DOI:10.19476/j.ysxb.1004.0609.2019.12.11

回火工艺对烧结(CePrNd)-Fe-B磁体内禀矫顽力的影响

刘路军1,刘 政2

(1. 江西理工大学 材料科学与工程学院,赣州 341000;

2. 江西理工大学 机电工程学院,赣州 341000)

摘 要:

以双主相法制备不同Ce含量的烧结(CePrNd)-Fe-B磁体,研究不同回火温度下磁体的磁性能,并对微观组织断口进行BSE和EDS分析。结果表明:含Ce磁体的共晶温度和居里温度随Ce含量的增加呈减小的趋势;回火温度对烧结(CePrNd) -Fe-B磁体的剩磁影响不显著;Ce取代量为12%(质量分数)的磁体经回火温度410 ℃处理后,内禀矫顽力从762.6 kA/m上升到1357.2 kA/m,相应提高77.97%,方形度达到最佳值0.953。经410 ℃回火后,磁体主相晶粒间的微观结构形成的壳核结构,晶界分布着较多的条状富Nd相分布。富Nd相中的Ce含量增高,浸润性相对提高,因而有利于减少主相晶粒间的反向磁耦合,提高了室温和高温下磁体的内禀矫顽力。

关键词:

文章编号:1004-0609(2019)-12-2785-08 中图分类号:TM273 文献标志码:A

烧结Nd2Fe14B型永磁材料是稀土应用领域稀土消耗量最大的,年消耗稀土量接近我国稀土总用量的一半。烧结Nd2Fe14B生产中大量使用Pr、Nd等稀土元素,因需求巨大而导致价格高昂,造成磁体成本高。近年来,我国越来越重视对稀土这一重要战略资源的宏观调控和环境监管。高效、合理、均衡利用稀土资源成为我国稀土产业可持续发展战略的重点。实现Ce在钕铁硼的应用,不仅可显著降低钕铁硼的材料成本,而且拓展了高丰度稀土的应用范围,促进我国稀土资源的高效和平衡应用。使用Ce制备永磁材料己经成为国内外稀土永磁发展趋势[1-5]。同时,又希望含Ce磁体高温下性能稳定。为此如何提高磁体的内禀矫顽力一直是近期烧结Nd-Fe-B材料研究的热点[6-9]。但是受限于Ce2Fe14B在室温下的内禀磁特性4πMs=1.17 T,Hcj=2069.6 kA/m[10],随着Ce含量的不断增加,磁体的各向异性场随之下降。因此,在使用Ce部分取代Nd以制造烧结磁体的同时,如何提高含Ce磁体的内禀矫顽力以扩大(CePrNd)-Fe-B的应用范围显得尤为迫切。前期的研究[11-13]表明,采用添加(Nd, Pr)-H、Nd-Fe等能有效提高含Ce烧结磁体的内禀矫顽力,此方法仍需要添加较多的Nd和Pr元素。烧结(PrNd)-Fe-B经过适当的回火处理,有利于提高磁体的性能[14-16]。而通过优化热处理工艺制度提高烧结(CePrNd)-Fe-B磁体的内禀矫顽力研究较少。针对于此,本文以双主相法制备不同Ce含量的烧结(CePrNd)-Fe-B为对象,研究了不同回火温度烧结(CePrNd)-Fe-B的磁性能和温度稳定性与微观组织与成分的规律,揭示其相应的影响机制。

1 实验

选用稀土PrNd(Nd与Pr质量比75:25)、Ce质量分数为99.5%以上、工业纯铁(纯度大于99 %)、硼铁质量分数为19.2%、电解铜、电解铝等,原材料纯度99.5%以上,按双合金法分别制备名义成分不含Ce的(PrNd)33.5FeBal.B1M(Al、Cu、Zr)2.6(质量分数,%)和名义成分含Ce的[(PrNd)Ce]32.7FeBal.B1M(Al、Cu、Zr)2.4(质量分数,%)的磁体为研究对象。首先采用真空感应速凝炉制备得到厚度为0.1~0.5 mm的合金片,将含Ce与不含Ce两种速凝片按一定比例混合后,分别制备PrNd代替质量分数为6%、12%、18%的混合速凝带,经过氢破碎处理,在纯度为99.9%的氮气保护下,经气流磨将氢碎后的颗粒粉碎至2~4 μm的磁粉。采用马尔文激光粒径仪测量磁粉的粒径。磁粉在氮气保护环境下采用1900 mT的取向磁场,以垂直磁场方向压制的方式获得密度约为4.0 g/cm3的压坯。压坯再经过压力为220 MPa的冷等静压处理后获得密度约为4.6 g/cm3的生坯,采用900~1020 ℃烧结5 h的工艺对生坯进行烧结,为了系统地分析回火工艺对烧结Nd-Fe-B磁性能的影响,采用DSC分析未进行回火烧结磁体的相变温度。之后,烧结磁体经过700~900 ℃热处理2 h,为改善磁体的内禀矫顽力,本试验将对烧结(CePrNd)-Fe-B磁体进行适当的回火处理。回火温度分别是410、430和460 ℃,以确保回火温度在共晶温度以上;保温时间为5.5 h,以确保样品回火充分。

最终获得尺寸为50 mm×50 mm×20 mm (20 mm方向为取向方向)的烧结Nd-Fe-B磁体。样品S6、S12、S18分别对应磁体的Ce含量为6%、12%、18%。

机械磨削烧结(CePrNd)-Fe-B磁体以除去表面的氧化薄膜,然后用线切割在磁体中心制作出直径和取向方向都为10 mm的测试样柱,经酸洗后,采用NIM-2000型永磁精密测量系统进行磁性能测试。在JSM-6610型扫描电镜上观察烧结(CePrNd)-Fe-B试样的微观组织。用Oxford能谱分析仪分析试样的组成成分。

2 实验结果

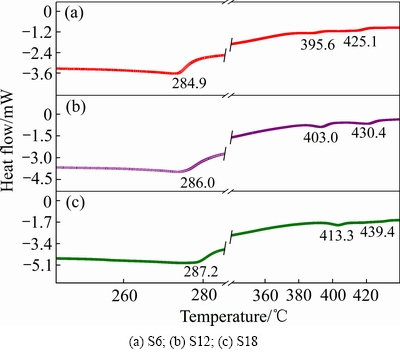

图1所示为样品S6、S12、S18的高温烧结态磁体的DSC测试曲线。由DSC曲线可知,在本实验条件下,添加不同含量的Ce后,烧结(CePrNd)-Fe-B磁体的居里温度在284.9~287 ℃,明显低于Nd2Fe14B磁体的局里温度点315 ℃[11]。通过对DSC曲线的分析,发现了烧结(CePrNd)-Fe-B磁体的共晶温度转变点。

图1 不同Ce含量的烧结(CePrNd)-Fe-B的DSC测试曲线

Fig. 1 DSC test curves of as-sintered with variation Ce content (CePrNd)-Fe-B magnet measured at heating rate of 10 ℃/min

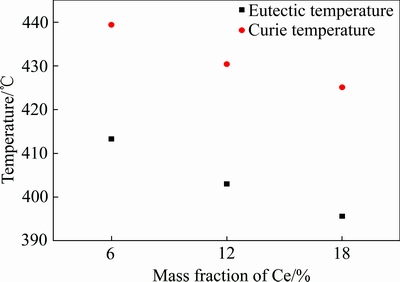

图2所示为不同Ce含量的烧结(CePrNd)-Fe-B的居里温度和二元共晶温度曲线。随着Ce添加量的增加,烧结(CePrNd)-Fe-B的居里温度呈下降趋势,S6样品的居里温度最高,达到287.2 ℃,S18的居里温度最低,降低到284.9 ℃。同时,随着Ce含量的增加,烧结(CePrNd)-Fe-B共晶转变点的温度下降。S6的共晶转变点温度最高,达到413.3 ℃和439.4 ℃,S18的居里温度最低,降低到395.6 ℃和425.1 ℃。相对于不含Ce的烧结NdFeB磁体[14-16],因为Ce元素的添加,使(CePrNd)-Fe-B降低了烧结磁体的共晶转变温度点。有研究表明[17],烧结态的磁体的内禀矫顽力相对较低。回火热处理是进一步提高内禀矫顽力的重要手段。只有当回火温度高于最低共晶转变温度时,磁体晶界处的富Nd相才会发生共晶转变。即在回火过程中,主相晶粒边存在的高温液相过冷态发生L→T1+T2+富Nd相变,在此过程中,富Nd相渗透到主相间的晶界,在主相间形成连续的富Nd相,有助于消除主相晶粒表面缺陷、改变富Nd相的分布,经回火处理后磁体的内禀矫顽力才能进一步提高[7]。不同成分的烧结Nd-Fe-B磁体对应有最佳的回火温度[18]。对比不同Ce含量DSC曲线,样品S12在共晶转变点时DSC曲线的波谷相对最低,说明样品S12在此时共晶转变最剧烈,因此,选择样品S12进行进一步的回火工艺研究。

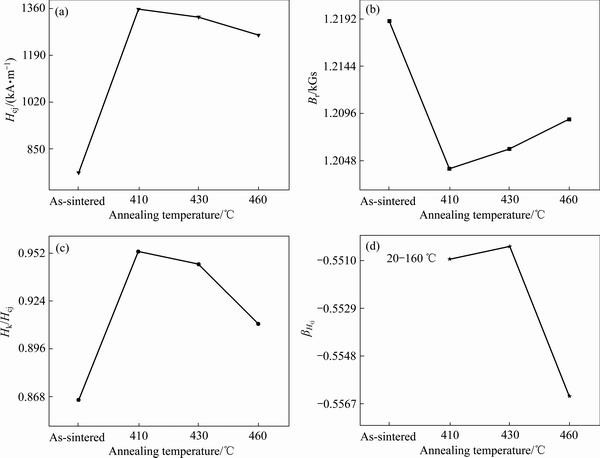

图3所示为经410 ℃、430 ℃、460 ℃回火热处理后的烧结(CePrNd)-Fe-B磁体的剩磁和内禀矫顽力。由图3(a)可知,与回火前的磁性能对比,烧结(CePrNd)-Fe-B磁体的内禀矫顽力显著提升,这与烧结Nd-Fe-B的研究结果相同[19]。在本实验范围内,经大于最低共晶点温度的410 ℃回火后的样品内禀矫顽力提升效果最佳,内禀矫顽力从762.5 kA/m上升到1357.2 kA/m,相应提高了77.97%。随着回火温度的升高,内禀矫顽力提升幅度减小,如经过430 ℃回火热处理后,烧结(CePrNd)-Fe-B的内禀矫顽力增加了566.8 kA/m,相应提高74.32%,而经过460 ℃回火热处理后,烧结(CePrNd)-Fe-B内禀矫顽力增加了500.7 kA/m,相应提高65.66%。与回火前对比,剩磁的变化并不显著,如图3(b)所示,经410 ℃回火热处理后,烧结(CePrNd)-Fe-B样品剩磁降低最大,但是也仅降低1.23%。图3(c)所示为不同回火温度下烧结(CePrNd)-Fe-B的SF(Square factor, SF=Hk/Hcj)。经回火处理后,烧结(CePrNd)-Fe-B磁体的SF也得到较大的改善,在本实验范围内,方形度从回火前0.866升到回火后的0.9以上,达到主流烧结Nd-Fe-B磁体的相应水平,在回火温度为410 ℃时,方形度达到最佳的0.953。方形度的提高,有助于烧结磁体在实际使用中长时间确保磁性能稳定性[20],因此,可进一步提高低成本烧结(CePrNd)-Fe-B的实用价值。随后在160 ℃下测试烧结(CePrNd)-Fe-B在高温下的内禀矫顽力,如图3(d)所示。随着回火温度的降低,烧结(CePrNd)-Fe-B在高温下的内禀矫顽力逐渐提高,回火温度为410 ℃时,160 ℃的内禀矫顽力最高,达到310.4 kA/m。当回火温度为460 ℃时,160 ℃的内禀矫顽力最低,仅为279.3 kA/m。

图2 居里温度和共晶温度随Ce含量变化

Fig. 2 Curie temperature and lower Eutectic temperature with variation Ce content

磁体的内禀矫顽力温度系数可表示为

(1)

(1)

式中: 为磁体的内禀矫顽力的温度系数,%/℃;t为高温测试时的温度,℃;t0为常温测试时的温度,℃。由此式计算得到的温度系数为负值,

为磁体的内禀矫顽力的温度系数,%/℃;t为高温测试时的温度,℃;t0为常温测试时的温度,℃。由此式计算得到的温度系数为负值, 的绝对值越小,即说明磁体的温度稳定性越好。

的绝对值越小,即说明磁体的温度稳定性越好。 的绝对值随着回火温度的降低而降低,回火温度410 ℃时

的绝对值随着回火温度的降低而降低,回火温度410 ℃时 为-0.550%/℃,回火温度为430 ℃时,

为-0.550%/℃,回火温度为430 ℃时, 为-0.550%/℃;回火温度460 ℃时,

为-0.550%/℃;回火温度460 ℃时, 为-0.556%/℃。从温度系数随回火温度的变化规律可知,在越接近最低共晶点的回火温度进行回火的磁体其内禀矫顽力的温度稳定性越好。

为-0.556%/℃。从温度系数随回火温度的变化规律可知,在越接近最低共晶点的回火温度进行回火的磁体其内禀矫顽力的温度稳定性越好。

图3 不同回火温度后的磁性能

Fig. 3 Dependence of coercivity Br(a), remanence(b) and SF(c), βHcj(d) on variation annealing temperatures

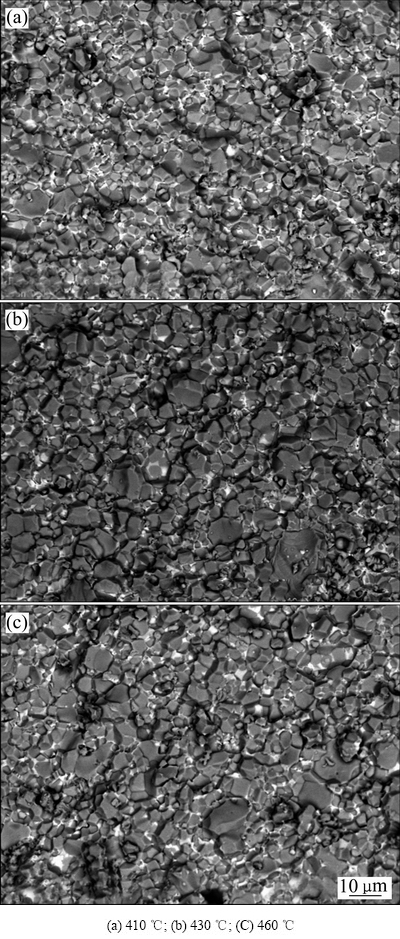

图4 S12经不同回火温度后烧结(CePrNd)-Fe-B的SEM像

Fig. 4 SEM images of samples at different annealing temperatures

图4所示为经不同回火温度后烧结磁体的背散射图像。图中灰白色为烧结磁体的主相,而呈明亮的区域或条状为烧结磁体的富Nd相。从图4可以看到,烧结(CePrNd0-Fe-B微观结构致密连续,没有发现晶粒异常长大的现象,也没有发现异物夹杂。从图4(a)可以看出,经410 ℃回火处理的烧结磁体明亮区域的分布更分散、均匀。从图4(b)中可以看出,经430 ℃回火处理的磁体的条状富Nd相明显要少于从图4(a),说明经430 ℃回火后在主相晶粒的间的分布要少于经410 ℃回火后的磁体。而经460 ℃回火后的磁体中块状富Nd相明显增多,见图4(c)所示,说明富Nd相团聚趋势增加。

3 分析与讨论

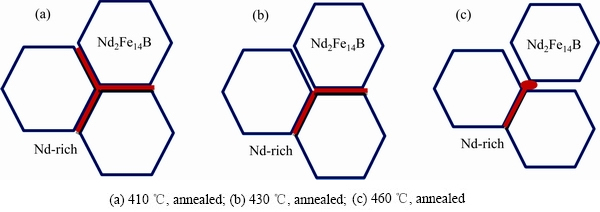

图5所示为不同回火温度后主相晶粒四周富Nd相的分布示意图。经410 ℃回火后富钕相与主相主要以壳-核形态存在,富Nd相主要分布在主相晶粒之间。在烧结及后续的热处理过程中,块状富Nd相作为形成薄层晶界相的富Nd相的来源[21]。经460 ℃回火后,大量的富Nd相已块状分布在主相晶粒之间,较少部分分布在主相晶粒之间,而经430 ℃回火的富Nd相分布则介于两者的分布之间,块状富Nd相的存在影响了富Nd相的利用率。只有当这些富Nd相沿主相晶粒边界并且连续分布时,仅需要厚度为2.1nm[22]就可以有效的隔离相邻的Nd2Fe14B主相晶粒,具有去磁交换耦合作用、使主相之间不易形成反磁化畴核,同时有效阻滞反向磁畴的传播,因而提高磁体的内禀矫顽力。晶间薄层富Nd相的缺失,不会阻碍畴壁的位移,一个晶粒的反磁化就会带动其他晶粒的反磁化,使J-H退磁曲线的Hk降低,SF因子下降。

不同回火温度制备的磁体的在160 ℃下的磁性能也呈现较大区别。分析高温下的矫顽力形成机制通常可以用形核型表示[23]。

图5 不同回火温度主相晶粒四周的富钕相分布

Fig. 5 Schematic diagram of microstructure around Nd2Fe14B grains and Nd-rich phase

(2)

(2)

式中: 表示晶粒外层存在低磁晶各向异性常数区域时的调节系数;

表示晶粒外层存在低磁晶各向异性常数区域时的调节系数; 表示主相晶粒边界不存在薄层富Nd相时,相邻晶粒之间存在的交换耦合作用系数;Neff是与主相晶粒外形与平均晶粒尺寸相关的散磁场因子。从烧结(CePrNd)-Fe-B磁体在410 ℃、430 ℃、460 ℃回火温度下的BSE图像分析,在410 ℃回火后的磁体的富Nd相更多的以薄片状分布在相邻主相晶粒之间,从而有效减少了短程交换耦合作用系数

表示主相晶粒边界不存在薄层富Nd相时,相邻晶粒之间存在的交换耦合作用系数;Neff是与主相晶粒外形与平均晶粒尺寸相关的散磁场因子。从烧结(CePrNd)-Fe-B磁体在410 ℃、430 ℃、460 ℃回火温度下的BSE图像分析,在410 ℃回火后的磁体的富Nd相更多的以薄片状分布在相邻主相晶粒之间,从而有效减少了短程交换耦合作用系数 ,极大地提高了磁体的在20 ℃以及160 ℃下的内禀矫顽力,改善了磁体的矫顽力温度系数,提高了烧结(CePrNd)-Fe-B磁体在高温工作性能,进一步扩大了该类型磁体的应用领域。

,极大地提高了磁体的在20 ℃以及160 ℃下的内禀矫顽力,改善了磁体的矫顽力温度系数,提高了烧结(CePrNd)-Fe-B磁体在高温工作性能,进一步扩大了该类型磁体的应用领域。

当主相间的晶界出现未被富Nd相填充的缝隙时,两两主相之间邻近富Nd相的微观区域出现垂直于c轴的磁极,在这些区域存在反向的微观退磁场。随着缝隙的增多与延长,造成内部杂散场增加[18]。这些因素结果都会导致Neff的上升。由式(2)可知,所以在本实验范围内,410 ℃回火处理后的烧结(CePrNd)-Fe-B的20 ℃和160 ℃的内禀矫顽力最高。

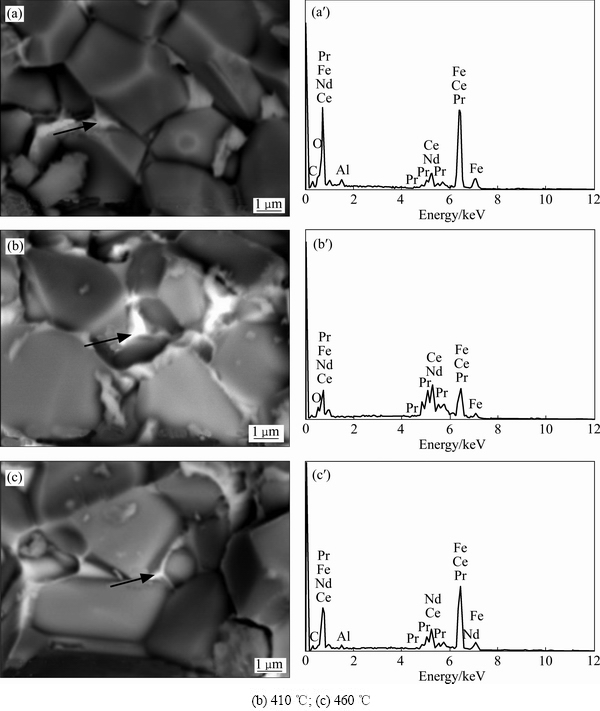

为进一步分析经410 ℃回火后矫顽力提高原因,采用JSM-6610型的扫描电镜和Oxford能谱分析仪观察试样的显微组织,并进行微区成分分析,结果见图6所示。通过EDS对分布在主相晶粒间交隅处(箭头所示)的富Nd相进行微区成分分析,其成分分析结果如表1所示。

图6 高温烧结后及不同回火温度下BSE图像和EDS分析结果

Fig. 6 BSE images and EDS analyses results on as-sintered magnet(a) and at different annealing temperatures

表1 不同回火温度富Nd相稀土含量

Table 1 Element content in Nd-rich phase at different annealing temperatures

由回火热处理前后富Nd相的能谱成分分析可知,回火热处理过程使富Nd相发生了成分上的变化。经460 ℃回火后,富Nd相中的Fe元素的摩尔分数为48.82%,接近烧结态中的Fe元素的摩尔分数41.7%,高于经410 ℃回火后的Fe元素摩尔分数的29.36%,而富Nd相稀土含量为41.55%,富Nd相中Fe和Nd的原子比相对于烧结态变化较大。

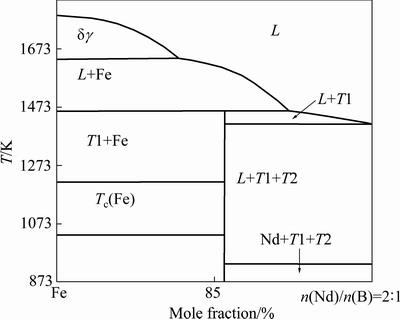

图7所示为钕铁硼三元相图的截面图[17]。由图7可知,在高于三元共晶温度时进行回火时,高温液相过冷态发生L(过冷液态)→T1+T2的转变,共晶产物中包含较多的Fe元素。而回火温度介于低共晶温度和三元共晶温度之间时,高温液相过冷态发生L(过冷液态)→T1+T2+富Nd相的共晶转变,主相晶粒表面层中超过平衡浓度的Nd原子扩散进入了富Nd相,从而使得回火态中的Nd含量相对烧结态时的有所提高,实现了主相晶粒表面的磁硬化[17]。

图7 钕铁硼系的n(Nd):n(B)=2:1纵截面图[17]

Fig. 7 Slit section digram of n(Nd):n(B)=2:1[17]

实际生产的烧结(CePrNd)-Fe-B磁体中相组成及其复杂。磁体中除存在(CeNd)2Fe14B磁性主相、富B相、富Nd相外,非常容易出现Ce2Fe17相,还存在较多的CeFe2等富Fe相,磁体的最优成分与烧结Nd-Fe-B磁体不同,而烧结Nd-Fe-B磁体中并无类似的相。Fe含量越高越倾向于形成熔点较高的CeFe2、Ce2Fe17。以前的研究认为[24-25],独立存在的CeFe2 Lave相实际上降低了富Nd相的浸润性,使得填充到晶间的起退磁耦合的富Nd相减少。CeFe2 Laves相的存在妨碍了高Ce含量烧结磁体获得高内禀矫顽力。在最优回火工艺热处理后,富Nd相中的Fe原子进入主相晶粒表面层, Fe元素含量的减少有利于提高非铁磁性晶界相的比例。因此在本实验范围内,经最佳回火温度410 ℃回火后内禀矫顽力最高,460 ℃回火后的烧结磁体的内禀矫顽力最低。在最佳回火温度下得到的烧结(CePrNd)-Fe-B磁体中,Ce更倾向于富集在富Nd相中,从而提高了富Nd相的润湿性,使得富Nd相充分填充到主相间,降低了晶间的反向磁耦合,提高了烧结(CePrNd)-Fe-B的内禀矫顽力。

4 结论

1) 含Ce磁体的共晶相变点温度和居里温度随Ce添加量的增加明显下降。

2) 适当的回火处理可以提升磁体的内禀矫顽力。通过实验研究,获得了改善烧结(CePrNd)-Fe-B磁体内禀矫顽力的合适工艺参数:410 ℃回火热处理5.5 h。

3) 经不同回火温度制备磁体后,磁体内禀矫顽力随回火温度的降低单调升高,回火温度为410 ℃时,烧结(CePrNd)-Fe-B磁体室温下内禀矫顽力、在160 ℃下的内禀矫顽力,SF出现极大值;回火温度对烧结(CePrNd)-Fe-B磁体的剩磁影响不显著。

4) 经460 ℃回火后,在此磁体中发现较多的块状富Nd相,经410 ℃回火后发现较多的条状富Nd相分布,磁体主相晶粒间的微观结构明显优化。经410 ℃回火后的富Nd相中的Ce含量明显高于经460 ℃回火后的磁体。

5) 在最佳回火温度下得到的烧结(CePrNd)- Fe-B磁体中,Ce更倾向于富集在富Nd相中,从而提高了富Nd相的润湿性,使得富Nd相充分填充到主相间,降低了晶间的反向磁耦合,提高了烧结(CePrNd)-Fe-B的内禀矫顽力。

REFERENCES

[1] DORMIDONTOV N A, DORMIDONTOV AG, LILEEV AS, KAMYNIN A V,LUKIN A A. Effect of partial substitution of neodymium with praseodymium on the magnetic and process properties of sintered magnets of type NdFeB[J]. Metal Science and Heat Treatment, 2016, 58(10): 27-33.

[2] ZHANG Xue-feng, SHI Meng-fei, LI Pei-zhong, DAI Yong-feng, MA Qiang, LI Yong-feng. Effect of Ce addition on magnetic properties and microstructure of NdFeB based rare earth permanent magnets[J]. Chinese Rare Earths, 2013, 34(4): 12-16.

[3] ZHU Ming-gang, LI Wei, WANG Jing-dai, ZHENG Li-yun, LI Yan-feng, ZHANG Ke, FENG Hai-bo, LIU Tao. Influence of Ce content on the rectangularity of demagnetization curves and magnetic properties of Re-Fe-B magnets sintered by double main phase alloy method[J]. IEEE Transactions on Magnetics, 2013, 50(1): 1-4.

[4] LI Zhi, LIU Wei-qiang, ZHA Shan-shun, LI Yu-qing, WANG Yun-qiao, ZHANG Dong-tao, ZHANG Jiu-xing. Effects of lanthanum substitution on microstructures and intrinsic magnetic properties of sintered Nd-Fe-B alloy[J]. Journal of Rare Earths, 2015, 33(9): 961-964.

[5] MURAL Z, KOLNES M, AFSHARI H, LAURI K, JOOSEP L, RENNO V. Fabrication and microstructural analysis of didymium-iron-boron magnet alloys with cerium additions[J]. Proceedings of the Estonian Academy of Sciences, 2016, 65(2): 166-171.

[6] YAN G H, CHEN R J, DING Y, GUO S, LEE D, YAN A R. The preparation of sintered NdFeB magnet with high-coercivity and high temperature-stability[J]. Journal of Physics: Conference Series, 2011, 266: 012052-012057.

[7] 王 静, 梁 乐, 武梦艳, 陈诗豪, 祝隐峰, 曲冠雄, 郑博瀚, 张澜庭. 烧结NdFeB永磁体的晶界微细结构及性能研究进展[J]. 中国有色金属学报, 2014, 24(6): 1562-1577.

WANG Jin, LIANG Le, WU Meng-yan, CHEN Shi-hao, ZHU Yin-feng, QU Guan-xiong, ZHENG Bo-han, ZHANG Lan-ting. Research progress on grain boundary fine microstructure and magnetic properties of sintered Nd-Fe-B magnet[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1562-1577.

[8] WANG Xiao-li, ZHAO Li-na, DING Kai-hong, CUI Sheng-li, SUN Yong-cong, LI Mu-sen. Influence of dysprosium distribution on properties of sintered and aged Dy-doped NdFeB permanent magnets[J]. Rare Metal Materials and Engineering, 2016, 45(2): 0309-0314.

[9] CHEN Bi-cheng, LIU Xing-min, CHEN Ren-jie, GUO Shuai, YAN Chang-jiang, LEE Don, YAN A-ru. Design and fabrication of Dy-free sintered permanent magnets with high coercivity[J]. Journal of Applied Physics, 2012, 111(7): 344-347.

[10] 周丽娟, 裴文利, 郭小莲, 朱明刚. 含Ce烧结Nd-Fe-B磁体的腐蚀行为[J]. 材料与冶金学报,2015,14(3): 217-221.

ZHOU Li-juan, PEI Wen-li, GUO Xiao-lian, ZHU Ming-gang. Corrosion behavior of low cost sintered Nd-Fe-B magnet containing element Ce[J]. Journal of Materials and Metallurgy, 2015, 14(3): 217-221.

[11] MA Tian-yu, WU Bo, ZHANG Yu-jing, JIN Jia-ying, WU Kai-yun, TAO Shan, XI Wei-xing, YAN Mi. Enhanced coercivity of Nd-Ce-Fe-B sintered magnets by adding (Nd, Pr)-H powders[J]. Journal of Alloys and Compounds, 2017, 721: 1-7.

[12] CHEN Kan, GUO Shuai, FAN Xiao-dong, DING Guang-fei, CHEN Ling, CHEN Ren-jie, LEE Don, YAN A-ru. Coercivity enhancement of Ce-Fe-B sintered magnets by low-melting point intergranular additive[J]. Journal of Rare Earths, 2017, 35(2): 158-163.

[13] MA Tian-yu, YAN Mi, WU Kai-yun, WU Bo, LIU Xiao-lian, WANG Xue-jiao, QIAN Ze-yu, WU Chen, XIA Wei-xing. Grain boundary restructuring of multi-main-phase Nd-Ce-Fe-B sintered magnets with Nd hydrides[J]. Acta Materialia, 2018(142):18-28.

[14] 谭春林, 白书欣, 张 虹, 高艳丽, 蔡 珣. 回火处理对烧结钕铁硼永磁材料组织和磁性的影响[J].中国有色金属学报, 2002, 12(S1): 64-66.

TAN Chun-lin, BAI Shu-xin, ZHANG Hong, GAO Yan-li, ZHANG Jia-chun, CAI Xun. Effect of tempering on microstructure and magnetic properties of sintered Nd-Fe-B magnets[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 64-66.

[15] LI Zhi-jie, LI Xu, LI Jia, TIAN Ming, LI Zhan-ju. Effect of annealing on magnetic properties of rapid quenching Nd-Fe-B magnets[J]. Materials Protection 2014, 47(S1): 140-142.

[16] LIANG Le, WU Meng-yan, LIU Li-hua, MA Chong, WANG Jing, ZHANG Jiang-dong, ZHANG Lan-ting. Sensitivity of coercivity and squareness factor of a Nd-Fe-B sintered magnet on post-sintering annealing temperature[J]. Journal of Rare Earths, 2015, 33(5): 507-513.

[17] 周寿增,董清飞.超强永磁体[M].北京:冶金工业出版社, 2004: 254.

ZHOU Shou-zeng, DONG Qing-fei. Super magnets: Fe-based rare earth permanent magnetic materials[M]. Beijing: Metallurgical Industry Press, 2004: 254.

[18] AKIYA T, SASAKI T T, OHKUBO T, UNE Y, SAGAWA M, KATO H, HONO K. The origin of the coercivity reduction of Nd-Fe-B sintered magnet annealed below an optimal temperature[J]. Journal of Magnetism & Magnetic Materials, 2013, 342(9): 4-10.

[19] DING Xia, DING Kai-hong, CUI Sheng-li, SUN Yong-cong, LI Mu-sen. Effect of optimal aging treatment on magnetic performance and mechanical properties of sintered Nd-Fe-B permanent magnets[J]. Journal of Central South University, 2016, 23(3): 515-522.

[20] HAAVISTO M, TUOMINEN S, SANTANOKKI T, KANKAANPAA H, PAJU M, RUUSKANEN P. Magnetic behavior of sintered NdFeB magnets on a long-term timescale[J]. Advances in Materials Science & Engineering, 2014, 2014(7): 1-7.

[21] ZHANG Pei, MA Tian-yu, LIANG Li-ping, YAN Mi. Influence of Ta intergranular addition on microstructure and corrosion resistance of Nd-Dy-Fe-B sintered magnets[J]. Journal of Alloys & Compounds, 2014, 593: 137-140.

[22] LIU Xiao-lian, MA Tian-yu, WANG Xue-jiao, MI Yan. Coercivity enhancement of low rare earth Nd-Fe-B sintered magnets by optimizing microstructure[J]. Journal of Magnetism & Magnetic Materials, 2015, 382: 26-30.

[23] JIANG Qing-zheng, ZHONG Ming-long, QUAN Qi-chen, ZHANG Jia-sheng, ZHONG Zhen-chen. Striking effect of Hf addition on magnetic properties and thermal stability of Nd13Fe81-xB6Hfx, (x=0-1.0) alloys[J]. Journal of Alloys & Compounds, 2016, 688: 363-367.

[24] RAO Xiao-lei,NIU E,HU Bo-ping. Effects of cerium on permanent magnetic properties of sintered Nd-Fe-B magnets[J]. Materials China, 2017, 36(1): 63-74.

[25] LI An-hua, LI Wei,ZHANG Yue-ming, FENG Hai-bo, ZHAO Yang, ZHU Ming-gang. New progress in research and development of (Ce, RE)-Fe-B permanent magnetic materials[J]. Journal of the Chinese Society of Rare Earths, 2016, 34(6): 715-725.

Effect of annealing technology on coercivity and thermal stability in (CePrNd)-Fe-B sintered magnet

LIU Lu-Jun1, LIU Zheng2

(1. School of Materials Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Mechanical and Electrical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Resource-saving (PrNdCe)FeB sintered magnets with nominal composition (PrNd)CeFeB were prepared using a dual alloy method by mixing (PrNd)CeFeB with (PrNd)FeB powders. In this work, the magnetic properties at different annealing temperatures were investigated. The microstructures were examined by SEM and EDS. The results show that the eutectic temperature and the Curie temperature of (CePrNd)-Fe-B magnets have a downward tendency with increasing Ce content. When the magnets with substitution of 12% Ce were annealed at 410 ℃, the intrinsic coercivity increases from 762.6 kA/m to 1357.2 kA/m. The Hk/Hcj is improved to peak value of 0.953. The core-shelled structures form between the main phase grains in the magnet annealed at 410 ℃, in which more Nd-rich phases with strip-like distribute at the grain boundary. The wettability of Nd-rich phase is relatively improved with increasing Ce content, which is beneficial to reduce the reverse magnetic coupling between the main phase grains, thus the coercivity of (CePrNd)-Fe-B magnets at the room and high temperature is improved. Strip Nd-rich phase is discovered in the magnet under 410 ℃ annealing condition and Ce content is higher in the Nd-rich phase, the core-shell microstructure deforms which is beneficial to the coercivity of (CePrNd)-Fe-B magnets.

Key words: Ce-Fe-B magnet; dual alloy; magnetic property; annealing

Foundation item: Project(2010AA03A401) supported by the National High-tech Research and Development Program of China; Project( [2018]50) supported by the Science and Development in Ganzhou City, China; Project (203200800148) supported by the Special Fund of Postgraduate Innovation, China

Received date: 2018-09-20; Accepted date: 2019-07-20

Corresponding author: LIU Zheng; Tel: +86-13879729585; E-mail: liukk66@163.com

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2010AA03A401);赣市科发项目([2018]50号);研究生创新专项基金资助项目(203200800148)

收稿日期:2018-09-20;修订日期:2019-07-20

通信作者:刘 政,教授,博士;电话:13879729585;E-mail:liukk66@163.com

摘 要:以双主相法制备不同Ce含量的烧结(CePrNd)-Fe-B磁体,研究不同回火温度下磁体的磁性能,并对微观组织断口进行BSE和EDS分析。结果表明:含Ce磁体的共晶温度和居里温度随Ce含量的增加呈减小的趋势;回火温度对烧结(CePrNd) -Fe-B磁体的剩磁影响不显著;Ce取代量为12%(质量分数)的磁体经回火温度410 ℃处理后,内禀矫顽力从762.6 kA/m上升到1357.2 kA/m,相应提高77.97%,方形度达到最佳值0.953。经410 ℃回火后,磁体主相晶粒间的微观结构形成的壳核结构,晶界分布着较多的条状富Nd相分布。富Nd相中的Ce含量增高,浸润性相对提高,因而有利于减少主相晶粒间的反向磁耦合,提高了室温和高温下磁体的内禀矫顽力。