DOI: 10.11817/j.ysxb.1004.0609.2020-36343

新型超弹性轴承材料TiNi60合金的研究进展

燕 超1,曾群锋1, 2,杨华斌3

(1. 西安交通大学 现代设计及转子轴承系统教育部重点实验室,西安 710016;

2. 材料腐蚀与防护四川省重点实验室,自贡 643000;

3. 西安赛特金属开发有限公司,西安 710021)

摘 要:

TiNi60合金是一种弹性模量低、硬度大、比强度高、无磁性、尺寸稳定性好、耐腐蚀性强的新型超弹性轴承材料,NASA等国外研究机构对其进行了深入研究。系统阐述了TiNi60合金材料的特性,重点论述了其在熔炼与加工、硬度强化机理、力学性能、摩擦学性能、高温抗氧化行为以及超弹性等方面的国内外最新研究进展,分析了相关研究中存在的问题,并简要阐述了超弹性TiNi60合金在航空航天领域的应用前景,探讨了有关TiNi60合金材料亟需研究的内容,以期推动国内外相关研究进展。

关键词:

文章编号:1004-0609(2020)-05-1038-11 中图分类号:TG135 文献标志码:A

高性能轴承、齿轮等高端装备的关键零部件材料需满足强度高、硬度大、尺寸稳定性好以及摩擦学性能优异等要求,而在极端环境下,如旋翼机发动机轴承、直接暴露在海洋环境中的水上飞机以及需长期储存的航空飞行器,还要遭受轴承、齿轮以及其他零部件腐蚀问题的困扰。此外,在涉及灵敏元器件的应用领域,还需材料具有良好的导电性以及非磁性[1]。

传统工具钢、不锈钢等轴承材料,如M50、52100、440C等,硬度高、可加工性能好且摩擦学性能优异,但耐腐蚀性能差且磁性高,在磁性、耐腐蚀性要求苛刻的工况下,其应用受到了严格的限制。氮化硅陶瓷密度低、耐腐蚀性优异且非常耐磨,使其成为高负载、高速以及腐蚀介质中服役轴承的可供选择材料。但陶瓷材料刚度大,热膨胀系数低,导致其加工工艺复杂,成本高昂,难以实现大规模应用。有色金属合金强度低、硬度小、耐磨性和抗高温性能差,应用范围受到限制[1-2]。在通常应用中,可以通过调整设计来规避轴承材料的缺陷,但在某些应用中,同时拥有高硬度、强耐腐、易加工、高尺寸稳定性以及无磁性的轴承材料就显得尤为重要。为此,自2004年以来,NASA就着手开发TiNi金属间化合物轴承材料,其中TiNi60合金因其优异的综合性能,备受科研人员的青睐[2]。

TiNi60合金是一种含Ti 40%、Ni 60%(质量分数)的有序金属间化合物,其特点是弹性模量低、硬度大、比强度高、无磁性、尺寸稳定性好、耐腐蚀性强且具有良好的可润滑性[2-4],被认为是能够在腐蚀介质中长寿命服役的高端轴承、齿轮材料[5-6],国外研究人员给予其极大的关注[7],国内有关TiNi60合金的研究正处于起步阶段。为推动国内相关研究工作,本文作者详细综述了有关TiNi60合金的国内外最新研究进展,分析并阐述了目前有待解决的关键问题,并就未来研究方向进行了展望。

1 国内外研究现状

TiNi60合金自1962年问世以来,因其优异的综合性能备受关注。然而1962~2003年间,由于其加工难度大,当时技术无法实现加工制造,相关研究几乎处于停滞状态。直到21世纪初,美国有关企业才具备TiNi60合金的加工能力,应用方面的研究才逐渐展开。

目前,国外对TiNi60合金应用基础研究的机构包括美国NASA格林研究中心、海军装备实验室、托雷多大学、美国阿拉巴马大学、加州大学、卡内基梅隆大学、兰利研究中心等,其中NASA格林研究中心的研究最具连续性。近五年来,伊朗伊斯兰阿萨德大学、阿米尔卡比尔理工大学,土耳其安那多鲁大学、印度国立科技大学,新西兰奥克兰理工大学等也在着手TiNi60合金的研制。国内对TiNi60合金的关注始于2012年,主要研究机构包括西安交通大学、西安赛特金属材料开发有限公司、南昌航空大学、北京航空航天大学、四川大学,文献数量10余篇,正处于研究的起步阶段。

1.1 国外研究现状

国外对TiNi60合金的研究主要涉及熔炼与加工、硬度强化机理、力学性能、摩擦学性能及其超弹性等,具体如下。

1.1.1 熔炼与加工

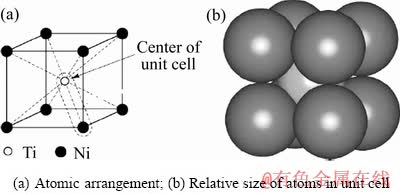

TiNi60合金是一种含CsCl型B2立方晶体结构母相的有序金属间化合物。如图1所示,立方单晶胞中,钛原子位于立方体中心,八个镍原子位于八个顶点。Ti-Ni间通过共用电子对形成的共价键使其既有部分陶瓷的特性,又有金属材料的弹性和塑性[7],与传统金属材料相比,拥有无可比拟的性能优势。然而,共价键的存在使其难以加工,曾一度阻碍了应用方面的研究[8]。近年来,先进加工与制造工艺,包括粉末冶金、陶瓷切割以及放电加工技术,使利用TiNi60合金材料加工复杂精密零件成为可能[9-11]。铸造和热等静压是目前制备高性能TiNi60合金的主要途径[12],JULIEN[13-14]采用压铸和模铸工艺,制备了TiNi60合金材料零部件,确立了热加工和变形的温度,并提出了制造TiNi60合金轴承外圈以及球的有效工艺。DEHGHAN等[15]还发现TiNi60合金的高温可加工性可以通过高变形温度诱导下的动态重结晶而得到增强。

图1 TiNi60合金B2单晶胞[11]

Fig. 1 TiNi60 alloy B2 unit cell[11]: (a) Atomic arrangement; (b) Relative size of atoms in unit cell

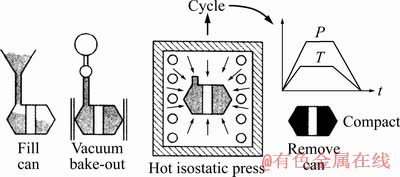

此外,Ti和Ni都是高活性金属,熔炼过程中熔体的污染、夹杂物的形成以及铸造中的孔洞,都会造成材料局部应力集中,造成裂纹扩展,最终导致 TiNi60合金铸件的加工更加困难[3, 6, 16]。热等静压是 一种先进的成型工艺,其原理如图2[17]所示,相对铸造而言,其具有很大的优势,可近净成型,大幅减少机械加工[9],而且热等静压中颗粒的随机取向,使得材料获得更多各向同性的力学性能[12],并会减少污染、夹杂物以及孔洞的形成[18]。但高活性粉末颗粒的表面氧化,会导致合金力学性能下降,是热等静压工艺面临的关键问题[12]。

图2 热等静压工艺步骤示意图[17]

Fig. 2 Schematic diagram of hot isostatic pressing process[17]

综上所述,传统真空电弧/感应熔炼工艺中熔体的氧化、坩埚对熔体的污染所形成的夹杂物以及铸造过程中缩孔等缺陷,是影响合金质量的主要因素。粉末冶金与传统工艺相比,具有无可比拟的优势,如熔体污染小、可近净成型等,但高活性粉末颗粒的表面氧化,也导致产品力学性能下降。TiNi60合金的激光熔覆工艺鲜有研究,仅有一篇文献报道,主要对其可行性进行了初探[19]。

1.1.2 硬度强化机理

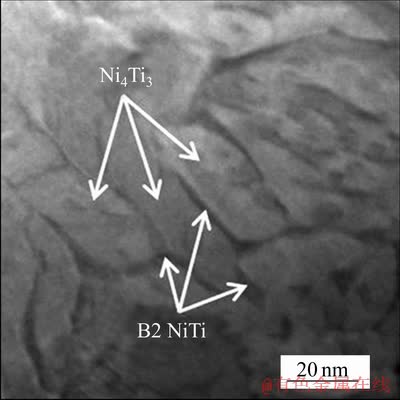

固溶态TiNi60的硬度可与440C和M50的媲美,针对其硬度强化机理,国外学者进行了深入研究。DELLACORTE等[1]采用热等静压工艺预制TiNi60合金球,经热处理后硬度可达58 RC~62 RC。显微分析表明,此时TiNi60合金的主体相为B2 TiNi相,体积分数约占78%,其次为分散在B2 TiNi相中的亚稳态Ni4Ti3相,体积分数约为11%,余量为 Ni3Ti和 Ti2Ni相。STANFORD等[6]研究了铸态TiNi60合金在不同温度固溶处理后的硬度变化,发现试样硬度随固溶温度的升高而增大,900~1050 ℃固溶后硬度范围为56 RC~63 RC。进一步研究表明,固溶温度升高,Ni3Ti会向TiNi奥氏体相转变,强化合金硬度。HORNBUCKLE等[20]研究发现,TiNi60合金1050 ℃固溶处理会形成大量的纳米级沉淀相Ni4Ti3(如图3所示),其硬度达到(644±5.1) HV;再经400 ℃短暂时效处理,硬度增加到650 HV;继续增加时效时间,亚稳态沉淀相Ni4Ti3将会分解为Ni3Ti2或Ni3Ti,合金硬度随即开始降低。THOMAS[21]研究了淬火介质对TiNi60合金硬度和显微结构的作用规律,发现淬火介质对其硬度强化相Ti3Ni4的影响很小。NASEHI等[22]采用热加工,退火以及时效处理相结合的工艺对铸态TiNi60进行热处理。结果发现,沉淀相Ni4Ti3尺寸越小,合金的硬度越大。KHANLARI等[23]还发现快速冷却和添加少量的Hf元素都可以抑制TiNi60合金中软相Ni3Ti2 和 Ni3Ti的形成,从而强化合金硬度。由此可见,Ni4Ti3沉淀相和B2 TiNi相含量和晶粒尺寸是决定TiNi60硬度的主要因素。

分子动力学计算发现,B2 NiTi和Ni4Ti3都具有高的堆垛层错能,纳米级Ni4Ti3沉淀相的大量析出,阻碍了位错的滑移,而且Ni4Ti3是一种菱形晶体结构,与B2立方结构的TiNi相比对称性小,硬度更高[20, 24],理论计算与实验结果吻合。

基于理论计算和实验结果,不难看出,TiNi60合金的高硬度主要是归功于纳米级亚稳态Ni4Ti3在B2 TiNi相上的大量析出,阻碍了位错的滑移。而亚稳态Ni3Ti2和热力学平衡态 Ni3Ti相则会导致TiNi60合金的脆性增大,硬度降低。固溶处理是实现TiNi60合金高硬度的有效途径。

图3 固溶态TiNi60合金的STEM-HAADF图[20]

Fig. 3 STEM-HAADF image of hardened TiNi60 alloy[20]

1.1.3 力学性能

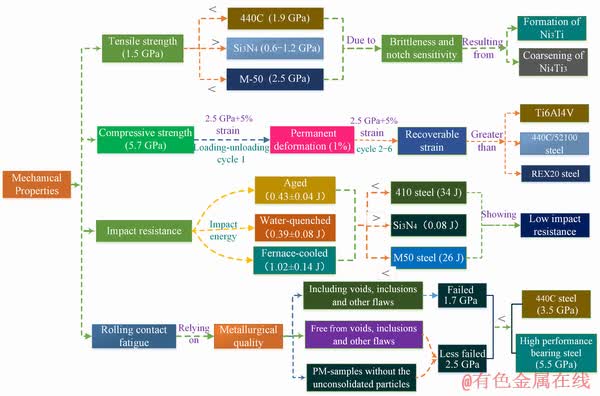

图4 TiNi60合金力学性能研究现状

Fig. 4 Research status for mechanical properties of TiNi60 alloy

TiNi60合金表现出金属间化合物常见的抗拉-抗压强度不对称性[5, 25]。如图4所示,拉伸状态下,TiNi60可以承受约1.5 GPa载荷,远小于高性能轴承钢440C和M50,与Si3N4陶瓷相当。而压缩状态下,却可以承载约2.5 GPa的负载,而且还表现出高韧性[25]。负载极限测试还表明,在5.7 GPa的压载荷下,不会发生永久的塑性变形,抗压强度远大于钛合金、440C不锈钢和REX20[26]。BENAFAN等[27]研究发现,拉伸过程中由于外部应力对Ti3Ni4和TiNi3相间的局部应力场的影响,造成Ti3Ni4相的选择性生长以及热力学平衡相TiNi3的形成,最终导致合金强度下降。ADHARAPURAPU等[28]还研究了固溶态TiNi60的高应变率动态压缩性能,发现其具有高的动态抗压强度和韧性,屈服强度随着变形温度的升高和应变速率的下降而降低,此外,热压过程还出现动态再结晶[15]。DELLACORTE等[29]对硬化TiNi60合金施加了2.5 GPa的六次循环压载荷,最大应接近6%。结果发现,首次卸载后,产生了约1%的塑性变形。随后加载-卸载循环过程中,处于完全弹性变形状态,这主要归功于TiNi60合金的可逆奥氏体-马氏体相变。实际应用中,通常采用预应力来确保超弹性材料的弹性行为,因此,首次循环载荷作用下产生的塑性变形不会对其实际工程应用产生负面影响[16]。

STANFORD等[30]考察了采用不同制备工艺的TiNi60合金试样在冲击载荷作用下的失效机制,发现在冲击载荷作用下,TiNi60合金都会发生晶间和穿晶的脆性断裂,抗冲击性能相对较差。这可能由于冲击载荷会产生拉应力[10, 30],而TiNi60合金中滑移系的缺乏以及B2晶体结构中原子的规则排布,都会造成拉应力作用下合金的脆性断裂。

DELLACORTE等[31]探究了TiNi60合金的滚动接触疲劳性能,发现其滚动接触疲劳性能主要取决于试样的冶金质量。含有氧化物、夹杂物以及缩孔等缺陷的试样在1.7 GPa的应力作用下就会失效,主要原因是缺陷形成的应力集中源,为脆性裂纹扩展提供了路径,最终导致合金力学性能的下降。而无夹杂物和缩孔的高质量铸造试样,在2.5 GPa中等强度的应力作用下,极少出现失效[17]。微量元素合金化可提升材料微观结构的均匀性,有研究表明,添加微量的Hf,可以使TiNi60合金铸造试样的滚动接触疲劳性能接近甚至超过高质量的粉末冶金试样[31]。尽管如此,TiNi60合金的滚动接触疲劳强度仍无法达到3.6 GPa,小于传统轴承钢440C(约3.5 GPa),远小于高性能轴承钢(约5.5 GPa)[17, 31]。

综上所述,TiNi60合金抗压性能优异,但抗拉强度、抗冲击性能以及滚动接触疲劳强度相对较差。冲击载荷作用下,TiNi60合金的晶间和穿晶断裂以及滚动接触疲劳失效演变机制及其强化措施是亟待解决的关键问题。

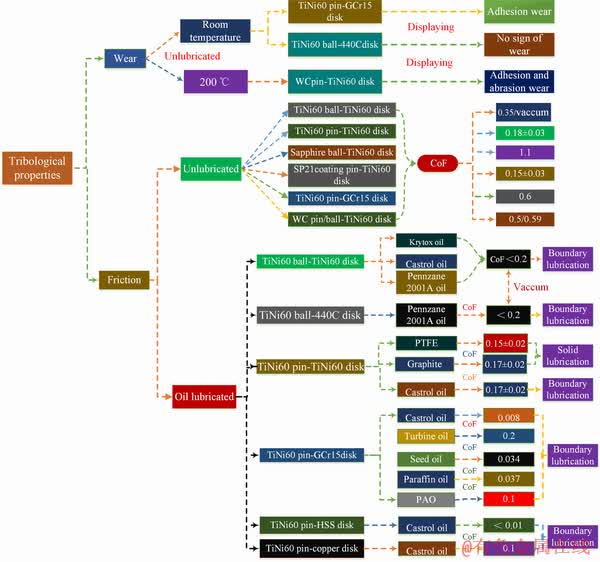

1.1.4 摩擦学性能

TiNi60的摩擦学性能,NASA的DELLACORTE等[1]给予了极大关注。如图5所示,常温干摩擦工况下,TiNi60销-440C盘配副,摩擦因数虽高,但销表面无磨损[1],当采用 TiNi60盘后,摩擦因数为0.18[32],且增加滑动速度,摩擦因数呈现下降趋势;这主要得益于TiNi60低热传导率,使表面形成氧化膜,起到固体润滑作用。盘表面涂覆石墨烯、PTFE薄膜后,摩擦因数可分别降到0.15和0.17,销表面未出现磨损。200 ℃干摩擦工况下,WC销-TiNi60盘配副,也会出现严重磨损[22]。真空油润滑下,TiNi60合金球-TiNi60盘/440C盘配副,摩擦因数小0.2[16]。常温常压蓖麻油润滑下,TiNi60销-TiNi60盘配副摩擦因数为0.17±0.02,当使用铜盘时,摩擦因数可降低到0.1,而用 GCr15钢盘配副,摩擦因数可降到0.01以下。

NEUPANE等[33]研究了TiNi60合金的抗磨损性能,发现固溶和时效态TiNi60合金会出现黏着磨损和磨粒磨损,而退火态则会出现剥层磨损和黏着磨损,但强化硬度对其耐磨性的影响甚微[22]。这与经典耐磨理论有显著的不同[34-35],但却可以用TL Oberl 的理论来解释[29],即高硬度并不是决定耐磨性的唯一因素,材料耐磨性与其H/E(H—硬度,E—弹性模量)有着紧密的关联。

KHANLARI等[35]对比研究了TiNi60合金和440C不锈钢在干摩擦条件下往复滑动的磨损行为,发现TiNi60合金硬度虽高于440C,抗磨损性与440C相比明显较差,主要表现为黏着和疲劳磨损。添加3%Hf可改善其抗磨损性,这主要得益于Hf元素对其抗疲劳性能的强化[31],但58Ni39Ti-3Hf合金比TiNi60更易发生开裂和脆性断裂[36]。

国外对TiNi60合金在真空/常温常压下的可润滑性进行了系统的研究,充分体现了其优异的润滑性能,这是传统钛合金所无法比拟的。磨损方面,TiNi60合金拥有可媲美440C和M50钢的硬度,然而抗磨损性能却远不如440C和M50钢。目前,对其磨损机制及其强化措施缺乏深入系统的研究。

1.1.5 形状记忆性和超弹性

图5 TiNi60合金摩擦学性能的研究现状

Fig. 5 Research status for tribological properties of TiNi60 alloy

形状记忆性和超弹性其本质都属于可逆马氏体相变,不同之处在于形状记忆是处于低温马氏体状态的TiNi合金,在应力作用下发生“表观”塑性变形,当加热到温度高于奥氏体相变开始温度时,发生逆相变,转变为奥氏体,并恢复在奥氏体状态时的形状。而超弹性则是处于奥氏体状态的TiNi合金,经应力诱发相变,形成应力诱发马氏体相变,卸载应力后,应变因应力诱发马氏体相变的逆相变而全部恢复。马氏体相变温度是决定TiNi合金形状记忆性和超弹性的最根本因素,而马氏体相变温度与Ni含量和热处理工艺有强关联性[1, 9]。TiNi60合金是一种富Ni的TiNi合金,高的Ni含量使其马氏体相变温度低于室温,表现出超弹性,压应力作用下拥有超5%的弹性应变[16]。热处理工艺对TiNi60合金马氏体相变温度的影响同样显著,有研究表明,热等静压制备的TiNi60合金试样,炉冷后,马氏体相变温度为-15 ℃,然而,固溶-水淬后的马氏体相变温度则转变为-100 ℃[5, 37]。此外,与等原子TiNi合金不同的是,TiNi60合金的超弹性效应不仅仅局限在奥氏体转变结束温度以上50 ℃,至少在600 ℃仍可观察到超弹性效应[13]。美国波音公司的研究表明,TiNi60合金的马氏体相变温度严重依赖热处理工艺,其变化范围为-55~70 ℃[38]。TiNi60合金对热处理工艺的敏感性主要归咎于亚稳态、稳态富Ni沉淀相的析出使得基体Ni含量降低,进而改变马氏体相变温度[25]。此外,加载速率的增加会导致TiNi60合金的超弹性效应下降5%~10%,NEUPANE等[33]认为这是应力诱变马氏体相变的滞后所导致的。

由此可见,基于实际需要,TiNi60合金可通过调整热处理工艺实现形状记忆合金与超弹性合金之间的相互转化,充分体现了其广泛的适用性。然而当TiNi60合金用于齿轮以及其他高频率滑动组件时,需要特别关注加载速率对其超弹性的影响。

1.1.6 高温氧化行为和耐腐蚀性

TiNi60合金的高温氧化行为强烈依赖于体系温度和氧分压[9]。由于热力学上Ti比Ni更容易氧化,温度高于300 ℃时,会有TiO2、NiTiO3等Ti的氧化物形成[39-40]。MIYOSHI等[41]还发现,在常压无气体保护的情况下将TiNi60合金盘试样加热到850~950 ℃之间,会形成由Ti和O组成的氧化层,起到减摩作用。

早在1968年,美国海军装备实验室研究了TiNi60合金空泡腐蚀、应力腐蚀以及间隙腐蚀性能,结果证明其具有优异的耐海水腐蚀性[42]。然而,时至今日,针对其腐蚀方面的研究,国外未见其他报道。

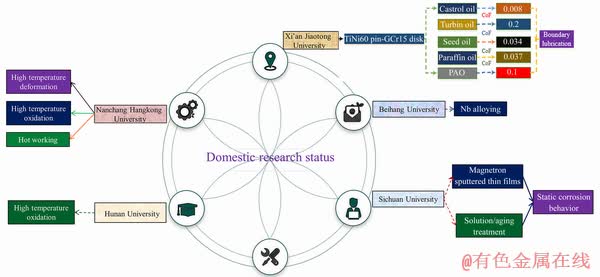

1.2 国内研究现状分析

国内对TiNi60合金的关注始于2012年,如图6所示,主要研究机构包括西安交通大学、西安赛特金属材料公司、南昌航空大学、北京航空航天大学、四川大学,主要涉及高温性能、摩擦学性能、微量稀土元素合金化以及耐腐蚀性能。

南昌航空大学的鲁世强课题组主要针对TiNi60合金的高温性能进行了研究,涉及高温变形特性以及高温抗氧化性[43-44]。在高温变形方面,对轧态TiNi60合金进行了等温恒应变速率拉伸试验,研究了该合金在650~850 ℃和0.01~1 s-1 范围内的高温变形特性[44],并基于动态材料模型加工技术,优化了高温变形参数范围,探究了变形参数对其高温变形特性的影响规律;微观组织观察表明,TiNi60合金的高温变形机制为动态再结晶[45]。对比分析了本构方程和人工神经网络模型在TiNi60合金高温变形行为预测方面的准确性,发现后者比前者预测的结果更有效、更准确[46]。在高温抗氧化方面,该课题组研究了锻态TiNi60合金在750~850 ℃的空气中的高温循环氧化行为;结果表明,氧化温度升高,氧化速率加快,最终形成梯度分布的氧化层[43]。基于第一性原理的理论计算结果表明,发生氧化后,Ti—Ni的键长增加,Ti—Ni键的结合强度减弱。TiNi的110晶面氧化过程中,Ni原子代替Ti原子和O原子扩散进入晶格的过程都是放热的,不存在能量势垒,而001晶面O原子向晶格内的扩散却是吸热的,而且氧化是Ni原子由表层向内扩散的驱动力[47]。

本文作者课题组系统研究了TiNi60合金销-钢盘配副在PAO润滑油下的摩擦学性能。发现TiNi60合金表现出良好的可润滑性[48];并探究其在可再生且生物降解能力强的植物油润滑工况下的摩擦学性能,发现菜籽油润滑下的低摩擦,并在蓖麻油润滑时实现了摩擦因数0.008的超低摩擦[49-50]。增加负载,摩擦因数可进一步降低,而增大速度,摩擦因数则有所增加,但始终处于超低摩擦状态;摩擦副表面光滑,无明显磨损痕迹[51]。

北京航空航天大学郑立静等研究了微量稀土元素合金化对TiNi60合金的沉淀相形态和硬度的影响;结果表明,添加微量Nb后,富Ni沉淀相的形态发生了转变,而且硬度得到了较大幅度的强化[52]。

图6 TiNi60合金国内研究现状

Fig. 6 Domestic research status of TiNi60 alloy

文玉华等[53]研究了热处理工艺与TiNi60合金耐腐蚀性能的关联性;结果表明,铸态TiNi60合金的耐腐蚀性能可媲美316不锈钢,固溶和时效态TiNi60的耐腐蚀性能更佳。彭华备等[54]采用磁控溅射技术制备了粘结性和抗冲击性能优异的TiNi60合金膜,并研究退火工艺对其硬度和耐腐蚀性的作用规律;结果发现,退火处理后,其硬度可媲美TiNi60基体,而耐腐蚀性比基体更佳优异。

西安赛特金属开发有限公司研究了热处理工艺对TiNi60合金显微组织和硬度的影响,发现800 ℃固溶处理后,随时效温度的升高,鱼骨状晶逐渐消失,线状晶逐渐增多,但材料硬度会明显下降[55-56]。

综合国内研究现状,基本可以看出以下几点:

1) 涉及TiNi60合金的研究始于2012年,对其研究尚处于起步阶段。

2) 有关TiNi60合金及其涂层的腐蚀性能研究还局限在静态溶液中的腐蚀行为,缺乏对其腐蚀演变过程及其机制的深入探究,更未涉及动态腐蚀方面的研究。

3) 本文作者课题组对于TiNi60合金摩擦学性能研究比较深入,并在蓖麻油润滑条件下实现了超滑,但并未专门针对其磨损行为及其机理的研究。

4) 有关稀土元素合金化只有一篇文献报道,而且仅就硬度强化方面进行了探讨,并未涉稀土元素合金化对力学性能的作用规律。

5) 对于TiNi60合金抗拉强度、抗压强度、抗冲击性以及滚动接触疲劳等力学性能的研究几乎为空白。

2 超弹性TiNi60合金的应用前景

2.1 蒸馏装置离心机轴承

蒸馏装置是宇宙空间站废水处理体统的一个关键组件,用于净化航天器中各种废液,生产生活必须的饮用水。离心机卷筒支承轴承是一个在低速(200 r/min)、中载(~100到300 N)下运行的50 mm滚动轴承。此工况对滚动轴承而言本不具有挑战性。然而,蒸馏装置离心机轴承却直接暴露在强酸性(pH~2.0)废液中,这对轴承材料而言是一种巨大的挑战。实践证明,即使440C不锈钢,也易被腐蚀。目前的策略是用硬度相对较低的钴合金轴承(HRC~40),但装配过程的损伤以及服役中产生的磨损,严重威胁其使用寿命,无法满足现实需求。TiNi60合金是兼顾高硬度和强耐腐蚀的合金材料,是解决这一问题最理想、最有效的材料。NASA对此进行了尝试,发现TiNi60合金圈与Si3N4球组成的混合轴承,表现出优异的耐磨性和强抗腐蚀性,有望解决离心机轴承的这一难题。目前,NASA正在进行进一步测试[2]。

2.2 蒸馏装置压缩机-真空泵驱动齿轮

真空泵驱动齿轮处在蒸馏装置的内部,可免受强酸性废水的腐蚀,但却仍暴露在热蒸汽流中。齿轮咬合过程中的过度磨损是真空泵驱动齿轮面临的主要问题。硬质钢具有良好的耐磨性,但腐蚀问题限制了其应用。兼顾高硬度和强耐腐蚀的TiNi60合金为驱动齿轮过度磨损的解决提供了新思路。为此,NASA以此服役工况为背景,研究了其应用的可能性,结果显示,TiNi60合金的摩擦因数低、磨损率小,加之优异的耐腐蚀性能和良好的固体润滑性,在此领域将具有广阔的应用前景[2, 32]。

2.3 航空器反作用轮装配轴承

反作用轮主要用于航空器运动姿态的控制,支撑反作用轮的是一组电机驱动的滚动轴承。此类轴承必须长期提供低且稳定的运行扭矩,而且要经受发射载荷的严酷考验。航空器在发射过程中,由于球与内圈接触面积小,内圈承载了很高的应力,往往会受到局部损坏。与传统轴承钢相比,超弹性TiNi60合金轴承,可承受更高的静态载荷,从而确保反作用轮的稳定、安全、高效运行。为此,NASA将TiNi60合金轴承与其他轴承进行了对比研究,结果表明,超弹性TiNi60合金轴承的承载能力超出了反作用轮轴的屈服强度,与其他轴承材料相比,具有明显的优势。此外,TiNi60合金密度小,还可以减少发射质量,降低燃料消耗,节约成本[2]。

2.4 人工关节材料

人工关节材料需具有高硬度、高韧性以及优异的耐腐蚀、摩擦学性能和生物相容性等特性。现存人工关节材料主要有CoCr合金、Ti6Al4V、316L不锈钢和陶瓷材料,尽管陶瓷材料力学性能和生物相容性优异,但韧性不足;CoCr合金的刚度过大,会导致不利的应力遮挡,最终可能造成骨吸收;Ti6Al4V摩擦学性能差,过度磨损会造成关节疏松。TiNi60合金摩擦学性能、生物相容性良好,压缩韧性、耐腐蚀性优异,弹性模量远低于CoCr合金,可显著降低应力遮挡效应。基于此,TiNi60合金被认为是人工关节合适的替代材料[38, 57-59]。

3 结论与展望

1) TiNi60合金比强度高、硬度大、无磁性、尺寸稳定性好、耐腐蚀性强且具有良好的可润滑性,是一种能在腐蚀介质中长寿命服役的高性能摩擦副材料。

2) 国外对TiNi60合金的制备、力学性能、摩擦学性能以及硬度强化机理等进行了大量研究,并已获得许多研究成果。国内相关研究处于起步阶段,主要涉及高温变形及高温抗氧化性、耐腐蚀性以及摩擦学性能等。

3) 综合国内外研究报道,可以发现要实现TiNi60合金的有效应用,还亟需解决以下关键问题:真空电弧/感应熔炼中熔体氧化、坩埚对熔体的污染所形成的夹杂物以及铸造中的缩孔等缺陷导致的滚动接触疲劳强度相对较差,难以满足日益增长的性能需求;热等静压工艺中粉末高活性表面的氧化问题;冲击载荷作用下TiNi60合金晶间和穿晶断裂及其强化措施;TiNi60合金的磨损机制有待明确;腐蚀介质中的腐蚀-磨损耦合作用演变机制;表面强化工艺及其机理。

4) 以期进一步挖掘TiNi60合金的性能潜力,满足不断发展的性能需求,开拓钛镍合金的新应用点。

REFERENCES

[1] DELLACORTE C, PEPPER S V, NOEBE R, HULL D R. Intermetallic nickel-titanium alloys for oil-lubricated bearing applications[C]// ASME/STLE 2009 International Joint Tribology Conference. Memphis: American Society of Mechanical Engineers, 2009: 225-227.

[2] CORTE C D. Novel super-elastic materials for advanced bearing applications[J]. Advances in Science & Technology, 2014, 89: 1-9.

[3] DELLACORTE C, The effect of indenter ball radius on the static load capacity of the superelastic 60NiTi for rolling element bearings[C]// 2014 Society of Tribologists and Lubrication Engineers (STLE) Annual Meeting. Orlando: Society of Tribologists and Lubrication Engineers, 2014.

[4] DELLACORTE C, WOZNIAK W A. Design and manufacturing considerations for shockproof and corrosion-immune superelastic nickel-titanium bearings for a space station application[R]. Cleveland: NASA Glenn Research Center, 2012.

[5] PEPPR S V, DELLACORTE C, GLENNON G. Lubrication of Nitinol60[R]. Cleveland: NASA Glenn Research Center, 2010.

[6] STANFORD M K, THOMAS F, DELLACORTE C. Processing issues for preliminary melts of the intermetallic compound 60-Nitinol[R]. Cleveland: NASA Glenn Research Center, 2012.

[7] CANTER N. Corrosion-proof nickel titanium bearings[J]. Tribology & Lubrication Technology, 2014, 70(2): 10-11.

[8] DAN J C, CALKINS F T, SMITH J P. Thermomechanical properties of Ni60% weight Ti40% weight[C]// Proceedings of the SPIE. Bellingham: Society of Photo-Optical Instrumentation Engineers, 2003: 219-229.

[9] INGOLE S. 60NiTi alloy for tribological and biomedical surface engineering applications[J]. JOM, 2013, 65(6): 792-798.

[10] LOTFINEYESTANAK A A, DANESHMAND S. The effect of operational cutting parameters on nitinol-60 in wire electrodischarge machining[J]. Advances in Materials Science and Engineering, 2013, 2013: 1-6.

[11] STANFORD M K,WOZNIAK W A,MCCUE T R. Addressing machining issues for the intermetallic compound 60-Nitinol[R]. Cleveland: NASA Glenn Research Center, 2012.

[12] STANFORD M K, CENTER G. Hot isostatic pressing of 60-Nitinol[R]. Cleveland: NASA Glenn Research Center, 2015.

[13] JULIEN G J. Manufacturing of nitinol parts and forms: United States, 6422010[P]. 2002-07-23.

[14] JULIEN G J. Nitinol ball bearing element and process for making: United States, #6886986[P]. 2005-05-03.

[15] DEHGHAN K, KHAMEI A A. Hot deformation behavior of 60Nitinol (Ni60wt%-Ti40wt%) alloy: Experimental and computational studies[J]. Materials Science & Engineering A, 2010, 527(3): 684-690.

[16] DELLACORTE C. The effect of pre-stressing on the static indentation load capacity of the superelastic 60NiTi[R]. Cleveland: NASA Glenn Research Center, 2013.

[17] JAMES W B. Powder metallurgy & particulate materials processing[J]. International Journal of Powder Metallurgy, 2005, 41(6): 59.

[18] CORTE C D, STANFORD M K, JETT T R. Rolling contact fatigue of superelastic intermetallic materials (SIM) for use as resilient corrosion resistant bearings[J]. Tribology Letters 2015, 57(3): 26-1-10.

[19] WALKER J, ANDANI M T, HABRLAND C, ELAHINA M. Additive manufacturing of nitinol shape memory alloys to overcome challenges in conventional nitinol fabrication[C]// Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition. Montreal: American Society of Mechanical Engineers, 2014: 1-5.

[20] HORNBUCKLE B C, YU X X, NOEBE R D, MARTENS R, WEAVER M L, THOMPSON G B. Hardening behavior and phase decomposition in very Ni-rich nitinol alloys[J]. Materials Science & Engineering A, 2015, 639(4): 336-344.

[21] THOMAS F. The effect of various quenchants on the hardness and microstructure of 60-Nitinol[R]. Cleveland: NASA Glenn Research Center, 2015.

[22] NASEHI J, GHASEMI H M, ABEDINI M. Effects of aging treatments on the high-temperature wear behavior of 60Nitinol alloy[J]. Tribology Transactions, 2016, 59(2): 1-24.

[23] KHANLARI K, RAMEZANI M, KELLY P, NEITZERT T. Effect of hafnium addition in 60NiTi alloy hardened under open atmosphere conditions[J]. Metallography, Microstructure, and Analysis, 2018, 7: 476-486

[24] STANFORD M K. Hardness and microstructure of binary and ternary Nitinol compounds[R]. Cleveland: NASA Glenn Research Center, 2016.

[25] ADHARAPURAPU R R, WECCHIO K S. Superelasticity in a new bioimplant material: Ni-rich 55NiTi alloy[J]. Experimental Mechanics, 2007, 47(3): 365-371.

[26] DELLACORTE C. Resilient and corrosion-proof rolling element bearings made from Ni-Ti alloys for aerospace mechanism applications and the ultimate space technology development platform[R]. Cleveland: NASA Glenn Research Center, 2014.

[27] BENAFAN O, GARG A, NOEBE R D, SKORPENSKE H D, AN K, SCHELL N. Deformation characteristics of the intermetallic alloy 60NiTi[J]. Intermetallics, 2017, 82: 40-52.

[28] ADHARAPURAPU R R, JIANG F, VECCHIO K S. Aging effects on hardness and dynamic compressive behavior of Ti-55Ni (at.%) alloy[J]. Materials Science & Engineering A, 2010, 527(7): 1665-1676.

[29] DELLACORTE C, NOEBE R D, STANFORD M K, PADULA, LL S A. Resilient and corrosion-proof rolling element bearings made from superelastic Ni-Ti alloys for aerospace mechanism applications[R]. Cleveland: NASA Glenn Research Center, 2012.

[30] STANFORD M K. Charpy impact energy and microindentation hardness of 60-Nitinol[R]. Cleveland: NASA Glenn Research Center, 2012.

[31] DELLACORTE C, HOWARD S A, THOMAS F, STANDORD M K. Microstructural and material quality effects on rolling contact fatigue of highly elastic intermetallic NiTi ball bearings[R]. Cleveland: NASA Glenn Research Center, 2017.

[32] DELLACORTE C, THOMAS F. Tribological evaluation of candidate gear materials operating under light loads in highly humid conditions[R]. Cleveland: NASA Glenn Research Center, 2015.

[33] NEUPANE R, FARHAT Z. Wear resistance and indentation behavior of equiatomic superelastic TiNi and 60NiTi[J]. Materials Sciences & Applications, 2015, 6(7): 694-706.

[34] LIU R, LI D Y. Modification of archard’s equation by taking account of elastic/pseudoelastic properties of materials[J]. Wear, 2001, 251(1): 956-964.

[35] KHANLARI K, RAMEZANI M, KELLY P, CAO P, NEITZERT T. Reciprocating sliding wear behavior of 60NiTi as compared to 440C steel under lubricated and unlubricated conditions[J]. Tribology Transactions, 2018, 61(6): 991-1002.

[36] KHANLARI K, RAMEZANI M, KELLY P, CAO P, NEITZERT T. Comparison of the reciprocating sliding wear of 58Ni39Ti-3Hf alloy and baseline 60NiTi[J]. Wear, 2018, 408/409: 120-130.

[37] PEPPER S V, DELLACORTE C, NOEBE R D, HULL D R, GLENNON G. Nitinol 60 as a material for spacecraft triboelements[C]// 13th European Space Mechanisms and Tribology Symposium Conference. Vienna: ESA Communication Production Office ESTEC, 2009.

[38] KHANLARI K, RAMEZANI M, KELLY P. 60NiTi: A review of recent research findings, potential for structural and mechanical applications, and areas of continued investigations[J]. Transactions of the Indian Institute of Metals, 2017, 27(2): 1-19.

[39] FIRSTOV G S, VITCHEV R G, KUMAR H, BLANPAIN B, HUMBEECK J V. Surface oxidation of NiTi shape memory alloy[J]. Biomaterials, 2002, 23(24): 4863-4871.

[40] SANTO PADULA I I, QIU S P, DARRELL G, NOEBE R, GLEN B, GARG A, VAIDYANATHAN R. Effect of upper-cycle temperature on the load-biased, strain- temperature response of NiTi[J]. Metallurgical & Materials Transactions A, 2012, 43(12): 4610-4621.

[41] MIYOSHI K, LUKC D, CYTRON S J. Oxide ceramic films grown on 55Ni-45Ti for NASA and department of defense applications: Unidirectional sliding friction and wear evaluation[R]. Cleveland: NASA Glenn Research Center, 2004.

[42] BUEHLER W J, WANG F E. A summary of recent research on the nitinol alloys and their potential application in ocean engineering[J]. Ocean Engineering, 1968, 1(1): 105-108.

[43] 舒小勇, 胡林丽, 鲁世强, 李贵发, 王克鲁. 锻态Ni60Ti形状记忆合金的高温循环氧化行为[J]. 特种铸造及有色合金, 2017, 37(8): 882-886.

SHU Xiao-yong, HU Lin-li, LU Shi-qiang, LI Gui-fa, WANG Ke-lu. High temperature cyclic oxidation behavior of as-forged Ni60Ti shape memory alloy[J]. Special Casting & Nonferrous Alloys, 2017, 37(8): 882-886.

[44] 舒小勇, 胡林丽, 鲁世强, 李贵发, 王克鲁. Nitinol60形状记忆合金高温变形特性研究[J]. 特种铸造及有色合金, 2017, 37(6): 593-597.

SHU Xiao-yong, HU Lin-li, LU Shi-qiang, LI Gui-fa. High temperature deformation characteristics of Nitinol60 Shape memory alloy base on processing map[J]. Special Casting & Nonferrous Alloys, 2017, 37(6): 593-597.

[45] SHU X Y, LU S Q, WANG K L, LI G F. Optimization of hot working parameters of as-forged Nitinol60 shape memory alloy using processing maps[J]. Metals & Materials International, 2015, 21(4): 726-733.

[46] SHU X Y, LU S Q, WANG K L, LI G F. A comparative study on constitutive equations and artificial neural network model to predict high-temperature deformation behavior in nitinol 60 shape memory alloy[J]. Journal of Materials Research, 2015, 30(12): 1988-1998.

[47] SHU X Y, HU L L, LI G F, LU S Q, WANG K L, PENG P. High-temperature oxidation resistance of the Ni60Ti alloy: An experimental and first-principles study[J]. Journal of Alloys & Compounds, 2017, 706: 297-304.

[48] ZENG Qun-feng, ZHAO Xi-meng, DONG Guang-neng, WU Hong-xing. Lubrication properties of Nitinol 60 alloy used as high-speed rolling bearing and numerical simulation of flow pattern of oil-air lubrication[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2431-2438.

[49] ZENG Qun-feng, DONG Guang-neng. Superlubricity behaviors of Nitinol60 alloy under oil lubrication[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 354-359.

[50] ZENG Q F, DONG G N, MARTIN J M. Green superlubricity of Nitinol60 alloy against steel in presence of castor oil[J]. Scientific Reports, 2016, 6: 29992.

[51] ZENG Q F. Influence of load and sliding speed on super-low friction of Nitinol60 alloy under castor oil lubrication[J]. Tribology Letters, 2013, 52(1): 47-55.

[52] ZHANG F X, ZHENG L J, WANG F F, ZHANG H. Effects of Nb additions on the precipitate morphology and hardening behavior of Ni-rich Ni 55 Ti 45 alloys[J]. Journal of Alloys & Compounds, 2017, 735: 2453-2461.

[53] QIN Q H, WEN Y H, WANG G X, ZHANG L H. Effects of solution and aging treatments on corrosion resistance of as-cast 60NiTi alloy[J]. Journal of Materials Engineering & Performance, 2016, 25(12): 5167-5172.

[54] ZHANG L H, PENG H B, QIN Q H, FAN Q C, BAO S L, WEN Y H. Effects of annealing on hardness and corrosion resistance of 60NiTi film deposited by magnetron sputtering[J]. Journal of Alloys & Compounds, 2018, 746: 45-53.

[55] 薛 飒, 曹继敏, 杨华斌, 牛中杰, 林海峰. NiTi60合金耐磨材料显微组织及硬度的研究[J]. 材料开发与应用, 2012, 27(1): 29-31.

XUE Sa, CAO Ji-min, YANG Hua-bin, NIU Zhong-jie, LIN Hai-feng. Research on the microstructure and hardness of wear resistant NiTi60 alloy[J]. Development and Application of Materials, 2012, 27(1): 29-31.

[56] 薛 飒, 曹继敏, 杨华斌, 牛中杰, 罗斌莉. 热处理对高耐磨性NiTi基合金材料性能的影响[J]. 功能材料, 2012, 43(B08): 152-154.

XUE Sa, CAO Ji-min, YANG Hua-bin, NIU Zhong-jie, LUO Bin-li. Effect pf heat treatment on the properties of high wear resistance materials of TiNi alloys[J]. Journal of Functional Materials, 2012, 43(B08): 152-154.

[57] KHANLARI K, RAMEZANI M, KELLY P, CAO P, NEITZERT T. Mechanical and microstructural characteristics of as-sintered and solutionized porous 60NiTi[J]. Intermetallics, 2018, 100: 32-43.

[58] KHANLARI K, RAMEZANI M, KELLY P, HAYAT M, CAO P, NEITZERT T. Effects of open atmosphere solutionizing treatment on the microstructural and mechanical properties of porous 60NiTi parts[J]. Key Engineering Materials, 2018, 770: 87-94.

[59] KHANLARI K, RAMEZANI M, KELLY P, HAYAT M, CAO P, NEITZERT T. An investigation on microstructural and mechanical properties of porous 60NiTi parts solutionized by different cost-effective methods[J]. Metallography Microstructure & Analysis, 2018, 7(3): 1-13.

Research progress of new superelastic bearing material TiNi60 alloy

YAN Chao1, ZENG Qun-feng1, 2, YANG Hua-bin3

(1. Key Laboratory of Education Ministry for Modern Design and Rotor-Bearing System, Xi’an Jiaotong University, Xi’an 710049, China;

2. Material Corrosion and Protection Key Laboratory of Sichuan Province, Zigong 643000, China;

3. Xi’an Saite Metal Material Co., Ltd., Xi’an 710021, China)

Abstract: TiNi60 alloy was considered as a new type of superelastic bearing material with excellent properties of low elasticity modulus, high hardness, high specific strength, non-magnetism, good dimensional stability and strong corrosion resistance. It was deeply investigated by NASA and other foreign research institutes. The characteristics of TiNi60 alloy were systematically described, the latest research progress in smelting and processing, hardness strengthening mechanism, mechanical properties, tribological properties, high temperature oxidation resistance and superelasticity were discussed, and some problems in current research were analyzed. Moreover, the application prospects in aerospace and research direction of TiNi60 alloy were discussed in order to promote the development of related research.

Key words: TiNi60; bearing material; research progress

Foundation item: Projects(51675409, 51305331)supported by the National Natural Science Foundation of China; Project(2018CL12) supported by the Opening Project of Material Corrosion and Protection Key Laboratory of Sichuan Province, China

Received date: 2019-02-22; Accepted date: 2019-05-30

Corresponding author: ZENG Qun-feng; Tel: +86-18792747296; E-mail: zengqf1949@gmail.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51675409,51305331);材料腐蚀与防护四川省重点实验室开放基金项目(2018CL12)

收稿日期:2019-02-22;修订日期:2019-05-30

通信作者:曾群锋,副教授,博士;电话:18792747296:E-mail:zengqf1949@gmail.com

摘 要:TiNi60合金是一种弹性模量低、硬度大、比强度高、无磁性、尺寸稳定性好、耐腐蚀性强的新型超弹性轴承材料,NASA等国外研究机构对其进行了深入研究。系统阐述了TiNi60合金材料的特性,重点论述了其在熔炼与加工、硬度强化机理、力学性能、摩擦学性能、高温抗氧化行为以及超弹性等方面的国内外最新研究进展,分析了相关研究中存在的问题,并简要阐述了超弹性TiNi60合金在航空航天领域的应用前景,探讨了有关TiNi60合金材料亟需研究的内容,以期推动国内外相关研究进展。

[13] JULIEN G J. Manufacturing of nitinol parts and forms: United States, 6422010[P]. 2002-07-23.

[43] 舒小勇, 胡林丽, 鲁世强, 李贵发, 王克鲁. 锻态Ni60Ti形状记忆合金的高温循环氧化行为[J]. 特种铸造及有色合金, 2017, 37(8): 882-886.

[44] 舒小勇, 胡林丽, 鲁世强, 李贵发, 王克鲁. Nitinol60形状记忆合金高温变形特性研究[J]. 特种铸造及有色合金, 2017, 37(6): 593-597.

[55] 薛 飒, 曹继敏, 杨华斌, 牛中杰, 林海峰. NiTi60合金耐磨材料显微组织及硬度的研究[J]. 材料开发与应用, 2012, 27(1): 29-31.

[56] 薛 飒, 曹继敏, 杨华斌, 牛中杰, 罗斌莉. 热处理对高耐磨性NiTi基合金材料性能的影响[J]. 功能材料, 2012, 43(B08): 152-154.