文章编号:1004-0609(2016)-10-2065-06

1561铝合金双面双弧TIG焊接接头的组织和力学性能

闫德俊1, 2,韩端锋1,王 毅2,罗玖强2,刘晓莉2,梁志敏3

(1. 哈尔滨工程大学 船舶工程学院,哈尔滨 150003;

2. 中船黄埔文冲船舶有限公司,广州 510715;

3. 河北科技大学 材料科学与工程学院,石家庄 050018)

摘 要:

采用双面双弧错位TIG填丝立向焊工艺对1561高镁铝合金进行焊接,并对接头的显微组织和力学性能进行分析。结果表明:焊缝中无气孔和裂纹缺陷;1561铝合金双面双弧错位立向焊缝横截面存在着“人”字形粗晶区,粗晶区两侧和下方有细晶区,同时,在部分熔化区出现了范围较窄的粗晶区;正反面焊道的显微硬度均低于母材的,但热影响区并没有表现出明显的软化现象。焊接接头的抗拉强度达到了母材的90%以上,力学性能良好;接头粗晶区的存在与双面双弧错位TIG焊的温度场和熔池流场有关。

关键词:

中图分类号:TG444 文献标志码:A

铝镁合金具有密度小、比强度大、耐海水腐蚀性好、无磁性、低温性能好等优点。用其作船体材料可以有效地减轻船舶的质量,提高稳定性和航速,增强舰艇的技术战术性能。对于高速滑行艇、水翼艇、登陆艇、小水面船及一些特殊用途船,选用铝镁合金尤为适宜。俄制1561铝合金因具有强度高、耐腐蚀性好等优点,被应用于特种铝合金船舶中[1]。

双面双弧焊接具有效率高、免除清根、工序简化、焊后残余应力和变形小等优点,近年来受到高度关注[2-4],在船舶领域逐渐展开应用[5]。大多数学者主要研究了双面双弧TIG焊的工艺性、焊缝的力学性能,铝合金焊缝的组织特征主要集中在基体与第二项粒子上,而对于铝合金双面双弧TIG焊缝的晶粒特征研究较少[6-9],WECKMAN等[10]研究了等离子与TIG两种方法的平-仰双面焊接的焊缝组织特征。因此,本文作者针对新型1561高强铝镁合金双面双弧TIG同步错位立焊焊接工艺进行研究,重点研究立焊接头不同区域的组织分布特点和显微硬度分布。本研究对指导铝质船舶双面双弧TIG填丝立焊工艺具有重要意义。

1 实验

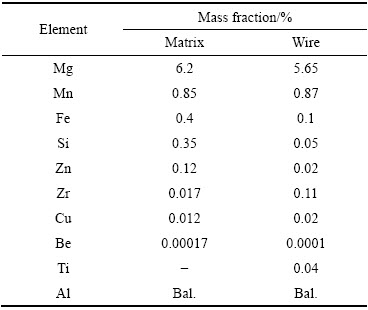

该合金镁含量高,易生成Al2O3和MgO氧化膜,MgO含量越高,形成的氧化膜越不致密,更易于吸收水分而促使气孔产生。故焊前对铝板及焊丝(指未经光亮化处理)表面上的油污、氧化膜等进行化学清理,尤其是容易产生气孔的母材的坡口部位。为了提高焊缝质量、防止气孔、夹杂等缺陷产生,焊前对坡口及两侧50 mm范围内用丙酮溶液进行擦拭,保证没有残留油污。采用双人双面同步TIG填丝焊工艺,如图1所示,由两名焊工各持一把TIG焊枪,正反面同时进行施焊、同时填丝。母材规格为400 mm×150 mm×4 mm的铝板,采用机械方式开双V型坡口,坡口角度为 60°、无钝边,装配间隙 1.5~2 mm。1561高强铝合金及焊丝的实际化学成分如表1所列,Mg为主要合金元素,Mn含量较低,其次为Fe、Si等杂质元素,1561铝合金属于5×××系列高镁铝合金。本试验中采用两台福尼斯脉冲TIG焊机,保护气为99.995%纯Ar。

图1 1561铝合金双面双弧焊接照片

Fig. 1 Double-sided arc welding photo for 1561 aluminum alloy

表1 1561铝合金母材与焊丝化学成分

Table 1 Chemical composition of 1561 aluminum alloy and wire (mass fraction, %)

经过多次试验发现,前面电弧焊接电流为85~90 A、后面电弧焊接电流为65~70 A,焊接速度为1.6~1.8 mm/s,两个电弧间距离为4 mm左右时焊缝成型最好。

采用蔡司光学显微镜观察了1561铝合金双面双弧TIG立焊接头金相组织特征,并利用显微硬度计测定双面双弧TIG焊焊接接头硬度分布规律。

2 结果与分析

2.1 焊接接头微区的显微组织

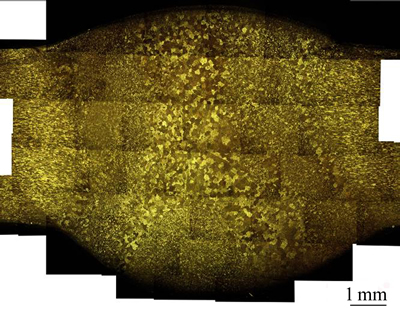

镁含量高达6%的1561铝合金采用双面双弧TIG立向焊接工艺后,经X射线拍片检查,气孔率大大降低,夹杂、咬边等缺陷也很少,达到船级社I级焊缝标准。对该焊接接头的横端面进行取样观察,将多张显微组织照片拼合后获得的金相组织宏观照片如图2所示。由图2可以看出,焊缝中没有气孔等缺陷。根据图2可以将焊缝组织分成5个区域,分别为中心 “人”字形粗晶区,粗晶区外侧的两个细晶区,熔合线附近部分熔化区的两个粗晶区,“人”字形粗晶区下方所包围的细晶区。粗晶区尺寸高达100 μm以上,细晶区尺寸仅为30 μm左右,表现出严重的组织非均匀性[11]。

图2 1561铝合金双面双弧焊接接头的显微组织

Fig. 2 Microstructure of double-sided arc welding joint of 1561 aluminum alloy

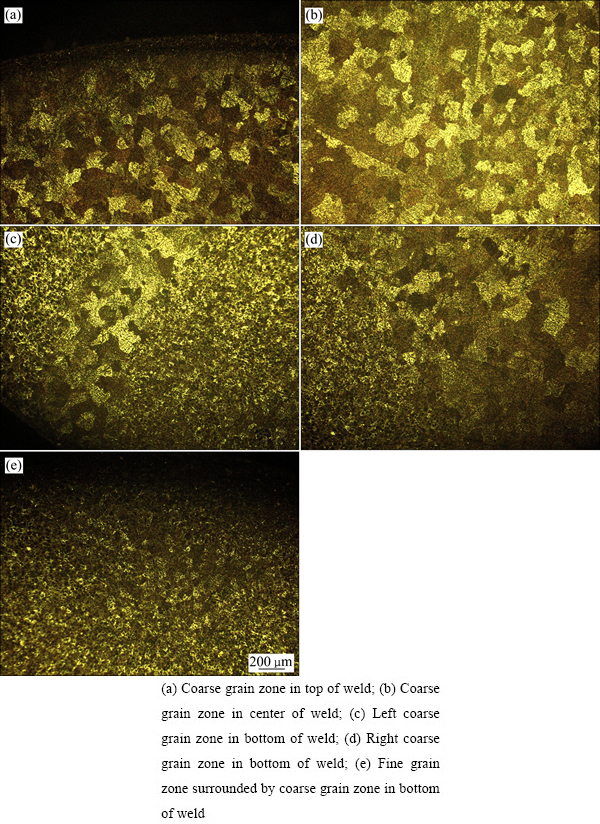

图3所示为熔化区微观组织放大图。图3(a)所示为电弧在上部的焊缝粗晶区,一方面是由于电弧中心部分温度较高,是热量散发中心,在熔池中通过对流与热传导方式传递到熔池周围;另一方面是由于背面电弧的二次加热作用,从而导致正面焊缝中心部位的冷却速度较小,因此,产生的晶粒尺寸较大[12]。图3(b)所示为焊缝中部的粗晶区,该区处于焊缝中心部分,温度高散热慢、冷却速度小,又是正反面电弧的共同熔化区,进一步降低了冷却速度,因此,产生的晶粒尺寸大。图3(c)和(d)所示为背面焊缝的左右侧粗晶区,这可能是由于前面电弧热量还未来得及传递走,后面电弧热量又要通过该处传递到焊缝周围金属中,所以导致该区域的冷却速度较小,因此,晶粒尺寸较大。图3(e)所示为背面焊缝中“人”字形粗晶区所包围的细晶区,与图3(a)情况不同,该区域没有对面电弧的二次加热作用,故温度梯度较大,又由于该区域的热量通过两侧金属传递到熔池周围的原因,该区域的冷却速度相对较大,所以晶粒较细小。

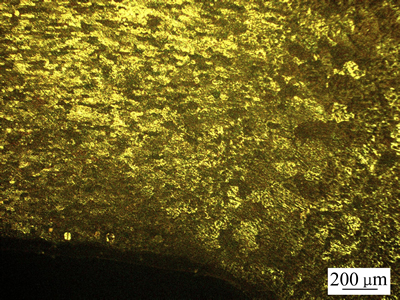

此外,在熔合线附近还出现了较窄的粗晶区,如图4所示。这可能是由于母材金属在焊接热循环作用下发生熔化,但由于边界处熔池流场流动速度很小,未能与相邻液体金属发生充分混合,而几乎保留了母材的成分。在随后的冷却过程中,母材金属的重新凝固,由于焊缝边缘处的生长速率相对较小,因此,母材金属生成了较为粗大的等轴晶组织,其晶粒明显大于其周围经过轧制后的母材组织。

图3 熔化区的显微组织

Fig. 3 Microstructures of melted zone

图4 熔合线附近粗晶区

Fig. 4 Coarse grain zone near fusion line

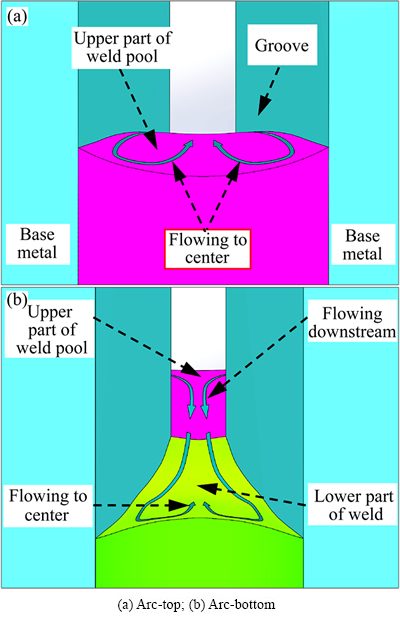

根据DONG等[13]和崔旭明等[14]对双面双弧平-仰焊熔池流动特点的研究结论,并结合本试验中正反面电弧错位特征,建立了如图5所示的双面双弧错位TIG填丝立焊的熔池流动示意图。电弧在上部的焊接熔池,在洛伦兹力的主导驱动下,由外向内流动,如图5(a)所示,流到根部时,会在重力和表面张力共同作用下,流向背面焊接熔池;电弧在下部的焊接熔池中,也在洛伦兹力的主导驱动下,由外向内流动。同时,遇到上部电弧流下来的液态金属,二者相互作用后,使得下部熔池中产生图5(b)的流动特征,即上部液体向外流动,内部液体从外部向内部流动。由于二者在外部边缘的流动方向一致,流动速率可能得到提高,这样,导致凝固时间变长,晶粒变得粗大。

图5 双面双弧TIG填丝焊熔池流动示意图

Fig. 5 Schematic diagram of molten pool flow in double- sided arc TIG wire welding

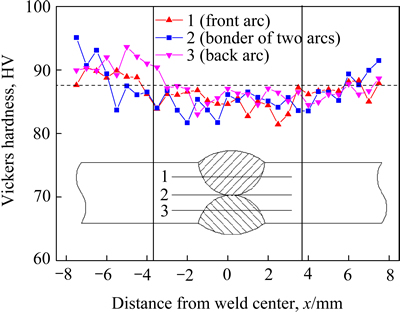

2.2 焊接接头不同区域的显微硬度

为了测试1561高强度铝合金双面双弧TIG填丝立焊的软化倾向,分别对接头上部电弧侧、下部电弧侧以及接头中心位置的硬度进行测试,间隔0.5 mm取点测试,具体测试位置和显微硬度分布如图6所示。由图6可以看出,双面双弧TIG填丝立焊的焊缝区和热影响区的硬度均低于母材的,焊缝区硬度下降幅度较大,而热影响区硬度下降幅度相对于焊缝来说较 小。这是由于焊缝区是由熔池中熔融的液态金属快速结晶形成,冷却过程迅速,第二相粒子来不及析出及长大,从而失去了母材的强化效果,所以硬度比母材低[15-16]。对于上部电弧焊道中心处,由于晶粒粗大而导致显微硬度较低,最低值约为82HV;下部电弧焊道人字形的粗晶区显微硬度值较低,最低约为83HV,下部电弧焊道的中心处细晶区显微硬度值高于人字形粗晶区,最高值为87HV。

图6 1561铝合金焊接接头显微硬度

Fig. 6 Vickers hardness of 1561 aluminum alloy welded joint

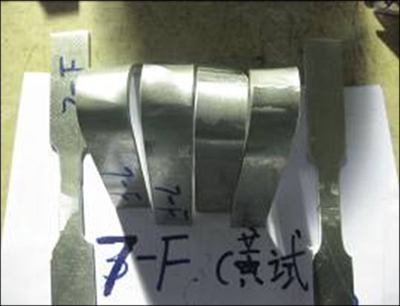

2.3 焊接接头的力学性能

图7所示为正弯与背弯试验以及拉伸试验测试。由图7可以看出,正弯与背弯时,受拉面上没有出现长度超过3 mm的裂纹及其他缺陷。因此,正弯与背弯试验合格,满足船级社检验标准,表明该接头塑性良好。经测试接头抗拉强度为327.4 MPa(母材的抗拉强度为350 MPa,达到母材强度的90%以上),比单面自动TIG焊接接头的抗拉强度294.3 MPa高出33 MPa。这可能是由双面双弧焊接的速度和热输入较小,焊缝中产生的等轴晶数量增多的原因导致的[12]。说明双面双弧TIG立向焊接工艺更适合于高镁含量的1561铝合金的立向焊接。

图7 焊接接头拉伸与弯曲测试

Fig. 7 Tensile and bending test of welded joints

3 结论

1) 1561铝合金双面双弧TIG立向填丝焊缝表现出较特殊的组织不均匀性。在焊缝中心出现了“人”字形粗晶区,在该粗晶区包围中出现了细晶区;在部分熔化区出现了两条较窄的粗晶区。

2) 探讨了铝合金双面双弧错位TIG填丝立向焊接熔池中液体流动规律:上部熔池在洛伦兹力主导作用下,由外向内流动,且通过焊缝根部流向背面焊接熔池;下部熔池在洛伦兹力作用下,也由外向内流动,并与上面熔池流入的液态金属发生交汇,在重力与洛伦兹力作用下,背面熔池中液态金属总体上表现出从外部流向内部,流动速率可能得到加快。

3) 1561铝合金双面双弧错位TIG填丝立向焊缝的显微硬度比母材的低些,热影响区的显微硬度并不比焊缝的低。焊缝的抗拉强度达到母材抗拉强度的90%以上,力学性能比较理想。

致谢:

本论文在实验过程中得到了中船黄埔文冲船舶有限公司杨侦高级技术、广州有色金属研究院蔡德涛、韩善果工程师提供试验的帮助,在此表示感谢。

REFERENCES

[1] 韩善果, 闫德俊, 刘晓莉, 蔡得涛, 郑世达, 罗玖强. 1561铝合金TIG焊接头组织与力学性能分析[J]. 焊接技术, 2015, 44(1): 18-21.

HAN Shan-guo, YAN De-jun, LIU Xiao-li, CAI De-tao, ZHENG Shi-da, LUO Jiu-qiang. Analysis of microstructure and mechanical properties of 1561 aluminum alloy TIG welded joint[J]. Welding Technology, 2015, 44(1): 18-21.

[2] ZHANG Y M, ZHANG S B. Double-sided arc welding increases weld joint penetration[J]. Welding Journal, 1998, 77(6): 57-61.

[3] ZHANG Y M, ZHANG S B. Welding aluminum alloy 6061 with the opposing dual-torch GTAW process[J]. Welding Journal, 1999, 78(6): 202-206.

[4] ZHAO Yao-bang, LEI Zheng-long, CHEN Yan-bin, TAO Wang. A comparative study of laser-arc double-sided welding and double-sided arc welding of 6 mm 5A06 aluminium alloy[J]. Materials and Design, 2011, 32(4): 2165-2171.

[5] 刘殿宝, 张广军, 吴 林. 大厚板双面双TIG电弧打底焊熔池成形特性[J]. 焊接学报, 2012, 33(3): 37-40.

LIU Dian-bao, ZHANG Guang-jun, WU Lin. Characteristics of pool formation in backing weld for large and thick plates using double-sided double TIG arc welding[J]. Transactions of the China Welding Institution, 2012, 33(3): 37-40.

[6] 郭小辉, 刘志颖, 何 刚, 王乃友, 唐 磊. 5083铝合金的双枪双面TIG焊工艺和接头性能研究[J]. 材料开发与应用, 2009, 24(5): 29-31.

GUO Xiao-hui, LIU Zhi-ying, HE Gang, WANG Nai-you, TANG Lei. Research of double-gun double-faced TIG welding of 5083 aluminum alloy[J]. Development and Application of Materials, 2009, 24(5): 29-31.

[7] 强 伟, 王克鸿, 林祥礼. 铝合金双面双弧同步立焊工艺特征与接头组织性能分析[J]. 机械工程学报, 2015, 51(24): 82-89.

QIANG Wei, WANG Ke-hong, LIN Xiang-li. Analysis on characteristics of double-sided synchronization vertical welding for aluminum alloy and structure property of joint[J]. Chinese Journal of Mechanical Engineering, 2015, 51(24): 82-89.

[8] MOULTON J A, WECKMAN D C. Double sided arc welding of AA5182-O aluminium sheet for tailor welded bland applications[J]. Welding Journal, 2010, 89: 11-24.

[9] ZHANG Y M, PAN C, MALE A T. Solidification behavior of Al-Mg aluminum alloy using double-sided arc welding process[J]. Journal of Materials Science Letters, 2000, 19: 831-833.

[10] KWON Y, WECKMAN D C. Double sided arc welding of AA5182 aluminium alloy sheet[J]. Science and Technology of Welding and Joining, 2008, 13(6): 485-495.

[11] 张 亮, 方洪渊, 王林森, 刘雪松. A7N01铝合金焊接接头的不均匀特性[J]. 焊接学报, 2012, 33(11): 97-100.

ZHANG Liang, FANG Hong-yuan, WANG Lin-sen, LIU Xue-song. Inhomogeneity for A7N01 aluminum alloy welded joint[J]. Transactions of the China Welding Institution, 2012, 33(11): 97-100.

[12] SINDO K. Welding metallurgy[M]. New Jersey: John Wiley & Sons, Inc, 2003.

[13] DONG Hong-gang, GAO Hong-ming, WU Lin. Heat transfer and fluid flow in fusion type PA~GTA double sided welding[J]. Modeling and Simulation in Materials Science and Engineering, 2005, 13: 1205-1215.

[14] 崔旭明, 李刘合, 张彦华. 双面电弧焊接熔池穿透机制[J]. 航空制造技术, 2008, 35(18): 85-93.

CUI Xu-ming, LI Liu-he, ZHANG Yan-hua. Melt-through and penetrate-through mechanism of DSAW[J]. Aeronautical Manufacturing Technology, 2008, 35(18): 85-93.

[15] 张 平, 李 奇, 赵军军, 曾庆强. 7A52铝合金中第二相分析及微区电位测试[J]. 中国有色金属学报, 2011, 21(6): 1252-1257.

ZHANG Ping, LI Qi, ZHAO Jun-jun, ZENG Qing-qiang. Analysis of secondary phases and measurement of volta potential of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1252-1257.

[16] 张国君, 刘 刚, 丁向东, 孙 军, 陈康华. 含有不同尺度量级第二相的高强铝合金拉伸延性模型[J]. 中国有色金属学报, 2002, 12(S1): s1-s9.

ZHANG Guo-jun, LIU Gang, DING Xiang-dong, SUN Jun, CHEN Kang-hua. Model for tensile ductility of high strength Al alloys containing second particles of various sized scales[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): s1-s9.

Microstructure and mechanical properties of 1561 aluminum alloy joints made by double-sided arc welding

YAN De-jun1, 2, HAN Duan-feng1, WANG Yi2, LUO Jiu-qiang2, LIU Xiao-li2, LIANG Zhi-min3

(1. School of Shipbuilding Engineering, Harbin Engineering University, Harbin 150003, China;

2. China State Shipbuilding Corporation Huangpu Wenchong Shipbuilding Company Limited,

Guangzhou 510715, China;

3. School of Materials Science and Engineering, Hebei University of Science and Technology,

Shijiazhuang 050018, China)

Abstract: 1561 high magnesium aluminum alloy was welded by double-sided arc misplaced arc welding process, and the microstructure and mechanical properties of the joints were analyzed. The results show that the welds are free of pores and cracks, pores and cracks are not observed in the welds cross section of 1561 aluminum alloy. The herringbone coarse grain zone is observed in the weld cross section of 1561 aluminum alloy by the double-sided arc dislocation vertical welding, mixing fine grain zones on both sides of and below the herringbone coarse grain zone, and there is narrow range of coarse grain zone in the partially melted zone. The microhardness on positive and negative of the weld is lower than that in the base metal, but there is no obvious softening phenomenon in the heat affected zone. The tensile strength of welded joints reaches 90% of that of the base metal, so, the mechanical properties are good. The occurrence of coarse grain zone in the weld is studied and may be related to the temperature field and the flow field of double-sided arc dislocation TIG welding.

Key words: welded joint; double-sided dislocation vertical welding; tissue heterogeneity; Vickers hardness

Foundation item: Project(2013DFR7016) supported by the National International Science and Technology Cooperation Program, China; Project(A0720133002) supported by the Military Industry Basic Research Program, China; Project(201518) supported by the Science and Technology Program of Huangpu District, China

Received date: 2015-11-01; Accepted date: 2016-04-10

Corresponding author: YAN De-jun; Tel: +86-20-82096191; E-mail: yandejun_2003@163.com

(编辑 李艳红)

基金项目:国家国际合作项目(2013DFR7016);国防科学技术工业基础研究项目(A0720133002);黄埔区科技计划项目(201518)

收稿日期:2015-11-01;修订日期:2016-04-10

通信作者:闫德俊,高级工程师,博士;电话:020-82096191;E-mail: yandejun_2003@163.com

摘 要:采用双面双弧错位TIG填丝立向焊工艺对1561高镁铝合金进行焊接,并对接头的显微组织和力学性能进行分析。结果表明:焊缝中无气孔和裂纹缺陷;1561铝合金双面双弧错位立向焊缝横截面存在着“人”字形粗晶区,粗晶区两侧和下方有细晶区,同时,在部分熔化区出现了范围较窄的粗晶区;正反面焊道的显微硬度均低于母材的,但热影响区并没有表现出明显的软化现象。焊接接头的抗拉强度达到了母材的90%以上,力学性能良好;接头粗晶区的存在与双面双弧错位TIG焊的温度场和熔池流场有关。

[1] 韩善果, 闫德俊, 刘晓莉, 蔡得涛, 郑世达, 罗玖强. 1561铝合金TIG焊接头组织与力学性能分析[J]. 焊接技术, 2015, 44(1): 18-21.

[5] 刘殿宝, 张广军, 吴 林. 大厚板双面双TIG电弧打底焊熔池成形特性[J]. 焊接学报, 2012, 33(3): 37-40.

[6] 郭小辉, 刘志颖, 何 刚, 王乃友, 唐 磊. 5083铝合金的双枪双面TIG焊工艺和接头性能研究[J]. 材料开发与应用, 2009, 24(5): 29-31.

[7] 强 伟, 王克鸿, 林祥礼. 铝合金双面双弧同步立焊工艺特征与接头组织性能分析[J]. 机械工程学报, 2015, 51(24): 82-89.

[11] 张 亮, 方洪渊, 王林森, 刘雪松. A7N01铝合金焊接接头的不均匀特性[J]. 焊接学报, 2012, 33(11): 97-100.

[12] SINDO K. Welding metallurgy[M]. New Jersey: John Wiley & Sons, Inc, 2003.

[14] 崔旭明, 李刘合, 张彦华. 双面电弧焊接熔池穿透机制[J]. 航空制造技术, 2008, 35(18): 85-93.

[15] 张 平, 李 奇, 赵军军, 曾庆强. 7A52铝合金中第二相分析及微区电位测试[J]. 中国有色金属学报, 2011, 21(6): 1252-1257.

[16] 张国君, 刘 刚, 丁向东, 孙 军, 陈康华. 含有不同尺度量级第二相的高强铝合金拉伸延性模型[J]. 中国有色金属学报, 2002, 12(S1): s1-s9.