DOI: 10.11817/j.ysxb.1004.0609.2020-35790

掺镍Fe3Si合金介电性能的第一性原理计算及其电磁特性分析

任 芬1, 2,马 瑞1, 2,黄志东1, 2,谢 泉2

(1. 贵州大学 材料与冶金学院,贵阳 550025;

2. 贵州大学 先进光电子材料与技术研究所,贵阳 550025)

摘 要:

采用基于密度泛函理论的赝势平面波法,研究了Ni元素对Fe3Si合金电子结构及介电性能的影响。计算结果表明:添加Ni元素后体系金属性增强,电导率增大。Ni元素使体系的介电常数实部和虚部在高频段显著提高,并具有展宽吸收频带所期望的频响特性。利用机械球磨和真空退火方法制备了Fe75Si25和Fe71.875Ni3.125Si25合金粉末,测试了试样在2~18 GHz的微波介电常数和磁导率。实验结果表明:添加Ni元素后,合金体系的磁导率和介电常数都增大,且两者的虚部增大更加显著,尤其在10.6 GHz处介电常数虚部峰值达1.31,较Fe75Si25合金粉末高1.11,进一步验证了理论计算结果,并讨论了微波损耗机制。

关键词:

文章编号:1004-0609(2020)-06-1399-07 中图分类号:TB34 文献标志码:A

随着微波通讯和电子技术的不断发展,电磁干扰和电磁污染问题日趋严重。人们通常采用微波吸收材料将不需要的电磁波转换为热能等形式耗散掉,从而抑制电磁干扰并减小电磁污染所带来的危害。Fe基磁性金属粉末具有初始磁导率、自然共振频率高以及饱和磁化强度大的优点,用其制备的吸波材料吸波强度高、吸收频带宽、易于加工,是最为重要的电磁波吸收剂。Fe-Si系较于羰基铁粉(CIP)、Fe-Ni系和Fe-Co系,具有较强抗腐蚀能力和较高的磁导率,使其阻抗匹配能力更强,更有利于减小入射电磁波在材料表面的反射[1-4]。目前,研究人员主要针对Fe-Si系中的FeSi合金和FeSiAl合金电磁特性进行了深入研究[5-8],而对Fe3Si合金的报道还较少。Fe3Si 合金具有高磁导率、高饱和磁化强度、低矫顽力、高频下低铁损、高居里温度及优良抗腐蚀性能等特性[9],在吸波材料领域有着很好的应用前景。然而,单一的Fe3Si 合金远远不能满足新型吸波材料“薄、轻、宽、强”等性能要求,因此,通过对其掺杂[10]或将其做成复合材料[11]是现在国内外研究的热点。陈志彦等[12]采用原位聚合制备了纳米Fe3Si/SiC复合吸收剂,指出 Fe3Si相可提高材料的复介电常数。KUANG等[13]采用机械活化辅助法制备了Co掺杂SiC粉末,相比于未掺杂,Co掺杂后在8.2~12.4 GHz频率范围内提高了材料的高温介电性能和微波吸收性能,并结合第一性原理计算表明Co掺杂后引进了大量缺陷,进一步促进了极化损耗。XIE等[14]也指出Fe3Si相的出现可提高材料的吸波性能,但Fe3Si 合金本征脆性较大[15],粉体在球磨过程中很容易碎化,限制了片状化程度的提升。因此,合金化成为改善Fe3Si合金吸波性能的理想方法。

为了进一步认识合金化对Fe3Si合金吸波材料电磁特性的影响和作用机制,本文采用基于密度泛函理论的第一性原理方法,系统地计算分析了Ni元素添加对Fe3Si合金电子结构、磁学性能及介电性能。进一步采用机械球磨和真空退火方法制备了Fe75Si25和Fe71.875Ni3.125Si25合金粉末吸波剂,与计算结果进行了比较,最后对其微波损耗机理进行了探讨。

1 计算方法和实验

1.1 计算模型和方法

Fe3Si具有面心立方 D03结构,其空间群为Fm-3m (No.225),Pearson符号为cF16,晶格常数为5.65  。

。

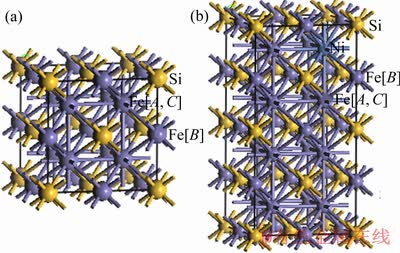

以等效点系(Wyckoff)符号表征,Fe原子占据4b亚晶格位置和8c亚晶格位置,Si原子占据4a亚晶格位置;其中,b、c和a为多重性(Multiplicity),且4b亚晶格位置的等效内部坐标为A(0.5, 0.5, 0.5),8c亚晶格位置的等效内部坐标为B(0.25, 0.25, 0.25)和C(0.75, 0.75, 0.75)位置,而Si原子占据的4a亚晶格位置的等效内部坐标为D(0, 0, 0)。本文Ni的掺杂浓度为3.125% ,取代8c亚晶格位置[B, C]上的Fe原子[16-17]。Fe75Si25和Fe71.875Ni3.125Si25的晶体结构分别如图1(a)和(b)所示。

图1 Fe3Si单晶和Fe71.875Ni3.125Si25超胞

Fig. 1 Fe3Si unit cell(a) and Fe71.875Ni3.125Si25 supercell(b) (1×1×2)

本文采用Materials Studio软件包中的CASTEP模块进行计算。计算中采用广义梯度近似(GGA)的PBE处理电子之间的交换关联能,选择 BFGS(Broyden Fletcher Goldfarb Shanno)[18]算法对晶体模型进行几何结构优化,以求得局域最稳定结构,离子实与电子之间相互作用采用超软赝势[19]处理,用平面波矢量展开原胞中的价电子波函数。采用周期性边界条件,平面波数目由动能截断点决定,平面波的截断能量取 330 eV,K点网格数[20]取 4×4×4,自洽场计算(SCF)时应用Pulay密度混合法,体系总能量收敛值取10-6 eV/atom,每个原子上的力要求低于 0.05 eV/nm,公差偏移小于2×10-3 nm,应力偏差小于 0.05 GPa。

1.2 掺镍Fe3Si合金粉体吸收剂的制备及其电磁特性测试

本实验采用市售还原铁粉、硅粉和镍粉(纯度≥99.9%,粒度为74 mm)作为原始粉末,按摩尔分数配制成Fe75Si25和Fe71.875Ni3.125Si25混合粉末,在XQM-4L变频行星式球磨机进行机械合金化,选用

不锈钢罐和淬火钢球,球料比为30:1,球磨机转速为330 r/min,球磨35 h,球磨后的合金粉末于真空退火炉中退火1 h,退火温度为900 ℃;采用X’PertProMPD多功能X射线衍射仪对试样进行物相分析(Cu Kα射线,扫描速度4 (°)/min,歩宽0.02°);利用AV3618矢量网络分析仪在2~18 GHz范围内对试样的电磁参数进行测试。

2 结果与讨论

2.1 电子结构

图2所示为总态密度和分波态密度图。如图2所示,Fe3Si价带底部-11.5~-8.6 eV较低能量的区域,Si 原子3s轨道对态密度做出贡献。价带的上部-7.2 eV以上区域,态密度主要源于 Fe 原子 3d轨道和 Si 原子 3p轨道。而费米能级附近区域的波峰,则主要由 Fe的d态电子和Si的3p态电子贡献。费米能级两侧分别出现尖峰,表明有共价电子的作用,且其态密度均来源于Fe原子3d轨道,轨道上d电子相对较局域。同时费米能级附近存在明显的赝能隙。

图3所示为能带结构。如图3所示,费米能级与能带相交,表明体系呈金属性,且费米能级以下的价带区域能带明显多以上的导带区域,这说明价带区的电子贡献多余导带区,这都与态密度图吻合。

添加Ni元素后,成键电子数增多,价电子间相互作用增强,价带底部和导带顶部区域的态密度除来自Si 3p态和Fe 3d态的贡献外,还有来自Ni 3d电子的贡献。同时费米面位于赝能隙谷底,Fe的d轨道电子分别与Fe和Ni的d轨道电子之间发生强烈的相互作用。由此可见,添加Ni元素,一方面有利于提高体系相结构稳定性。另一方面,d-d电子间的相互作用增强了系统的金属性,而相对较弱的d-p电子间相互作用则降低了共价键的方向性。其次,费米能级与第一激发态峰位间距减小,表明晶体费米能级处的电子跃迁到第一激发态更容易,并使得价带中的载流子的浓度增大, 增强了Fe3Si体系的电导率。此外,由于在费米能级处提供了更多的自由电子参与导带电子杂化,从而改变了费米能级处的态密度。根据波尔兹曼方程,电导率与费米面处态密度成正比,即σFe71.875Ni3.125Si25<σFe3Si,电阻率的变化趋势与之相反,因此添加Ni后,合金更适用于高频环境。

图2 总态密度和分波态密度图

Fig. 2 Total density of states and partial density of states

图3 能带图

Fig. 3 Energy band diagram

2.2 介电常数

图4所示为Fe75Si25和Fe71.875Ni3.125Si25的介电常数实部ε' 和虚部ε" 随能量变化的曲线。如图4所示,在4~12.79 eV能量区域,Fe71.875Ni3.125Si25的介电常数实部大于Fe75Si25的,且在4~10 eV能量区间出现两个峰值,分别位于5.13和8.09 eV。在7.46~14 eV范围内,Fe71.875Ni3.125Si25的介电常数虚部远大于Fe75Si25的,且于9.08 eV处具有最大值。

因此,Ni元素的添加有利于介电常数实部和虚部的提高,尤其在高能量范围内介电常数虚部显著提高,这有利于提高合金的介质损耗(tan δE=ε"/ε'),同时具有展宽吸收频带所期望的频响特性,尤其是在我们关注的2~18 GHz频率范围即在图4中大于7.46 eV能量范围内(E=nhv:E为能量,h为普朗克常数,v为频率)。根据公式E=hν,提高频率,正是提高单个量子的能量,然而高频振子是一种“低效光源”,与低频振子相比,高频振子的能量虽然增大了,但是处于第一激发态的振子的相对数目却大幅度减少,所以高频段的总辐射能量大大减小[21]。

图4 Fe75Si25和Fe71.875Ni3.125Si25的介电常数实部ε' 和虚部ε" 与能量的关系曲线

Fig. 4 Relation curves between dielectric constant and energy of Fe75Si25 and Fe71.875Ni3.125Si25: (a) Real part of dielectric constant ε'; (b) Imaginary part of dielectric constant ε"

在交变外场作用下,介电常数是频率ω的函数,表示为[22]:

(1)

(1)

式中: 表示复介电常数;实部

表示复介电常数;实部 表示储存电磁能的能力;虚部

表示储存电磁能的能力;虚部 表示损耗电磁能的能力;j表示虚部单位。在一定的微波频率范围内,介电常数虚部则可表示为[23]:

表示损耗电磁能的能力;j表示虚部单位。在一定的微波频率范围内,介电常数虚部则可表示为[23]:

(2)

(2)

式中: 为直流电导率;ε0 为真空介电常数;εac为高频时的介电损耗贡献。由式(2)可知,Ni元素的添加可提高电导率,增加产生的载流子在高频下的损耗贡献,从而有利于提高微波范围内的介电损耗。可见,Ni元素的添加使Fe3Si在高频范围内有较大的介电常数实部和虚部,增大了Fe3Si软磁体的介电损耗和阻抗匹配特性。

为直流电导率;ε0 为真空介电常数;εac为高频时的介电损耗贡献。由式(2)可知,Ni元素的添加可提高电导率,增加产生的载流子在高频下的损耗贡献,从而有利于提高微波范围内的介电损耗。可见,Ni元素的添加使Fe3Si在高频范围内有较大的介电常数实部和虚部,增大了Fe3Si软磁体的介电损耗和阻抗匹配特性。

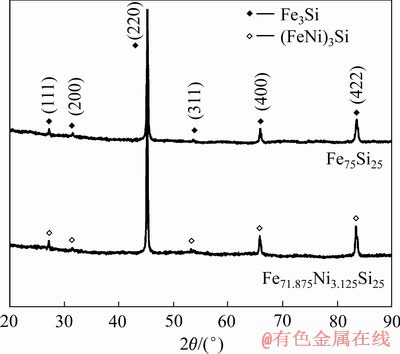

2.3 掺镍Fe3Si合金粉末物相分析

为进一步验证Ni元素添加提高Fe3Si合金电磁特性的理论计算结果,本文采用机械合金化和真空退火方法制备了Fe75Si25和Fe71.875Ni3.125Si25合金粉体吸波材料。图5所示为两种合金的XRD谱。从图5可知,

两种合金的衍射谱中均只有单一的Fe3Si相,在低角度处均出现了两条微弱的超结构衍射峰,表明形成了D03有序结构。Fe71.875Ni3.125Si25衍射峰较Fe75Si25略向低角度发生偏移,这是由于 Ni原子半径(0.1246 nm)大于Fe原子半径(0.1241 nm),随 Ni原子进入Fe3Si中取代部分Fe原子,造成点阵畸变。此外,Fe71.875Ni3.125Si25合金的衍射峰强度更强,这是由于Ni 元素可降低Fe75Si25相变的析出温度[24],因而具有更高的结晶度和析出量。

图5 900 ℃退火1 h的XRD谱

Fig. 5 XRD patterns of alloys annealing 1 h at 900 ℃

2.4 掺镍Fe3Si合金粉末电磁特性分析

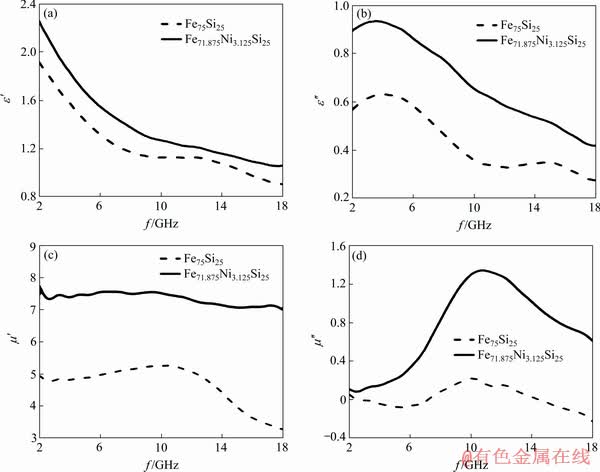

图6所示为掺Ni前后Fe75Si25合金粉末的复介电常数和复磁导率与频率的关系曲线。如图6所示,Fe71.875Ni3.125Si25合金粉体的介电常数实部ε' 和介电常数虚部ε" 较Fe75Si25的有所增大,且ε" 增加更为显著,同时又都随频率的增大而不断降低,即具备频响特性,添加Ni后更有利于提高材料的衰减特性。其原因可能是由于Ni原子取代Fe原子随机分布在亚点阵内,增加了混乱度(构型熵增加),使合金获得了更好的各向异性场,从而改善了其高频特性[25]。另一方面是机械球磨过程因减小了合金的晶粒尺寸,从而减小了趋肤效应,增大了材料的复介电常数。

此外,Fe71.875Ni3.125Si25合金的磁导率实部μ′ 和磁导率虚部μ″ 大幅增大,在10.5~18 GHz范围内,磁导率实部并未急速下降,而是保持于约7.5。在10.6 GHz处磁导率虚部峰值达1.31,较Fe75Si25合金粉末高1.11。其原因一方面是由于Ni 原子置换了部分亚晶格位置的Fe原子,Ni 原子比Fe 原子多两个d电子,多出的电子形成点缺陷,而点缺陷的附近又形成空穴,在交变外场的作用下,该空穴将不断的往复运动产生电子式的松弛极化和损耗[26]。另一方面,Ni 原子的添加引起晶体中载流子浓度的增大,提高了体系的电导率,进而增加了交变外场下的电导损耗,且由式(2)可知,电导率越大,其介电常数越大。这些与理论计算结果均一致。由此可见,以磁损耗为主的Fe3Si 合金,添加Ni元素后,其介电损耗大幅度增加且不会降低磁导率,同时增加了材料的阻抗匹配特性和衰减特性,可进一步提高材料的吸波性能。

图6 Fe75Si25和Fe71.875Ni3.125Si25合金粉体的复介电常数和复磁导率与频率的关系曲线

Fig. 6 Frequency dependence on complex permittivity ((a),(b)) and complex permeability ((c),(d)) of Fe75Si25 and Fe71.875Ni3.125Si25

3 结论

1) 随Ni元素的添加,合金金属性增强,电导率增大。Ni元素的添加促进Fe3Si合金的ε' 和ε" 显著提高,尤其是在8~14 eV高能量范围更具有展宽吸收频带所期望的频响特性。

2) 在2~18 GHz频率范围内,Fe71.875Ni3.125Si25合金粉末的ε' 和ε" 较Fe75Si25合金粉末的均有所增大,且都随频率的增大而不断降低,即具备频响特性。Fe71.875Ni3.125Si25合金粉末的μ′ 和μ″ 增大明显,μ″ 起伏波动较大,表明Ni元素的添加可有效提高Fe3Si合金的电磁参数。实验研究结果与理论计算结果一致。

REFERENCES

[1] 曹 琦, 龚荣洲, 冯则坤, 聂 彦. Fe-Si-Al系合金粉微波吸收特性[J]. 中国有色金属学报, 2006, 16(3): 524-529.

CAO Qi, GONG Rong-zhou, FENG Ze-kun, NIE Yan. Microwave absorption property of Fe-Si-Al magnetic alloy powder[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 524-529.

[2] SUN J, XU H, SHEN Y, BI H, LIANG W, YANG R B. Enhanced microwave absorption properties of the milled flake-shaped FeSiAl/graphite composites[J]. Journal of Alloys and Compounds, 2013, 548: 18-22.

[3] JAVID M, ZHOU Y L, WANG D G, LI D, SHI G M, KIM U C, ZHOU L, DONG X L, ZHANG Z D. Magnetic behavior, electromagnetic multi-resonances and microwave absorption of the interfacial engineered Fe@FeSi/SiO2 nanocomposite[J]. ACS Applied Nano Materials, 2018, 1(3): 1309-1320.

[4] 邓联文, 熊惟皓, 冯则坤, 江建军, 何华辉. FeSi纳米晶片状微波吸收剂研究[J]. 电子元件与材料, 2006, 25(9): 52-54.

DENG Wen-lian, XIONG Wei-hao, FENG Ze-kun, JIANG Jian-jun, HE Hua-hui. Study on FeSi nano-crystalline flake microwave absorber[J]. Electronic Components & Materials, 2006, 25(9): 52-54.

[5] XU Y G, YAN L M, CAI J, ZHANG D Y. Absorbing/ shielding property of graphite-FeSi by mechanical milling[J]. Applied Mechanics and Materials, 2013, 341: 166-170.

[6] LIU C, YUAN Y, JIANG J T, GONG Y X, ZHEN L. Microwave absorption properties of FeSi flaky particles prepared via a ball-milling process[J]. Journal of Magnetism and Magnetic Materials, 2015, 395: 152-158.

[7] 王建江, 蔡旭东, 温晋华, 许宝才. FeSiAl软磁合金空心微珠的微观结构控制及其低频吸波性能[J]. 稀有金属材料与工程, 2018, 47(10): 3072-3078.

WANG Jian-jiang, CAI Xu-dong, WEN Jin-huang, XU Bao-cai. Microstructure control of FeSiAl magnetically soft alloy hollow microspheres and their microwave absorption properties at low frequency[J]. Rare Metal Materials and Engineering, 2018, 47(10): 3072-3078.

[8] 周影影, 谢 辉, 周万城. 球料比对FeSiAl合金吸波性能的影响[J]. 功能材料, 2018, 49(2): 2108-2112.

ZHOU Ying-ying, XIE Hui, ZHOU Wan-cheng. Influence of ball-to-powder ratio on microwave absorbing property of FeSiAl alloy[J]. Functional Materials, 2018, 49(2): 2108-2112.

[9] 周 琦, 赵红顺, 贾建刚, 马 勤, 邹欣伟. Fe3Si基金属件化合物的研究进展[J]. 甘肃科学学报, 2007, 19(4): 29-33.

ZHOU Qi, ZHAO Hong-shun, JIA Jian-gang, MA Qin, ZOU Xin-wei. The progress of research in Fe3Si-based intermetallic compounds[J]. Journal of Gansu Science, 2007, 19(4): 29-33.

[10] WANG C, WAN W H, GE Y F, ZHAO Y H,ZHANG K C, LIU Y. Electronic, magnetic, and optical properties of Mn-doped GaSb: A first-principles study[J]. Physica B-Condensed Matter, 2019, 572: 225-229.

[11] WANG S S, XU Y C, FU R R, ZHU H H, JIAO Q Z, FENG T Y, FENG C H, SHI D X, LI H S, ZHAO Y. Rational construction of hierarchically porous Fe-Co/N-doped carbon/rGO composites for broadband microwave absorption[J]. Nano-micro Letters, 2019, 11(1): 236-240.

[12] 陈志彦, 王 军, 李效东. 纳米Fe3Si/SiC吸收的制备及电磁参数的调节[J]. 宇航材料工艺, 2010, 40(4): 33-36.

CHENG Zhi-yan, WANG Jun, LI Xiao-dong. Preparation of nano-Fe3Si/SiC absorption and regulation of electromagnetic parameters[J]. Aerospace Material Technology, 2010, 40(4): 33-36.

[13] KUANG B Y, DOU Y K, WANG Z H, NING M Q, JIN H B, GUO D Y, CAO M S, FANG X Y, ZHAO Y J, LI J B. Enhanced microwave absorption properties of Co-doped SiC at elevated temperature[J]. Applied Surface Science, 2018, 445: 383-390.

[14] XIE G Z, YUAN L K, WANG P, ZHANG B S, LIN P G, LU H X. GHz microwave properties of melt spun Fe-Si alloys[J]. Journal of Non-Crystalline Solids, 2010, 356: 83-86.

[15] PENG J H, CHEN G L. Effect of testing environment on fracturing behavior of Fe3Si based alloy[J]. Acta Metallurgica Sinica, 2003, 16(2): 104-109.

[16] BURCH T J, BUDICK J I, NICULESCU V A. Transition- metal impurities in dilute Fe3-xTxSi alloys: A spin-echo NMR investigation[J]. Physical Review B, 1981, 24: 3866-3883.

[17] MA R, XIE Q, HUANG J. Electronic structure and ferromagnetism of Fe11NiSi4, Fe11CoSi4, Fe11CrSi4 and Fe3Si from first principles[J]. Intermatellics, 2014, 46: 12-17.

[18] BROYDEN C G. The convergence of a class of double-rank minimization algorithms II. The new algorithm[J]. Journal of the Institute of Mathematics and Its Applications, 1970, 6: 222-231.

[19] VANDERBILT D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism[J]. Physical Review B, 1990, 41(11): 7892-7895.

[20] PACK H J D. Special points for brillouin-zone integrations—A reply[J]. Physical Review B, 1977, 16(4): 1748-1749.

[21] 徐 美. 对普朗克公式的再认识[J]. 物理与工程, 2018, 28(1): 62-65.

XU Mei. A new understanding of Planck’s formula[J]. Physics and Engineering, 2018, 28(1): 62-65.

[22] SUN Y, XU W, QIAO X, XU X, ZHANG W, ZHANG K, ZHANG X, CHEN W, ZHANG W, DU Y. Constructing two-, zero-, and one-dimensional integrated nanostructures: An effective strategy for high microwave absorption performance[J]. ACS Applied Materials& Interfaces, 2016, 8(46): 31878-31886.

[23] LUO F, LIU X, ZHOU D, ZHOU W. Effect of aluminum doping on microwave permittivity of silicon carbide[J]. Journal of the American Ceramic Society, 2008, 91(12): 4151-4153.

[24] 张学明, 马 瑞, 谢 泉. Ni 掺杂量对Fe3Si合金微波吸收性能的影响[J]. 电子元件与材料, 2014, 33(5): 38-41.

ZHANG Xue-ming, MA Rui, XIE Quan. Effects of Ni doping amount on microwave absorptive properties of Fe3Si alloy[J]. Electronic Components and Materials, 2014, 33(5): 38-41.

[25] NICULESCU V A, HINES W A, BUDNICK J I. Local environment model for the hyperfine interactions in Fe3-xNixSi[J]. Physical Review B, 1981, 23: 2388-2396.

[26] LI Z M, ZHOU W C, SU X L, HUANG Y X, LI G F, WANG Y P. Dielectric property of aluminum-doped SiC powder by solid-state reaction[J]. Journal of the American Ceramic Society, 2009, 92: 2116-2118.

First principles calculation on dielectric properties of Ni doped Fe3Si microwave absorber and analysis of its electromagnetic characteristics

REN Fen1, 2, MA Rui1, 2, HUANG Zhi-dong1, 2, XIE Quan2

(1. College of Material and Metallurgy, Guizhou University, Guiyang 550025, China;

2. Institute of Advanced Optoelectronic Materials and Technology, Guizhou University, Guiyang 550025, China)

Abstract: The influences of Ni element on the electronic structure and dielectric properties of Fe3Si alloys were studied by the pseudopotential plane wave method based on density functional theory. The calculated results show that the metallic properties of the system are enhanced and the conductivity is increased by adding Ni element. The Ni element greatly improves the real and imaginary parts of the dielectric constant of the system in the high frequency band, and the frequency response characteristic of broadening the absorption band is obtained. The Fe75Si25 and Fe71.875Ni3.125Si25 alloy powders were prepared by mechanical ball grinding and vacuum annealing method, and the microwave dielectric constant and permeability of the samples were measured in the frequency range of 2-18 GHz by vector network analyzer. The experimental results show that the permeability and dielectric constant of the alloy increase with the addition of Ni, especially the imaginary part. The imaginary part peak value of dielectric constant at 10.6 GHz is 1.31, which is 1.11 higher than that of Fe75Si25 alloy and validates the results of theoretical calculation. The mechanism of microwave loss was discussed.

Key words: Fe3Si microwave absorber; first principles; electronic structures; dielectric properties; electromagnetic properties

Foundation item: Project(61264004) supported by the National Natural Science Foundation of China; Project (Qian Project Funding(2016-05)) supported by the Science and Technology Innovation Project for Overseas Students of Ministry of Human Resources and Social Security of China

Received date: 2019-04-24; Accepted date: 2019-12-23

Corresponding author: MA Rui; Tel: +86-851-3623248; E-mail: mm.rma@gzu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(61264004);人社部留学人员科技创新项目(黔人项目资助(2016-05))

收稿日期:2019-04-24;修订日期:2019-12-23

通信作者:马 瑞,副教授,博士;电话:0851-3623248;E-mail:mm.rma@gzu.edu.cn

摘 要:采用基于密度泛函理论的赝势平面波法,研究了Ni元素对Fe3Si合金电子结构及介电性能的影响。计算结果表明:添加Ni元素后体系金属性增强,电导率增大。Ni元素使体系的介电常数实部和虚部在高频段显著提高,并具有展宽吸收频带所期望的频响特性。利用机械球磨和真空退火方法制备了Fe75Si25和Fe71.875Ni3.125Si25合金粉末,测试了试样在2~18 GHz的微波介电常数和磁导率。实验结果表明:添加Ni元素后,合金体系的磁导率和介电常数都增大,且两者的虚部增大更加显著,尤其在10.6 GHz处介电常数虚部峰值达1.31,较Fe75Si25合金粉末高1.11,进一步验证了理论计算结果,并讨论了微波损耗机制。

[1] 曹 琦, 龚荣洲, 冯则坤, 聂 彦. Fe-Si-Al系合金粉微波吸收特性[J]. 中国有色金属学报, 2006, 16(3): 524-529.

[4] 邓联文, 熊惟皓, 冯则坤, 江建军, 何华辉. FeSi纳米晶片状微波吸收剂研究[J]. 电子元件与材料, 2006, 25(9): 52-54.

[7] 王建江, 蔡旭东, 温晋华, 许宝才. FeSiAl软磁合金空心微珠的微观结构控制及其低频吸波性能[J]. 稀有金属材料与工程, 2018, 47(10): 3072-3078.

[8] 周影影, 谢 辉, 周万城. 球料比对FeSiAl合金吸波性能的影响[J]. 功能材料, 2018, 49(2): 2108-2112.

[9] 周 琦, 赵红顺, 贾建刚, 马 勤, 邹欣伟. Fe3Si基金属件化合物的研究进展[J]. 甘肃科学学报, 2007, 19(4): 29-33.

[12] 陈志彦, 王 军, 李效东. 纳米Fe3Si/SiC吸收的制备及电磁参数的调节[J]. 宇航材料工艺, 2010, 40(4): 33-36.

[21] 徐 美. 对普朗克公式的再认识[J]. 物理与工程, 2018, 28(1): 62-65.

XU Mei. A new understanding of Planck’s formula[J]. Physics and Engineering, 2018, 28(1): 62-65.

[24] 张学明, 马 瑞, 谢 泉. Ni 掺杂量对Fe3Si合金微波吸收性能的影响[J]. 电子元件与材料, 2014, 33(5): 38-41.