界均引起广泛关注。

增材制造(Additive manufacturing, AM),也称为3D打印或快速成形,具有直接从3D计算机辅助设计数据中逐层生产近终形尺寸3D零件的能力,有些增材制造技术甚至不需要后期处理,生产的零件可以直接应用[1],从而实现制造商缩短供应链和交货时间的目的。增材制造技术的主要优势之一在于节省原材料,提高生产具有成本效益的定制产品和混合材料的可能性,获得传统制备工艺难以实现的高性能。SAMES等[2]列出金属增材制造从1984年到2012年的重大事件时间表,对于了解增材制造的发展历史提供了详细的信息。目前,增材制造技术可以分为以下三类:(a) 粉末床熔融(Powder-bed fusion, PBF),(b) 直接能量沉积(Direct energy deposition, DED),(c) 液滴按需系统(Droplet-on- demand systems, DDS)[3]。激光选区熔化(Selective laser melting, SLM)和电子束熔化(Electron beam melting, EBM)是两种重要的粉末床熔融技术,并且SLM和EBM零件已经在许多工业领域得到应用。

1 激光选区熔化技术概述

激光选区熔化技术于1995年由德国Fraunhofer激光技术研究所提出[4],其基本原理是将零件的三维模型通过计算机辅助设计(Computer-aided design, CAD)软件分解,然后逐层地添加材料直至成形出整个零件。激光选区熔化技术采用的激光光斑直径小,制品尺寸精度很高,是制备精细、复杂结构金属零件领域最具发展前景的金属增材制造技术之一。

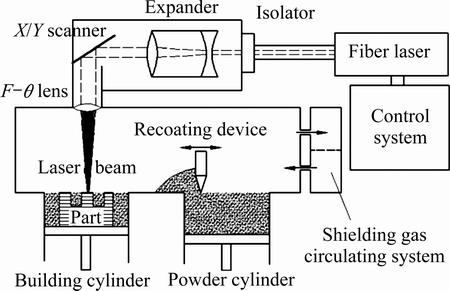

激光选区熔化设备的基本结构如图1所示[5],典型构件的激光选区熔化工序包括以下几个主要步骤[3]:

1) 借助CAD将模型转换成一个STL (Stereo Lithography, 立体光刻)文件;

2) 选择最佳的建造方向(取决于Z轴的高度、表面光洁度和支撑结构的最小化),生成支撑结构;

3) 对盖板进行预热(避免不均匀的热膨胀引起卷曲),然后在盖板上涂上一层预先规定厚度的粉末;

4) 高能量密度的激光束发射到X-Y平面上,通过移动激光束选择性地扫描和熔化所需要的区域;

5) 熔化完成后将盖板降低到与上一层粉末厚度相等的距离,然后重新铺粉继续沉积下一层;

6) 重复步骤3)~5)步骤,得到激光选区熔化零件。

近年来,激光选区熔化技术在航空航天、生物医疗和汽车等领域获得应用,具有成形性能好、成形工件致密度高的合金逐渐成为增材制造技术的研究热点[6]。激光选区熔化过程具有复杂的非平衡物理和化学性质,可以使增强体在基体中分散均匀,并在增强体与基体之间的界面处诱发复杂的相互作用,从而可以通过调整合金成形件的微观结构获得所需性能。XI等[7]对比激光选区熔化Al-12Si/TiB2复合材料与Al-12Si合金的微观组织和结构,发现Al-12Si/TiB2复合材料不仅形成均匀的微观组织,组织由具有随机晶体取向的细等轴晶粒组成,而且具有更高的屈服强度和显微硬度。ZHAO等[8]利用激光选区熔化技术制备出AlSi10Mg/ 8.5%SiC(体积分数)复合材料,并分析三个特征区域的微观组织演变机理,发现熔池中心和边界处分别具有较高的纳米硬度(2.3 GPa和2.2 GPa)和弹性模量(78.9 GPa和75.5 GPa),远高于传统方法制备的材料。

图1 激光选区熔化设备的基本结构[5]

Fig. 1 Basic structure of selective laser melting equipment[5]

2 铝合金及铝基复合材料激光选区熔化技术

铝合金及铝基复合材料具有轻质、力学性能高、耐腐蚀性良好、成本低等综合优势,广泛应用于航天航空、汽车和船舶工业等领域[9]。但是,在激光选区熔化过程中,铝合金的激光吸收率低、热导率高等特点严重影响其成形性能,大约有90%的激光能量会被反射。因此,铝合金及铝基复合材料的激光选区熔化对设备提出更苛刻的要求,对工艺条件和环境的要求高于铁基合金、钛基合金等[10-11]。

国内外对激光选区熔化铝合金的研究主要集中于Al-Si、Al-Si-Mg、Al-Li系等合金材料,其中Al-Si系成形零件较为成熟,学者们对AlSi10Mg和Al-12Si两种合金的激光选区熔化成形研究较多,并且部分已经成功应用于工程实际。

2006年,张冬云[12]在德国Fraunhofer激光技术研究所的支持下,采用激光选区熔化技术制备出AlSi25、AlSi10Mg、AlMg3和AlMgSi0.5四种合金,研究表明每种合金都存在一个加工阈值,当以高于加工阈值的激光功率对合金粉末进行加热时,四种铝合金的致密度都随着扫描速度的提高而降低,并且激光选区熔化AlSi10Mg拉伸试样的力学性能显著优于铸造件。耿遥详等[13]应用“团簇+连接原子”模型,通过增加合金液-固局域结构相容性,获得一种激光选区熔化专用新成分Al91.0Si7.5Mg1.5,通过调整工艺参数获得近乎全致密的成形铝合金,其综合力学性能明显优于AlSi10Mg合金,该工作为设计激光选区熔化铝合金的成分提供了新思路。

激光选区熔化技术制备高导电金属尤其困难,对于一些难熔金属,由于熔点高和脆性大的特点,成形难度更大。为实现合金的最小孔隙率,选择合适的工艺参数是必不可少的,但是目前的开发策略仍然存在局限性。BAJAJ等[14]提出一种使用标准化流程图进行快速流程开发的简单方法,利用归一化能量密度与归一化舱口间距的关系图,首先确定一个宽的加工窗口;然后利用这种方法开发用于钼和铝合金的激光选区熔化工艺参数,采用200 W脉冲激光和400 W连续激光分别获得致密度为97.4%和99.7%的成形件。

近年来,为提高激光选区熔化铝合金的力学性能,研究人员采用原位合成的方法将增强颗粒添加到合金中[15]。颗粒增强铝基复合材料(Particle reinforced aluminum matrix composites, PRAMCs)的增强材料一般都是硬质颗粒,如SiC、TiC、TiB2、ZrB2和Al2O3等陶瓷颗粒,这些增强颗粒往往自身就具有高熔点、高硬度和优良的力学性能,其中一些除了可以提高复合材料的强度、硬度和耐磨性外,还可以作为晶粒细化的形核位点,具体的各种颗粒通过原位反应制备的方法在文献[16]中已详述。XIAO等[17]发现将纳米TiB2颗粒添加到AlSi10Mg合金后,基体晶粒组织为细小的等轴晶,没有择优的晶粒织构,各向异性显著降低。LI等[18]采用激光选区熔化技术制备出完全致密、无裂纹的原位纳米TiB2增强AlSi10Mg合金,力学性能测试表明该复合材料具有很高的抗拉强度(530 MPa)、优良的延展性(15.5%)和较高的显微硬度(191HV0.3),结合微观组织表征结果作者进一步讨论了该复合材料的强韧化机理,为利用原位颗粒增强金属基复合材料提供了新的途径。

3 激光选区熔化的主要工艺参数

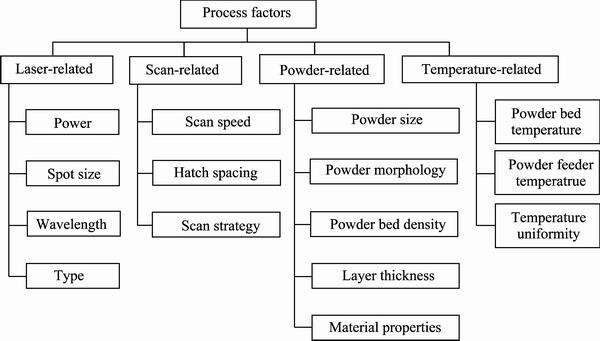

激光选区熔化技术的主要工艺参数,例如扫描速度、舱口间距、激光能量、层厚等,是铝合金及铝基复合材料成形的关键所在,很多文献报道了关于这些工艺参数对零件致密度和成形件力学性能的影响。ZHANG等[19]综述了激光选区熔化成形的缺陷形成机制,如图2所示,工艺参数可以分为四类:激光输入(Laser-related)、扫描相关(Scan-related)、粉末特性(Powder-related)、温度状况(Temperature-related),分别影响激光选区熔化零件的组织缺陷以及宏观性能。

3.1 粉末特性

图2 激光选区熔化的工艺参数分类[19]

Fig. 2 Classification of processing factors of selective laser melting[19]

激光选区熔化的原材料是专用的金属粉末,粉末特性影响工艺参数的制定以及成形零件的组织性能。激光选区熔化金属粉末要求粉末粒度小、粒度分布均匀、球形度高和氧含量低。对于金属成分的定性分析和定量分析,一般使用化学分析法和光谱分析法,而氧含量作为一项指标在航天航空等领域要求十分严格,通常需要控制在0.15%以下[20]。激光选区熔化金属粉末的粒度也是一项关键指标,粉末粒度一般要求不能过大,但是粒度过小会影响粉末流动性,阻碍粉末的熔融,常用的金属激光选区打印粉末的粒度范围是15~63 μm(细粉)和63~105 μm(粗粉)。

唐鹏钧等[21]采用超音速气体雾化设备制备AlSi10Mg粉末,通过气流分级去除细小和粗大的原始粉末颗粒,获得的合金粉末可以满足激光选区熔化成形的要求,粉末大多数为球形颗粒,少数为不规则形状,在粉末内部残留的气体会导致出现一些空心粉,对零件的致密度有不利影响。BAITIMEROV等[22]发现具有良好流动性的粉末表现出较好的激光选区熔化成形性,由于颗粒集聚的原因,大量细颗粒的粉末表现出非常差的流动性,不利于激光选区熔化成形。

3.2 激光能量输入

激光能量输入直接决定金属粉末的熔融环境,在激光选区熔化成形过程中影响成形件的组织缺陷和力学性能,对于铝合金及铝基复合材料尤其重要,与激光能量输入有关的主要参数有激光功率、扫描速度、舱口间距和层厚等[19]。

当其他工艺参数一定时,激光功率过低则形成的熔池尺寸小、温度低,粉末未完全熔化,熔液粘度和表面张力都较大,从而降低溶液的流动性,熔液容易分裂成金属球体产生球化,最终出现孔隙[23-24]。即使激光选区熔化过程是在惰性气氛中进行,熔池自由表面也会形成薄的氧化层,因此有必要使用较高的激光功率来破碎氧化膜。此外,由于铝的低激光吸收率,激光束的大部分辐照被反射,适当提高激光功率是必要的。TONELLI等[25]在研究粉末及工艺参数对A357铝合金致密度和硬度的影响时,发现合金的致密度严格依赖于激光功率,随着激光功率增加,样品的致密度相应增加,而且不同的粉末存在不同的功率阈值,激光功率只有在超过阈值的情况下,致密度才随着激光功率的增加而线性增加。

虽然高激光功率是降低孔隙率的必要条件,但当激光功率过高时,熔池宽度也随之增大,易出现过烧现象,同时伴有球化现象[23]。张红昌等[26]采用“分组变向”的扫描方式研究不同工艺参数对2024铝合金微观组织和力学性能的影响,结果表明在扫描速度一定时,合金致密度随着激光功率的增加呈先升高后降低的趋势,当激光功率为260 W时致密度最高。

扫描速度越大,输入的激光线能量密度则越低,随之导致熔池宽度变窄、深度变浅,前一层未熔化部位的粉末难以被后一层熔池覆盖,因而出现层间部分粉末没有熔化的现象,并留下工艺孔隙;当扫描速度较小时,即使是较大的扫描间距也仍然有较高的搭接率,获得的成形件质量更好[27]。HANEMANN等[28]研究通过添加硅来控制激光选区熔化原位AlSi10Mg合金的热膨胀系数,发现随着激光功率增加和扫描速度降低,裂纹的形成减少,但是当激光功率≤225 W时,相对密度随着扫描速度的提高而降低,当激光功率≥275 W时,相对密度随着扫描速度的降低而减小。

以上结果表明,激光功率和扫描速度等工艺参数并不是作为单一变量各自影响成形件的组织和性能,而是存在相互耦合的作用。当扫描速度相对较低、激光功率较高时,会导致熔池在高能量输入下的不稳定性,残余应力也较高,常出现微裂纹;当扫描速度相对较高、激光功率较低时,能量输入较低不足以熔化粉末,导致出现未熔合缺陷[19]。激光能量密度还可以用以下公式[29-30]来表示:

(1)

(1)

式中:E表示激光能量密度(J/mm3);P表示激光功率(W);v表示扫描速度(mm/s);h表示舱口间距(mm);t表示层厚(mm)。

粉末层的厚度会影响原位反应和凝固时的热量,进而影响激光选区熔化零件的微观结构和宏观性能。从式(1)可以看出,当舱口间距增大时,合金致密度会降低,但是间距过小会导致激光能量过度集中,产生翘曲变形。DADBAKHSH等[31]探讨了粉层厚度对激光选区熔化Al/5%Fe2O3(质量分数)复合材料微观结构的影响,通过对比50 μm、75 μm和较厚粉层获得的微观组织,发现粉层厚度越小,氧含量会越高,因为较厚的粉层会降低冷却速度,激活更多的放热反应,最终减少基体中的氧气含量。高氧含量可以促进形成硬质氧化物,例如Al2O3和Fe2+Al2O4,增强基体。MAAMOUN等[32]研究工艺参数对激光选区熔化铝合金零件质量的影响,在层厚恒定为30 μm的条件下,采用控制变量的方法调整制备AlSi10Mg样品的工艺参数(激光功率、扫描速度、舱口间距),优化工艺参数后获得的样品相对密度高达99.7%。

3.3 扫描策略

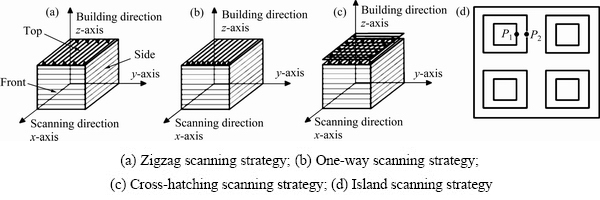

激光选区熔化的常用扫描策略如图3[33]所示,有“单向”、“锯齿形”、“交叉阴影形”和“岛屿式扫描策略”,对于前面两种扫描方式,在扫描轨道的初期和末期,激光能量经常不稳定故而要降低扫描速度,导致激光能量输入相对较大。而“交叉阴影形”可以使能量输入在层与层之间更加平衡,有效防止缺陷的萌生和传播。“岛屿式扫描策略”先将填充层分为几个“岛”,每个“岛”随机且连续地构建,然后将连续的层移动一定的距离,可以避免缺陷的积累。此外,这种方式可以平衡激光选区熔化零件的残余热应力,减少裂纹的产生。由于扫描顺序的变化,缺陷往往会在小岛边界形成,这需要进一步改善。

VALENTE等[34]优化了岛屿式扫描策略,获得的表面粗糙度更高,但是表面纹理更均匀,而且岛屿式扫描策略的平均硬度值(494 MPa)高于线扫描策略(474 MPa)。MUGWAGWA等[35]对比岛屿式、连续式、连续棋盘式和最小热影响(LHI)四种扫描策略对成形件残余应力和变形的影响,连续棋盘式扫描策略获得的样品平均残余应力最小,与残余应力研究结果相似,连续棋盘式的结果与岛屿式策略相比,形状偏差较小,而且连续棋盘式策略的扫描时间略低于岛屿式和LHI棋盘策略。

4 激光选区熔化铝合金及复合材料的微观组织与性能

4.1 致密度

影响激光选区熔化铝合金及铝基复合材料致密度的主要因素是孔隙,孔隙对零件的成形结构有严重影响,激光选区熔化零件的孔隙可以分为三类:熔合误差、气孔和缩孔[36]。熔合误差主要是因为激光能量密度不足,导致最后一个凝固层重熔不完全,冶金结合不良;粉末颗粒间夹带气体时也容易产生熔合误差,这些孔隙一般呈不规则形状。气孔是在激光扫描时,气体逸出后形成空腔,熔池中的流体力与空腔中的蒸汽压力趋于平衡,导致液态金属坍塌形成周期性孔隙。缩孔的形成主要归因于凝固过程中液态金属供应不足。目前,研究人员主要通过优化激光选区熔化工艺参数、粉末干燥、表面重熔等方法来抑制孔隙的产生,以此来提高成形铝合金及复合材料的致密度。

图3 激光选区熔化的常用扫描策略[33]

Fig. 3 Scanning strategy diagram of selective laser melting[33]

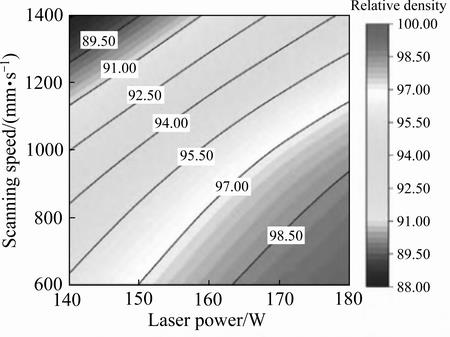

邹亚桐等[24]利用田口方法研究激光功率、扫描速度、扫描间距等工艺参数对激光选区熔化AlSi10Mg合金致密度的影响,当激光功率较低时,粉末容易产生球化效应,导致铺粉不均匀。张骁丽等[23]也提出球化严重将造成下一层表面更加粗糙,产生“连锁效应”,甚至终止成形;通过适当提高激光功率可以减少孔隙,最终确定的激光功率为160~180 W。扫描速度不宜过低或者过高,过低会引起部分蒸发气体残留在内部形成气孔,过高则导致粉末熔化不完全,极易产生大量孔隙,优化后的扫描速度为800~1100 mm/s,并且扫描间距为0.05 mm时成形效果最好。当然,获得高致密度零件的充分条件还包括足够的能量密度输入,但能量密度过高会引起过烧,一般在4.0~6.0 J/mm2之间合适。柯宇等[37]通过激光选区熔化制备的AlSi10Mg合金的平均致密度达到99.6%,并且分析了影响合金致密度的主要因素包括粉末碰撞飞溅、冷却速度快和氧化杂质;另外,作者还给出了工艺参数与致密度的优化云图,如图4所示,该结果为提高激光选区熔化铝合金及铝基复合材料的致密度提供了重要参考。

图4 激光选区熔化工艺参数与合金致密度的关系[37]

Fig. 4 Relationship between selective laser melting parameters and relative density of alloys[37]

重熔对合金表面粗糙度和孔隙率都有一定的影响,并且有利于表面光洁度的提高。YU等[38]分析两种重熔策略对激光选区熔化AlSi10Mg合金孔隙率的影响,发现重熔方向相同的样品中心区域和边缘区域的孔隙率显著降低,而重熔方向相反的样品总孔隙率较高,孔隙主要分布在边缘处。此外,重熔还可以促进残余颗粒的熔解,通过多次重熔循环,随着凝固层温度升高和再熔区温度梯度降低,残余应力也可以得到降低。对于致密度不高的激光选区熔化零件,裂纹一般在孔隙集中区域萌生并迅速扩展,最终导致断裂。合金的抗疲劳性能受残余气孔的控制,其次受强度和微观结构的影响[39]。

4.2 微观组织

微观组织直接决定激光选区熔化零件的性能,但激光选区熔化铝合金及铝基复合材料的微观组织形态复杂、形式多样。目前,为改善微观组织的一致性,主要采用工艺优化、颗粒掺杂和热处理等方式[4]。

SUWAS[40]研究激光选区熔化Al-12Si和AlSi10Mg合金的微观组织、织构和力学性能的演变规律,Al-12Si合金的微观组织由Al-Si共晶和初生α(Al)基体组成,微观组织较传统铸造细小,晶粒边界富集Si相;AlSi10Mg合金的微观组织与Al-12Si合金相似,晶粒边界以α(Al)为核心并且富集Si相,晶粒细化和固溶体的硬化有助于提升合金力学性能。朱小刚等[41]研究平行和垂直于激光选区熔化方向AlSi10Mg合金的微观组织,发现在平行方向有排列整齐的白色柱状晶穿插熔池区,而垂直方向的熔池则呈现椭圆形,在边缘区域分布着较为明显的沉淀相。

LI等[42]研究添加微量TiB2陶瓷颗粒(质量分数为1%)对激光选区熔化AlSi10Mg合金微观组织和性能的影响。与AlSi10Mg合金相比,TiB2颗粒增强复合材料的组织均匀,TiB2颗粒分布均匀,在增强颗粒与基体的界面处有少量Si颗粒析出,显微硬度分布更为稳定,拉伸强度、屈服强度和伸长率等性能都有所提升。胡亮等[43]研究TiB2含量对2024铝合金微观组织及力学性能的影响,质量分数为1%的纳米TiB2颗粒可以将晶粒尺寸由19.9 μm细化至4.25 μm,组织由柱状晶转化为短棒状和等轴状,力学性能得到提升,但当TiB2质量分数增加至3%时,晶粒细化效果减弱,TiB2颗粒出现团聚现象,综合力学性能急剧下降。

相比于工艺参数优化和纳米颗粒掺杂,热处理对改善激光选区熔化铝合金及铝基复合材料微观组织的研究较少。马如龙等[44]对激光选区熔化Al-4.0Mg-0.7Sc-0.4Zr-0.5Mn进行不同温度热处理(300、350和400 ℃),微观组织由柱状晶区和细等轴晶区组成,随着温度升高,组织没有发生明显的变化,但温度过高(>350 ℃)会导致Al3(Sc,Zr)和Al6Mn强化相长大,从而导致合金强度降低。

4.3 力学性能

力学性能是评价激光选区熔化工艺可行性的基础指标,目前关于激光选区熔化铝合金及铝基复合材料力学性能的研究主要集中在拉伸性能和疲劳性能两个方面。

在拉伸性能方面,SUBBIAH等[45]研究支撑结构、建造方向和后处理工艺对激光选区熔化AlSi10Mg合金力学性能的影响,与常规铸造试件相比,激光选区熔化成形件的抗拉强度为431.1 MPa,相对提高20%;极限抗拉强度的增加是由于快速凝固过程导致晶粒细化,更多的晶界可以阻止位错移动;但激光选区熔化样品的伸长率相对较低,这可能是由于样品中存在孔隙和未熔粉末;激光选区熔化成形件在550℃/2h热处理后,伸长率提高至未热处理样品的两倍。

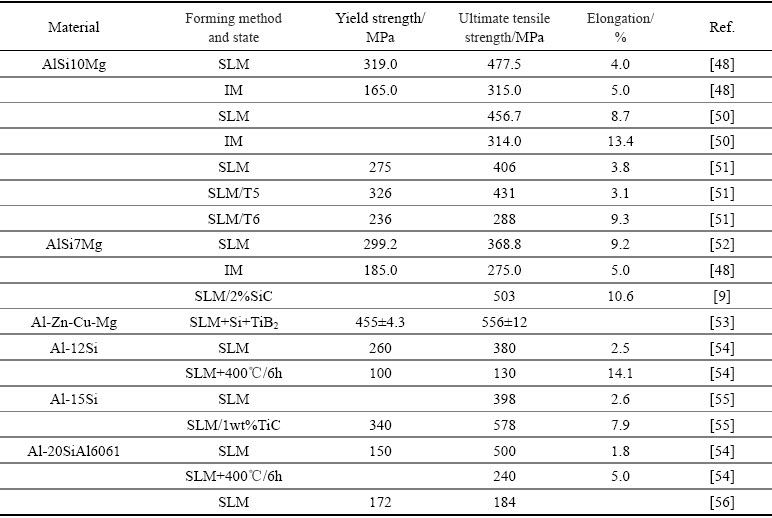

不同预热温度和扫描策略也影响着铝合金及铝基复合材料的力学性能,郭妙贤等[46]发现在棋盘式扫描路径下预热到120 ℃后获得的AlSi10Mg零件,抗拉强度和硬度均较高。CHEN等[47]开展AlSi10Mg合金的激光选区熔化成形研究,发现网状Al-Si共晶组织的生长方向不同,且横向强度和纵向强度没有明显区别,横向硬度(100HV)略高于纵向硬度(90HV)。表1中列出激光选区熔化和铸造(Ingot Metallurgy, IM)铝合金及铝基复合材料的部分力学性能。

在疲劳性能方面,邹田春等[48]研究激光选区熔化AlSi7Mg合金的高周疲劳性能,获得加载应力与疲劳寿命之间关系的曲线,加载应力与疲劳寿命大致呈线性关系,随着加载应力增大,疲劳寿命逐渐变短。AWD等[49]研究Al-Si和Ti-6Al4V两种轻量化合金的疲劳性能,通过微计算机断层扫描和负荷增加试验,验证重熔策略的有效性,并与热等静压试样进行对比,激光选区熔化合金的微观组织更加均匀,热导率更高,疲劳强度也更优异。

4.4 尺寸精度

尺寸精度是衡量机件的重要指标之一,为使零件具有可替换性,必须保证零件尺寸的一致性,即要求尺寸在某一合理的范围内。在复杂的精密金属零件制造领域,零件尺寸精度越高,零件的后处理时间越短,可以降低制造成本[57]。目前,国内外针对激光选区成型的几何尺寸精度的研究还比较少,且暂时没有激光选区成型尺寸设计规则供设计工程师参考。

付立定[58]初步研究了扫描速度、激光功率、扫描间距对激光选区成型件尺寸精度的影响。

杨永强等[59]为了实现薄壁零件的快速制造,利用Dimetal-280快速成型设备进行激光选区成型工艺试验,在优化工艺参数后得到变截面的薄壁零件,薄壁零件底部壁宽为142.0 μm,顶部壁宽为101.3 μm,与设计值相差分别为22.0 μm和21.3 μm,与极限值相吻合,分析表明成型设备成型零件壁厚的绝对误差极限值在20 μm左右。TANG等[60]通过选区激光熔化对铜基合金进行原型件制造,发现增加扫描间距有利于提高精度,而扫描层厚对成型件精度几乎没有影响。

表1 激光选区熔化铝合金及铝基复合材料的力学性能

Table 1 Mechanical properties of aluminum alloys and composites prepared by selective laser melting

5 激光选区熔化铝合金及铝基复合材料的后处理

为了提高运动部件的服役性能和可靠性,激光选区熔化铝合金及铝基复合材料通常需要经过适合的后处理以提高综合性能,例如采用热处理和表面重熔等方式来改变合金的微观组织,从而提高激光选区熔化铝合金及铝基复合材料的强度与韧性的配合。

5.1 热处理

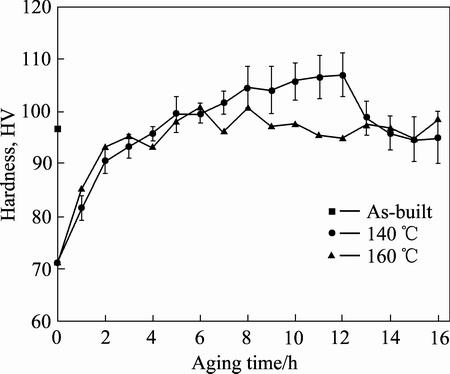

国内外针对激光选区熔化铝合金及铝基复合材料的后处理以固溶和时效(T6)热处理为主。CLEMENT等[61]对激光选区熔化AlSi10Mg合金拉伸试样进行T6热处理,包括在540 ℃、6 h固溶以及140 ℃和160 ℃人工时效1~16 h,时效后样品的微观组织沿晶界均匀分布。图5所示为两个试样在140℃和160℃下的时效硬度曲线。ZAKAY等[62]评估热处理温度对激光选区熔化AlSi10Mg合金腐蚀性能的影响,在300 ℃下进行热处理后,合金获得较好的抗应力腐蚀能力,这主要归因于激光选区熔化过程的快速凝固特点达到了应力释放的条件以及α(Al)基质和细Si网的稳定结合,但较高的热处理温度(400 ℃)会形成粗大的Si相和Mg2Si相颗粒,从而对合金腐蚀性能产生不利影响。

闫成鑫[63]研究T6热处理对AlSi10Mg合金微观组织和性能的影响,发现热处理后均匀网状Si相发生断裂、溶解,重新聚集成不规则形状或者成为细小弥散的Si相,并且随着热处理时间的增加,Si颗粒逐渐增大,颗粒数量逐渐减少[64]。合金抗拉强度和屈服强度均有所降低,但伸长率从6.4%增加至10.7%。

图5 激光选区熔化AlSi10Mg合金140 ℃和160 ℃时效处理的硬度曲线[61]

Fig. 5 Hardness curves of selective laser melted AlSi10Mgalloy aged at 140 ℃ and 160 ℃[61]

5.2 表面重熔

激光表面重熔(Laser surface remelting, LSR)工艺对激光选区熔化铝合金及铝基复合材料微观组织和力学性能具有一定的影响[65]。激光表面重熔工艺可以降低合金抗拉强度,提高合金显微硬度,同时通过晶粒长大和残余应力释放提高塑性,并且激光表面重熔有助于改善成形件的表面光洁度。

IRURRIOUZ等[66]通过测试对比不同热处理工艺下激光选区熔化AlSi10Mg合金的力学性能,从而确定了最佳性能组合的热处理工艺。此外,MATJEKE等[67]研究热处理时间对AlSi10Mg合金微观组织和力学性能的影响,结果表明随着应力消除时间的增加,变形性能得到改善,样品表现出更高的韧性。

5.3 变形加工

变形加工也是提高激光选区熔化材料综合性能的常用方法之一。热等静压(Hot isostatic pressing, HIP)可以有效降低零件的残余孔隙,并以牺牲合金强度的方式提高其抗疲劳性能,是提高激光选区熔化试样综合性能的途径之一。

SCHNELLER等[68]探讨热等静压处理对激光选区熔化AlSi10Mg合金微观组织和疲劳性能的影响,在经过高于固溶温度的热等静压处理和低温退火后,合金孔隙率显著降低,由于硅沉淀物在晶粒边界生长,晶粒边界变得模糊,硅沉淀物团聚体延缓裂纹缺陷的扩展,从而有效提高合金抗疲劳裂纹扩展的能力,并基于实验结果进一步阐述合金的断裂机理。根据FINFROCK[69]的研究结果,激光选区熔化并经过热等静压的复合材料具有较弱的(001)织构,并且热等静压处理可以有效消除激光选区熔化合金的内部和表面孔隙。

马如龙等[70]通过选区激光熔化制备Al-4.0Mg- 0.7Sc-0.4-Zr-0.5Mn合金,在冷轧和300 ℃退火1 h后,可以进一步细化选区激光熔化合金的微观组织,获得的平均晶粒尺寸为(2.4±1.3) μm,轧制合金强度的提高源自晶粒细化和高密度的Al3(Sc, Zr)相。此外,Al3(Sc, Zr)颗粒可以增强微观结构的稳定性。

6 激光选区熔化铝合金及复合材料的应用

随着激光选区熔化技术的飞速发展以及基础理论的不断深入,激光选区熔化铝合金及复合材料已经成功应用于航空航天、医疗生物和汽车制造等领域,并取得了良好的应用成效。

6.1 航空航天领域

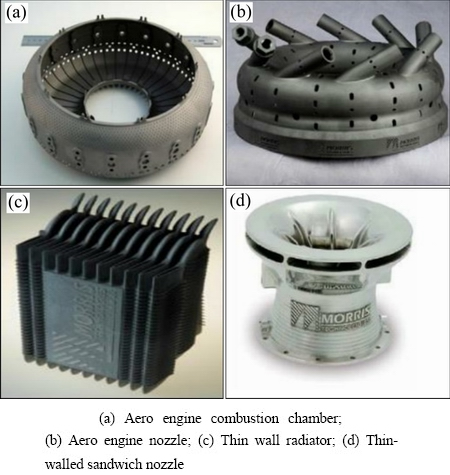

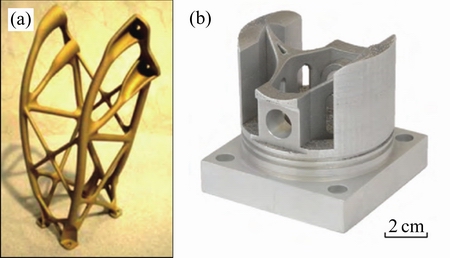

激光选区熔化技术具有表面质量好、制造精度高等特点,能够实现悬空、型面和复杂内腔的整体制造,是满足航天航空制造领域中复杂薄壁精密构件高性能的理想制造方法。在应用方面,美国通用电气公司率先成立激光选区熔化金属材料研发团队,并在2012年收购了Morris和RQM公司。图6为GE/Morris公司利用激光选区熔化技术制造的复杂结构金属零件[71]。

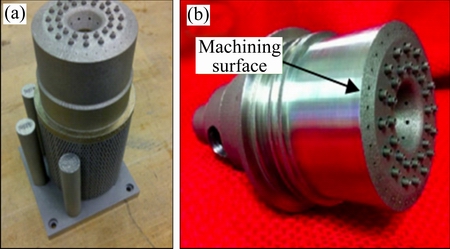

2013年,美国国家航空航天局马歇尔航天飞行中心(National Aeronautics and Space Administration’s Marshall Space Flight Center)利用激光选区熔化技术制备的喷注器成功应用于J-2X发动机,如图7所示[71]。

2015年,英国采用激光选区熔化技术制造的铝合金结构支架成功应用于Eurostar E3000卫星[72],如图8(a)所示。图8(b)所示为美国加州大学将纳米细化剂添加至铝合金粉末,采用激光选区熔化技术制备的高热裂敏感性6061铝合金[72]。

图6 典型激光选区熔化金属零件[71]

Fig. 6 Typical metal components prepared by selective laser melting[71]

图7 激光选区熔化喷注器和加工后样品[71]

Fig. 7 Selective laser melted injector(a) and parts after processing(b)[71]

图8 激光选区熔化航空航天铝合金结构支架零件和拓扑优化的6061合金活塞[72]

Fig. 8 Selective laser melted aerospace aluminum alloy structural support parts(a) and topology optimized 6061 alloy piston(b)[72]

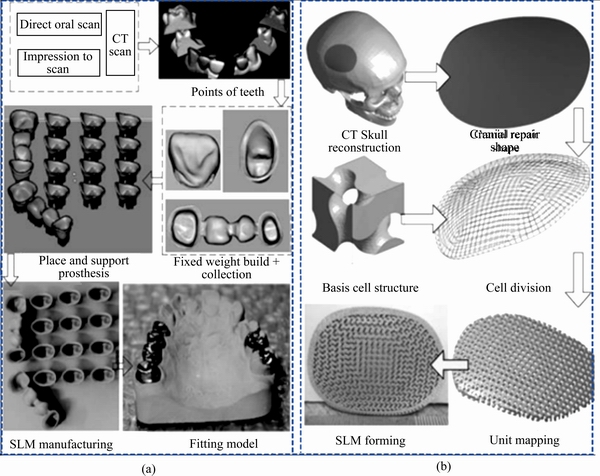

6.2 医疗生物领域

激光选区熔化技术在生物医疗领域的应用主要集中在人体骨骼假体、牙科、外科手术辅助工具等[73],医用激光选区熔化金属材料主要有316L不锈钢、CoCrMo合金和Ti6Al4V。考虑到金属材料与人体内部的排斥关系,激光选区熔化铝合金应用于医疗领域还鲜有报道。激光选区熔化技术可以以患者的需求为目的,设计出与宿主骨最相近的几何形貌。杨永强[74]阐述了牙冠牙桥、舌侧正畸托槽、手术导板、全膝置换股骨假体以及多孔植入体的激光选区熔化制造。图9所示为个性化牙冠牙桥激光选区熔化制造和颅骨多孔修复体设计与激光选区熔化制造。

6.3 汽车制造领域

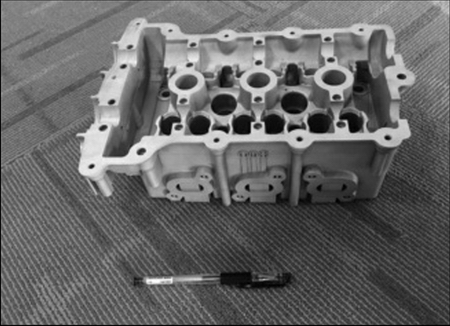

传统的开模铸造周期一般较长,影响研发效率,而且存在缩孔和内部微裂纹的问题,而激光选区熔化工艺可以快速制造出复杂的汽车构件,力学性能接近锻件水平。高志鹏等[75]针对研发效率问题提出一种发动机缸盖的激光选区熔化成形方案,并打印出发动机缸盖结构样件,如图10所示。

7 存在的问题及展望

图9 个性化牙冠牙桥激光选区熔化制造和激光选区熔化制造颅骨多孔修复设计[74]

Fig. 9 Individualized crown and bridge prepared by selective laser melting(a) and skull porous restoration design based on selective laser melting technology(b)[74]

图10 激光选区熔化铝合金发动机缸盖外观[75]

Fig. 10 Appearance of selective laser melted aluminum alloy engine cylinder head[75]

激光选区熔化技术与传统加工方式相比具有成型速率快、成型件性能优良等优势,但是目前铝合金及复合材料的激光选区熔化技术及其成形件的组织性能仍然存在一些问题,主要包括以下三个方面:

1) 适用于激光选区熔化的铝合金种类少。铝合金的激光吸收率小、热导率大,因此激光成形难度较大,目前适用于激光选区熔化成形的铝合金仍集中于Al-Si、Al-Cu、Al-Mg-Si和Al-Zn系传统铸造或可焊铝合金。

2) 激光选区熔化铝合金及复合材料的工艺条件还不成熟。激光选区熔化技术目前面临着设备水平、环境要求和研发成本高、成形效率低的问题,合金材料力学性能极大地受到成形过程中工艺参数和后热处理的影响,例如激光功率、扫描速度等工艺参数,对熔池温度和表面张力有显著影响,从而导致成形件的性能存在一致性差的问题。

3) 激光选区熔化铝合金及复合材料的冶金缺陷难以控制,包括:

① 球化现象。根据表面能的最小原理,液态金属在与基板接触不良时会收缩成表面张力驱动的球形。球化现象会导致凝固层表面粗糙,并伴有大量的孔洞,最终降低零件的致密度和性能。

② 孔隙。孔隙一般分为熔合误差、气孔和缩孔,孔隙的产生严格受到生产过程工艺参数的影响。

③ 残余应力和裂纹缺陷。激光选区熔化过程中的快速熔化和凝固导致更高的冷却速率和温度梯度,不均匀的热分布导致凝固结构的热膨胀和收缩,因此不可避免地产生高残余应力。

④ 氧化。尽管零件可以在氩气保护气氛中成形,但实际生产过程中仍然存在0.1%的氧气,主要是由粉末原料的部分氧化和熔池表面残留的氧气引起的,形成的Al2O3阻碍了粉末颗粒的熔化,氧化物夹杂还会引起裂纹萌生。

目前,传统牌号的合金成分制备的成形件已经很难获得所需的性能,因此需要扩大适用于激光选区熔化铝合金类型的范围,并设计成分适合于激光选区熔化工艺特征的新材料。在未来,对铝合金及复合材料的综合性能研究将非常重要。为了实现激光选区熔化工艺的制造灵活性,可以通过结合晶格和多孔结构以及其他复杂的零件几何形状。由于激光选区熔化技术本质上是跨学科的,成形零件应用领域较为广泛,因此有意义的是将激光选区熔化的优势与机械和结构设计相结合,以实现从设计到制造完整结构或功能组件的完整过程。

REFERENCES

[1] 马如龙, 彭超群, 王日初, 等. 选区激光熔化铝合金的研究进展[J]. 中国有色金属学报, 2020, 30(12): 2773-2788.

MA Ru-long, PENG Chao-qun, WANG Ri-chu, et al. Research progress of selective laser melting of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(12): 2773-2788.

[2] SAMES W J, LIST F A, PANNALA S, DEHOFF R R, BABU S S. The metallurgy and processing science of metal additive manufacturing[J]. International Materials Reviews, 2016, 61(5): 315-360.

[3] ABOULKHAIR N T, SIMONELLI M, PARRY L, et al. 3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting[J]. Progress in Materials Science, 2019, 106.

[4] 苗秋玉, 刘妙然, 赵 凯, 等. 铝合金增材制造技术研究进展[J]. 激光与光电子学进展, 2018, 1(55): 56-88.

MIAO Qiu-yu, LIU Miao-ran, ZHAO Kai, et al. Research progress of aluminum alloy additive manufacturing technology[J]. Progress in Laser and Optoelectronics, 2018, 1(55): 56-88.

[5] LIU Yang, YANG Yong-qiang, WANG Di. A study on the residual stress during selective laser melting (SLM) of metallic powder[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87(1/4): 647-656.

[6] UZAN N E, RATZKER B, LANDAU P, et al. Compressive creep of AlSi10Mg parts produced by selective laser melting additive manufacturing technology[J]. Additive Manufacturing, 2019, 29.

[7] XI L, WANG P, PRASHANTH K G, et al. Effect of TiB2 particles on microstructure and crystallographic texture of Al-12Si fabricated by selective laser melting[J]. Journal of Alloys and Compounds, 2019, 786: 551-556.

[8] ZHAO Xuan, GU Dong-dong, MA Cheng-long, et al. Microstructure characteristics and its formation mechanism of selective laser melting SiC reinforced Al-based composites[J]. Vacuum, 2019, 160: 189-196.

[9] WANG Ming, SONG Bo, WEI Qing-song, et al. Improved mechanical properties of AlSi7Mg/nano-SiC p composites fabricated by selective laser melting[J]. Journal of Alloys and Compounds, 2019, 810.

[10] 高文英, 王 凯, 张伟强, 等. 选区熔化成形铝合金技术研究进展[J]. 热加工工艺, 2020, (18): 17-20.

GAO Wen-ying, WANG Kai, ZHANG Wei-qiang, et al. Research progress in selective melting forming of aluminum alloys[J]. Hot Processing Technology, 2020, (18): 17-20.

[11] 姜海燕, 林卫凯, 吴世彪, 等. 激光选区熔化技术的应用现状及发展趋势[J]. 机械工程与自动化, 2019(5): 223-226.

JIANG Hai-yan, LIN Wei-kai, WU Shi-biao, et al. Application status and development trend of selective laser melting technology[J]. Mechanical Engineering and Automation, 2019(5): 223-226.

[12] 张冬云. 采用区域选择激光熔化法制造铝合金模型[J]. 中国激光, 2007(12): 1700-1704.

ZHANG Dong-yun. Using area selective laser melting method to manufacture aluminum alloy model[J]. China Laser, 2007(12): 1700-1704.

[13] 耿遥祥, 樊世敏, 简江林, 等. 选区激光熔化专用AlSiMg合金成分设计及力学性能[J]. 金属学报, 2020, 56(6): 821-830.

GENG Yao-xiang, FAN Shi-min, JIAN Jiang-lin, et al. Composition design and mechanical properties of AlSiMg alloy for selective laser melting[J]. Acta Metallurgica Sinica, 2020, 56(6): 821-830.

[14] BAJAJ P, WRIGHT J, TODD I, et al. Predictive process parameter selection for Selective Laser Melting Manufacturing: Applications to high thermal conductivity alloys[J]. Additive Manufacturing, 2019, 27: 246-258.

[15] WANG P, ECKERT J, PRASHANTH K G, et al. A review of particulate-reinforced aluminum matrix composites fabricated by selective laser melting[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(8): 2001-2034.

[16] PRAMOD S L, BAKSHI S R, MURTY B S. Aluminum- based cast in situ composites: A review[J]. Journal of Materials Engineering and Performance, 2015, 24(6): 2185-2207.

[17] XIAO Y K, BIAN Z Y, WU Y, et al. Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting[J]. Journal of Alloys and Compounds, 2019, 798: 644-655.

[18] LI X P, JI G, CHEN Z, et al. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility[J]. Acta Materialia, 2017, 129: 183-193.

[19] ZHANG Bi, LI Yong-tao, BAI Qian. Defect formation mechanisms in selective laser melting: A review[J]. Chinese Journal of Mechanical Engineering, 2017, 30(3): 515-527.

[20] 许 德, 高华兵, 董 涛, 等. 增材制造用金属粉末研究进展[J]. 中国有色金属学报, 2021, 31(2): 245-257.

XU De, GAO Hua-bing, DONG Tao, et al. Research progress of metal powder for additive manufacturing[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 245-257.

[21] 唐鹏钧, 何晓磊, 杨 斌, 等. 激光选区熔化用AlSi10Mg粉末显微组织与性能[J]. 航空材料学报, 2018, 38(1): 47-53.

TANG Peng-jun, HE Xiao-lei, YANG Bin, et al. Microstructure and properties of AlSi10Mg powder for selective laser melting[J]. Journal of Aeronautical Materials, 2018, 38(1): 47-53.

[22] BAITIMEROV R, LYKOV P, ZHEREBTSOV D, et al. Influence of powder characteristics on processability of AlSi12 alloy fabricated by selective laser melting[J]. Materials (Basel), 2018, 11(5).

[23] 张骁丽, 齐 欢, 魏青松. 铝合金粉末选择性激光熔化成形工艺优化试验研究[J]. 应用激光, 2013, 33(4): 391-397.

ZHANG Xiao-li, QI Huan, WEI Qing-song. Experimental study on optimization of selective laser melting forming process for aluminum alloy powder[J]. Applied Laser, 2013, 33(4): 391-397.

[24] 邹亚桐, 魏正英, 杜 军, 等. AlSi10Mg激光选区熔化成形工艺参数对致密度的影响与优化[J]. 应用激光, 2016, 36(6): 656-662.

ZOU Ya-tong, WEI Zheng-ying, DU Jun, et al. The influence and optimization of AlSi10Mg selective laser melting forming process parameters on density[J]. Applied Laser, 2016, 36(6): 656-662.

[25] TONELLI L, LIVERANI E, VALLI G, et al. Effects of powders and process parameters on density and hardness of A357 aluminum alloy fabricated by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106(9).

[26] 张红昌, 宋 彬, 邢 明. 2024铝合金粉末选区激光熔化成形工艺研究[J]. 铸造技术, 2020, 41(1): 22-24.

ZHANG Hong-chang, SONG Bin, XING Ming. Research on selective laser melting process of 2024 aluminum alloy powder[J]. Casting Technology, 2020, 41(01): 22-24.

[27] 张文奇, 朱海红, 胡志恒, 等. AlSi10Mg的激光选区熔化成形研究[J]. 金属学报, 2017, 53(8): 918-926.

ZHANG Wen-qi, ZHU Hai-hong, HU Zhi-heng, et al. Research on selective laser melting forming of AlSi10Mg[J]. Acta Metall Sinica, 2017, 53(8): 918-926.

[28] HANEMANN T, CARTER L N, HABSCHIED M, et al. In-situ alloying of AlSi10Mg+Si using selective laser melting to control the coefficient of thermal expansion[J]. Journal of Alloys and Compounds, 2019, 795: 8-18.

[29] MAJEED A, MUZAMIL M, Lü J, et al. Heat treatment influences densification and porosity of AlSi10Mg alloy thin-walled parts manufactured by selective laser melting technique[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2019, 41(6).

[30] ZHU Yi, ZOU Jun, YANG Hua-yong. Wear performance of metal parts fabricated by selective laser melting: a literature review[J]. Journal of Zhejiang University-SCIENCE A. 2018, 19(2): 95-110.

[31] DADBAKHSH S, HAO L. Effect of layer thickness in selective laser melting on microstructure of Al/5wt.%Fe2O3 powder consolidated parts[J]. Scientific World Journal. 2014, 2014: 106129.

[32] MAAMOUN A H, XUE Y F, ELBESTAWI M A, et al. Effect of selective laser melting process parameters on the quality of al alloy parts: powder characterization, density, surface roughness, and dimensional accuracy[J]. Materials (Basel), 2018, 11(12).

[33] THIJS L, VERHAEGHE F, CRAEGHS T, et al. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V[J]. Acta Materialia, 2010, 58(9): 3303-3312.

[34] VALENTE E H, GUNDLACH C, CHRISTIANSEN T L, et al. Effect of scanning strategy during selective laser melting on surface topography, porosity, and microstructure of additively manufactured Ti-6Al-4V[J]. Applied Sciences, 2019, 9(24).

[35] MUGWAGWA L, DIMITROV D, MATOPE S, et al. Evaluation of the impact of scanning strategies on residual stresses in selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(5/8): 2441-2450.

[36] ZHANG Jin-liang, SONG Bo, WEI Qing-song, et al. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends[J]. Journal of Materials Science & Technology, 2019, 35(2): 270-284.

[37] 柯 宇, 马 盼, 马永超, 等. 激光选区熔化AlSi10Mg合金微观组织及力学性能研究[J]. 应用激光, 2019, 39(2): 198-203.

KE Yu, MA Pan, MA Yong-chao, et al. Study on the microstructure and mechanical properties of AlSi10Mg alloy by selective laser melting[J]. Applied Laser, 2019, 39(2): 198-203.

[38] YU Wen-hui, SING S L, CHUA C K, et al. Influence of re-melting on surface roughness and porosity of AlSi10Mg parts fabricated by selective laser melting[J]. Journal of Alloys and Compounds, 2019, 792.

[39] TANG Ming, PISTORIUS P C. Fatigue life prediction for AlSi10Mg components produced by selective laser melting[J]. International Journal of Fatigue, 2019, 125: 479-490.

[40] SUWAS S, KUMAR D. Microstructure-texture-mechanical property relationship in alloys produced by additive manufacturing following selective laser melting (SLM) technique[J]. Transactions of the Indian National Academy of Engineering, 2020, 5(1): 1-10.

[41] 朱小刚, 孙 靖, 王联凤, 等. 激光选区熔化成形铝合金的组织、性能与倾斜面成形质量[J]. 机械工程材料, 2017, 41(02): 77-80.

ZHU Xiao-gang, SUN Jing, WANG Lian-feng, et al. Microstructure, properties and forming quality of inclined surface of aluminum alloy formed by selective laser melting[J]. Materials for Mechanical Engineering, 2017, 41(2): 77-80.

[42] LI Yuxin, GU Dong-dong, ZHANG Han, et al. Effect of trace addition of ceramic on microstructure development and mechanical properties of selective laser melted AlSi10Mg alloy[J]. Chinese Journal of Mechanical Engineering, 2020, 33(1).

[43] 胡 亮, 刘允中, 涂 诚, 等. 纳米TiB2对激光选区熔化2024铝合金显微组织与力学性能的影响[J]. 粉末冶金材料科学与工程, 2019, 24(4): 365-373.

HU Liang, LIU Yun-zhong, TU Cheng, et al. Effect of nano-TiB2 on the microstructure and mechanical properties of 2024 aluminum alloy by selective laser melting[J]. Powder Metallurgy Materials Science and Engineering, 2019, 24(4): 365-373.

[44] MA Ru-long, PENG Chao-qun, CAI ZHI-yong, et al. Manipulating the microstructure and tensile properties of selective laser melted Al-Mg-Sc-Zr alloy through heat treatment[J]. Journal of Alloys and Compounds, 2020, 154773.

[45] SUBBIAH R, BENSINGH J, KADER A, et al. Influence of printing parameters on structures, mechanical properties and surface characterization of aluminium alloy manufactured using selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106(11/12): 5137-5147.

[46] GUO Miao-xian, YE Yi, JIANG Xiao-hui, et al. Microstructure, mechanical properties and residual stress of selective laser melted AlSi10Mg[J]. Journal of Materials Engineering and Performance, 2019, 28(11): 6753-6760.

[47] CHEN Jing, HOU Wei, WANG Xiu-zhuan, et al. Microstructure, porosity and mechanical properties of selective laser melted AlSi10Mg[J]. Chinese Journal of Aeronautics, 2020, 33(7): 2043-2054.

[48] 邹田春, 陈敏英, 祝 贺, 等. 激光选区熔化AlSi7Mg合金高周疲劳性能研究[J]. 激光与光电子学进展, 1-13.

ZOU Tian-chun, CHEN Min-ying, ZHU He, et al. Research on high-cycle fatigue performance of selective laser melting of AlSi7Mg alloy[J]. Progress in Laser and Optoelectronics, 1-13.

[49] AWD M, JOHANNSEN J, CHAN T, et al. In improvement of fatigue strength in lightweight selective laser melted alloys by in-situ and ex-situ composition and heat treatment, Cham, Springer International Publishing: Cham, 2020: 115-126.

[50] YAN Qian, SONG Bo, SHI Yu-sheng. Comparative study of performance comparison of AlSi10Mg alloy prepared by selective laser melting and casting[J]. Journal of Materials Science & Technology, 2020, 41: 199-208.

[51] PELLIZZARI M, MALFATTI M, LORA C, et al. Properties of laser metal fused AlSi10Mg alloy processed using different heat treatments[J]. BHM Bergund Hüttenmannische Monatshefte, 2020, 165(3): 164-168.

[52] WANG Min, SONG Bo, WEI Qing-song, et al. Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy[J]. Materials Science and Engineering A, 2019, 739: 463-472.

[53] ZHOU S Y, SU Y, WANG H, et al. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: Cracking elimination by co-incorporation of Si and TiB2[J]. Additive Manufacturing, 2020, 36.

[54] ZHANG Shi-kai, MA Pan, JIA Yan-dong, et al. Microstructure and mechanical properties of Al-(12-20)Si Bi-material fabricated by selective laser melting[J]. Materials (Basel), 2019, 12(13).

[55] ZHOU Yan, WEN Shi-feng, WANG Chong, et al. Effect of TiC content on the Al-15Si alloy processed by selective laser melting: Microstructure and mechanical properties[J]. Optics & Laser Technology, 2019, 120.

[56] MAAMOUN A H, XUE Y F, ELBESTAWI M A, et al. The effect of selective laser melting process parameters on the microstructure and mechanical properties of Al6061 and AlSi10Mg alloys[J]. Materials (Basel), 2018, 12(1).

[57] 杨永强, 卢建斌, 王 迪, 等. 316L不锈钢选区激光熔化成型非水平悬垂面研究[J]. 材料科学与工艺, 2011, 19(6): 94-99.

YANG Yong-qiang, LU Jian-bin, WANG Di, et al. A study of 316L stainless steel non-horizontal overhanging surface in selective laser melting[J]. Material Science & Technology, 2011, 19(6): 94-99.

[58] 付立定. 不锈钢粉末选择性激光熔化直接制造金属零件研究[D]. 武汉: 华中科技大学, 2008.

FU Li-ding. Investigation into manufacturing metal parts direct from stainless steel powders via selective laser melting[D]. Wuhan: Huazhong University of Science & Technology, 2008.

[59] 杨永强, 罗子艺, 苏旭彬, 等. 不锈钢薄壁零件选区激光熔化制造及影响因素研究[J]. 中国激光, 2011, 38(1): 60-67.

YANG Yong-qiang, LUO Zi-yi, SU Xu-bin, et al. Study on process and effective factors of stainless steel thin-wall parts manufactured by selective laser melting[J]. Chinese J Lasers, 2011, 38(1): 0103001.

[60] TANG Y, LOHA H T, WONG Y S, et al. Direct laser sintering of a copper-based alloy for creating three-dimensional metal parts[J]. Jounal of Materials Processing Technology, 2003, 140(1): 368-372.

[61] CLEMENT C D, MASSON J, KABIR A S. On the heat treatment of AlSi10Mg fabricated by selective laser melting process[C]// TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, 2020: 425-434.

[62] ZAKAY A, AGHION E. Effect of post-heat treatment on the corrosion behavior of AlSi10Mg alloy produced by additive manufacturing[J]. JOM, 2019, 71(3): 1150-1157.

[63] 闫成鑫, 张惠帝, 于宝义, 等. SLM成形和热处理对AlSi10Mg合金组织与性能的影响[J]. 特种铸造及有色合金, 2020, 40(2): 160-164.

YAN Cheng-xin, ZHANG Hui-di, YU Bao-yi, et al. The influence of SLM forming and heat treatment on the structure and properties of AlSi10Mg alloy[J]. Special Casting & Nonferrous Alloys. 2020, 40(2): 160-164.

[64] 袁广辰, 卢 云, 郑学儒. T6热处理对选择性激光熔化AlSi10Mg合金组织和力学性能的影响[J]. 热加工工艺, 1-6.

YUAN Guang-chen, LU Yun, ZHENG Xue-ru. Effect of T6 heat treatment on microstructure and mechanical properties of selective laser melting AlSi10Mg alloy[J]. Hot Processing Technology, 1-6.

[65] HAN Quan-quan, JIAO Yang. Effect of heat treatment and laser surface remelting on AlSi10Mg alloy fabricated by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9/12): 3315-3324.

[66] ITURRIOZ A, GIL E, PETITE M M, GARCIANDIA F, et al. Selective laser melting of AlSi10Mg alloy: influence of heat treatment condition on mechanical properties and microstructure[J]. Welding in the World, 2018, 62(4): 885-892.

[67] MATJEKE V J, MOOPANAR C, BOLOKANG A S, et al. Effect of heat treatment time on the microstructure and mechanical deformation behavior of additive-manufactured AlSi10Mg components[J]. Progress in Additive Manufacturing, 2020.

[68] SCHNELLER W, LEITNER M, SPRINGER S, et al. Effect of HIP treatment on microstructure and fatigue strength of selectively laser melted AlSi10Mg[J]. Journal of Manufacturing and Materials Processing, 2019, 3(1).

[69] FINFROCK C B, EXIL A, CARROLL J D, et al. Effect of hot isostatic pressing and powder feedstock on porosity, microstructure, and mechanical properties of selective laser melted AlSi10Mg[J]. Metallography, Microstructure, and Analysis, 2018, 7(4).

[70] MA Ru-long, PENG Chao-qun, CAI Zhi-yong, et al. Enhanced strength of the selective laser melted Al-Mg-Sc-Zr alloy by cold rolling[J]. Materials Science & Engineering A, 2020, 775.

[71] 董 鹏, 陈济轮. 国外选区激光熔化成形技术在航空航天领域应用现状[J]. 航天制造技术, 2014(1): 1-5.

DONG Peng, CHEN Ji-lun. The application status of foreign selected laser melting forming technology in the aerospace field[J]. Aerospace Manufacturing Technology, 2014(1): 1-5.

[72] 甘武奎, 彭金贵, 李仕豪, 等. 铝合金选区激光熔化精密成形及其在航空领域的应用[J]. 航空制造技术, 2019, 62(16): 53-63.

GAN Wu-kui, PENG Jin-gui, LI Shi-hao, et al. Selective laser melting precision forming of aluminum alloy and its application in aviation[J]. Aviation Manufacturing Technology, 2019, 62(16): 53-63.

[73] 杨永强. 激光选区熔化在医学领域应用前景广阔[J]. 信息技术时代, 2013(6): 40-42.

YANG Yong-qiang. The application prospects of selective laser melting in the medical field are broad[J]. Information Technology Times, 2013(6): 40-42.

[74] 杨永强, 宋长辉, 王 迪. 激光选区熔化技术及其在个性化医学中的应用[J]. 机械工程学报, 2014, 50(21): 140-151.

YANG Yong-qiang, SONG Chang-hui, WANG Di. Selective laser melting technology and its application in personalized medicine[J]. Chinese Journal of Mechanical Engineering, 2014, 50(21): 140-151.

[75] 高志鹏, 明平才, 卿辉斌, 等. 铝合金汽车发动机缸盖复杂结构的SLM制造工艺研究[J]. 新技术新工艺, 2019(9): 24-30.

GAO Zhi-peng, MING Ping-cai, QING Hui-bin, et al. Research on SLM manufacturing process of aluminum alloy automobile engine cylinder head with complex structure[J]. New Technology and New Process, 2019(9): 24-30.

Progress in aluminum alloys and composites fabricated by selective laser melting

CAI Zhi-yong1, 2, LIU Hai-jiang1, WANG Ri-chu1, 2, 3, PENG Chao-qun1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410000, China;

2. Key Laboratory of Electronic Packaging and Advanced Functional Materials, Changsha 410083, China;

3. National Key Laboratory of Science and Technology for National Defence on High-strength Structural Materials, Central South University, Changsha 410083, China)

Abstract: Aluminum alloys and composites have the characteristics of low density, high specific strength, and excellent corrosion resistance. The selective laser melting technology is applied to the structure-function integrated aluminum alloys and composites with precise and complex structure, which have broad application prospects in aerospace, transportation, electronic devices and so on. This article mainly introduces the research, development, and application of selective laser melting of aluminum alloys and composites at home and abroad. Firstly, it explains the basic principles of selective laser melting technology. Secondly, it introduces the main process parameters of selective laser melting, the microstructure of aluminum alloys and composites, performances and post-processing technology, and the key applications of selective laser melting of aluminum alloys and composites. Finally, it describes and prospects the main problems faced by selective laser melting of aluminum alloys and composites.

Key words: selective laser melting; aluminum alloy; aluminum matrix composite; relative density; mechanical property

Foundation item: Project(51804349) supported by the National Natural Science Foundation of China; Project (2018M632986) supported by China Postdoctoral Science Foundation; Project(2019JJ50766) supported by the Natural Science Foundation of Hunan Province, China; Project(JCKY201851) supported by 轻质高强结构材料国防重点实验室开放基金资助项目

Received date: 2020-11-13; Accepted date: 2021-05-07

Corresponding author: WANG Ri-chu; Tel: +86-731-88836638; E-mail: wrccsu@163.com

(编辑 )

基金项目:国家自然科学基金资助项目(51804349);中国博士后科学基金资助项目(2018M632986);湖南省自然科学基金资助项目(2019JJ50766);轻质高强结构材料国防重点实验室开放基金资助项目(JCKY201851)

收稿日期:2020-11-13;修订日期:2021-05-07

通信作者:王日初,教授,博士;电话:0731-88836638;E-mail:wrccsu@163.com

摘 要:铝合金及铝基复合材料具有密度小、比强度高、耐腐蚀性能优异等特点,将激光选区熔化技术应用于制备结构-功能一体化铝合金及铝基复合材料精密复杂构件,在航空航天、交通运输、电子器件等领域具有广阔的应用前景。本文主要介绍国内外激光选区熔化铝合金及铝基复合材料的研究、开发及应用情况。首先,阐述激光选区熔化技术的基本原理;其次,分析激光选区熔化的主要工艺参数、铝合金及铝基复合材料的微观组织、宏观性能以及后处理工艺等,并概述激光选区熔化铝合金及铝基复合材料的主要应用情况;最后,阐述激光选区熔化铝合金及铝基复合材料面临的主要问题并进行展望。

[1] 马如龙, 彭超群, 王日初, 等. 选区激光熔化铝合金的研究进展[J]. 中国有色金属学报, 2020, 30(12): 2773-2788.

[4] 苗秋玉, 刘妙然, 赵 凯, 等. 铝合金增材制造技术研究进展[J]. 激光与光电子学进展, 2018, 1(55): 56-88.

[10] 高文英, 王 凯, 张伟强, 等. 选区熔化成形铝合金技术研究进展[J]. 热加工工艺, 2020, (18): 17-20.

[11] 姜海燕, 林卫凯, 吴世彪, 等. 激光选区熔化技术的应用现状及发展趋势[J]. 机械工程与自动化, 2019(5): 223-226.

[12] 张冬云. 采用区域选择激光熔化法制造铝合金模型[J]. 中国激光, 2007(12): 1700-1704.

[13] 耿遥祥, 樊世敏, 简江林, 等. 选区激光熔化专用AlSiMg合金成分设计及力学性能[J]. 金属学报, 2020, 56(6): 821-830.

[20] 许 德, 高华兵, 董 涛, 等. 增材制造用金属粉末研究进展[J]. 中国有色金属学报, 2021, 31(2): 245-257.

[21] 唐鹏钧, 何晓磊, 杨 斌, 等. 激光选区熔化用AlSi10Mg粉末显微组织与性能[J]. 航空材料学报, 2018, 38(1): 47-53.

[23] 张骁丽, 齐 欢, 魏青松. 铝合金粉末选择性激光熔化成形工艺优化试验研究[J]. 应用激光, 2013, 33(4): 391-397.

[24] 邹亚桐, 魏正英, 杜 军, 等. AlSi10Mg激光选区熔化成形工艺参数对致密度的影响与优化[J]. 应用激光, 2016, 36(6): 656-662.

[26] 张红昌, 宋 彬, 邢 明. 2024铝合金粉末选区激光熔化成形工艺研究[J]. 铸造技术, 2020, 41(1): 22-24.

[27] 张文奇, 朱海红, 胡志恒, 等. AlSi10Mg的激光选区熔化成形研究[J]. 金属学报, 2017, 53(8): 918-926.

[37] 柯 宇, 马 盼, 马永超, 等. 激光选区熔化AlSi10Mg合金微观组织及力学性能研究[J]. 应用激光, 2019, 39(2): 198-203.

[41] 朱小刚, 孙 靖, 王联凤, 等. 激光选区熔化成形铝合金的组织、性能与倾斜面成形质量[J]. 机械工程材料, 2017, 41(02): 77-80.

[43] 胡 亮, 刘允中, 涂 诚, 等. 纳米TiB2对激光选区熔化2024铝合金显微组织与力学性能的影响[J]. 粉末冶金材料科学与工程, 2019, 24(4): 365-373.

[48] 邹田春, 陈敏英, 祝 贺, 等. 激光选区熔化AlSi7Mg合金高周疲劳性能研究[J]. 激光与光电子学进展, 1-13.

[57] 杨永强, 卢建斌, 王 迪, 等. 316L不锈钢选区激光熔化成型非水平悬垂面研究[J]. 材料科学与工艺, 2011, 19(6): 94-99.

[58] 付立定. 不锈钢粉末选择性激光熔化直接制造金属零件研究[D]. 武汉: 华中科技大学, 2008.

[59] 杨永强, 罗子艺, 苏旭彬, 等. 不锈钢薄壁零件选区激光熔化制造及影响因素研究[J]. 中国激光, 2011, 38(1): 60-67.

[63] 闫成鑫, 张惠帝, 于宝义, 等. SLM成形和热处理对AlSi10Mg合金组织与性能的影响[J]. 特种铸造及有色合金, 2020, 40(2): 160-164.

[64] 袁广辰, 卢 云, 郑学儒. T6热处理对选择性激光熔化AlSi10Mg合金组织和力学性能的影响[J]. 热加工工艺, 1-6.

[71] 董 鹏, 陈济轮. 国外选区激光熔化成形技术在航空航天领域应用现状[J]. 航天制造技术, 2014(1): 1-5.

[72] 甘武奎, 彭金贵, 李仕豪, 等. 铝合金选区激光熔化精密成形及其在航空领域的应用[J]. 航空制造技术, 2019, 62(16): 53-63.

[73] 杨永强. 激光选区熔化在医学领域应用前景广阔[J]. 信息技术时代, 2013(6): 40-42.

[74] 杨永强, 宋长辉, 王 迪. 激光选区熔化技术及其在个性化医学中的应用[J]. 机械工程学报, 2014, 50(21): 140-151.

[75] 高志鹏, 明平才, 卿辉斌, 等. 铝合金汽车发动机缸盖复杂结构的SLM制造工艺研究[J]. 新技术新工艺, 2019(9): 24-30.